Академический Документы

Профессиональный Документы

Культура Документы

Tribology Notes

Загружено:

PRAVIN PATOLEИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Tribology Notes

Загружено:

PRAVIN PATOLEАвторское право:

Доступные форматы

15ME742 Tribology

15ME742

TRIBOLOGY

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 1

15ME742 Tribology

ATME COLLEGE OF ENGINEERING

VISION

Development of academically excellent, culturally vibrant, socially responsible and

globally competent human resources

MISSION

1. To keep pace with advancements in knowledge and make the students competitive and

capable at the global level.

2. To create an environment for the students to acquire the right physical, intellectual,

emotional and moral foundations and shine as torch bearers of tomorrow's society.

3. To strive to attain ever-higher benchmarks of educational excellence.

DEPARTMENT OF MECHANICAL ENGINEERING

VISION

To impart excellent technical education in mechanical engineering to develop technically competent,

morally upright and socially responsible mechanical engineering professionals.

MISSION:

1. To provide an ambience to impart excellent technical education in mechanical engineering.

2. To ensure state of-the- art facility for learning, skill development and research in mechanical

engineering.

3. To engage students in co-curricular and extra-curricular activities to impart social &

ethical values and imbibe leadership quality.

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 2

15ME742 Tribology

PROGRAM EDUCATIONAL OBJECTIVES (PEO’S)

After successful completion of program, the graduates will be

PEO 1: Able to have successful professional career in the allied areas and be proficient to perceive higher

education.

PEO2: Attain the ability to understand the need, technical ability to analyse, design and manufacture the

product.

PEO 3: Work effectively, ethically and socially responsible in allied fields of Mechanical Engineering.

PEO 4: Work in a team to meet personal and organizational objectives and to contribute to the

development of the society at large.

PROGRAM OUTCOMES (PO’S)

The Mechanical engineering program students will attain:

PO1.Engineering knowledge: Apply the knowledge of mathematics, science, engineering

fundamentals, and an engineering specialization to the solution of complex engineering

problems

PO2.Problem analysis: Identify, formulate, research literature, and analyze complex

engineering problems reaching substantiated conclusions using first principles of

mathematics, natural sciences, and engineering sciences

PO3.Design/development of solutions: Design solutions for complex engineering problems

and design system components or processes that meet the specified needs with

appropriate consideration for the public health and safety, and the cultural, societal, and

environmental considerations

PO4.Conduct investigations of complex problems: Use research-based knowledge and

research methods including design of experiments, analysis and interpretation of data,

and synthesis of the information to provide valid conclusions

PO5. Modern tool usage: Create, select, and apply appropriate techniques, resources, and

modern engineering and IT tools including prediction and modeling to complex

engineering activities with an understanding of the limitations

PO6.The engineer and society: Apply reasoning informed by the contextual knowledge to

assess societal, health, safety, legal and cultural issues and the consequent responsibilities

relevant to the professional engineering practice

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 3

15ME742 Tribology

PO7.Environment and sustainability: Understand the impact of the professional

engineering solutions in societal and environmental contexts, and demonstrate the

knowledge of, and need for sustainable development

PO8. Ethics: Apply ethical principles and commit to professional ethics and

responsibilities and norms of the engineering practice

PO9. Individual and team work: Function effectively as an individual, and as a

member or leader in diverse teams, and in multidisciplinary settings

PO10.Communication: Communicate effectively on complex engineering activities

with the engineering community and with society at large, such as, being able to

comprehend and write effective reports and design documentation, make effective

presentations, and give and receive clear instructions

PO11.Project management and finance: Demonstrate knowledge and understanding

of the engineering and management principles and apply these to one’s own work,

as a member and leader in a team, to manage projects and in multidisciplinary

environments

PO12.Life-long learning: Recognize the need for, and have the preparation and ability

to engage in independent and life-long learning in the broadest context of

technological change

PROGRAM SPECIFIC OUTCOMES (PSO’S)

After successful completion of program, the graduates will be

PSO 1: To comprehend the knowledge of mechanical engineering and apply them to

identify, formulate and address the mechanical engineering problems using latest

technology in a effective manner.

