Академический Документы

Профессиональный Документы

Культура Документы

Caretaker Risk Assessment Working at Height

Загружено:

Mohamed Ali MaherОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Caretaker Risk Assessment Working at Height

Загружено:

Mohamed Ali MaherАвторское право:

Доступные форматы

Caretaker

ingCarCa

risk assessment –

working at height

PROMPT SHEET – This sheet should only be used for guidance, in order for you to complete your

own risk assessment on working at height. The purpose of this assessment is to assess the

management of working at height activities. Individual tasks should be assessed separately.

Hazard Suggested action/control measure

Something with a potential to If hazard This list is not exhaustive. Below are

cause harm. exists some control measures which you may

and who it find useful when completing your risk

could assessment.

harm

01. Poor maintenance of access Regular inspections of equipment before

equipment e.g. ladders, steps, every use and records kept.

scaffolds. Three-monthly inspections of access

equipment by a competent person and

records kept. This will normally be in-

house and carried out by the competent

person trained to work at height.

Defective equipment to be reported to

manager.

Immediate removal and repair or

disposal of access equipment found to

be defective.

02. Inappropriate use of tower Equipment to be used only where there

scaffolds causing trips and is a firm, level surface.

falls. All equipment to be visually inspected

before use and records kept.

Appropriate footwear to be worn.

Safe system of work in place for work

involving tower scaffolds.

Staff who use tower scaffolds to be

PASMA trained.

Equipment should be suitably stored

after use.

Work at height training to be undertaken.

03. Inappropriate use of Refer to HSE’s ‘Safe use of ladders and

ladders/stepladders. stepladders’ guide.

Ladders only to be used for low risk work

and a short duration of time. If any

longer than 30 minutes, alternatives

should be considered.

Ladders to be made secure by tying or

footed by a person at the base of the

ladder.

Health and Safety Team May 2018

Consider the use of a stand-off device to

ensure a strong resting point if the upper

surface where the ladder would make

contact is fragile or weak.

Ladder should be placed on a suitable

firm and level base. Also consider the

use of a stability device.

Safe procedures e.g. three points of

contact to be maintained at all times

when working to avoid overreaching.

Equipment used must be class 1

‘Industrial’ or EN131 ‘trade/industrial’

types. From 2018 new ladder standards

are replacing the previous these

standards. New ladders will now be

classed as EN131 Professional or

EN131 Non-Professional. Any new

ladder purchased will need to be of the

EN131 Professional standard, although

the old Class 1 Industrial is still

acceptable for use. There is no need to

replace old ladders in order to meet the

standard unless they require

replacement due to condition.

Appropriate footwear to be worn.

Equipment should be suitably stored

after use.

Work at height training to be undertaken.

04. Working on fragile surfaces; Refer to HSE guidance ‘Working on

carrying out roof work. roofs’ for full information and

requirements.

Complete ‘Health and safety roof work

checklist’.

Avoid the need to work on/near/pass

across a fragile surface wherever

possible, e.g. repairing a skylight from

underneath using a tower scaffold.

No access to fragile surface allowed

except by authorised persons or

specialist contractors using appropriate

equipment.

Use of suitable fixed access e.g.

stairs/ladders rather than temporary

equipment where possible.

Fragile surface identified with suitable

and prominent signage.

Use of suitable working platforms with

guard rails during work on or near a

fragile surface. Skylights will normally be

classed as a fragile surface.

Use of suitable personal protective

equipment (PPE) identified from the

Health and Safety Team May 2018

personal protective equipment checklist.

05. Falls from height. Specific risk assessment to be

undertaken prior to all work at height

activities.

Use of long handled tools where

appropriate.

Suitable equipment used for specific

jobs.

Staff not to use furniture or other

inappropriate fixed/mobile structures for

working at height.

Consider use of fall arrest systems

depending on nature of task, equipment

and duration.

Adequate and appropriate signs in place

to warn of hazards below work area.

Work scheduled to take place when

persons/others are not in the immediate

area.

Ensure operatives are trained to work at

height. See ‘Lack of training’ below.

06. Carrying materials. Only carry light materials and tools –

read the manufacturers’ labels on the

ladder and assess the risks;the person

and anything they are taking up should

not exceed the highest load stated on

the ladder.

Avoid holding items when climbing

(consider using a tool belt).

07. Poor weather conditions No work at height to be conducted

causing slips. outside in poor weather.

08. Risk of electrocution. Contact with overhead and hidden

cables. Contact with overhead and

hidden cables. Do not work within 6m

horizontally of any overhead power line,

unless it has been made dead or it is

protected with insulation. Use a non-

conductive ladder (eg fibreglass or

timber) for any electrical work.

