Академический Документы

Профессиональный Документы

Культура Документы

Pet Composition

Загружено:

tv0093340 оценок0% нашли этот документ полезным (0 голосов)

209 просмотров2 страницы"Polyester bottle resins - production, processing, Properties and Recycling" is a comprehensive examination of PET production and processing. Author, Dr Ulrich Thiele, is an acknowledged international expert on the subject of polyesters. He details all of the raw materials and answers such questions as "what is DMT?", "what role do co-monomers play?"

Исходное описание:

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документ"Polyester bottle resins - production, processing, Properties and Recycling" is a comprehensive examination of PET production and processing. Author, Dr Ulrich Thiele, is an acknowledged international expert on the subject of polyesters. He details all of the raw materials and answers such questions as "what is DMT?", "what role do co-monomers play?"

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

209 просмотров2 страницыPet Composition

Загружено:

tv009334"Polyester bottle resins - production, processing, Properties and Recycling" is a comprehensive examination of PET production and processing. Author, Dr Ulrich Thiele, is an acknowledged international expert on the subject of polyesters. He details all of the raw materials and answers such questions as "what is DMT?", "what role do co-monomers play?"

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

MATERIAL / RECYCLING

PET – its production,

composition, quality analysis

and processing

“Polyester bottle resins he details all of the raw materials and

answers such questions as “What is

- Production, Processing, DMT?”, “What role do co-monomers

Properties and Recycling” is play?”

the title of a recently pub- The way that PET is produced

lished book in the “PET- from the basic building blocks is fully

described, with a clear explanation of

planet Print” series. As the melt phase polycondensation (MPP)

title suggests the new book and solid state polycondensation

is a comprehensive exami- (SSP). The explanations are backed

up by equations for those who wish

nation of PET production

to understand the processes in more

and processing, focussing in depth.

particular on bottle resin.

Why so many kinds

The author of the book, Dr Ulrich

of PET resin?

Thiele, is an acknowledged inter-

national expert on the subject of We all know that mineral water

polyesters. Today he is head of the packaging does not require the same

Polyester Technology consulting serv- grade of resin as, for example, a

ice in Bruchköbel, Germany. Before carbonated beverage - but why?

establishing an independent consult- What are the fundamental differences

ing service Dr. Thiele was engaged between the various grades, and how

for more than 30 years in almost all is IV and AA content controlled and

facets of polyester production, R&D adjusted. A key aspect of PET bottle

and recycling. manufacture is crystallisation. Dr.

Specifically the new book covers: Thiele explains why a higher level of

PET resin production crystallisation is important for hot fill

Resin types and their composition applications, and why heat set resins

Resin quality and its impact on the contain lower levels of co-monomer,

final product and less DEG.

Physical and chemical analysis of

PET resin Is the resin fit for purpose?

The handling and processing of

PET resin The characterisation and quality

Additives - what they are and an control of PET resin and intermediate

outline of their uses or final products calls for numerous

Polyester bottle recycling analysis methods and related labora-

Alternative bottle and packaging tory hardware. The successful execu-

polymers. tion of such methods also requires

well-trained laboratory technicians.

So what exactly is DMT? With PET resin becoming more and

more a standard bulk material, and

This, and many other similar bottle production today being a highly

questions are asked every day by competitive mass-market activity,

PET resin users. The author presents expenditure on quality control tends to

scientific information in a mature way, be kept to a minimum. From this point

without over-simplification. For exam- of few it is important to establish what

ple, in the chapter on PET production is the “right“ amount of analytical work

16 PETplanet insider Vol. 8 No. 07+07/07 www.petpla.net

MATERIAL / RECYCLING

in relation to the business of the resin 1990s. Nevertheless the variety of alternative at the moment. Never-

processor. Selective combination of PET materials, additives and blends theless other polymeric materials of

methods, cooperation, external exper- means that the increasing popularity similar properties in processing at a

tise and close relations with suppliers of PET enjoyed by the resin producers comparable price level and useful for

are all aspects discussed in the book. is becoming an increasing nightmare specific applications can be obtained.