PSO 2: To work successfully as a mechanical engineer in team, exhibit leadership

quality and provide viable solution to industrial and societal problems.

PSO 3: To apply modern management techniques and manufacturing techniques to

produce products of high quality at optimal cost.

PSO 4: To exhibit honesty, integrity, and conduct one responsibly, ethically and legally, holding

the safety and welfare of the society paramount

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 4

15ME742 Tribology

TRIBOLOGY

Assessment

Course Code Credits L-T-P Exam Duration

SEE CIA

TRIBOLOGY 15ME742 03 3-0-0 80 20 3 Hrs

Course objectives:

1. Understand the fundamentals of tribology and associated parameters.

2. Apply concepts of tribology for the performance analysis and design of components experiencing

relative motion.

3. Analyse the requirements and design hydrodynamic journal and plane slider bearings for a given

application.

4. Select proper bearing materials and lubricants for a given tribological application.

5. Apply the principles of surface engineering for different applications of tribology.

MODULE -1

Introduction to tribology: Historical background, practical importance, and subsequent use in the field.

Lubricants: Types and specific field of applications. Properties of lubricants,viscosity, its measurement,

effect of temperature and pressure on viscosity, lubrication types, standard grades of lubricants, and

selection of lubricants.

08 Hours

MODULE -2

Friction: Origin, friction theories, measurement methods, friction of metals and non-metals.

Wear: Classification and mechanisms of wear, delamination theory, debris analysis, testing methods and

standards. Related case studies.

08 Hours

MODULE -3

Hydrodynamic journal bearings: Friction forces and power loss in a lightly loaded journal bearing,

Petroff’s equation, mechanism of pressure development in an oil film, and Reynold’s equation in 2D.

Introduction to idealized journal bearing, load carrying capacity, condition for equilibrium, Sommerfeld’s

number and it’ssignificance;partial bearings, end leakages in journal bearing, numerical examples on full

journal bearings only. 08 Hours

MODULE -4

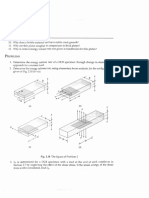

Plane slider bearings with fixed/pivoted shoe: Pressure distribution, Load carrying capacity, coefficient

of friction, frictional resistance in a fixed/pivoted shoe bearing, center of pressure, numerical examples.

Hydrostatic Lubrication: Introduction to hydrostatic lubrication, hydrostatic step bearings, load carrying

capacity and oil flow through the hydrostatic step bearing, numerical examples. 08 Hours

MODULE -5

Bearing Materials:Commonly used bearings materials, and properties of typical bearing materials.

Advantages and disadvantages of bearing materials.

Introduction to Surface engineering: Concept and scope of surface engineering. Surface modification –

transformation hardening, surface melting, thermo chemical processes. Surface Coating –

plating,fusionprocesses, vapor phase processes. Selection of coating for wear and corrosion resistance.

08 Hours

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 5

15ME742 Tribology

List of Text Books:

1.”Introduction to Tribology”, B. Bhushan, John Wiley & Sons, Inc., New York, 2002

2. “Engineering Tribology”, Prasanta Sahoo, PHI Learning Private Ltd, New Delhi, 2011.

3.“Engineering Tribology”, J. A. Williams, Oxford Univ. Press, 2005.

List of Reference Books:

1. “Introduction to Tribology in bearings”, B. C. Majumdar, Wheeler Publishing.

2. “Tribology, Friction and Wear of Engineering Material”, I. M.Hutchings, Edward Arnold,

London,1992.

3. “Engineering Tribology”, G. W. Stachowiak and A. W. Batchelor, Butterworth-Heinemann,1992.

4. “Friction and Wear of Materials”, Ernest Rabinowicz, John Wiley & sons,1995.

