Академический Документы

Профессиональный Документы

Культура Документы

TEST PILE and Load Test Procedure Details - New PDF

Загружено:

Rakesh Kumar MohantyИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

TEST PILE and Load Test Procedure Details - New PDF

Загружено:

Rakesh Kumar MohantyАвторское право:

Доступные форматы

Test pile and load test details

The pile ET4 is a bored pile with length equal to 24 m and diameter equal to 1 m. It was

drilled on December 15, 2014 using by a toothed bucket under polymer suspension. For the

stabilization of the upper

pper portion of the borehole, temporary steel casing (33 m in length, 1.1 m

in diameter)) was used. When the final depth was reached, the bottom of the borehole was

cleaned using the same bucket used for drilling.

dril After the de-sanding

sanding of the bentonite

b slurry,

the instrumented cage was placed in the borehole. The tremie method of concreting was then

used to pour the concrete in the borehole; the concrete had a slump of 24-25 25 cm (CIP IV, fck =

20 MPa).

The pile is fully instrumented along the shaft: 8 sections are instrumented by means of

Geokon vibrating wire strain gauges (Rebar Strainmeters Model 4911). The first instrumented

section lies at a depth z = 0.5 m below the ground level and the last at z = 23.5

2 m. Moreover, 4

still tubes were fixed to the cage to perform integrity testing (Cross-Hole,

(Cross Hole, CH, and Thermal

Integrity Profile, TIP) and to use one retrievable Geokon exensometer with 3 anchors (Model

(

A9) for additional strain measurements

measurement during loading.

In January, 2015, the integrity of the pile was checked by means of different non-destructive

non

techniques: PIT (Pile Integrity Testing),

Testing) CH and TIP. All the results are available on

o the web

site (see Download data).

In the next months, pile ET4 will be subjected to a static conventional axial load test. The load

will be applied by means of two hydraulic jacks reacting against a steel beam,

beam which is itself

anchored to 4 reaction piles (continuous

(c flight auger (CFA) piles 20 m in length and 0.8 m in

diameter,, reinforced by 3 Dywidag bars with diameter of 36 mm).

The pile head displacements will be measured by 4 Linear Vertical Displacement Transducers

(LVDTs), supported by reference beams.

The test procedure will follow International Standards (a compromise

compromise between Eurocode 7

Part 1;; ASTM D1143 and ABNT NBR 12131). After a pre-loading pre loading stage of maximum

5%Qmax to control and adjust loading and measurement equipment, the pile will be unloaded

to a small residual load. The static loading force will then be increased in steps, which will be

held constant over a fixed time.

time

The maximum load will be removed by means of 5 unloading steps.

Additional details on the pile instrumentation and on the pile position are reported in attached

drawings.

Вам также может понравиться

- Analysis of P-Y Curves From Lateral Load Test of Large Diameter Drilled Shaft in Stiff Clay - 6thSDW - 2001 - Paper - 05-105Документ13 страницAnalysis of P-Y Curves From Lateral Load Test of Large Diameter Drilled Shaft in Stiff Clay - 6thSDW - 2001 - Paper - 05-105senhuОценок пока нет

- Chapter 214. The Use of Osterberg Cell Load Tests To Predict Piles ResistanceДокумент6 страницChapter 214. The Use of Osterberg Cell Load Tests To Predict Piles ResistanceTony ChanОценок пока нет

- Veludo - Bond Strength of Micropile-Grout-Concrete Interfaces in RC Footings With MicropilesДокумент48 страницVeludo - Bond Strength of Micropile-Grout-Concrete Interfaces in RC Footings With Micropilesgilliancooper025Оценок пока нет

- Centrifuge Modeling On Manhole Uplift in A Liquefied 2011 Soils and FoundatiДокумент12 страницCentrifuge Modeling On Manhole Uplift in A Liquefied 2011 Soils and FoundatiroshnaОценок пока нет

- Deep Foundation Practice - BarrettesДокумент9 страницDeep Foundation Practice - Barrettesssi3k100% (1)

- A New Approach in The Design of First Lining Steel RibДокумент8 страницA New Approach in The Design of First Lining Steel RibMesut ÜnalОценок пока нет

- Pseudo-Dynamic Test of A Full-Scale CFT/BRB Frame: Part 2 - Construction and TestingДокумент15 страницPseudo-Dynamic Test of A Full-Scale CFT/BRB Frame: Part 2 - Construction and TestingDiego Matias Burgos FuentesОценок пока нет

- Findings From Instrumented Pile Load TestsДокумент5 страницFindings From Instrumented Pile Load TestsMuhammad ShoaibОценок пока нет