Dr Thiele gives some initial guidelines for the recycling industry and calls for The last chapter of the book looks one

for the establishment of a laboratory sophisticated sorting and decontami- by one at these alternatives, includ-

for chemical and physical analysis of nation technologies. ing metallocene-based polypropylene,

PET resin, and the type of tests that Dr Thiele reviews the current and of course PLA, together with their

can be carried out. Since this is not status of post-consumer PET collec- thermal data and their potential uses.

a realistic proposition for most small tion, flake production and recycling Taken altogether this new PET-

converters an extensive listing of con- and the various technologies in use. planet Print publication is a genuinely

tract analytical labs is also given. He makes regional comparisons, pro- useful book for processors, convert-

vides estimates of future growth, and ers and bottle blowers, as well as

Storage, handling and lists equipment and system suppliers. students and trainees in the plastics

packaging industry. It is a technical

preparation for processing

Can PET be replaced? introduction to the whole spectrum of

Having accepted a shipment PET production and processing, pre-

of PET resin it is important for the An alternative to standard PET sented in a clearly-expressed manner

converter to treat the material cor- resin would be a second polymeric that not only describes the way that

rectly. PET is susceptible to degrada- material which is able to replace PET PET behaves along its journey from

tion in many ways, including friction resin in all of its applications. Accord- the manufacturing plant to the filling

and overheating during conveying, ing to this definition there is no real line, but also explains the “hows” and

which can result in fish-eyes, specks, the “whys”.

and other quality defects in the pre-

form. The author points out some of

the dangers and common mistakes

that converters make in storing and

conveying resin within the plant, and

makes specific recommendations in

this respect.

The drying of the resin is a critical PETplanet print Vol. 5:

aspect of PET processing and one Polyester Bottle Resins

which is considered in some depth, Production, Processing,

differentiating between the drying of

Properties and Recycling

amorphous pellets and the drying of

SSP pellets. The drying of amorphous Dr. Ulrich K. Thiele

pellets is carried out in two steps - Over 300 pages, with colour illustrations

crystallisation and drying. SSP pellets * prices in EUR + VAT.

are always crystalline, and so call for ISBN: 978-3-9807497-4-9 € 149.–*

a different drying process.

Additives

The wide range of applications

for PET means that the standard

material frequently has to be modi-

fied to provide optimum performance

characteristics. The additives that are

used may be CO2 and oxygen barrier,

colours, UV and IR absorption, AA

or oxygen scavengers, antistatics,

anti-friction additives etc. Dr. Thiele’s

book lists the various PET additives

which are used for specific purposes

and explains their function, as well as

pointing out any negative side effects.

Recycling

Following initial pioneering work

on PET recycling in the 1970s new

recycling processes and companies

popped up like mushrooms during the

PETplanet insider Vol. 8 No. 07+08/07 www.petpla.net 17

Вам также может понравиться

- Bottles, Preforms and Closures: A Design Guide for PET PackagingОт EverandBottles, Preforms and Closures: A Design Guide for PET PackagingРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Polyester Recycling Forum2006Документ100 страницPolyester Recycling Forum2006Atika Anan ToryОценок пока нет

- Additives for Polyolefins: Getting the Most out of Polypropylene, Polyethylene and TPOОт EverandAdditives for Polyolefins: Getting the Most out of Polypropylene, Polyethylene and TPOОценок пока нет

- PET Plastic (Polyethylene Terephthalate) - Uses, Properties & StructureДокумент7 страницPET Plastic (Polyethylene Terephthalate) - Uses, Properties & StructureFITIWI100% (2)

- Due Care Petpreform-RILДокумент40 страницDue Care Petpreform-RILSyauqi AkmalaОценок пока нет

- Thermoforming of Single and Multilayer Laminates: Plastic Films Technologies, Testing, and ApplicationsОт EverandThermoforming of Single and Multilayer Laminates: Plastic Films Technologies, Testing, and ApplicationsОценок пока нет

- 5.Động học, xúc tácДокумент14 страниц5.Động học, xúc tácVân Tú NguyễnОценок пока нет

- Completing The Puzzle:: 100% Plant-Derived PETДокумент4 страницыCompleting The Puzzle:: 100% Plant-Derived PETAtif AzamОценок пока нет