Use of hand tools or battery operated

tools wherever possible.

All portable equipment must be PAT

tested every year.

Regular inspections of equipment before

and after use.

Health and Safety Team May 2018

09. Lack of training. All staff who are involved with working at

height need to be trained and be

competent. This includes involvement in

organisation, planning, supervision and

the supply and maintenance of

equipment.

For use of stepladders below 4 steps,

online ‘work at height’ training may be

undertaken or receive a toolbox talk from

a competent person. For use of ladders

or stepladders above 4 steps a ‘face to

face’ training course must be

undertaken, incorporating a practical

element of instruction.

10. Lack of personal protective PPE may be required. As part of the risk

equipment (PPE). assessment, the personal protective

equipment checklist should also be

completed.

11. Being hit by falling objects. Good housekeeping in place to ensure

nothing is stored in such a way that it will

fall from height.

Materials, tools or debris must not be

thrown down from height if it is likely to

unjure anyone.

Areas where there is a risk of a falling

object needs to be clearly indicated and

unauthorised people need to be kept

from it. Use barriers, cones or, as a last

resort, a person standing guard at the

base.

Tool belts to be used to prevent fall of

tools/materials from pockets etc.

PPE may be required. The personal

protective equipment checklist should be

completed.

12. Poor flooring or area where Each individual area where work at

work at height is to be carried height is to be carried out needs to be

out. inspected before use, e.g. floors

surfaces, guard rails etc, and records

kept.

Health and Safety Team May 2018

Health and Safety Team May 2018

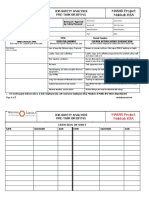

Generic risk assessment

Topic/activity/operation: Working at height

Name of establishment/school:

Risk assessment completed by: (name) Signed:

Name of operative:

Sign here only after giving consideration to

additional control measures. Date:

Head of establishment: (name) Signed:

Sign here only after agreeing control measures Operative’s signature:

and action points. Date:

Review date:

Risk rating: (Liklihood) Outcome:

Insignificant injury Significant injury Major injury

Unlikely Trival risk Low risk Medium risk

Possible Low risk Medium risk High

Date Signed: risk

___________________

Probable Medium risk High risk Stop

Risk level: Action and timescales:

Trivial No action required and no documentary records are required.

Low Consider if the risk can be reduced further. Monitoring is required to ensure that the controls are maintained.

Medium Risk reduction measures should be implemented within a defined period.

High Give priority to removing or reducing the risk urgent action should be taken.

Stop ‘Work’ activity should NOT be started or continued until the risk has been removed or at least reduced.

Health and Safety Team May 2018

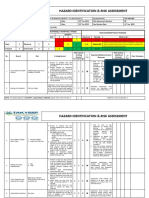

Step 1 Step 2 Step 3 Step 4 Step 5

What are the Who might be What are you Current Is anything further Date further action(s) New

hazards? harmed and doing already? risk level needed? was/were completed risk

how? level

By whom and by when? Date of next review

Poor

01. maintenance Date completed:

of access

equipment

e.g. ladders, Name:

steps, Review date:

scaffolds Date:

Inappropriate

02. use of tower Date completed:

scaffolds

causing trips Name:

and falls Date completed:

Date:

Inappropriate

03. use of Date completed:

ladders/

stepladders

Name:

Review date:

Date:

Working on

04. fragile Date completed:

surfaces;

carrying out

roof work Name:

Review Date:

Date:

Health and Safety Team May 2018

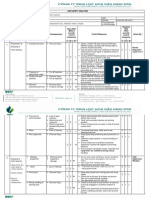

Step 1 Step 2 Step 3 Step 4 Step 5

What are the Who might be What are you Current Is anything further Date further action(s) New

hazards? harmed and doing already? risk level needed? was/were completed risk

how? level

By whom and by when? Date of next review

Falls from

05. height Date completed:

Name:

Review date:

Date:

Carrying

06. materials Date completed:

Name:

Review date:

Date:

Poor weather

07. conditions Date completed:

Name:

Review date:

Date:

Risk of

08. electrocution Date completed:

Name:

Review date:

Date:

Health and Safety Team May 2018

Step 1 Step 2 Step 3 Step 4 Step 5

What are the Who might be What are you Current Is anything further needed? Date further action(s) was/were

hazards? harmed and how? doing already? risk level completed

By whom and by when? Date of next review

Lack of

09. training Date completed:

Name:

Review date:

Date:

Lack of

10. personal Date completed:

protective

equipment Name:

(PPE) Review date:

Date:

Being hit by

11. falling objects Date completed:

Name:

Review date:

Date:

Poor flooring

12. or area where Date completed:

work at height

is to be carried

out Name:

Review date:

Date:

Health and Safety Team May 2018

Вам также может понравиться

- Working at Height Risk AssessmentДокумент9 страницWorking at Height Risk AssessmentNebosh Diploma Assignment83% (6)

- Working at Height Risk AssessmentДокумент7 страницWorking at Height Risk AssessmentAshish100% (3)

- Jsa forOperatingAForkliftДокумент2 страницыJsa forOperatingAForkliftsupahing supahingОценок пока нет

- Job Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSAДокумент2 страницыJob Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSAmahammed saleem100% (2)

- Job Safety Analysis (Jsa) Piling Activity: Document No: Rev. 01 Date: 12.03.2021Документ7 страницJob Safety Analysis (Jsa) Piling Activity: Document No: Rev. 01 Date: 12.03.2021Sanjay Kumar GhadaiОценок пока нет

- JSA Ladders Working at Heights 001Документ2 страницыJSA Ladders Working at Heights 001Raman SawОценок пока нет

- TBT-Driving in FogДокумент2 страницыTBT-Driving in FogImran KhanОценок пока нет

- 022 - HSSE - Full Body Harness Inspection ChecklistДокумент1 страница022 - HSSE - Full Body Harness Inspection ChecklistShashwat PandeyОценок пока нет

- Jsa For Piping and Erection RevisedДокумент1 страницаJsa For Piping and Erection RevisedAlvin Smith77% (26)

- JSA-017 Lifting With ForkliftДокумент3 страницыJSA-017 Lifting With ForkliftMoaatazz Nouisri67% (6)

- Man Basket Operation. HSE AsadДокумент5 страницMan Basket Operation. HSE AsadAsad RazaОценок пока нет

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSДокумент2 страницыProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (1)

- Job Safety Analysis Worksheet: Yes NoДокумент8 страницJob Safety Analysis Worksheet: Yes NoBorislav VulićОценок пока нет

- TRA of Lifting of EquipmentsДокумент3 страницыTRA of Lifting of EquipmentsandreОценок пока нет

- Working at Height Risk AssessmentДокумент2 страницыWorking at Height Risk Assessmentvismay83% (6)

- 28.1.1 Mobile Equipment Inspection ChecklistДокумент1 страница28.1.1 Mobile Equipment Inspection Checklistmohamed abdelmoniemОценок пока нет

- Winch MachineДокумент1 страницаWinch MachineJomar Rudolph Cabesas100% (6)

- 7 Hand Held Power ToolsДокумент4 страницы7 Hand Held Power ToolsGilmar MonteiroОценок пока нет

- JOB HAZARD ANALYSIS - Cable TrayДокумент10 страницJOB HAZARD ANALYSIS - Cable TrayJayson Escamillan100% (1)

- Jsa ExcavatorДокумент1 страницаJsa Excavatorbladeliger220% (1)

- Risk Assessment For Back FillingДокумент6 страницRisk Assessment For Back FillingBhargav BbvsОценок пока нет

- TRA For Fabrication, Cutting, Grinding and WeldingДокумент3 страницыTRA For Fabrication, Cutting, Grinding and WeldingSaif Ali100% (1)

- Risk Assessment: Project Name: Se-57, Construction of 10 Villas at Giardino VillageДокумент5 страницRisk Assessment: Project Name: Se-57, Construction of 10 Villas at Giardino VillageFrancis Enriquez Tan100% (3)

- DLF PCC HiraДокумент6 страницDLF PCC HiraskfahimuddinОценок пока нет

- Project HS Risk AssessmentДокумент6 страницProject HS Risk AssessmentParas100% (1)

- Jsa For Mechanical Activity: H/M/L H/M/LДокумент1 страницаJsa For Mechanical Activity: H/M/L H/M/Ljithin shankarОценок пока нет

- Tie in Hot Work JHAДокумент4 страницыTie in Hot Work JHAmalik jahan100% (2)

- Jha RoofingДокумент4 страницыJha Roofingahmadhatake100% (1)

- 002 Working at Height Risk AssessmentДокумент3 страницы002 Working at Height Risk Assessmentmyo lwin75% (4)

- 004 Annexure D Job Safety SAnalysis JSAДокумент3 страницы004 Annexure D Job Safety SAnalysis JSAAvoor Khan75% (4)

- JSA E&I 10.electrical Instrument Panels RemovalДокумент3 страницыJSA E&I 10.electrical Instrument Panels RemovalAmyОценок пока нет