5. “Basic Lubrication Theory”, A. Cameron, Ellis Hardwoods Ltd., UK.

6. “Handbook of tribology: materials, coatings and surface treatments”, B.Bhushan, B.K. McGraw-

Hill,1997.

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 6

15ME742 Tribology

Module 1

Contents:

Introduction To Tribology:Historical Background,

Practical Importance, And Subsequent Use in the field.

Lubricants: Types and Specific Field of Applications.

Properties of Lubricants, Viscosity, Its Measurement,

Effect of Temperature and Pressure on Viscosity,

Lubrication Types,

Standard Grades of Lubricants, and Selection of Lubricants.

Objectives

1. Basics of tribology

2. Basics of lubricants and lubrication

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 7

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 8

15ME742 Tribology

1.4

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 9

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 10

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 11

15ME742 Tribology

1.5

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 12

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 13

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 14

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 15

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 16

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 17

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 18

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 19

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 20

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 21

15ME742 Tribology

1.6

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 22

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 23

15ME742 Tribology

Questionnaires

1. What is the practical important of Tribology?

2. Write briefly about historical background of Tribology.

3. List the properties of Lubricants.

4. Explain the classification of lubricants and explain briefly.

5.Explain the effect of Temperature and Pressure on Viscocity.

Further Reading:

1. “Introduction to Tribology in bearings”, B. C. Majumdar, Wheeler Publishing.

2. “Basic Lubrication Theory”, A. Cameron, Ellis Hardwoods Ltd., UK.

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 24

15ME742 Tribology

Module 2

Contents:

o Friction: Origin, Friction Theories,

o Measurement Methods,

o Friction Of Metals And Non-Metals.

o Wear: Classification And Mechanisms Of Wear,

o Delamination Theory,

o Debris Analysis,

o Testing Methods And Standards.

o Related Case Studies.

Objectives

1. Introduction to friction and wear mechanisms

2. Measurement of friction and wear

2.1

.1

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 25

15ME742 Tribology

2.2

.1

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 26

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 27

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 28

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 29

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 30

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 31

15ME742 Tribology

2.3

.1

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 32

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 33

15ME742 Tribology

2.4

.1

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 34

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 35

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 36

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 37

15ME742 Tribology

2.5

.1

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 38

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 39

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 40

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 41

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 42

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 43

15ME742 Tribology

2.6

.1

2.7

.1

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 44

15ME742 Tribology

2.8

.1

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 45

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 46

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 47

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 48

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 49

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 50

15ME742 Tribology

2.9

.1

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 51

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 52

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 53

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 54

15ME742 Tribology

2.10

.1

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 55

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 56

15ME742 Tribology

2.11

.1

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 57

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 58

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 59

15ME742 Tribology

2.12

.1

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 60

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 61

15ME742 Tribology

2.13.

1

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 62

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 63

15ME742 Tribology

2.14

.1

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 64

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 65

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 66

15ME742 Tribology

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 67

15ME742 Tribology

2.15

.1

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 68

15ME742 Tribology

2.16

.1

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 69

15ME742 Tribology

Questionnaires

1. What is friction and wear?. Explain briefly

2. Explain different friction measurement methods with suitable sketch

3. Explain the different friction theories.

4. Briefly explain friction of metals and non metals

5. Classify the wear and explain briefly

6. Explain the wear mechanisms.

Further Reading:

1. “Tribology, Friction and Wear of Engineering Material”, I. M.Hutchings, Edward Arnold,

London,1992.

2.“Engineering Tribology”, G. W. Stachowiak and A. W. Batchelor, Butterworth-

Heinemann,1992.

3. “Friction and Wear of Materials”, Ernest Rabinowicz, John Wiley & sons,1995.