- Loading Tests - Concrete SleepersДокумент14 страницLoading Tests - Concrete SleepersSzabolcs Attila KöllőОценок пока нет

- The Effects of Loaded Bored Piles On Existing TunnelsДокумент7 страницThe Effects of Loaded Bored Piles On Existing TunnelsGeotech Designers IITMОценок пока нет

- CESMM3 Class B Ground InvestigationДокумент24 страницыCESMM3 Class B Ground InvestigationmorrisioОценок пока нет

- Behavior of Ground Anchors For Taipei Sedimentary SoilsДокумент5 страницBehavior of Ground Anchors For Taipei Sedimentary SoilsArges KLОценок пока нет

- Recent Development in Pile Instrumentation Technology For Driven, Jacked-In and Bored Cast-In-Place PilesДокумент25 страницRecent Development in Pile Instrumentation Technology For Driven, Jacked-In and Bored Cast-In-Place Pileszzz_monsterОценок пока нет

- A Refinery Expansion Project With Piles PDFДокумент8 страницA Refinery Expansion Project With Piles PDFJean-Louis KouassiОценок пока нет

- Al Maryah CentralДокумент19 страницAl Maryah CentralKaram JaradatОценок пока нет

- Experimental Determination of Damping Ratio of A Transparent Pier With Steel Piles and Reinforced Concrete BoarДокумент13 страницExperimental Determination of Damping Ratio of A Transparent Pier With Steel Piles and Reinforced Concrete BoarAngga Fajar SetiawanОценок пока нет

- Test11 SummaryДокумент18 страницTest11 SummaryFransisca WijayaОценок пока нет

- Theoretical and Experimental Analysis of The Cracking Moment in Reinforced Concrete Footing Supported in Granular SoilДокумент9 страницTheoretical and Experimental Analysis of The Cracking Moment in Reinforced Concrete Footing Supported in Granular SoilFernando JoveОценок пока нет

- The Use of Osterberg Cell Load Tests To Predict Piles ResistanceДокумент6 страницThe Use of Osterberg Cell Load Tests To Predict Piles Resistancedidiet noer affendiОценок пока нет

- Preliminary Design Outline: 3.1 ObjectiveДокумент10 страницPreliminary Design Outline: 3.1 Objectivemohamed ahmedОценок пока нет

- Arching of SoilДокумент14 страницArching of SoilKanako NozawaОценок пока нет

- Journal Fatima, Z. M (2011) AlgeriaДокумент10 страницJournal Fatima, Z. M (2011) AlgeriaSutarno -Оценок пока нет

- Pile Capacity Prediction in Minnesota Soils Using Direct CPT and Cptu MethodsДокумент8 страницPile Capacity Prediction in Minnesota Soils Using Direct CPT and Cptu MethodsJurie_sk3608Оценок пока нет

- Flexural Strength of ConcreteДокумент4 страницыFlexural Strength of ConcreteAicet Guru0% (1)

- 1-04 GOST-A New Cone PenetrometerДокумент10 страниц1-04 GOST-A New Cone PenetrometerPablo Cesar TrejoОценок пока нет

- Static Cone Penetration TestДокумент9 страницStatic Cone Penetration TestRuchit GandhiОценок пока нет

- Resistance of A Drilled Shaft Footing To Overturning Loads, Model Tests and Correlation With TheoryДокумент19 страницResistance of A Drilled Shaft Footing To Overturning Loads, Model Tests and Correlation With TheoryAakar ConsultantsОценок пока нет

- O.M.Alsamman, J.H.Long - (1993) - Prediction of Drilled Shafts Axial Capacities Using CPT ResultsДокумент6 страницO.M.Alsamman, J.H.Long - (1993) - Prediction of Drilled Shafts Axial Capacities Using CPT ResultsAnonymous PibYPghОценок пока нет

- Articulo Stres - Wave Lisboa 2008Документ5 страницArticulo Stres - Wave Lisboa 2008RICARDO ANDRES PALACIOS SIERRAОценок пока нет

- C 577 - 99 AstmДокумент4 страницыC 577 - 99 AstmLoan100% (1)

- Failure Mechanism of Reinforced Concrete Structural Walls With and Without ConfinementДокумент9 страницFailure Mechanism of Reinforced Concrete Structural Walls With and Without ConfinementKillian WismanОценок пока нет

