Академический Документы

Профессиональный Документы

Культура Документы

CRT Flyback Datasheet PDF

Загружено:

Edgar DauzonОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CRT Flyback Datasheet PDF

Загружено:

Edgar DauzonАвторское право:

Доступные форматы

COPIA ASSEGNATA A:

Copy assigned to:

PHILIPS

FLYBACK TRANSFORMER SPECIFICATION

CODE : 1372.7077 D

Esplanade 100Hz

FIRST ISSUE DATE : 25/10/2004 32” 16:9 RF

Table of contents:

1.0 GENERAL INFORMATION

2.0 MECHANICAL CHARACTERISTICS

3.0 ELECTRICAL CHARACTERISTICS 06/06/2005

4.0 QUALIFICATION TESTS

5.0 SAFETY

6.0 PRECAUTIONS

ENCLOSURE 1: DRAWING OF CABLES ALONE

ENCLOSURE 2: WINDING AND CORE DATA

APPROVAL FORM

TABLE OF ISSUES: DOCUMENT NBR:

W4.04 220 571

CHANGED

ISSUE DATE ISSUED BY: CHECKED BY: APPROVED BY: PAGES: CHANGE DESCRIPTION:

A 30.03.2005 Sala S. Frasca M. Toscano G.

15-E1 Focus cables length 450500mm

B 15.05.2005 Sala S. Frasca M. Toscano G.

11-12-13 Material list updated

1.1 Description

This specification describes a slots wound flyback transformer.

The magnetic circuit of the transformer comprises two soft ferrite U-cores gluedtogether.

The primary and high voltage windings are wound on two plastic bobbins placedconcentrically. They are

encapsulated with epoxy resin in a pre-moulded case together with the HV diodes and all the annexed materials.

Potentiometers for focus and Vg2 adjustment are fully incorporated.The connection to the external circuit is made

via terminal pins which enable the mounting on a printed-circuit board.

The EHT voltage is provided via an EHT cable consisting of an HV lead wire and a rubber cap for the CRT anode.

The focus and Vg2 connections are once-only insertions.

1.2 Application

The transformer has been designed to provide the required scanning amplitude and voltages to a 90°-110° colour

CRT for TV set or colour monitors.

1.2.1 Operating conditions

Operating ambient temperature: -10°C to +60°C

Operating humidity range non condensing 10% to 90%RH

Ambient temperature is the medium value measured at 30 mm. of distance from the surface of the transformer.

When the transformer is placed inside a metallic shield the above temperature value will be referred to the inside of

the shield even if it is closer then 30 mm to the FBT.

1.3 Storage conditions

Short term storage temperature -25°C to +60°C, RH 95%

The transformer can be stored for 6 months in the original packaging at the following average conditions

Tamb +40°C, RH 90%

After storage to allow a minimum of 24 hours recovery time before using.

1.4 Marking

On the transformer body there will be placed a label indicating:

- Test House Approval

- Pulse part number

- Changing index of revision A: a letter wich is increased from A to Z for every FBT modification

- Customer part number

- Work Order

TEST HOUSE

- Production date APPROVAL

Day of week (Monday/Saturday) D: a letter from “a” to “f” PULSE part number A

Week of year WW: a number from 1 to 52 Customer part number

Work Order

Year YY: last two digit

D WW YY

1.5 Packaging

Refer to Eldor specification CEI 4.2 225 004.

1.6 Weight

The transformer weight is approx 415 g.

1.7 Process controll

100% of the FBT controlled in production.

FLYBACK TRANSFORMER SPECIFICATION 1372.7077 D

CUSTOMER CODE 242253100079 ISSUE B

This document and its content are property of PULSE CONSUMER DIVISION.No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of PULSE CONSUMER DIVISION. DOC.N. W4.04 220 571 PAG. 2 / 17

2.0 MECHANICAL CHARACTERISTICS

2.1 Mechanical drawing

See drawing page 16

2.2 Drilling plane

See drawing page 16

2.3 Performances

2.3.1 Twist strength

The anode lead wire gripped at 120 ± 5mm from the chimney top shall be able to be rotated by 180° in both

directions for 2 cycles without presenting any cut or damage at the way out position.

2.3.2 Lead pulling test

The high voltage anf focus output cable lead shall withstand the pulling test (at 5Kg for 30 seconds) without any

damage of the mechanical structure or without affecting electrical characteristics.

2.3.3 Lead Bending test

The high voltage and focus output lead shall be put in the direction of the axis of the lead and pulled by the weight

(gradually up to 1Kg). Then the lead shall be bent as shown in the fig. below. After 3 bends both mechanical and

electrical characteristics shall not be affected.

LEAD WIRE HANDLING LEAD WIRE HANDLING

POSITION POSITION

HIGH VOLTAGE LEAD

HIGH VOLTAGE LEAD

100 mm

100 mm

° 90

90 °

° 90

90 °

PLASTIC CLIP

BUSHING

FBT BODY

FBT BODY

2.3.4 Robustness of termination

The robustness of the terminations for printed wiring pins must be in accordance with IEC 60068 PT2-21 test

Ua1/Ub method 1.

2.3.5 Inclination of the pins

The inclination of the pins shall be less than 0.2mm as shown in the figure below.

0.2 mm

2.3.6 Solderability of the terminals (pins and leads)

Solderability test shall be done according to IEC 60068 PT2-20 test Ta, method 1 (wetting).

Temperature: 235°C ± 5°C (time 2 ± 0.5sec).

The wetted area must be 95%

2.3.7 Bending pin

All the pins can be bent except pins: 10

FLYBACK TRANSFORMER SPECIFICATION 1372.7077 D

CUSTOMER CODE 242253100079 ISSUE B

This document and its content are property of PULSE CONSUMER DIVISION.No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of PULSE CONSUMER DIVISION. DOC.N. W4.04 220 571 PAG. 3 / 17

2.3.8 Potentiometers mechanical characteristics

Approved supplier Eldor

Focus 180 ± 10°

Shaft rotation angle

Screen 140 ± 10°

Operating torque The force needed to rotate the 3 to 20mN∙m

Starting torque shaft will be from 20mN∙m

Torque against stop It shall be max 900mN∙m

Axial thrust on shaft 150N

Radial thrust on shaft Not applicable

Focus and Vg2 rotors at minimum position (counter clock wise) at delivery.