Dept of Mechanical Engineering, ATME College of Engineering,, Mysore Page 70

Вам также может понравиться

- Materials Forming and Machining: Research and DevelopmentОт EverandMaterials Forming and Machining: Research and DevelopmentРейтинг: 3 из 5 звезд3/5 (1)

- MSM Lab Manual - 2021-22Документ61 страницаMSM Lab Manual - 2021-22Divyaraj VaghelaОценок пока нет

- ME8512 Thermal Lab ManualДокумент186 страницME8512 Thermal Lab ManualManikandanОценок пока нет

- Tribology QP & Syllabus Vtu PRASHANTHДокумент21 страницаTribology QP & Syllabus Vtu PRASHANTHpachieduОценок пока нет

- Chp1 Introduction Lect 240717 EДокумент39 страницChp1 Introduction Lect 240717 EGooftilaaAniJiraachuunkooYesusiin100% (1)

- ME 202 Advanced Mechanics of Solids PDFДокумент3 страницыME 202 Advanced Mechanics of Solids PDFPradeep GsОценок пока нет

- Bio Composite HelmetДокумент57 страницBio Composite HelmetRohanОценок пока нет

- Applied Mechanics Micro ProjectДокумент12 страницApplied Mechanics Micro ProjectSarvesh MoreОценок пока нет

- (Updated) Report - Batch 4 PDFДокумент77 страниц(Updated) Report - Batch 4 PDFShreya Muralidharan0% (1)

- Final Year Seminar Report UG-2019 Batch11-156 PDFДокумент34 страницыFinal Year Seminar Report UG-2019 Batch11-156 PDFsaket3sanidhy0% (1)

- Seminar MicromachiningДокумент33 страницыSeminar Micromachiningkshitij shahОценок пока нет

- Tribology Lesson PlanДокумент3 страницыTribology Lesson Plankumar100% (1)

- Thermal Barrier CoatingДокумент41 страницаThermal Barrier CoatingDineshОценок пока нет

- 1 - Introduction To TribologyДокумент5 страниц1 - Introduction To TribologyAbdulla Camal100% (1)

- Case Study Project Description - IDP - Oct2022-Feb2023Документ1 страницаCase Study Project Description - IDP - Oct2022-Feb2023haziqОценок пока нет

- ROE-035 Polymer Science and TechnologyДокумент1 страницаROE-035 Polymer Science and TechnologyJatin Sharma0% (1)

- Lecture Manual-TribologyДокумент3 страницыLecture Manual-TribologySujit Mishra100% (1)

- Hybrid Metal Additive ManufacturingДокумент75 страницHybrid Metal Additive ManufacturingNursultan JyeniskhanОценок пока нет

- Study On Mechanical Behaviour of Banana Fiber Reinforced Epoxy CompositesДокумент30 страницStudy On Mechanical Behaviour of Banana Fiber Reinforced Epoxy Compositespramo_dassОценок пока нет

- Micro Project: Title of The ProjectДокумент11 страницMicro Project: Title of The Projectomkar digamabar sononeОценок пока нет

- Design of Machine ElementsДокумент12 страницDesign of Machine ElementsSai ThotaОценок пока нет

- Design and Fabrication of Compression Molding Machine For Plastic Waste Recycling in NigeriaДокумент20 страницDesign and Fabrication of Compression Molding Machine For Plastic Waste Recycling in NigeriaShan SangarОценок пока нет

- Mahindra Gears Transmiision Training ReportДокумент32 страницыMahindra Gears Transmiision Training Reportbestmadeeasy50% (2)

- Air Less Tyer Seminar ReportДокумент31 страницаAir Less Tyer Seminar ReportAnsil MP EastОценок пока нет

- Mini Project Presentation PPT For First PresentationДокумент4 страницыMini Project Presentation PPT For First PresentationAbhishek XОценок пока нет

- Fasl 1,2 PDFДокумент3 страницыFasl 1,2 PDFalvin tehraniОценок пока нет

- Dynamics Lab Sheet 1 - Free Vibration Experiment - PKPДокумент3 страницыDynamics Lab Sheet 1 - Free Vibration Experiment - PKPfaqhrulОценок пока нет

