Академический Документы

Профессиональный Документы

Культура Документы

Radiography Acceptance

Загружено:

agus sukmanaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Radiography Acceptance

Загружено:

agus sukmanaАвторское право:

Доступные форматы

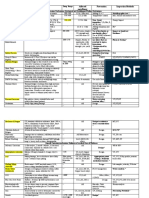

RADIOGRAPHS ACCEPTANCE CRITERIA

SUCOFINDO - MINAS ( BASED ON REFERENCE STANDARDS ) Sheet : 01 of 01

TECHNICAL INSPECTION & NDE SERVICES

NO TYPE OF API STD 1104 ASME SECT. IX ASME B 31.3 ASME SECT VIII ASME B31.1 ASME SECT I

DISCONTINUITIES INDIVIDUAL AGREGATE L IND / RANDOM ISOLATED NORMAL FLUID SEV. CYCLIC RANDOM ISOLATED RANDOM ISOLATED RANDOM ISOLATED

1 CRACKS ( NP *) NP * NP * NP * NP * NP * NP * NP * NP * NP * NP * NP *

2 INCOMPLETE PENETRATION 1" 1" - 12" length NP * NP * 1.5" in 6" L NP * NP * NP * NP * NP * NP * NP *

8% ttl. Length

3 LACK OF INTERRUN / 1" 1" for 12" L NP * NP * NP * NP * NP * NP * NP * NP * NP * NP *

ROOT FUSIONS

4 LACK OF FUSIONS 2" 2" NP * NP * NP * NP * NP * NP * NP * NP * NP * NP *

DUE TO COLD LAP

5 ISOLATED SLAG INCLUSION L = 1/2" 8% ttl.length 1/8" - t<3/8" - L<2tw L < 1/3 t w 1/4" - t<3/4 1/4"- t 3/4 1/4t - t= 3/4"

w =>1/8" or 2t 1/3t - to 21/4" w = 1/8" /tw/2 w = 3/32" 1/3t - t to 2 1/4" 1/3 t for t to 2 1/4 " 1/3 t for t to 2 1/4"

6 WAGON TRACKS 2" 2" in 12" L 1/3t 1/32"

7 BURN TROUGH 1/4" and 1/2" in 12" L d < t Bm - d < tW d < tW d < t Bm - Den < t Bm - Den < t Bm -

Den > t

8 INTERNAL CONCAVITY Den > t N/A d < t Bm - w.reinf > tw w.reinf > tw d < t Bm - Den < t Bm - Den < t Bm -

9 EXTERNAL CONCAVITY d > 1/16" NP * NP * - w.reinf > tw w.reinf > tw

10 HOLLOW BEAD 1/2" 1/4" in 2" Chart App.I App.4 1/3 t < t - 12t L Por Chart: - Por Chart: -

space or 8% ASME IX ASME VIII-1 App.A250 App. A250

11 LACK OF PENETRATION 2" 3" in any NP * NP * d = 1/32" NP * NP * NP * NP * NP * NP * NP *

DUE TO HIGH LOW cont'd 12"L 1.5" in 6" L

12 CLUSTER POROSITY 1/2" 1/2" in 12" L

Chart App.I - Ref BPV Ref BPV 1" or 2 t > 2 CP Por Chart: - 1" or 2 t if more 2 CP

1/3t or 20% t ASME VIII ASME VIII 1"-6"length App.A250 1" in 6" L

13 POROSITY / GAS POCKET 1/8" or 25% tw whichever 1/3t or 1/8" - Ref BPV Ref BPV 1/4 t 1/3 t or 1/4 t 1/3 t or

(Ref. App.std for Table/Chart) less (Chart App.I) ASME VIII ASME VIII Chart Ap.4 Chart A250

14 INTERNAL UNDERCUT 2" 1/6 weld length NP * NP * d < 1/32"or NP *

<tw/4

15 EXTERNAL UNDERCUT 2"/ d=1/32" 1/6 weld length NP * NP * d < 1/32"or NP * 1/64" for V - d > 1/32" - max 1/32" 10% tn

<tw/4 1/32" for H -

16 ELONG. SLAG INCLUSION 2" 2" - 12" length 1/8" - t<3/8" > t - 12 t L<2tw L<3tw 1/4" - t<3/4 1/4" - t 3/4 1/4"-t<3/4"

> 1/2" 1/3t- t to 2 1/4 in 6" length w < 1/8"/tw/2 w = 3/32" & 1/3 t for t to 2 1/4" 1/3 t for t to 2 1/4" 1/3 t for t to 2 1/4"

