Академический Документы

Профессиональный Документы

Культура Документы

Hurst Boiler - Pneumatic Air Feed System

Загружено:

quang kinhluanengineering0 оценок0% нашли этот документ полезным (0 голосов)

27 просмотров1 страницаDRY TYPE FUELS

Оригинальное название

Hurst Boiler_ Pneumatic Air Feed System

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документDRY TYPE FUELS

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

27 просмотров1 страницаHurst Boiler - Pneumatic Air Feed System

Загружено:

quang kinhluanengineeringDRY TYPE FUELS

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

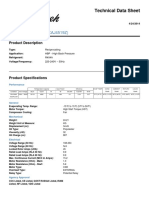

The Hybrid PF design is suitable for

applications to produce high pressure

steam or hot water in ranges from

3,450 – 60,000 lbs/hr (3.4 mmBTU –

60 mmBTU) output from 100 up to 400

PSI. This system is designed by HBC

to combine the best technologies from

the "old school" of biomass

combustion and the latest advanced

combustion control technologies.

HBC’s Pneumatic Feed Stoker

Systems have proven their ability to

provide a very low turn-down rate

making it particularly suitable for

heating applications in lumber dry

kilns, veneer log vats, veneer dryers,

greenhouses and factories. This

combination enables these systems to

provide a flexible and reliable

operation utilizing a consistent "grade"

of biomass waste with low moisture

contents ranging from 8 – 20%. Ash

removal is a manual operation. The

boiler vessel is a two pass hybrid

design incorporating a water tubed

boiler-type water membrane and a

two-pass fire tube scotch marine

vessel. This vessel’s advantages over

standard water tube boilers include

much larger steam disengagement

area providing high quality steam,

larger steam storage capability for

quicker response to sudden steam

demand and much larger thermal

storage that provides fast demand

response times and safer operation.

HURST BOILER & WELDING CO., INC.

P. O. Drawer 530

CAT# W-06

21971 Highway 319 N.

Coolidge, Georgia 31738

Toll Free: 1-877-994-8778

Tel: (229) 346-3545

Fax.(229) 346-3874

Email: info@hurstboiler.com HYBRID PF

Pneumatic Air Feed System

Вам также может понравиться

- TECHNICAL PROPOSAL LIGHTNING SYSTEM - Franklin RodДокумент5 страницTECHNICAL PROPOSAL LIGHTNING SYSTEM - Franklin Rodquang kinhluanengineeringОценок пока нет

- Elbow Dimension PDFДокумент2 страницыElbow Dimension PDFquang kinhluanengineeringОценок пока нет

- TT 04-2017-BXDДокумент24 страницыTT 04-2017-BXDquang kinhluanengineeringОценок пока нет

- Thermax Combipac CPDДокумент2 страницыThermax Combipac CPDquang kinhluanengineering0% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Unjuk Kerja Turbin Uap Pembangkit Listrik Tenaga Panas Bumi Dalam Pandangan Pendidikan IslamДокумент6 страницUnjuk Kerja Turbin Uap Pembangkit Listrik Tenaga Panas Bumi Dalam Pandangan Pendidikan Islamalkhawarizmi vebriОценок пока нет

- CoalMetalAsia 148th EditionДокумент96 страницCoalMetalAsia 148th EditionharrybasukiОценок пока нет

- GD - 8pp - FM30-150 - RS - AUS - 0519 v3Документ8 страницGD - 8pp - FM30-150 - RS - AUS - 0519 v3Andres AlejandroОценок пока нет

- Resistance Equivalent Length FittingsДокумент3 страницыResistance Equivalent Length FittingsRicardo DaclanОценок пока нет

- Thermal Tests of The 45MW SGT-800 Gas Turbine EquipmentДокумент7 страницThermal Tests of The 45MW SGT-800 Gas Turbine Equipmentbagusu_6Оценок пока нет

- Model:AJE4519ZFZ (CAJ4519Z) : Technical Data SheetДокумент1 страницаModel:AJE4519ZFZ (CAJ4519Z) : Technical Data SheetSamer ChahroukОценок пока нет

- 17909-17910 HATP HSG 0100wlДокумент23 страницы17909-17910 HATP HSG 0100wlCristian BogadoОценок пока нет