2.3.9 Potentiometers electrical characteristics

Total resistance = 75 Mohm ± 15%

Focus setting ability: not available

Vg2 setting ability: not available

REMARK: Vfocus and Vg2 measured with equipment with Internal Resistance ≥ 10GΩ

2.3.10 Drawing of knob

hexag. 2 ±0.1

ø 6 -0.15

1 ±0.1 (2x)

4.4 ±0.1 (2x)

3.8 ±0.2

5.4 ±0.2

2.3.11 EHT Cable with Anode Cap

Push-in into the FBT chimney 30N or less

EHT Cable Strength

Pull-out from the FBT chimney 45N for 1 minute

FLYBACK TRANSFORMER SPECIFICATION 1372.7077 D

CUSTOMER CODE 242253100079 ISSUE B

This document and its content are property of PULSE CONSUMER DIVISION.No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of PULSE CONSUMER DIVISION. DOC.N. W4.04 220 571 PAG. 4 / 17

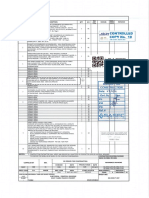

3.0 ELECTRICAL CHARACTERISTICS

For pins identification refer to drawing of page 16

3.1 Static characteristics

3.1.1 Inductance and DC resistance:

Measurement of inductance is made using a LCR bridge at frequency of 1KHz at output voltage of 1 V r.m.s.

Measurement of resistance is made using a four wire ohmmeter.

Temperature should be 23 ± 2°C.

L(µH) Tol.(%) R(m) Tol.(%)

Between pin 1 and pin 3 1290 ± 10 214 ±10

3.1.2 Insulation resistance

The insulation resistance shall be more than 150M in the following conditions:

- between windings

- between each winding and the core

The applied voltage shall be 1000Vdc for 60 seconds.

3.1.3 Withstanding voltage

The transformer shall withstand a voltage of 1.5kV r.m.s. for 60 seconds between each winding and the core.

The frequency of the test voltage shall be 50 or 60Hz.

3.1.4 Breakdown voltage

The transformer shall withstand for 1 minute an EHT value 1.3 times the nominal value without showing any

corona, arcing or other failure.

FLYBACK TRANSFORMER SPECIFICATION 1372.7077 D

CUSTOMER CODE 242253100079 ISSUE B

This document and its content are property of PULSE CONSUMER DIVISION.No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of PULSE CONSUMER DIVISION. DOC.N. W4.04 220 571 PAG. 5 / 17

3.2 Test circuit diagram and application conditions

EHT

600M

FOCUS 1

30M 30M

FOCUS 2

500pF

1

500pF

22K

307µH

DYN

G2

11

BU2525AF To beam limiter

10

4 7

5

4K5

27 5n6F

Supply Voltage 0 5

+141Vdc 6

3 10

12µH

1

12

30 7

11

0 5 1

9 8

16 63 5

(Brand) W76ERF072X44

CRT

(Type) 32” 16:9 RF

Deflection angle (°) 110

Neck diameter (mm) 29

Horizontal frequency (kHz) 31.250

Horizontal blanking time (μsec) 6

Active video time (μsec) 26

Active video size (%) 6 overscan

FLYBACK TRANSFORMER SPECIFICATION 1372.7077 D

CUSTOMER CODE 242253100079 ISSUE B

This document and its content are property of PULSE CONSUMER DIVISION.No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of PULSE CONSUMER DIVISION. DOC.N. W4.04 220 571 PAG. 6 / 17

3.3 Electrical performances

@ 0 mA @ 1.8 mA

Electrical parameters Tol. Notes

Beam Min Beam Max

Supply voltage (VDC) 141 141 Nom.

Supply current (mA) 395 740 ± 40

Flyback time (μsec) 5.45 ± 0.2 1)

Peak collector voltage (Vpp) 1209 1253 ± 20

Peak collector current (Ap) 7.2 7.65

Iy deflection current (App) 11 11

Ringing ratio (%) 11 9 15 max 2)

HV output voltages

EHT voltage (kV) 31.4 29.8 ± 0.8

Riht (from 0 to 1.8) (MΩ) 0.88 1 max

Focus 1 min (%of EHT) 19.6 ± 2.1

Focus 1 max (%of EHT) 34.2 ± 1.3

Focus 2 min (%of EHT) 19.6 ± 2.1

Focus 2 max (%of EHT) 34.2 ± 1.3

G2 min (%of EHT) 0.3 + 0.3

G2 max (%of EHT) 5.4 ± 1.3

@ 0 mA Beam

Auxiliary voltages Vpp Vdc Vrms @I(mA) Tol. (%) 3)

Pin n° 5 +98 +204 45 ± 5.5

Pin n° 6 +73.5 -7.3 700 ± 3.5

Pin n° 8 -118 +13.7 200 ± 3.5

Pin n° 9 -118 +13.7 800 ± 3.5

Pin n° 12 +132 -15.3 500 ± 3.5

1) Flyback time must be measured 2) Ringing ratio must be measured

at zero level of collector pulse with placing a capacitive probe close to the

oscilloscope input set on AC upper face of the FBT at the centre of

vertical ripple, as per the following

drawing

B

RR= x 100

A A

0 Level

Ft B

3) All the measurements must be taken with the auxiliary voltages fully loaded.

FLYBACK TRANSFORMER SPECIFICATION 1372.7077 D

CUSTOMER CODE 242253100079 ISSUE B

This document and its content are property of PULSE CONSUMER DIVISION.No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of PULSE CONSUMER DIVISION. DOC.N. W4.04 220 571 PAG. 7 / 17

3.4 Temperatures

3.4.1 Temperature rise of the primary coil

The rise in primary winding or core shall be measured by thermo elements in the following condition: I beam 1.8mA

(long term average) and max loads, according to the test circuit.

See par. 3.2-3.3. Transformer must be placed in free air conditions (See IEC60068 PT1 clause 4.4)

Rise of temperature after 4 hours must be lower than 40°C.

3.4.2 Maximum allowable temperatures

In the application, TV set with cabinet closed, at the maximum allowable ambient temperature (See IEC60068-PT1

clause 4.6.2) and at the maximum working conditions after 4 hours the temperature of the transformer core must be

100°C.