L<4tw in 6"L <tw in 12 T

17 ACCUMULATION DISCONT. 2" 8% from total N/A - N/A - N/A - N/A - N/A -

(NOT INCL. IP, IF, UC) (in 12" length) weld length

The above acceptance criteria for ASME std. B31.3 is not criteria for engineering design for welding inspection (ref. Table K341.3.2 par K341.5 (ASME B31.3 - Piping Process) Prepared by : Aryono @rnidaz

NOTE

NP * = Not Permitted d = depth V = vertical joint

(NP*) = Not Permitted, except shallow cracks, star cracks L = length H = horizontal joint

t = thickness of material / tw = weld thickness w = width Den. = Density of radiograph

tn = Nominal thickness Depth of IC = EC Bm = Base metal

Вам также может понравиться

- 1.radiograph AcceptanceДокумент1 страница1.radiograph AcceptanceTURNO100% (2)

- RT IQI SelectionДокумент1 страницаRT IQI SelectionVipin Peter100% (1)

- Is 9902 2004 PDFДокумент11 страницIs 9902 2004 PDFAgniva DuttaОценок пока нет

- DIN EN 12517-1: Deutsche NormДокумент17 страницDIN EN 12517-1: Deutsche Normmarcos crisostoОценок пока нет

- UT ProbeДокумент16 страницUT ProbeHenry CruzОценок пока нет

- WeldingДокумент21 страницаWeldingprabhatkumar_6657012Оценок пока нет

- Penetrants TESTINGДокумент86 страницPenetrants TESTINGsankaran_muthukumarОценок пока нет

- MTC Er70s 2Документ1 страницаMTC Er70s 2Mirza BaigОценок пока нет

- Sa 961 PDFДокумент10 страницSa 961 PDFaruntpeОценок пока нет

- Industrial Radiography Image Forming TechniquesДокумент99 страницIndustrial Radiography Image Forming TechniquesAshish GuptaОценок пока нет

- Api 571 CorrosionДокумент5 страницApi 571 CorrosionArun GuptaОценок пока нет

- Sep 1922 enДокумент7 страницSep 1922 enIngo Becker100% (2)

- ASME P-NumbersДокумент9 страницASME P-NumbersAamer MohammedОценок пока нет

- Astm E747Документ3 страницыAstm E747AmithОценок пока нет

- RT Standards NotesДокумент4 страницыRT Standards NotesprabhuОценок пока нет

- A L F I: Cceptance Imit OR MperfectionsДокумент29 страницA L F I: Cceptance Imit OR MperfectionsDavid MacatangayОценок пока нет

- Portability Modularity Color Imaging Data Storage: Ultrasound, Ut Phased Array, Eddy Current, and Ec ArrayДокумент14 страницPortability Modularity Color Imaging Data Storage: Ultrasound, Ut Phased Array, Eddy Current, and Ec ArrayvrapciudorianОценок пока нет

- Asme Section II A Sa-263Документ8 страницAsme Section II A Sa-263Anonymous GhPzn1xОценок пока нет

- ASME P NumbersДокумент6 страницASME P NumbersAbdul KharisОценок пока нет

- E390-11 Standard Reference Radiographs For Steel Fusion WeldsДокумент4 страницыE390-11 Standard Reference Radiographs For Steel Fusion WeldsAhmed Shaban KotbОценок пока нет

- Multifilm Techinique PDFДокумент7 страницMultifilm Techinique PDFamitОценок пока нет

- ASNT-L3 Fees PDFДокумент4 страницыASNT-L3 Fees PDFElankumaran PeriakaruppanОценок пока нет

- Small Diameter Tube and Pipe Inspection With Phased Array PDFДокумент7 страницSmall Diameter Tube and Pipe Inspection With Phased Array PDFAlanka PrasadОценок пока нет

- PA Probe Catalog en 201308Документ24 страницыPA Probe Catalog en 201308Alvaro Alexis Mendoza PradaОценок пока нет

- Radiography Test Acceptance Criteria: Type of Defects Asme Sec - Ix ASME B31.1 Asme Sec - I Asme Sec Viii Div-1 IBRДокумент2 страницыRadiography Test Acceptance Criteria: Type of Defects Asme Sec - Ix ASME B31.1 Asme Sec - I Asme Sec Viii Div-1 IBRBalkishan DyavanapellyОценок пока нет

- Ct02 Ect Extended AsmeДокумент1 страницаCt02 Ect Extended AsmeVasyaОценок пока нет