- BackcalculationДокумент8 страницBackcalculationpierussoОценок пока нет

- Module-6 Materials and Hardwares CAR66 Ref:: Duration: 15 Hrs Aim of The Exercise: Tools/Equipment Required: Grinding Machine, Steel Samples, Protective Safety PrecautionДокумент7 страницModule-6 Materials and Hardwares CAR66 Ref:: Duration: 15 Hrs Aim of The Exercise: Tools/Equipment Required: Grinding Machine, Steel Samples, Protective Safety Precautionmithun doreОценок пока нет

- Methodology For Verticial Initial Cyclic Load Test by Reaction MethodДокумент4 страницыMethodology For Verticial Initial Cyclic Load Test by Reaction MethodvivekОценок пока нет

- Increasing The Structural Damping of A Steel Chimney Due To Wind OscillationДокумент8 страницIncreasing The Structural Damping of A Steel Chimney Due To Wind OscillationhikoОценок пока нет

- 1 IntroductionДокумент4 страницы1 Introductionmgi100% (1)

- Dynamic Loading Test For Pile Supported Tower Crane in Soft ClayДокумент14 страницDynamic Loading Test For Pile Supported Tower Crane in Soft ClayanwarОценок пока нет

- Experimental Study of Bridge Seismic Sliding Isolation SystemsДокумент10 страницExperimental Study of Bridge Seismic Sliding Isolation SystemsPunithan PunithanОценок пока нет

- An Experimental Study On Cyclic Loading of Piles in Sand: January 2007Документ7 страницAn Experimental Study On Cyclic Loading of Piles in Sand: January 2007Swamy ManiОценок пока нет

- Lecture26 PDFДокумент67 страницLecture26 PDFBinayak KumarОценок пока нет

- Toughness of Polymer Modified Binders (Force Ductilometer) : AUSTROADS Modified Binder Test MBT 23:2001Документ4 страницыToughness of Polymer Modified Binders (Force Ductilometer) : AUSTROADS Modified Binder Test MBT 23:2001तिप्लोकाची तिरुनचिपल्ली केरकेट्टाОценок пока нет

- Pile Integrity Test On Piling (LTA-M&W)Документ8 страницPile Integrity Test On Piling (LTA-M&W)tin aungtunОценок пока нет

- A5 WedgeSplittingTestДокумент9 страницA5 WedgeSplittingTestPrayush RajbhandariОценок пока нет

- Load Transfer Behavior of Full-Scale Instrumented Helical PilesДокумент10 страницLoad Transfer Behavior of Full-Scale Instrumented Helical PilesWimpsОценок пока нет

- General Cargo Containers - Prototype Test Procedures and Test ... - IACSДокумент6 страницGeneral Cargo Containers - Prototype Test Procedures and Test ... - IACSChahine KaddourОценок пока нет

- SM Triaxial Compression Test 1978 PDFДокумент5 страницSM Triaxial Compression Test 1978 PDFNicolás Silva0% (1)

- Foundation Rehabilitation of Bridge Over Danube - The Role of PileДокумент6 страницFoundation Rehabilitation of Bridge Over Danube - The Role of PileFernando ZarateОценок пока нет

- Method Statement PDA BoredДокумент5 страницMethod Statement PDA BoredFaoji TestindoОценок пока нет

- BehaviorofLaterallyLoadedPilesonSlopes PDFДокумент11 страницBehaviorofLaterallyLoadedPilesonSlopes PDFAndrew WinnerОценок пока нет

- Aggeragate Crushing Value TestДокумент2 страницыAggeragate Crushing Value TestSanjeev KumarОценок пока нет

- The Wedge Splitting Test, A New Method of Performing Stable Fracture Mechanics TestsДокумент8 страницThe Wedge Splitting Test, A New Method of Performing Stable Fracture Mechanics TestsPrayush RajbhandariОценок пока нет

- Ijciet 08 04 102 PDFДокумент16 страницIjciet 08 04 102 PDFLemuel TeopeОценок пока нет

- Tunnelling and Underground Space Technology: Leonardo M. Massone, Francisco NazarДокумент13 страницTunnelling and Underground Space Technology: Leonardo M. Massone, Francisco NazarnishantОценок пока нет

- 2016 MacDougall - ACI - Measured Load Capacity of Buried PipesДокумент12 страниц2016 MacDougall - ACI - Measured Load Capacity of Buried PipesAdeel FaisalОценок пока нет

- Method For Pile TestДокумент11 страницMethod For Pile TestsachinОценок пока нет

- Performance of Thin-Wall Concrete Pipe: Gabriel and BlowerДокумент10 страницPerformance of Thin-Wall Concrete Pipe: Gabriel and BlowerChristian LeobreraОценок пока нет

- Large Diameter Casing Piles, Design, Testing and MonitoringДокумент5 страницLarge Diameter Casing Piles, Design, Testing and MonitoringMustafaRamadanОценок пока нет