To satisfy the above conditions it is recommended to provide the FBT with sufficient cool air flow around it.

In particular It is reccomended that air flowing and power components locations around FBT area is able to

guarantee that even in the worst working conditions and at ambient temperature of 40°C, the temperature

at a distance of 3 cm from FBT doen’t overcome the limit of 60°C.

3.5 Core saturation

Test must be performed in the following way:

a) The FBT must be placed in oven at ambient temperature of 100°C for 2 hours.

b) Using the circuit below, connect the primary winding to LCR meter operating at frequency of 1 kHz and

output voltage of 1 V.

c) Superimpose through the power supply, step by step, a dc current and read on the LCR meter the

corresponding value of the inductance. Do this up to a current value of 1.35*nominal input current.

d) The value of the inductance must be greater than 0.7*Lnom.

C (40000 µF or more)

A +

CHOKE

(1H or more) LCR

SPECIMEN

METER

FLYBACK TRANSFORMER SPECIFICATION 1372.7077 D

CUSTOMER CODE 242253100079 ISSUE B

This document and its content are property of PULSE CONSUMER DIVISION.No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of PULSE CONSUMER DIVISION. DOC.N. W4.04 220 571 PAG. 8 / 17

4.0 QUALIFICATION TESTS

4.1 Environmental tests

TEST CONDITIONS IEC REF

1) Damp heat, T=+40°C; RH=93%

60068 PT2-78

steady state Test duration: 21 days

T=+100°C 60068PT2-2

2) Dry heat

Test duration: 96h test Ba

T=-25°C 60068 PT2-1

3) Cold

Test duration: 96h test Aa

21 cycles: +25°C/+40°C; 93%RH

4) Damp heat, 60068 PT2-30

11h@+25°; 11h@+40°

cyclic test Db

transition times: 1h - 21 days

5 cycles: -25°/+100°C

5) Change of 60068 PT2-14

3h@-25°; 3h@+100°; transition

temperature test Na

times<1'

Remarks:

After test, condensed humidity must be removed from surface.

After each of these tests the FBT shall satisfy the following:

a) Electrical parameters: All the electrical values of the FBT tested after 4 hours, in normal temperature

and humidity , must be within the margin fixed in the specification.

b) Mechanical parameters: The FBT must satisfy the specification of item 2.

c) Others: No defects such as crack in the case, crack between moulded resin and case must be found.

4.2 Life tests

TEST CONDITIONS IEC REF

T=+90°C

Very High

V=1.1xVnom output - I beam 100μA

Temperature

Test duration: 1000h

T=+40°C; RH=95%

High Temperature

V=1.1xVnom output - I beam 100μA

High Humidity

Test duration: 1000h

Remarks:

Temperature condition must be at 30 mm. distance from the surface of center body of the FBT.

After the tests the transformer must satisfy initial value within the tolerances.

FLYBACK TRANSFORMER SPECIFICATION 1372.7077 D

CUSTOMER CODE 242253100079 ISSUE B

This document and its content are property of PULSE CONSUMER DIVISION.No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of PULSE CONSUMER DIVISION. DOC.N. W4.04 220 571 PAG. 9 / 17

4.3 Other series qualification tests

TEST CONDITIONS IEC REF

P=600 mBar

Low air pressure 60068 PT2-13

V=Vnom - no load

Operation test M

Test duration: 30' (at room temp)

According to UL 94 standard

Flammability 60065

and IEC 60065, clause 14.4.1

T=235°C for 2" 0.5 after 24h of 60068 PT2-20

Solderability

high temperature test Ta method 1

Operating Primary winding & core temperature

60065

Temperature check vs. Spec.

5% NaCl solution. 10 shots per

Salt Spray Test direction (with chimney cap on the

EHT cable)

Core to primary winding:

Insulation

Core to secondary winding

resistance

Primary to secondary windings

According to specification (see par.

Breakdown voltage

3.1.4)

Room temp. - High Temp (100°C)

Core saturation

Saturation curve vs. Spec

5.0 SAFETY

According to international standard IEC 60065

5.1 Approvals

TEST HOUSE STANDARD REFERENCE NBR

VDE EN 60065 4936

UL UL 6500 E100521

FLYBACK TRANSFORMER SPECIFICATION 1372.7077 D

CUSTOMER CODE 242253100079 ISSUE B

This document and its content are property of PULSE CONSUMER DIVISION.No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of PULSE CONSUMER DIVISION. DOC.N. W4.04 220 571 PAG. 10 / 17

5.2 Safety material list

NR. KIND OF TRADE UL UL FILE

FBT PART NAME MANUFACTURER

MATERIAL MARK/TYPE RATING NUMBER

Polyphenylene

GE Plastics BV Noryl PX1394 94 V-0 E45329

1 FBT HOUSING Oxide

PPE Asahi Kasei Xyron 540Z 94 V-0 E82268

Polyphenylene

HIGH VOLTAGE GE Plastics BV Noryl SE 1 GFN 2 94 V-1 E45329

2 Oxide

BOBBIN

PPE Asahi Kasei Xyron G702V 94 V-1 E82268

Polybutylene

LOW VOLTAGE GE Plastics BV Valox 420 SE0 94V-0 E45329

3 terephtalate

BOBBIN Novaduran

PBT Mitsubishi 94 V-0 E53664

5010GN6-30

Huntsman LLC. XB 5711-XB 5712 94 V-0 E96722

CASTING Epoxy resin and Wuxi Wells Synthetic

4 9002 GA – 9002 GA 94-V-0 E197926

COMPOUND hardener Material Co. Ltd

Kyocera Chemical Co. TCG 1123A/B 94-V-0 E43857

Shin-Etsu Chemical

KE-5612GU 94 V-0 E48923

Silicone Rubber Co. Ltd.