- Biopolymers: New Materials for Sustainable Films and CoatingsОт EverandBiopolymers: New Materials for Sustainable Films and CoatingsDavid PlackettОценок пока нет

- Polymer Testing - 30 - 2010 - 60-68Документ9 страницPolymer Testing - 30 - 2010 - 60-68Carinna Saldaña - PierardОценок пока нет

- PET Depolymerization: A Novel Process For Plastic Waste Chemical RecyclingДокумент15 страницPET Depolymerization: A Novel Process For Plastic Waste Chemical RecyclingFabianОценок пока нет

- FinalManuscript PETintousefulenergyRathnayakeHHMPДокумент7 страницFinalManuscript PETintousefulenergyRathnayakeHHMPMatthues Ace MartinezОценок пока нет

- Simulationand Optimizationof Polymerization ReactorДокумент5 страницSimulationand Optimizationof Polymerization ReactorArmiee InfiniteОценок пока нет

- Blends of Poly (Ethylene Terephthalate) and Poly (Butylene Terephthalate)Документ9 страницBlends of Poly (Ethylene Terephthalate) and Poly (Butylene Terephthalate)NÄndo PelÄezОценок пока нет

- Pet 1Документ15 страницPet 1Martin GeorgeОценок пока нет

- Plastic Sorting PDFДокумент9 страницPlastic Sorting PDFJamie RandolphОценок пока нет

- The Fats About PET (Update 2018) : September 2018Документ6 страницThe Fats About PET (Update 2018) : September 2018Sanem Hazal TürkayОценок пока нет

- Study On Preparation Process and Properties of Polyethylene Terephthalate (PET)Документ1 страницаStudy On Preparation Process and Properties of Polyethylene Terephthalate (PET)Richard ParkerОценок пока нет

- Polyethylene Terephthalate (PET) : A Comprehensive Review: What Is PET Plastic?Документ8 страницPolyethylene Terephthalate (PET) : A Comprehensive Review: What Is PET Plastic?Ahmad Shah 8999Оценок пока нет

- Review - RECYCLED POLYESTER AND ITS PHYSICAL PROPERTIES - Review - USAДокумент28 страницReview - RECYCLED POLYESTER AND ITS PHYSICAL PROPERTIES - Review - USAAhmedОценок пока нет

- Journal - PET Recycling Evaluation of The Solid State Polymerization ProcessДокумент7 страницJournal - PET Recycling Evaluation of The Solid State Polymerization Processy.s.6saputroОценок пока нет

- Membranes 12 01105 With CoverДокумент24 страницыMembranes 12 01105 With Coverjoyhar9Оценок пока нет

- New Motivation For The Depolymerization Products Derived From Poly (Ethylene Terephthalate) (PET) Waste: A ReviewДокумент19 страницNew Motivation For The Depolymerization Products Derived From Poly (Ethylene Terephthalate) (PET) Waste: A ReviewGabriel AparicioОценок пока нет

- In Uence of Blending Proportion On Properties of Melt Spun Monofilaments Produced From Virgin PET and Recycled PET BlendДокумент20 страницIn Uence of Blending Proportion On Properties of Melt Spun Monofilaments Produced From Virgin PET and Recycled PET Blendsiddiqui4303379Оценок пока нет

- MogesB2022m 1aДокумент80 страницMogesB2022m 1aDAVOOD FAZILATОценок пока нет

- VaT 2018 3 3Документ11 страницVaT 2018 3 3Hữu LộcОценок пока нет

- PBL - Polymer - 2021: Topic PBL - 1: Petroleum-Based and Bio-Based PolymersДокумент2 страницыPBL - Polymer - 2021: Topic PBL - 1: Petroleum-Based and Bio-Based PolymersBima SetyaputraОценок пока нет

- CARNIEL A Comprehensive and Critical Review On Key Elements To Implement Enzymatic PET Depolymerization For Recycling PurposesДокумент15 страницCARNIEL A Comprehensive and Critical Review On Key Elements To Implement Enzymatic PET Depolymerization For Recycling PurposesAnonymous HijNGQtNОценок пока нет

- Indones. J. Chem., 2019, 19 (3), 545 - 555: AbstractДокумент11 страницIndones. J. Chem., 2019, 19 (3), 545 - 555: Abstractt3guhku2hОценок пока нет