- Vertical Uplift Capacity of Circular Anchor PlatesДокумент6 страницVertical Uplift Capacity of Circular Anchor PlatesMita BhattacharyaОценок пока нет

- Failure of Railway EmbankmentДокумент6 страницFailure of Railway EmbankmentM Sajid IqbalОценок пока нет

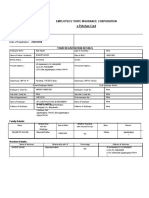

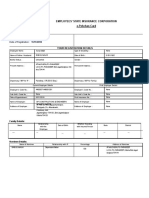

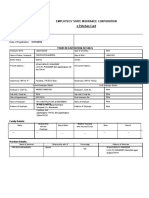

- Employees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationДокумент3 страницыEmployees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationRakesh Kumar MohantyОценок пока нет

- Employees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationДокумент3 страницыEmployees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationRakesh Kumar MohantyОценок пока нет

- Employees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationДокумент3 страницыEmployees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationRakesh Kumar MohantyОценок пока нет

- Employees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationДокумент3 страницыEmployees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationRakesh Kumar MohantyОценок пока нет

- Employees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationДокумент3 страницыEmployees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationRakesh Kumar MohantyОценок пока нет

- Employees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationДокумент3 страницыEmployees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationRakesh Kumar MohantyОценок пока нет

- Employees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationДокумент3 страницыEmployees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationRakesh Kumar MohantyОценок пока нет

- Employees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationДокумент3 страницыEmployees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationRakesh Kumar MohantyОценок пока нет

- Employees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationДокумент3 страницыEmployees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationRakesh Kumar MohantyОценок пока нет

- Employees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationДокумент3 страницыEmployees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationRakesh Kumar MohantyОценок пока нет

- Odisha Labour RatesДокумент6 страницOdisha Labour RatesRakesh Kumar MohantyОценок пока нет

- Employees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationДокумент3 страницыEmployees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationRakesh Kumar MohantyОценок пока нет

- Employees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationДокумент3 страницыEmployees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationRakesh Kumar MohantyОценок пока нет

- Employees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationДокумент3 страницыEmployees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationRakesh Kumar MohantyОценок пока нет

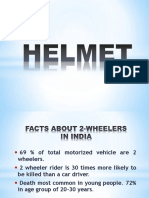

- Helmet PDFДокумент21 страницаHelmet PDFRakesh Kumar MohantyОценок пока нет

- The Necessary Art of PersuasionДокумент14 страницThe Necessary Art of PersuasionAnugragha SundarОценок пока нет

- PostmanPat Activity PackДокумент5 страницPostmanPat Activity PackCorto Maltese100% (1)

- Certification Programs: Service As An ExpertiseДокумент5 страницCertification Programs: Service As An ExpertiseMaria RobОценок пока нет

- Theories of GrowthДокумент33 страницыTheories of Growthdr parveen bathlaОценок пока нет

- Common Rail Injector Tester CR-C +S60H Multifunction Test MachineДокумент3 страницыCommon Rail Injector Tester CR-C +S60H Multifunction Test MachineAlen HuangОценок пока нет

- E Catalog YooilДокумент10 страницE Catalog Yooilom jangidОценок пока нет

- Concordance C Index - 2 PDFДокумент8 страницConcordance C Index - 2 PDFnuriyesanОценок пока нет

- The Mutant Epoch Mature Adult Content Mutations v1Документ4 страницыThe Mutant Epoch Mature Adult Content Mutations v1Joshua GibsonОценок пока нет

- Syllabus (2020) : NTA UGC-NET Computer Science and ApplicationsДокумент24 страницыSyllabus (2020) : NTA UGC-NET Computer Science and ApplicationsDiksha NagpalОценок пока нет

- How Plants SurviveДокумент16 страницHow Plants SurviveGilbertОценок пока нет

- PQS Catalogue 4 2Документ143 страницыPQS Catalogue 4 2sagarОценок пока нет

- Lesson 3: Letters of RequestДокумент4 страницыLesson 3: Letters of RequestMinh HiếuОценок пока нет

- Quiz Application in Visual BasicДокумент20 страницQuiz Application in Visual BasicShivangi SahaОценок пока нет

- Perceptual Objective Listening Quality Assessment (POLQA), The Third Generation ITU-T Standard For End-to-End Speech Quality Measurement Part I-Temporal AlignmentДокумент19 страницPerceptual Objective Listening Quality Assessment (POLQA), The Third Generation ITU-T Standard For End-to-End Speech Quality Measurement Part I-Temporal AlignmentmewarulesОценок пока нет