6 ANODE CAP

Compound GE Toshiba Silicone

TSE2186U 94 V-0 E56745

Co Ltd

Style 3239 AWG20

Sumitomo Electric

40kV DC 105°C CSA VW-1 E41105

Industries Ltd.

type TV-40

Style 3239 AWG20

Taisho Electric

40kV 105°C DC VJE VW-1 E35688

7 EHT CABLE PVC Insulated Wire Industrial Co. Ltd.

261K

Style 3239 AWG20

LG Cable Ltd. VW-1 E52853

40kV DC 105°C

Style 3239 AWG20

Hangzhou Yongjin VW-1 E209647

40kV DC 105°C

Style 3239 AWG20

Sumitomo Electric

20kV DC 105°C CSA VW-1 E41105

Industries Ltd.

type TV-20

Style 3239 AWG20

Taisho Electric

20kV 105°C DC VJE VW-1 E35688

8 FOCUS CABLE PVC Insulated Wire Industrial Co. Ltd.

261K

Style 3239 AWG20

LG Cable Ltd. VW-1 E52853

20kV DC 105°C

Style 3239 AWG20

Hangzhou Yongjin VW-1 E209647

20kV DC 105°C

PBT GE Plastics Japan Ltd. PDR4908 94 V-0 E45587

POTENTIOMETER

9

HOUSING

Polycarbonate GE Plastics Japan Ltd. PC940 94 V-0 E45587

ROTOR OF

10 Polycarbonate GE Plastics Japan Ltd. Lexan 500R 94 V-0 E45587

POTENTIOMETER

SEE PAGE 17

FLYBACK TRANSFORMER SPECIFICATION 1372.7077 D

CUSTOMER CODE 242253100079 ISSUE B

This document and its content are property of PULSE CONSUMER DIVISION.No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of PULSE CONSUMER DIVISION. DOC.N. W4.04 220 571 PAG. 11 / 17

5.2 Safety material list

KIND OF TRADE UL UL FILE

NR. FBT PART NAME MANUFACTURER

MATERIAL MARK/TYPE RATING NUMBER

Style 3476 AWG20

Sumitomo Electric

3KV DC 105°C CSA VW-1 E41105

Industries Ltd.

type TV-6

Style 1032 AWG20

Sumitomo Electric

1.2kV DC 90°C CSA VW-1 E41105

Industries Ltd.

type TR-32

11 SCREEN CABLE PVC Insulated Wire

Style 3476 AWG20

LG Cable Ltd. 3KV DC 105°C CSA VW-1 E52853

type TV-6

Style 1032 AWG20

Hangzhou Yongjin VW-1 E209647

1.2kV DC 90°C

POTENTIOMETER Polyphenylene

12 GE Plastics Japan Ltd. Noryl PX9406P 94 V-0 E45587

BACK COVER Oxide

TSE 2183U 94V-0 E56745

GE Toshiba Silicones

Silicone Rubber Co. Ltd.

13 CHIMNEY CAP TSE 2186U 94V-0 E56745

Compound

Shin-Etsu Chemical

KE-5612GU 94V-0 E48923

Co. Ltd.

BRACKET and

16 Polycarbonate GE Plastics Japan Ltd. Lexan 500R 94 V-0 E45587

BLEEDER HOLDER

SEE PAGE 17

FLYBACK TRANSFORMER SPECIFICATION 1372.7077 D

CUSTOMER CODE 242253100079 ISSUE B

This document and its content are property of PULSE CONSUMER DIVISION.No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of PULSE CONSUMER DIVISION. DOC.N. W4.04 220 571 PAG. 12 / 17

Other materials

NR. FBT PART NAME KIND OF MANUFACTURER TRADE UL UL FILE

MATERIAL MARK/TYPE RATING NUMBER

CRIMPED Brass copper tin- Eklinker,

SIN-21T-1.8S (B) E60389

TERMINAL plated JST,

Nexans VW-1 E67139

Class F (155°C)

WIRES x Enamelled copper Dong Yang cable ltd Grade 2 Ø 0.40mm VW-1 E206407

Low voltage wire

Heng Ya Electric 0.25mm (LV)

VW-1 E245514

Kun Shan Ltd.

Class F (155°C)

WIRES x Enamelled copper Elektrisola Atesina

Grade3 Ø 0.060mm VW-1 E125650

high voltage wire SRL

(HV)

Tianjin Zhong-Huan

2CL01

DIODES semiconductor Co

Fuji ESJA08-08

DMEGC Magnetics

CORE Soft ferrite DMR40

co. Ltd.

Dongyangguan

Ferroxcube 3C30

TDG (Tiantong)

King Tech

Isu

Samhwa

Epcos AG Ferrites

Div.

CONDUCTIVE Helvoet

Silicon conductive

RUBBER Hsiang Wei Rubber

FIXING GLUE Polyurethane Rohm&Haas RX-3

De Galeazzi

CONNECTING TAG Tinned brass Thickness 0.5mm

Ekinler

Neumayer

CONNECTING Edelhoff Adolf

Tinned brass Thickness 0.8mm

WIRE Wencheng

Hong YI

Thick film metal Hokuriku

BLEEDER

glaze resistor Chunlon corp.

Carbon Kamaya

RESISTOR

Carbon film Uni-Royal

Taitsu

HIGH VOLTAGE

Polyester film Taiwan Thick-Film

CAPACITORS

ind corp

Neumayer NS 6218 type

Edelhoff Adolf

PRIMARY PINS Nickel silver

Wencheng

Hong YI

FLYBACK TRANSFORMER SPECIFICATION 1372.7077 D

CUSTOMER CODE 242253100079 ISSUE B

This document and its content are property of PULSE CONSUMER DIVISION.No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of PULSE CONSUMER DIVISION. DOC.N. W4.04 220 571 PAG. 13 / 17

6.0 PRECAUTIONS

The following instructions must be strictly followed by the transformer user.

Any deviation not specifically authorised in writing by Pulse Italy S.r.l. will relieve the company of all responsibility

including safety and warranty on the product.

6.1 Application

The transformer has been designed, optimized and tested according to the enclosed circuit (par. 3.2).

Changes in critical components (i.e. deflection yokes, flyback capacitor, supply voltage, etc.) or working conditions

could compromise performances, reliability and safety of the product.

FBT protection circuit: materials of FBT are organic compound. In case of short circuit it may generate smoking.

Therefore, it is requested to provide a protective circuit which stops FBT operation by detecting input current to

prevent the smoke release.

6.2 Mounting precautions

6.2.1 Clearance area

The FBT must be located in such a manner that all the peripheral metal/conductive parts stay outside of the area

as indicated in the figure below.

The core under the dry High Temperature Atmosphere may charge a few thousand Volt. Therefore, pay attention to

placing components around the core to avoid the core discharge.