- Ultrasonic Examination Austenitic and Dissimilar WeldsДокумент6 страницUltrasonic Examination Austenitic and Dissimilar WeldshocimtmОценок пока нет

- NDT Code Book Made Easy For AsmeДокумент398 страницNDT Code Book Made Easy For AsmeJosé Pablo Espinoza SolísОценок пока нет

- Selection of Leak Testing Method PDFДокумент3 страницыSelection of Leak Testing Method PDFdcsamaraweeraОценок пока нет

- USM 35X Operating ManualДокумент228 страницUSM 35X Operating ManualMakhfud EdyОценок пока нет

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCДокумент7 страницJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCTrường Tùng LýОценок пока нет

- NDT Procedure BS EN 10307:2001 (Full Version Available From N-D-T.com)Документ6 страницNDT Procedure BS EN 10307:2001 (Full Version Available From N-D-T.com)Mark BrailsfordОценок пока нет

- Material Grades ChartДокумент2 страницыMaterial Grades ChartShanmuga NavaneethanОценок пока нет

- Wps PQRДокумент7 страницWps PQRsobariОценок пока нет

- IQI Standards of RTДокумент1 страницаIQI Standards of RTHiren Panchal100% (1)

- A General Review of The Causes and Acceptance of Shape ImperfectionsДокумент7 страницA General Review of The Causes and Acceptance of Shape ImperfectionsMuhammed SulfeekОценок пока нет

- Omniscan TofdДокумент4 страницыOmniscan Tofdsdmkl85Оценок пока нет

- QW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) ExaminationДокумент8 страницQW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) Examinationডঃ শুভম চ্যাটার্জীОценок пока нет

- 136.4.2 Visual ExaminationДокумент1 страница136.4.2 Visual ExaminationrohimОценок пока нет

- Phased Array Practical ExamДокумент2 страницыPhased Array Practical ExamMarcus AntoniusОценок пока нет

- Steel - of Any Shape, in Any DirectionДокумент20 страницSteel - of Any Shape, in Any Directionpoludo10Оценок пока нет

- Mce Gulf Contracting Co. Welder Performance QualificationДокумент2 страницыMce Gulf Contracting Co. Welder Performance QualificationhamidjoyiaОценок пока нет

- TofdДокумент4 страницыTofdrhapknexxОценок пока нет

- Pipe Schedule ChartДокумент1 страницаPipe Schedule ChartNejat AbabayОценок пока нет

- Iqi TableДокумент3 страницыIqi TableverdiblueОценок пока нет

- Relevant Discontinuities Visual Testing (VT), (Ebook)Документ98 страницRelevant Discontinuities Visual Testing (VT), (Ebook)abdoОценок пока нет

- UT Formula SheetДокумент2 страницыUT Formula SheetOktayKulОценок пока нет

- Inspection Report Bifab Ut On Duplex Stainless Steel Piping PDFДокумент11 страницInspection Report Bifab Ut On Duplex Stainless Steel Piping PDFquiron2014Оценок пока нет

- Flaw Manufacturing TechnologyДокумент31 страницаFlaw Manufacturing Technologyツ ツОценок пока нет

- Production and Evaluation of Field Metallographic Replicas: Standard Practice ForДокумент6 страницProduction and Evaluation of Field Metallographic Replicas: Standard Practice ForGonzalo TelleríaОценок пока нет

- MR Zubair - NotesДокумент39 страницMR Zubair - NotesAnjali Singh100% (1)

- Rangkuman Acceptance Criteria Defect of WeldДокумент1 страницаRangkuman Acceptance Criteria Defect of Weldbhinta ramadhaОценок пока нет

- List Monitoring Preparation Oil Purifier: ( - ) Spv. Electrical CEP Date: NoteДокумент3 страницыList Monitoring Preparation Oil Purifier: ( - ) Spv. Electrical CEP Date: NoteAfandi AffanОценок пока нет

- BOQ Format - Electrical PDFДокумент7 страницBOQ Format - Electrical PDFKurama Basket100% (1)

- BOQ Format - Electrical PDFДокумент7 страницBOQ Format - Electrical PDFAr VinОценок пока нет

- 200-669FPS DescriptionДокумент3 страницы200-669FPS DescriptionGreen MichaelsОценок пока нет

- GEN - MLG GCT Delta Inventory Check ListДокумент3 страницыGEN - MLG GCT Delta Inventory Check ListWSG Sandy SETIAWANОценок пока нет