- School of Chemical Engineering (Scheme) Digital Assignment - I, Fall Semester 2021-22 B.Tech. (Chemical Engineering)Документ3 страницыSchool of Chemical Engineering (Scheme) Digital Assignment - I, Fall Semester 2021-22 B.Tech. (Chemical Engineering)DcrUz 003Оценок пока нет

- ARUN072BTE4: Ton Outdoor Unit Multi V™ IV Heat Pump 6.0Документ2 страницыARUN072BTE4: Ton Outdoor Unit Multi V™ IV Heat Pump 6.0Sistemas VRF MexicoОценок пока нет

- 01-Steam Power Plant 26 OctДокумент64 страницы01-Steam Power Plant 26 OcthuusenaliОценок пока нет

- PLTMG Jayapura Peaker: Power Plant & Energy DepartmentДокумент2 страницыPLTMG Jayapura Peaker: Power Plant & Energy Departmentmilhahanisti22Оценок пока нет

- Turbine Inlet Cooling: Reference ChartsДокумент10 страницTurbine Inlet Cooling: Reference ChartsKhanh TrangОценок пока нет

- Turbine Bypass SystemsДокумент10 страницTurbine Bypass SystemsZaqPoilmОценок пока нет

- 2 Technology EvolutionДокумент20 страниц2 Technology EvolutionRokan Uddin100% (1)

- Nuclear EnergyThe Sun and Stars Are Seemingly Inexhaustible Sources of EnergyДокумент4 страницыNuclear EnergyThe Sun and Stars Are Seemingly Inexhaustible Sources of EnergyMohammad AhsanОценок пока нет

- QS1A Datasheet EN MXДокумент2 страницыQS1A Datasheet EN MXkurtkaukinenОценок пока нет

- Axial and Radial Turbines - TMI 11-12 - P 32 PDFДокумент1 страницаAxial and Radial Turbines - TMI 11-12 - P 32 PDFJavad AmnianОценок пока нет

- Cesc ProjectДокумент49 страницCesc ProjectMainak NaskarОценок пока нет

- Manager Mechanical-Maintenance (BOP) : Role of The PositionДокумент4 страницыManager Mechanical-Maintenance (BOP) : Role of The Positionjust_4_u_dear_in9549Оценок пока нет

- Steam Boilers: WTTCMOD2.PPT Slide 1 Printed On 5/17/2008Документ96 страницSteam Boilers: WTTCMOD2.PPT Slide 1 Printed On 5/17/2008aliОценок пока нет

- Flame Arrestor White Paper en 5364202Документ15 страницFlame Arrestor White Paper en 5364202ksvvijОценок пока нет

- RANQUE-HILSCH VORTEX TUBE-To StudentsДокумент12 страницRANQUE-HILSCH VORTEX TUBE-To StudentsMohamed MoatazОценок пока нет

- Xiao 2010Документ8 страницXiao 2010vitor_alberto_7Оценок пока нет

- 2012 York Tech Guide - VA AirДокумент36 страниц2012 York Tech Guide - VA AirAndrea LemusОценок пока нет

- Mini Water Service StationДокумент46 страницMini Water Service StationAakash DindigulОценок пока нет

- Babcock and Wilcox Boiler.Документ9 страницBabcock and Wilcox Boiler.Sajid RazaОценок пока нет

- Supercritical Co2 Power Cycle Developments and Commercialization Why Sco2 Can Displace SteamДокумент15 страницSupercritical Co2 Power Cycle Developments and Commercialization Why Sco2 Can Displace Steamvivek pandeyОценок пока нет

- SFC 75-125-AC-460V-CAGI-Datasheet - 46-64978Документ1 страницаSFC 75-125-AC-460V-CAGI-Datasheet - 46-64978Well Countryson Lumban TobingОценок пока нет

- Hydraulic FoundationsДокумент41 страницаHydraulic FoundationsJay PandyaОценок пока нет

- Mandava Institute of Engineering and Technology: Iii Mechanical I Sem I I Mid ExaminationsДокумент1 страницаMandava Institute of Engineering and Technology: Iii Mechanical I Sem I I Mid ExaminationsRkrishna AОценок пока нет