- 1 s2.0 S1096717621000471 MainДокумент13 страниц1 s2.0 S1096717621000471 MainJorge Lima PérezОценок пока нет

- What Is Pet (Polyethylene Terephthalate) : Melting Temperature: 254-256 C Crystallinity: 45%Документ32 страницыWhat Is Pet (Polyethylene Terephthalate) : Melting Temperature: 254-256 C Crystallinity: 45%Sky ValleyОценок пока нет

- Development of New Automobile Components Based On Thermoplastic Elastomers From Recycled Polyethylene and Natural RubberДокумент8 страницDevelopment of New Automobile Components Based On Thermoplastic Elastomers From Recycled Polyethylene and Natural RubberInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- HTTP CDN - Cseindia.org Attachments 0.95433400 1626058399 Plastic-recycling-Decoded-web-uploadДокумент58 страницHTTP CDN - Cseindia.org Attachments 0.95433400 1626058399 Plastic-recycling-Decoded-web-uploadsolomonraj salikeetiОценок пока нет

- A Study On Thermo - Catalytic Degradation of PET (Polyethylene Terephthalate) Waste For Fuel Production and Chemical ProductsДокумент6 страницA Study On Thermo - Catalytic Degradation of PET (Polyethylene Terephthalate) Waste For Fuel Production and Chemical ProductsFaisal MumtazОценок пока нет

- Strategic Possibility Routes of Recycled PET: Polymers May 2021Документ36 страницStrategic Possibility Routes of Recycled PET: Polymers May 2021yuppeОценок пока нет

- Design and Study of Manufacturing of Polyester Plant Using Pta and Meg-Ijaerdv04i0425431 PDFДокумент8 страницDesign and Study of Manufacturing of Polyester Plant Using Pta and Meg-Ijaerdv04i0425431 PDFMary Grace Velitario100% (1)

- Design and Study of Manufacturing of Polyester Plant Using Pta and MegДокумент8 страницDesign and Study of Manufacturing of Polyester Plant Using Pta and MegUgurОценок пока нет

- European Polymer Journal 61 (2014) 285-299 PDFДокумент15 страницEuropean Polymer Journal 61 (2014) 285-299 PDFEstudiante2346Оценок пока нет

- RecyclingandreusesPlasticVol LNo 6162-1662022Документ7 страницRecyclingandreusesPlasticVol LNo 6162-1662022Dulina HansajaОценок пока нет

- Polymer Degradation and Stability: Nino Dimitrov, Ljerka Krato Fil Krehula, Anita Pti Cek Sirocic, Zlata Hrnjak-Murgi CДокумент8 страницPolymer Degradation and Stability: Nino Dimitrov, Ljerka Krato Fil Krehula, Anita Pti Cek Sirocic, Zlata Hrnjak-Murgi CCristina VladutaОценок пока нет

- Understanding Plastic Film PDFДокумент30 страницUnderstanding Plastic Film PDFtia silviaОценок пока нет

- Recycling of Polyethylene Terephthalate Bottles 1st Edition, Bottles/thomas/978-0-12-811361-5#Документ8 страницRecycling of Polyethylene Terephthalate Bottles 1st Edition, Bottles/thomas/978-0-12-811361-5#adamvenomОценок пока нет

- Review of Related LiteratureДокумент6 страницReview of Related LiteratureMontzo Diana BaltonadoОценок пока нет

- Polyethene CourseworkДокумент4 страницыPolyethene Courseworkf5dj7xvv100% (2)

- Final Project Report Plastic Bottle ManufactureДокумент101 страницаFinal Project Report Plastic Bottle Manufactureaskaridumbo82% (33)

- 1 s2.0 S2666893922000895 MainДокумент10 страниц1 s2.0 S2666893922000895 MainJeet LukhiОценок пока нет

- Thermal Stabilization of Recycled PET Through Chain Extension and Blending With PBTДокумент9 страницThermal Stabilization of Recycled PET Through Chain Extension and Blending With PBTMerve GüçlüОценок пока нет