- MHD Exam 6 MaterialДокумент179 страницMHD Exam 6 Materialnaexuis5467100% (1)

- Symbolic Interaction Theory: Nilgun Aksan, Buket Kısac, Mufit Aydın, Sumeyra DemirbukenДокумент3 страницыSymbolic Interaction Theory: Nilgun Aksan, Buket Kısac, Mufit Aydın, Sumeyra DemirbukenIgor Dutra BaptistaОценок пока нет

- Emerging and Less Common Viral Encephalitides - Chapter 91Документ34 страницыEmerging and Less Common Viral Encephalitides - Chapter 91Victro ChongОценок пока нет

- Tok EssayДокумент2 страницыTok EssayNeto UkpongОценок пока нет

- Library SectionsДокумент4 страницыLibrary SectionsGello Sotnuiq100% (4)

- Minolta Spotmeter f-1 PDFДокумент50 страницMinolta Spotmeter f-1 PDFmacpator100% (1)

- Youth and Moral ValuesДокумент6 страницYouth and Moral ValuesAlka SinghОценок пока нет

- Rights of An Accused Under Custodial InvestigationДокумент17 страницRights of An Accused Under Custodial Investigationadrianfrancis9100% (1)

- TSR 9294 DLA3 Dragons RestДокумент78 страницTSR 9294 DLA3 Dragons RestLéo Duarte100% (4)

- Mechatronics MaterialДокумент86 страницMechatronics MaterialKota Tarun ReddyОценок пока нет

- Make or Buy - ProblemДокумент4 страницыMake or Buy - ProblemTk KimОценок пока нет

- Copper For BusbarДокумент60 страницCopper For BusbarSunil Gadekar100% (3)

- 1 Raven's™ Standard Progressive Matrices Plus (SPM Plus) - PSI OnlineДокумент1 страница1 Raven's™ Standard Progressive Matrices Plus (SPM Plus) - PSI OnlineVINEET GAIROLAОценок пока нет

- 100 IELTS Essay Topics For IELTS Writing - My IELTS Classroom BlogДокумент16 страниц100 IELTS Essay Topics For IELTS Writing - My IELTS Classroom BlogtestОценок пока нет

- Bio-Lubricant Production From Vegetable Oil and Animal Fat: International UniversityДокумент52 страницыBio-Lubricant Production From Vegetable Oil and Animal Fat: International UniversityKiệtNguyễnОценок пока нет

- Bearing Repeater CompassДокумент4 страницыBearing Repeater CompassJohn PerdyОценок пока нет

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeОт EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeРейтинг: 4.5 из 5 звезд4.5/5 (59)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)От EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Оценок пока нет

- Process Plant Equipment: Operation, Control, and ReliabilityОт EverandProcess Plant Equipment: Operation, Control, and ReliabilityРейтинг: 5 из 5 звезд5/5 (1)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansОт EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansРейтинг: 4.5 из 5 звезд4.5/5 (21)

- To Engineer Is Human: The Role of Failure in Successful DesignОт EverandTo Engineer Is Human: The Role of Failure in Successful DesignРейтинг: 4 из 5 звезд4/5 (138)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyОт EverandSodium Bicarbonate: Nature's Unique First Aid RemedyРейтинг: 5 из 5 звезд5/5 (21)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetОт EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Well Control for Completions and InterventionsОт EverandWell Control for Completions and InterventionsРейтинг: 4 из 5 звезд4/5 (10)

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyОт EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyРейтинг: 4.5 из 5 звезд4.5/5 (5)

- Environmental Impact Assessment: Theory and PracticeОт EverandEnvironmental Impact Assessment: Theory and PracticeРейтинг: 5 из 5 звезд5/5 (5)

- An Applied Guide to Water and Effluent Treatment Plant DesignОт EverandAn Applied Guide to Water and Effluent Treatment Plant DesignРейтинг: 5 из 5 звезд5/5 (4)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsОт EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsРейтинг: 4 из 5 звезд4/5 (16)

- Piping Engineering Leadership for Process Plant ProjectsОт EverandPiping Engineering Leadership for Process Plant ProjectsРейтинг: 5 из 5 звезд5/5 (1)

- Skyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownОт EverandSkyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksОт EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksРейтинг: 5 из 5 звезд5/5 (1)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsОт EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsОценок пока нет

- Principles of Forensic Engineering Applied to Industrial AccidentsОт EverandPrinciples of Forensic Engineering Applied to Industrial AccidentsОценок пока нет