- Visvesvaraya Technological University: "Research On New Automobile Power Hydraulic Braking System by Vibratory Energy"Документ33 страницыVisvesvaraya Technological University: "Research On New Automobile Power Hydraulic Braking System by Vibratory Energy"abhishek b hosamathОценок пока нет

- Simple Design of Self-Powered Lawn Mower PDFДокумент6 страницSimple Design of Self-Powered Lawn Mower PDFAbdullah Omar Abou ReashaОценок пока нет

- A Progress Report On Design and Development of MEMS Based SensorДокумент3 страницыA Progress Report On Design and Development of MEMS Based Sensorarun14089Оценок пока нет

- Multi Type ForkliftДокумент46 страницMulti Type ForkliftlokeshОценок пока нет

- Market Research On JK Wall Putty in Kanpur: Ummer Internship Roject EportДокумент49 страницMarket Research On JK Wall Putty in Kanpur: Ummer Internship Roject EportRocky Rocky100% (1)

- Puneet Final Semester ProjectДокумент50 страницPuneet Final Semester ProjectPuneet MehraОценок пока нет

- ME369 TribologyДокумент3 страницыME369 Tribologynandan144Оценок пока нет

- Composite Materials Literature Review For Car Bumber: August 2016Документ12 страницComposite Materials Literature Review For Car Bumber: August 2016meita alviraОценок пока нет

- Imran Final MprintДокумент23 страницыImran Final Mprintvishal vallapureОценок пока нет

- Final Report EditedДокумент46 страницFinal Report EditedAXCОценок пока нет

- Ex1 PDFДокумент2 страницыEx1 PDFKushagra SinghalОценок пока нет

- Technical Seminar Report 2019-20 BatchДокумент21 страницаTechnical Seminar Report 2019-20 BatchKiran Kumar ShОценок пока нет

- SEMINAR On NanocompositesДокумент30 страницSEMINAR On NanocompositesRama GaurОценок пока нет

- Fabrication of Composite Natural FiberДокумент30 страницFabrication of Composite Natural FiberAditya GuptaОценок пока нет

- Format For Industrial Training Report0 PDFДокумент64 страницыFormat For Industrial Training Report0 PDFashawishОценок пока нет

- 1 Useful LifeДокумент12 страниц1 Useful LifeDon HaffisОценок пока нет

- MeiseДокумент62 страницыMeiseafnene1Оценок пока нет

- Shashi 2 Seminar Final - ReportДокумент26 страницShashi 2 Seminar Final - ReportDarshan bsОценок пока нет

- Satyabhama MechДокумент97 страницSatyabhama MechRahul Kumar KОценок пока нет

- NOTES SOCIETY CEM585 3aДокумент4 страницыNOTES SOCIETY CEM585 3aNadhirah LnfОценок пока нет

- A Seminar Report OnДокумент7 страницA Seminar Report OnSagar Pandit0% (1)

- UntitledДокумент3 страницыUntitledashish RautОценок пока нет

- Training Report at CGRДокумент18 страницTraining Report at CGRMohamed Ihsan75% (4)

- Energy Engg 18ME81 Introduction Syllabus MR Girish BДокумент22 страницыEnergy Engg 18ME81 Introduction Syllabus MR Girish BGirish DОценок пока нет

- OAT751 Production of Automotive Components LTPC 3 0 0 3 ObjectivesДокумент2 страницыOAT751 Production of Automotive Components LTPC 3 0 0 3 ObjectivesMr.Babu T50% (2)

- Failure Analysis and DesignДокумент2 страницыFailure Analysis and DesigndselvakumaranОценок пока нет

- Seed Sowing RobotДокумент10 страницSeed Sowing RobotPalash Gajbhiye0% (1)

- 2016 IA-HEV BOOK Web PDFДокумент339 страниц2016 IA-HEV BOOK Web PDFVMarochiОценок пока нет

- Advance Welding - Syllabus (KME-055)Документ3 страницыAdvance Welding - Syllabus (KME-055)Shashank DwivediОценок пока нет