- Journal of Polymer Science - 2021 - Sarda - Sustainability Performance of Polyethylene Terephthalate Clarifying ChallengesДокумент25 страницJournal of Polymer Science - 2021 - Sarda - Sustainability Performance of Polyethylene Terephthalate Clarifying ChallengesRielle Dela MercedОценок пока нет

- FINA2303 PET Chemicals Case Study On Capital BudgetingДокумент31 страницаFINA2303 PET Chemicals Case Study On Capital BudgetingRayne ChanОценок пока нет

- Experimental Development of A Plastic Bottle Usable As A Construction Building Block Created Out of Polyethylene Terephthalate - Testing PET (B) Rick 1.0 PDFДокумент19 страницExperimental Development of A Plastic Bottle Usable As A Construction Building Block Created Out of Polyethylene Terephthalate - Testing PET (B) Rick 1.0 PDFAniel DiasОценок пока нет

- Processing of Bioplastics: - A GuidelineДокумент40 страницProcessing of Bioplastics: - A GuidelineHerlili PeronikaОценок пока нет

- Recycling of Bottle Grade PET Influence of HDPE CoДокумент15 страницRecycling of Bottle Grade PET Influence of HDPE Cobrlinkblings xxОценок пока нет

- Chem 114 AsssignmentДокумент3 страницыChem 114 AsssignmentJohn harold De GuzmanОценок пока нет

- Dimethyl TerephthalateДокумент9 страницDimethyl Terephthalatehung_metalОценок пока нет

- Effect of Recycled Content and rPET Quality On TheДокумент11 страницEffect of Recycled Content and rPET Quality On TheJeung YuОценок пока нет

- Wikipedia Plastic RecyclingДокумент18 страницWikipedia Plastic Recyclingaditya_lomteОценок пока нет

- CE01030-1 Introduction To 3d Modelling For Games 1B AssignmentДокумент7 страницCE01030-1 Introduction To 3d Modelling For Games 1B Assignmenttv009334Оценок пока нет

- Damage ToleranceДокумент59 страницDamage Tolerancetv009334100% (8)

- List of TablesДокумент2 страницыList of Tablestv009334Оценок пока нет

- PET Bottle AuditДокумент7 страницPET Bottle AuditAsif MohammedОценок пока нет

- Intro KeramerДокумент26 страницIntro Keramertv009334Оценок пока нет

- 5 To 8exercise.... 2Документ1 страница5 To 8exercise.... 2tv009334Оценок пока нет

- Annular RaftДокумент8 страницAnnular RaftMamoudAbdoОценок пока нет

- Bus Stop Steel FinalДокумент33 страницыBus Stop Steel FinalanuarОценок пока нет

- Elgacore DWA 55EДокумент2 страницыElgacore DWA 55Ecfyjdyu_684672809Оценок пока нет

- Karasin e Gunaslan 2015 - Models For Confined Concrete Columns With Fiber CompositesДокумент10 страницKarasin e Gunaslan 2015 - Models For Confined Concrete Columns With Fiber CompositesLucas RibeiroОценок пока нет

- Phase Identifier Trough Partial DerivativesДокумент9 страницPhase Identifier Trough Partial DerivativesrelojucaОценок пока нет

- Flip-Chip III-V-To-Silicon Photonics Interfaces For Optical SensorДокумент7 страницFlip-Chip III-V-To-Silicon Photonics Interfaces For Optical Sensoranushpamathi SundararajanОценок пока нет

- Mass Transfer Coefficient and Interphase Mass TransferДокумент33 страницыMass Transfer Coefficient and Interphase Mass TransferpandianvijaybharathiОценок пока нет

- Design For Variable Loading 2 2012Документ43 страницыDesign For Variable Loading 2 2012tianshuguoОценок пока нет

- PB Sio2 BoraxДокумент9 страницPB Sio2 BoraxAnonymous FfIxH2o9Оценок пока нет

- Welding DefectsДокумент77 страницWelding DefectsBalakumar100% (1)

- InxAl1 XN Al0 53ga0 47N Multiple Quantum Wells On Al0 5ga0 2018 Journal of LДокумент6 страницInxAl1 XN Al0 53ga0 47N Multiple Quantum Wells On Al0 5ga0 2018 Journal of LVíctor SaldarriagaОценок пока нет