The distance between the anode cap and any low potential part must be at least 10mm.

In case of sharp edges the distance must be increased to 15mm minimum.

For a better reliability of the FBT, an EHT cable whit silicone chimney must be used.

B

B

B

B B B

L L

L

L L

L

L L

L L

L

L

L L L

L

L

60° 60° L

L L L

L = 10 mm (min.)

B = 20 mm (min)

L L

ANODE CAP

FLYBACK TRANSFORMER SPECIFICATION 1372.7077 D

CUSTOMER CODE 242253100079 ISSUE B

This document and its content are property of PULSE CONSUMER DIVISION.No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of PULSE CONSUMER DIVISION. DOC.N. W4.04 220 571 PAG. 14 / 17

6.3 Handling precautions

- do not give any mechanical shock to the FBT especially to the ferrite core which is very fragile. In case

of drop or shock the FBT must not be used.

- do not lift or move the FBT holding it by its anode, focus or Vg2 cables.

- do not bend the terminal pins of the transformer

- do not wet the transformer with any liquid, especially hydrocarbon halogenide (carbon tetrachloride,

freon, etc.) or aromatic hydrocarbon (toluene, etc.). These solvents which are sometimes used to clean

the PCBs after soldering, may cause cracks or melting of the FBT case.

- do not dirt the FBT with oil materials which may cause cracks in the FBT case. Fastening screws must

be cleaned from the adhered oil prior to use.

- do not push sharp pins or hard materials against the anode cap. They may pierce holes into the silicon

rubber and the high voltage may leak through them causing electric shock.

6.4 Arcing absorption

Provide the CRT electrodes circuit with spark gaps. In case of CRT flashover, the high voltage rectifiers diodes

inside the FBT night be damaged.

6.5 Anode cap connection

When connecting the anode cap to the CRT button, make sure to hook firmly both the legs of the anode spring into

the cavity.

Make sure also that the rubber cap adheres completely to the glass of the CRT funnel.

Once assembled on the CRT the anode cap must not be turned around.

6.6 Mounting on PCB

In order to prevent peeling off the PCB copper foil because of the moving of the pins, mount the transformer so that

the whole FBT base touches closely the PCB.

6.7 Soldering

Pins soldering shall be carried out at a temperature lower than 260°C for 5 seconds max.

FLYBACK TRANSFORMER SPECIFICATION 1372.7077 D

CUSTOMER CODE 242253100079 ISSUE B

This document and its content are property of PULSE CONSUMER DIVISION.No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of PULSE CONSUMER DIVISION. DOC.N. W4.04 220 571 PAG. 15 / 17

MECHANICAL DRAWINGS

ALL DIMENSIONS IN mm

14.5±0.05 14.5±0.05

GENERAL TOLERANCE ± 0.2

11.33±0.05

6

R1 = 740 ± 20mm

3

24.5 ± 0.2

0.05

24.5 ±0.2

13.7± 0.05

7.67 ±0.05

1.3 +0.1 R2 = 550 ± 20mm

11.33±

12 -0 1

(x14)

11 R3 = 565 ± 20mm

10

3

L4 = 10 ± 1mm

± 0.2

13

9 R6 = 525 ± 20mm

12.25 ±0.05

5

1.57 ±0.05

8

8.2 ±0.05

27.5

L7 = 10 ± 1mm

10.29 ± 0.05

14.4 ± 0.05

7 6

1.67 ±0.05

13.38± 0.05

R8 = 325 ± 20mm

4.75 ± 0.05

D1 = Ø65 ± 2mm

7.76± 0.05 10.22 ± 0.05

PIANO di FORATURA

12.31±0.05

LATO RAME 14.42±0.05

HOLES PATTERN 25.5 ±0.05

COPPER SIDE

15 15

44.3 nom 5 ± 0.1

5± 0.1

16.5 max

D1

max

37.35

24.5 ± 0.2

24.5 ± 0.2

12 1

18.7

0.2

13

17.5

20.4

24.8

27.5 ±

5 ± 0.1 ø 3.2 ± 0.2

30 max 19.7

47 max

ø 4.2 ± 0.2

L7

L4

40.7 nom

24.3 ø 2.51 ± 0.2

ø 3.2

R1

black cable

Static focus

Red cable

R3

8

Dynamic focus

ø

R2

R6

R8

113 max

F O

79 max

C U S

67 ± 0.5

2

± 0.3

+0.05

1.65 0

46.6

30.1 ± 0.3

E

E

R

S

C

N

10.1 ± 0.3

+1

0

4 ± 0.1

4.5

ø1± 0.1

FLYBACK TRANSFORMER SPECIFICATION 1372.7077 D

CUSTOMER CODE 242253100079 ISSUE B

This document and its content are property of PULSE CONSUMER DIVISION.No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of PULSE CONSUMER DIVISION. DOC.N. W4.04 220 571 PAG. 16 / 17

MATERIAL LIST REFERENCE

8 13

11

16

12

4

10

2

9

3

FLYBACK TRANSFORMER SPECIFICATION 1372.7077 D

CUSTOMER CODE 242253100079 ISSUE B

This document and its content are property of PULSE CONSUMER DIVISION.No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of PULSE CONSUMER DIVISION. DOC.N. W4.04 220 571 PAG. 17 / 17

DRAWINGS OF CABLES ALONE L1 = 710 ± 10mm

L2 = 500 ± 10mm

L3 = 560 ± 10mm

L4 = 10 ± 1mm

L6 = 500 ± 10mm

L7 = 10 ± 1mm

L8 = 320 ± 1mm

30°

L1

-0.5

5 +1

27 ±0.2

19.5 ±0.1

ø 63.5 ±2 Type Hungerle SK14

R2 ±0.75

R2 ±0.75

R3.75 ±0.2

R2 ±0.75

85 ± 1

14.7 ± 0.1

4 ±0.5

Ø 8 ±0.4

R2 ±0.75

Ø 4.2 ±0.2

R2 ±0.75

12.5 ±0.25

L2

5±1 F1 BLACK CABLE L4

Ø 3.2 ± 0.2

L3

5±1 SCREEN CABLE 5±1

Ø 2.5 ± 0.2

L6

5±1 F2 RED CABLE L7

Ø 3.2 ± 0.2

L8

5±1 DYN CABLE 5±1

Ø 2.5 ± 0.2

FLYBACK TRANSFORMER SPECIFICATION 1372.7077 D

CUSTOMER CODE 242253100079 ISSUE B

This document and its content are property of PULSE CONSUMER DIVISION.No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of PULSE CONSUMER DIVISION. DOC.N. W4.04 220 571 ENCLOSURE 1