- 18ME62Документ263 страницы18ME62Action Cut EntertainmentОценок пока нет

- Me6503 Dome QB PDFДокумент65 страницMe6503 Dome QB PDFmaniОценок пока нет

- 4th Sem Milling MachineДокумент32 страницы4th Sem Milling MachineKaran KantiОценок пока нет

- Foundry and Forging Laboratory ManualДокумент110 страницFoundry and Forging Laboratory Manualvampiredraak2712Оценок пока нет

- Balmatech Go Ep Tds 2022-03 GBДокумент2 страницыBalmatech Go Ep Tds 2022-03 GBAnalista De CalidadОценок пока нет

- Material Safety Data Sheet: KOMATSU Supercoolant AF-NAC (50/50 Pre-Diluted)Документ5 страницMaterial Safety Data Sheet: KOMATSU Supercoolant AF-NAC (50/50 Pre-Diluted)Thais Roberta CamposОценок пока нет

- DRS Rev.0 GTP-TR1!01!002 Condensate RecyclingДокумент4 страницыDRS Rev.0 GTP-TR1!01!002 Condensate RecyclingBalasubramanianОценок пока нет

- Wps Gtaw Monel b127 b164Документ2 страницыWps Gtaw Monel b127 b164Srinivasan Muruganantham67% (3)

- Citadel of Kirkuk 1Документ17 страницCitadel of Kirkuk 1ArézAzadОценок пока нет

- An Overview of The IEEE Color BooksДокумент6 страницAn Overview of The IEEE Color BooksOhm666Оценок пока нет

- Wind Load CompututationsДокумент31 страницаWind Load Compututationskim suarezОценок пока нет

- The Use of Proton Pump Inhibitors in Treating and Preventing NSAID-induced Mucosal DamageДокумент6 страницThe Use of Proton Pump Inhibitors in Treating and Preventing NSAID-induced Mucosal DamageFriska Rachmanita PrayogoОценок пока нет

- Chem 3052 CHAPTER 7 (Nuclear Magnetic Resonance Spectroscopy (NMR) )Документ6 страницChem 3052 CHAPTER 7 (Nuclear Magnetic Resonance Spectroscopy (NMR) )ashenafiОценок пока нет

- Traffic Cases in GSMДокумент18 страницTraffic Cases in GSMkamal100% (1)

- 02K inДокумент1 страница02K inAbbode HoraniОценок пока нет

- Igc 3 Practical NeboshДокумент20 страницIgc 3 Practical NeboshAbdelkader FattoucheОценок пока нет

- Idlers: TRF Limited TRF LimitedДокумент10 страницIdlers: TRF Limited TRF LimitedAjit SarukОценок пока нет

- MHT-CET 2021 Question Paper: 25 September 2021Документ3 страницыMHT-CET 2021 Question Paper: 25 September 2021Sank DamОценок пока нет

- The Seventh House in AstrologyДокумент6 страницThe Seventh House in Astrologytratak100% (1)

- Black Mamba Vs Mongoose Vs King Cobra Vs Komodo Vs PhythonДокумент44 страницыBlack Mamba Vs Mongoose Vs King Cobra Vs Komodo Vs PhythonmarcОценок пока нет

- Manual Elspec SPG 4420Документ303 страницыManual Elspec SPG 4420Bairon Alvira ManiosОценок пока нет

- Notes StressДокумент4 страницыNotes StressRohitKalraОценок пока нет

- Backlash SDPДокумент11 страницBacklash SDPPatrick Cyr GagnéОценок пока нет

- RestrictedДокумент51 страницаRestrictedsridharpalledaОценок пока нет

- Samsung Bd-p4600 SMДокумент101 страницаSamsung Bd-p4600 SMIonel CociasОценок пока нет