- Design Envelope For GRP Pipe As Per ISO 14692Документ5 страницDesign Envelope For GRP Pipe As Per ISO 14692Ashitava Sen100% (1)

- Characteristics (Typical Figures) Agip Arnica PSX 46Документ1 страницаCharacteristics (Typical Figures) Agip Arnica PSX 46AMAZING AGОценок пока нет

- Semiconductor FundamentalДокумент5 страницSemiconductor FundamentalluqmanОценок пока нет

- Cupola Malleable Iron: Standard Specification ForДокумент4 страницыCupola Malleable Iron: Standard Specification ForHenriqueОценок пока нет

- Ark Emad 362Документ13 страницArk Emad 362La Vita E BellaОценок пока нет

- Astm A295-52100Документ4 страницыAstm A295-52100Apurva GuptaОценок пока нет

- TPU Technical DatasheetДокумент2 страницыTPU Technical Datasheetromi supriyonoОценок пока нет

- Introducción, Contexto, Cantidades - Fundamentos CircuitosДокумент34 страницыIntroducción, Contexto, Cantidades - Fundamentos CircuitosJuan ConradoОценок пока нет

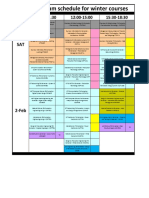

- Make Up Exam Schedule For Winter Courses 1.2Документ6 страницMake Up Exam Schedule For Winter Courses 1.2ANОценок пока нет

- Exp 6 Free & Forced Convection Heat ExchangerДокумент19 страницExp 6 Free & Forced Convection Heat ExchangerGriezmann Haziq50% (2)

- General Chemistry 1 Quarter 2 Weeks 2 and 3Документ17 страницGeneral Chemistry 1 Quarter 2 Weeks 2 and 3Shalou Beth FlorendoОценок пока нет

- Buckling A Mechanical Failure ModeДокумент238 страницBuckling A Mechanical Failure Modeindra100% (1)

- Design Equations For Flexural Strengthening of Singly Reinforced RC Rectangular Section With Steel PlatesДокумент9 страницDesign Equations For Flexural Strengthening of Singly Reinforced RC Rectangular Section With Steel PlatesMagdy Bakry100% (1)

- Abaqus Convergence DiscussionДокумент21 страницаAbaqus Convergence DiscussionBolarinwaОценок пока нет

- Dien-Tu-Y-Sinh Ho-Trung-My 02 Biomedical Instrumentation - Transducers Amplifiers Emi - (Cuuduongthancong - Com)Документ82 страницыDien-Tu-Y-Sinh Ho-Trung-My 02 Biomedical Instrumentation - Transducers Amplifiers Emi - (Cuuduongthancong - Com)hungnguyenok00Оценок пока нет

- 1 s2.0 S0379677917303041 MainДокумент6 страниц1 s2.0 S0379677917303041 MainAnonymous oSuBJMОценок пока нет

- Input - Output Module IOX SA 102 W-IДокумент1 страницаInput - Output Module IOX SA 102 W-IMarcelo Fabián OrtizОценок пока нет

- Capacitor ValueДокумент6 страницCapacitor ValueP.Rajan GuruОценок пока нет

- Why We Die: The New Science of Aging and the Quest for ImmortalityОт EverandWhy We Die: The New Science of Aging and the Quest for ImmortalityРейтинг: 4 из 5 звезд4/5 (3)

- Tales from Both Sides of the Brain: A Life in NeuroscienceОт EverandTales from Both Sides of the Brain: A Life in NeuroscienceРейтинг: 3 из 5 звезд3/5 (18)

- When the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisОт EverandWhen the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisРейтинг: 3.5 из 5 звезд3.5/5 (2)

- A Brief History of Intelligence: Evolution, AI, and the Five Breakthroughs That Made Our BrainsОт EverandA Brief History of Intelligence: Evolution, AI, and the Five Breakthroughs That Made Our BrainsРейтинг: 4 из 5 звезд4/5 (5)

- Gut: the new and revised Sunday Times bestsellerОт EverandGut: the new and revised Sunday Times bestsellerРейтинг: 4 из 5 звезд4/5 (392)