L1

45°

-0.5

5 +1

27 ± 1

20 ±0.5

Ø 65.5 ± 1 Type CHUNLON CS65

R4 ±0.5

R4 ±0.5

R4 ±0.5

85 ± 1

14.5 + 0.3

4 ±0.5

Ø 7.5 ±0.3

R4 ±0.5

Ø 4.2 ±0.2

R4 ±0.5

12 ± 0.5

ANODE CAP MARKING MANUFACTURER MATERIAL

CS 65 Shin-Etsu Chemical KE-5612G

Bayer AG Silopren LSR 2255 VP

SK-14 Wacker Chemie Elastosil LR 3001/55

Dow Corning Silastic 9220/55

FLYBACK TRANSFORMER SPECIFICATION 1372.7077 D

CUSTOMER CODE 242253100079 ISSUE B

This document and its content are property of PULSE CONSUMER DIVISION.No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of PULSE CONSUMER DIVISION. DOC.N. W4.04 220 571 ENCLOSURE 1

EHT output

WINDINGS AND CORE DATA 1

Primary, auxiliary and EHT windings.

Terminal No. Name Number of turns

1-3 V B / Collector 72

5-3 +210V 5

7-6 Heater 5

7-8 +13.8V 8

11-9 +13.2V 8

11-12 -15.4V 9

10-EHT EHT 2122

5

Magnetic circuit

3

Airgap = 1 mm (inside) + 100 μm (outside)

2 10

Ae = 194 mm

Le = 176 mm 12

Core materials = DMR40 or Equivalent 6

11 7

9 8

SATURATION CURVE @ 100°C

1,100

1,000

0,900

Relative primary Iductance (LP@0/LpxAdc)

0,800

0,700

0,600

0,500

0,400

0,300

0,200

0,100

0,000

0,000 0,200 0,400 0,600 0,800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400 2,600 2,800 3,000 3,200 3,400

Current (Adc)

FLYBACK TRANSFORMER SPECIFICATION 1372.7077 D

CUSTOMER CODE 242253100079 ISSUE B

This document and its content are property of PULSE CONSUMER DIVISION.No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of PULSE CONSUMER DIVISION. DOC.N. W4.04 220 571 ENCLOSURE 2

SCHEDA DI APPROVAZIONE

APPROVAL FORM

ATTENZIONE: PHILIPS DATA: 06/06/2005

ATTENTION: DATE:

Spett. Cliente, Vi chiediamo di controllare questa specifica e restituirci il presente modulo firmato per

l’approvazione. Preghiamo comunicare eventuali osservazioni in merito.

Distinti saluti.

Dear Customer, you are kindly requested to review this specification and send back to us only this form signed off

for approval.

If you have any remarks, please let us know.

Best regards.

PULSE ITALY s.r.l. con s.u.

Documentation Management

DATE OF

ISSUED BY: CHECKED BY: APPROVED BY:

APPROVAL:

REMARKS:

Mail for the attention of:

PULSE ITALY s.r.l. con s.u.

Documentation Management

Via Ticino, 2c

22070 SENNA COMASCO (Como)

ITALY

fax: +39 031 4630790

FLYBACK TRANSFORMER SPECIFICATION 1372.7077 D

CUSTOMER CODE 242253100079 ISSUE B

This document and its content are property of PULSE CONSUMER DIVISION.No part of this document may be

reproduced, published, disclosed or used in any form with out written permission of PULSE CONSUMER DIVISION. DOC.N. W4.04 220 571

Customer Approval Form Pag. 1 di 1 W4.04 220 571 K/4

Вам также может понравиться

- 01 Technical Specification For 160MVA 220 132 33KV Power TransformerДокумент88 страниц01 Technical Specification For 160MVA 220 132 33KV Power Transformerk. harikarasudhan33% (3)

- Harmonized Household Profiling ToolДокумент2 страницыHarmonized Household Profiling ToolJessa Mae89% (9)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Drug AbuseДокумент33 страницыDrug AbuseharshulnmimsОценок пока нет

- Transformer SpecificationДокумент24 страницыTransformer Specificationamrit90320Оценок пока нет

- Construction Electrical Boq NewДокумент7 страницConstruction Electrical Boq Newmudassir mОценок пока нет

- Tested by M/S Siemens Organized by M/S Emc Witnessed by M/S Pgcil Name G Ramesh Designation SignatureДокумент2 страницыTested by M/S Siemens Organized by M/S Emc Witnessed by M/S Pgcil Name G Ramesh Designation SignatureRK KОценок пока нет

- Plumbness Inspection ReportДокумент3 страницыPlumbness Inspection ReportDoris DorisОценок пока нет

- RCW Recloser Installation ManualДокумент9 страницRCW Recloser Installation ManualCesar VenturoОценок пока нет

- Transformers SpecДокумент13 страницTransformers SpecAkshay PanttОценок пока нет

- J0231 HV TR - FINAL变压器1Документ23 страницыJ0231 HV TR - FINAL变压器1SerhiiОценок пока нет

- LIGHTNING ARRESTORS - Rev 2Документ11 страницLIGHTNING ARRESTORS - Rev 2kajale.shrikantОценок пока нет

- NSTP1 MODULE 3 Disaster Awareness Preparedness and ManagementДокумент16 страницNSTP1 MODULE 3 Disaster Awareness Preparedness and Managementrenz dave100% (2)

- BS7-Touch Screen PanelДокумент96 страницBS7-Touch Screen PanelEduardo Diaz Pichardo100% (1)

- Studovaný Okruh: Physical Therapist Sample Test Questions (G5+)Документ8 страницStudovaný Okruh: Physical Therapist Sample Test Questions (G5+)AndreeaОценок пока нет

- J0231 LV TR - FINAL变压器2Документ21 страницаJ0231 LV TR - FINAL变压器2SerhiiОценок пока нет