- Catalogue Mp200Документ33 страницыCatalogue Mp200Adrian TudorОценок пока нет

- TamasДокумент180 страницTamaslike 2Оценок пока нет

- Grand Vitara 2005Документ35 страницGrand Vitara 2005PattyaaОценок пока нет

- Research On Strip Deformation in The Cage Roll-Forming Process of ERW Round PipesДокумент7 страницResearch On Strip Deformation in The Cage Roll-Forming Process of ERW Round PipesJames PhillipsОценок пока нет

- Money, Interest, and Inflation: Answers To CheckpointsДокумент16 страницMoney, Interest, and Inflation: Answers To Checkpointsb96309Оценок пока нет

- Hypomineralised Second Primary Molars May Be Indicative of Future Molar Incisor Hypomineralisation PDFДокумент6 страницHypomineralised Second Primary Molars May Be Indicative of Future Molar Incisor Hypomineralisation PDFnha khoa NHƯ NGỌCОценок пока нет

- TRL Explanations - 1Документ4 страницыTRL Explanations - 1Ana DulceОценок пока нет

- Short Moritz - LiverGB PDFДокумент3 страницыShort Moritz - LiverGB PDFPetra JobovaОценок пока нет

- Parker Valve Safety CrownДокумент11 страницParker Valve Safety Crownayman akrabОценок пока нет

- Hero Found: The Greatest POW Escape of the Vietnam WarОт EverandHero Found: The Greatest POW Escape of the Vietnam WarРейтинг: 4 из 5 звезд4/5 (19)

- The End of Craving: Recovering the Lost Wisdom of Eating WellОт EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellРейтинг: 4.5 из 5 звезд4.5/5 (82)

- Sully: The Untold Story Behind the Miracle on the HudsonОт EverandSully: The Untold Story Behind the Miracle on the HudsonРейтинг: 4 из 5 звезд4/5 (103)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationОт EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationРейтинг: 4.5 из 5 звезд4.5/5 (46)

- The Fabric of Civilization: How Textiles Made the WorldОт EverandThe Fabric of Civilization: How Textiles Made the WorldРейтинг: 4.5 из 5 звезд4.5/5 (58)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaОт EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaОценок пока нет

- The Future of Geography: How the Competition in Space Will Change Our WorldОт EverandThe Future of Geography: How the Competition in Space Will Change Our WorldРейтинг: 4 из 5 звезд4/5 (6)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyОт EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyОценок пока нет

- Pale Blue Dot: A Vision of the Human Future in SpaceОт EverandPale Blue Dot: A Vision of the Human Future in SpaceРейтинг: 4.5 из 5 звезд4.5/5 (588)

- Permaculture for the Rest of Us: Abundant Living on Less than an AcreОт EverandPermaculture for the Rest of Us: Abundant Living on Less than an AcreРейтинг: 4.5 из 5 звезд4.5/5 (33)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindОт EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindОценок пока нет

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerОт EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerРейтинг: 4.5 из 5 звезд4.5/5 (54)

- Four Battlegrounds: Power in the Age of Artificial IntelligenceОт EverandFour Battlegrounds: Power in the Age of Artificial IntelligenceРейтинг: 5 из 5 звезд5/5 (5)

- The Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeОт EverandThe Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeРейтинг: 4.5 из 5 звезд4.5/5 (99)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestОт EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestРейтинг: 4 из 5 звезд4/5 (28)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerОт EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerРейтинг: 4.5 из 5 звезд4.5/5 (122)

- Reality+: Virtual Worlds and the Problems of PhilosophyОт EverandReality+: Virtual Worlds and the Problems of PhilosophyРейтинг: 4 из 5 звезд4/5 (24)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)От EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Оценок пока нет

- Restoration Agriculture: Real-World Permaculture for FarmersОт EverandRestoration Agriculture: Real-World Permaculture for FarmersРейтинг: 4.5 из 5 звезд4.5/5 (86)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureОт EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureРейтинг: 5 из 5 звезд5/5 (125)

- A Place of My Own: The Architecture of DaydreamsОт EverandA Place of My Own: The Architecture of DaydreamsРейтинг: 4 из 5 звезд4/5 (242)