- Valvula de Diluvio Wet Pilot 2Документ1 страницаValvula de Diluvio Wet Pilot 2Pedro PeñaОценок пока нет

- FORM VESSEL Order SP-MSP 8Документ2 страницыFORM VESSEL Order SP-MSP 8MARCOОценок пока нет

- Tablas de Esfuerzos PDFДокумент729 страницTablas de Esfuerzos PDFSamuel PohezОценок пока нет

- List Manufacturers SteelДокумент5 страницList Manufacturers SteelSachin PillaiОценок пока нет

- MD ProbsДокумент134 страницыMD ProbsasapamoreОценок пока нет

- SteelДокумент89 страницSteelDebrup BanerjeeОценок пока нет

- Articulo Junker PDFДокумент11 страницArticulo Junker PDFPrateek JoshiОценок пока нет

- Magnetic Effects of Stainless SteelДокумент2 страницыMagnetic Effects of Stainless SteelIkhsan LyОценок пока нет

- N-Levels: 2014 Chemistry Notes For Secondary School Combined ChemistryДокумент44 страницыN-Levels: 2014 Chemistry Notes For Secondary School Combined ChemistryAnnie Tan100% (1)

- W The Rate in Weight Gain or Loss (G/CM I Current DensityДокумент12 страницW The Rate in Weight Gain or Loss (G/CM I Current Densityهدوء السماءОценок пока нет

- Tappi Extrution Coating and LaminatingДокумент26 страницTappi Extrution Coating and LaminatingKhương HuỳnhОценок пока нет

- MCE487 Steel Cage LiftingДокумент5 страницMCE487 Steel Cage LiftingAnonymous S7Cq7ZDgPОценок пока нет

- VT-25-70 75-24155 Operation ManualДокумент192 страницыVT-25-70 75-24155 Operation ManualJohana DelgadoОценок пока нет

- Summary ISO TR 15608 Metallic Materials Grouping SystemДокумент3 страницыSummary ISO TR 15608 Metallic Materials Grouping SystemharikrishnanОценок пока нет

- En1011 7Документ44 страницыEn1011 7A. ΒρατσισταОценок пока нет

- Topics SMAWДокумент2 страницыTopics SMAWYingying Mimay75% (4)

- Industrial Rolling Shutters and Rolling GrillesДокумент48 страницIndustrial Rolling Shutters and Rolling GrillesJhon BantingОценок пока нет

- Manufacture of SteelДокумент10 страницManufacture of SteelBGSSAP 2017Оценок пока нет

- Catalogue RamnäsДокумент13 страницCatalogue RamnäsSreekanthОценок пока нет

- MS-06-61 Swagelok SC-01 Ultrahigh-Purity Process SpecificationДокумент5 страницMS-06-61 Swagelok SC-01 Ultrahigh-Purity Process SpecificationLiu YangtzeОценок пока нет

- Physical Metallurgy: Lecture byДокумент78 страницPhysical Metallurgy: Lecture byqaОценок пока нет

- Geography Text Book PDFДокумент126 страницGeography Text Book PDFahmedОценок пока нет

- UTP Cladding en 2017Документ12 страницUTP Cladding en 2017Gourav SharmaОценок пока нет

- MMSE Journal Vol 2Документ106 страницMMSE Journal Vol 2Mmse JournalОценок пока нет

- RI 4 Defect CausesДокумент49 страницRI 4 Defect CausesDanang Ristu NugrohoОценок пока нет

- Flux RecipesДокумент4 страницыFlux RecipesNurameir Dzakareea100% (1)

- Steel Making Prof. Deepak Mazumdar Prof. S. C. Koria Department of Materials Science and Engineering Indian Institute of Technology, KanpurДокумент16 страницSteel Making Prof. Deepak Mazumdar Prof. S. C. Koria Department of Materials Science and Engineering Indian Institute of Technology, KanpurSyed HasniОценок пока нет

- Cladding & Overlay - Ni InstituteДокумент24 страницыCladding & Overlay - Ni Institutesajid aslamОценок пока нет

- Assignment Design 2Документ20 страницAssignment Design 2Nadia Refai100% (1)

- Shop and Fabrication of PipingДокумент49 страницShop and Fabrication of PipingAkmal Shauqy100% (1)

- MST Products: MST That Has Changed The Concept of P/M in A Big WayДокумент16 страницMST Products: MST That Has Changed The Concept of P/M in A Big Waykarthik venkatachalamОценок пока нет