- Specification For HV Transformer (Hyundai Heavy Industries CO., LTD.)Документ32 страницыSpecification For HV Transformer (Hyundai Heavy Industries CO., LTD.)Oleksandr RakshaОценок пока нет

- S753 E-32 6e2838105 TransformerДокумент27 страницS753 E-32 6e2838105 TransformerJosip ZohilОценок пока нет

- Specification For Approval: DC FanДокумент13 страницSpecification For Approval: DC FanElias CoelhoОценок пока нет

- Technical Specification - 2023 01 16 18 50 06Документ10 страницTechnical Specification - 2023 01 16 18 50 06abhishekgupta9990Оценок пока нет

- 010 OktoberДокумент36 страниц010 OktoberTri ananda putraОценок пока нет

- Specification For Power Transformer:::: Document No. Description Item/Tag Imo NumberДокумент30 страницSpecification For Power Transformer:::: Document No. Description Item/Tag Imo NumberFILIN VLADIMIRОценок пока нет

- Circuit Setter Plus: Calibrated Balance Valves With NPT and Solder Connections Lead FreeДокумент3 страницыCircuit Setter Plus: Calibrated Balance Valves With NPT and Solder Connections Lead Freefernandoperdomo20-1Оценок пока нет

- Dwyer 1950 G ATEXДокумент2 страницыDwyer 1950 G ATEXMarco CastroОценок пока нет

- Katalog RKS LAST 12 02 2019 ONEPAGE PDFДокумент18 страницKatalog RKS LAST 12 02 2019 ONEPAGE PDFivicaОценок пока нет

- Yamaha Rx-A1040 Rx-V1077 SMДокумент200 страницYamaha Rx-A1040 Rx-V1077 SMJunius du PlessisОценок пока нет

- Construction Check Sheet Power & Auxilliary Transformer E-012AДокумент2 страницыConstruction Check Sheet Power & Auxilliary Transformer E-012AhrimklimОценок пока нет

- Crompton DC MotorsДокумент6 страницCrompton DC MotorsAzed-dine BoughmarОценок пока нет

- B70-00-7010 Datasheets USДокумент4 страницыB70-00-7010 Datasheets USAlejandro Garcia MОценок пока нет

- Spec TN-2534Документ37 страницSpec TN-2534dharm rajОценок пока нет

- Hci634y 312Документ9 страницHci634y 312Nos GoteОценок пока нет

- Yuken Pressure SwitchДокумент4 страницыYuken Pressure Switchajay pandeyОценок пока нет

- HCI634K - Technical Data SheetДокумент8 страницHCI634K - Technical Data Sheetchock channel 19Оценок пока нет

- THD0924HEДокумент11 страницTHD0924HEFilipeОценок пока нет

- 02.06.05 3-Way Valve 1240 6519 - enДокумент6 страниц02.06.05 3-Way Valve 1240 6519 - enabuya3kubmОценок пока нет

- PT PLN (Persero) : 1 Based On Konsinyering Dated 11 Oct 2021 0 Original IssueДокумент18 страницPT PLN (Persero) : 1 Based On Konsinyering Dated 11 Oct 2021 0 Original IssueFaizal SetiawanОценок пока нет

- Hci634w 312Документ9 страницHci634w 312GUZMAN05Оценок пока нет

- Mps & Itt - Spiral SteelДокумент23 страницыMps & Itt - Spiral SteelSiswo YuwonoОценок пока нет

- 06-GR60-T-007.001 of 03Документ3 страницы06-GR60-T-007.001 of 03carrei JohnОценок пока нет

- 1-Spec 500 KV TransformerДокумент72 страницы1-Spec 500 KV TransformerAhsan SNОценок пока нет

- Kailh CPG1511F01S172Документ14 страницKailh CPG1511F01S172xujiaqi730Оценок пока нет

- Stereo CD Receiver: This Manual Is Applicable To The Following Model (S) and Type (S)Документ57 страницStereo CD Receiver: This Manual Is Applicable To The Following Model (S) and Type (S)Liviu LvuОценок пока нет

- Establishment of FC Hospital Peshawar: Established 1949 Our RefДокумент10 страницEstablishment of FC Hospital Peshawar: Established 1949 Our Refshaista fazalОценок пока нет

- Revised Offer For 2 MVA Transformer (R-3)Документ11 страницRevised Offer For 2 MVA Transformer (R-3)احمد العبيديОценок пока нет

- Transformers (Level-1 & 2)Документ45 страницTransformers (Level-1 & 2)SAGARОценок пока нет

- Samwha Electric Catalog EngДокумент140 страницSamwha Electric Catalog Englehaphuong03Оценок пока нет

- SMDY1 Series AC Line Rated Ceramic Disc Capacitors Class X1, 760 V, Class Y1, 500 VДокумент7 страницSMDY1 Series AC Line Rated Ceramic Disc Capacitors Class X1, 760 V, Class Y1, 500 Vumut bayОценок пока нет

- RMH-LC-ACV-DOC-006 RC Equipment Selection Seawater Cooled Package Air ConditionerДокумент21 страницаRMH-LC-ACV-DOC-006 RC Equipment Selection Seawater Cooled Package Air Conditionercmc261185Оценок пока нет

- Cupiagua CPF: UPS Inverter and Static Switch Function Test CertificateДокумент1 страницаCupiagua CPF: UPS Inverter and Static Switch Function Test CertificateKhaled FatnassiОценок пока нет

- Aisladores ABB - GSAДокумент16 страницAisladores ABB - GSALeonel BermudezОценок пока нет

- Item Description Qnty Unit Rate Amount Electrical InstallationДокумент10 страницItem Description Qnty Unit Rate Amount Electrical InstallationMohammed BasheeruddinОценок пока нет

- 18 8041 FT e Series en M o BD v1Документ2 страницы18 8041 FT e Series en M o BD v1Zain ShariffОценок пока нет

- TB2 SDC - VP101 00100 E M1A DCS 5002 - Rev0 PDFДокумент20 страницTB2 SDC - VP101 00100 E M1A DCS 5002 - Rev0 PDFNguyen NgocОценок пока нет

- Manual de Servicio PHILCO PF2175 PDFДокумент30 страницManual de Servicio PHILCO PF2175 PDFMingo YontoОценок пока нет