- Undeniable: How Biology Confirms Our Intuition That Life Is DesignedОт EverandUndeniable: How Biology Confirms Our Intuition That Life Is DesignedРейтинг: 4 из 5 звезд4/5 (11)

- Gut: The Inside Story of Our Body's Most Underrated Organ (Revised Edition)От EverandGut: The Inside Story of Our Body's Most Underrated Organ (Revised Edition)Рейтинг: 4 из 5 звезд4/5 (378)

- 10% Human: How Your Body's Microbes Hold the Key to Health and HappinessОт Everand10% Human: How Your Body's Microbes Hold the Key to Health and HappinessРейтинг: 4 из 5 звезд4/5 (33)

- Fast Asleep: Improve Brain Function, Lose Weight, Boost Your Mood, Reduce Stress, and Become a Better SleeperОт EverandFast Asleep: Improve Brain Function, Lose Weight, Boost Your Mood, Reduce Stress, and Become a Better SleeperРейтинг: 4.5 из 5 звезд4.5/5 (15)

- Seven and a Half Lessons About the BrainОт EverandSeven and a Half Lessons About the BrainРейтинг: 4 из 5 звезд4/5 (109)

- A Series of Fortunate Events: Chance and the Making of the Planet, Life, and YouОт EverandA Series of Fortunate Events: Chance and the Making of the Planet, Life, and YouРейтинг: 4.5 из 5 звезд4.5/5 (62)

- The Molecule of More: How a Single Chemical in Your Brain Drives Love, Sex, and Creativity--and Will Determine the Fate of the Human RaceОт EverandThe Molecule of More: How a Single Chemical in Your Brain Drives Love, Sex, and Creativity--and Will Determine the Fate of the Human RaceРейтинг: 4.5 из 5 звезд4.5/5 (516)

- Human: The Science Behind What Makes Your Brain UniqueОт EverandHuman: The Science Behind What Makes Your Brain UniqueРейтинг: 3.5 из 5 звезд3.5/5 (38)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionОт EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionРейтинг: 4 из 5 звезд4/5 (811)

- Good Without God: What a Billion Nonreligious People Do BelieveОт EverandGood Without God: What a Billion Nonreligious People Do BelieveРейтинг: 4 из 5 звезд4/5 (66)

- The Invention of Tomorrow: A Natural History of ForesightОт EverandThe Invention of Tomorrow: A Natural History of ForesightРейтинг: 4.5 из 5 звезд4.5/5 (5)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildОт EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildРейтинг: 4.5 из 5 звезд4.5/5 (44)

- Who's in Charge?: Free Will and the Science of the BrainОт EverandWho's in Charge?: Free Will and the Science of the BrainРейтинг: 4 из 5 звезд4/5 (65)

- The Other Side of Normal: How Biology Is Providing the Clues to Unlock the Secrets of Normal and Abnormal BehaviorОт EverandThe Other Side of Normal: How Biology Is Providing the Clues to Unlock the Secrets of Normal and Abnormal BehaviorОценок пока нет

- All That Remains: A Renowned Forensic Scientist on Death, Mortality, and Solving CrimesОт EverandAll That Remains: A Renowned Forensic Scientist on Death, Mortality, and Solving CrimesРейтинг: 4.5 из 5 звезд4.5/5 (397)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldОт EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldРейтинг: 4.5 из 5 звезд4.5/5 (18)

- Change Your Brain, Change Your Life (Before 25): Change Your Developing Mind for Real-World SuccessОт EverandChange Your Brain, Change Your Life (Before 25): Change Your Developing Mind for Real-World SuccessРейтинг: 4 из 5 звезд4/5 (18)

- Crypt: Life, Death and Disease in the Middle Ages and BeyondОт EverandCrypt: Life, Death and Disease in the Middle Ages and BeyondРейтинг: 4 из 5 звезд4/5 (4)

- Moral Tribes: Emotion, Reason, and the Gap Between Us and ThemОт EverandMoral Tribes: Emotion, Reason, and the Gap Between Us and ThemРейтинг: 4.5 из 5 звезд4.5/5 (115)

- Lymph & Longevity: The Untapped Secret to HealthОт EverandLymph & Longevity: The Untapped Secret to HealthРейтинг: 4.5 из 5 звезд4.5/5 (13)