- Approval Drawing: Drawing No. Date. Reference. Rev NoДокумент4 страницыApproval Drawing: Drawing No. Date. Reference. Rev NoYohanes Dimas PriambodhoОценок пока нет

- 824 (ALPHA 24mm Potentiometers)Документ1 страница824 (ALPHA 24mm Potentiometers)Adilson LucaОценок пока нет

- Crane Control Equ Pments Crane Control Equ Pments: Ma Ter O Tro ER SC NLL Ma Ter O Tro ER SC NLLДокумент6 страницCrane Control Equ Pments Crane Control Equ Pments: Ma Ter O Tro ER SC NLL Ma Ter O Tro ER SC NLLTamil PugazhОценок пока нет

- Eversendai Offshore RMC Fze: Request For TestingДокумент1 страницаEversendai Offshore RMC Fze: Request For Testingbharani dharanОценок пока нет

- Chasis CY-PH2529TOP PDFДокумент25 страницChasis CY-PH2529TOP PDFDaniel AvecillaОценок пока нет

- Alternator DatasheetДокумент8 страницAlternator Datasheetrushikesh panditОценок пока нет

- Diverter Valve Wam BrochureДокумент4 страницыDiverter Valve Wam BrochureEzequiel Guillermo Trejo NavasОценок пока нет

- Huf75344G3, Huf75344P3: N-Channel Ultrafet Power Mosfet FeaturesДокумент10 страницHuf75344G3, Huf75344P3: N-Channel Ultrafet Power Mosfet FeaturesChristina MullinsОценок пока нет

- SUNON MF40201V1-1000U-G99 pg8Документ15 страницSUNON MF40201V1-1000U-G99 pg8dkelicОценок пока нет

- HumareaderДокумент37 страницHumareaderStefan JovanovicОценок пока нет

- For Hand Grip Strength: NormsДокумент7 страницFor Hand Grip Strength: NormsPraneethaОценок пока нет

- Aliant Ommunications: VCL-2709, IEEE C37.94 To E1 ConverterДокумент2 страницыAliant Ommunications: VCL-2709, IEEE C37.94 To E1 ConverterConstantin UdreaОценок пока нет

- 51 - Methemoglobin ProducersДокумент20 страниц51 - Methemoglobin ProducersCabinet VeterinarОценок пока нет

- Biomolecules ExtractionДокумент6 страницBiomolecules ExtractionBOR KIPLANGAT ISAACОценок пока нет

- SAT Subject Chemistry SummaryДокумент25 страницSAT Subject Chemistry SummaryYoonho LeeОценок пока нет

- Espiritualidad AFPP - 2018 PDFДокумент5 страницEspiritualidad AFPP - 2018 PDFEsteban OrellanaОценок пока нет

- Marine Advisory 03-22 LRITДокумент2 страницыMarine Advisory 03-22 LRITNikos StratisОценок пока нет

- Pengaruh Penambahan Lateks Pada Campuran Asphalt Concrete Binder Course (AC-BC)Документ10 страницPengaruh Penambahan Lateks Pada Campuran Asphalt Concrete Binder Course (AC-BC)Haris FirdausОценок пока нет

- PD 984Документ38 страницPD 984mav3riick100% (2)

- BRC1B52-62 FDY-F Ducted Operation Manual - OPMAN01!1!0Документ12 страницBRC1B52-62 FDY-F Ducted Operation Manual - OPMAN01!1!0Justiniano Martel67% (3)

- Analyzing Activity and Injury: Lessons Learned From The Acute:Chronic Workload RatioДокумент12 страницAnalyzing Activity and Injury: Lessons Learned From The Acute:Chronic Workload RatioLukas ArenasОценок пока нет

- Aseptic TechniquesДокумент3 страницыAseptic TechniquesMacy MarianОценок пока нет

- SET 2022 Gstr1Документ1 страницаSET 2022 Gstr1birpal singhОценок пока нет

- OpenStax - Psychology - CH15 PSYCHOLOGICAL DISORDERSДокумент42 страницыOpenStax - Psychology - CH15 PSYCHOLOGICAL DISORDERSAngelaОценок пока нет

- 13 Lombe Mumba Ramson 2017 Knowledge Attitude and Practice of Breast Self Examination For Early Detectoin of Breast Cancer Among Women in Roan Constituency in Luanshya Copperbelt Province ZambiaДокумент9 страниц13 Lombe Mumba Ramson 2017 Knowledge Attitude and Practice of Breast Self Examination For Early Detectoin of Breast Cancer Among Women in Roan Constituency in Luanshya Copperbelt Province ZambiaArick Frendi AndriyanОценок пока нет

- S:/admin/mpi/MP1169 - Amaia Skies Samat/000 - ACTIVE DOCUMENTS/09 - SPECS/2013-07-23 - Design Development/04-Plumbing/15050Документ19 страницS:/admin/mpi/MP1169 - Amaia Skies Samat/000 - ACTIVE DOCUMENTS/09 - SPECS/2013-07-23 - Design Development/04-Plumbing/15050Lui TCC BariaОценок пока нет

- Human Rights Law - Yasin vs. Hon. Judge Sharia CourtДокумент7 страницHuman Rights Law - Yasin vs. Hon. Judge Sharia CourtElixirLanganlanganОценок пока нет

- Athletes Who Made Amazing Comebacks After Career-Threatening InjuriesДокумент11 страницAthletes Who Made Amazing Comebacks After Career-Threatening InjuriesანაОценок пока нет

- 4th Summative Science 6Документ2 страницы4th Summative Science 6brian blase dumosdosОценок пока нет

- #1 - The World'S Oldest First GraderДокумент6 страниц#1 - The World'S Oldest First GraderTran Van ThanhОценок пока нет

- Assignment Nutrition and HydrationДокумент17 страницAssignment Nutrition and Hydrationmelencio olivasОценок пока нет

- Pakeha (Maori For European New Zealanders) Thinking, in That They Tend To Go OutwardsДокумент11 страницPakeha (Maori For European New Zealanders) Thinking, in That They Tend To Go OutwardsDwi RahayuОценок пока нет

- Cranial Electrotherapy Stimulator (C.E.S.) Earlobe Stimulator, Pocket-Transportable, 9VДокумент1 страницаCranial Electrotherapy Stimulator (C.E.S.) Earlobe Stimulator, Pocket-Transportable, 9VemiroОценок пока нет