- JSA FORMAT For Materials LoadingДокумент2 страницыJSA FORMAT For Materials LoadingVikky KumarОценок пока нет

- Safety Inspection Checklist Abrasive Wheel Grinders Bench and PedestalДокумент1 страницаSafety Inspection Checklist Abrasive Wheel Grinders Bench and PedestalSanthosh Kumar100% (1)

- JSA For HILTIДокумент3 страницыJSA For HILTIMohammed Minhaj100% (1)

- JHA - To Carry Out Reinstate of Interlock StonesДокумент7 страницJHA - To Carry Out Reinstate of Interlock Stoneslinga201450% (2)

- JSA For Painting Works-Hazards ControlДокумент4 страницыJSA For Painting Works-Hazards Controlkaleem0% (2)

- JSA Lifting OperationsДокумент4 страницыJSA Lifting OperationsCristina Rican100% (1)

- Electric Hand Drill Risk AssessmentДокумент4 страницыElectric Hand Drill Risk AssessmentTariq AkhtarОценок пока нет

- RISK ASSESSMENT (Concrete Pouring & Vehicular Movement)Документ2 страницыRISK ASSESSMENT (Concrete Pouring & Vehicular Movement)Raza Muhammad Soomro100% (1)

- JSA-Manual Lifting of MaterialsДокумент3 страницыJSA-Manual Lifting of Materialsfrancis_e_tan75% (4)

- Jsa R B 6 ForkliftДокумент3 страницыJsa R B 6 Forkliftoscar67% (3)

- RISK ASSES-106-Erection of Steel Structure BuildinДокумент4 страницыRISK ASSES-106-Erection of Steel Structure BuildinRochdi Bahiri50% (2)

- Jsa For Civil Confined Space EntryДокумент11 страницJsa For Civil Confined Space EntryKhuda BukshОценок пока нет

- JSA To Perform Greasing of Motor BearingДокумент9 страницJSA To Perform Greasing of Motor BearingChung Trịnh100% (1)

- Risk Assessment - Lifting OperationsДокумент3 страницыRisk Assessment - Lifting Operationsdnmule100% (2)

- Welding and Gas CuttingДокумент2 страницыWelding and Gas CuttingKrishna Patil100% (2)

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityДокумент2 страницыJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelОценок пока нет

- Health, Safety & Environmental Program Jsa (Job Safety Analysis)Документ7 страницHealth, Safety & Environmental Program Jsa (Job Safety Analysis)Osiobe Ewomazino50% (2)

- 3-REV.1 - Hot Work - Risk Assessment JHAДокумент16 страниц3-REV.1 - Hot Work - Risk Assessment JHAnaiyar100% (1)

- Jsa Working at Height (Maintenance & Cleaning)Документ2 страницыJsa Working at Height (Maintenance & Cleaning)Nur Syafiqah Mat Rapie100% (2)

- HIRA For Concrete Pouring of Diaphragm WallДокумент4 страницыHIRA For Concrete Pouring of Diaphragm WallLoc Nguyen0% (1)

- Jsa For Lifting Crane 016Документ6 страницJsa For Lifting Crane 016kiran kumar100% (1)

- JSA-Vertical Load On Test Pile - REV 0Документ8 страницJSA-Vertical Load On Test Pile - REV 0Sanjay Kumar GhadaiОценок пока нет

- Diesel RefuelingДокумент3 страницыDiesel RefuelingAMINОценок пока нет

- JSA No. 9 - Safe Use of Pneumatic and Power ToolsДокумент2 страницыJSA No. 9 - Safe Use of Pneumatic and Power ToolsAshok Suresh100% (1)

- JSA Loading UnloadingДокумент2 страницыJSA Loading UnloadingXtra Babe100% (2)

- Caretaker Risk Assessment - Working at HeightДокумент8 страницCaretaker Risk Assessment - Working at HeightLina MarcelaОценок пока нет

- Working at Height Risk AssessmentДокумент9 страницWorking at Height Risk AssessmentBasky0% (1)

- Jobs Safety Analysis (JSA)Документ8 страницJobs Safety Analysis (JSA)uttam mishra100% (1)

- JSA Working at Height PDFДокумент2 страницыJSA Working at Height PDFVishnu VijayanОценок пока нет

- PDFДокумент255 страницPDFwrite2arshad_mОценок пока нет

- RDSL 993K Z4D - Z4ZДокумент11 страницRDSL 993K Z4D - Z4ZDAnielОценок пока нет

- USS ProtocolДокумент77 страницUSS Protocolreza2131Оценок пока нет

- Electromagnetic CompatibilityДокумент12 страницElectromagnetic Compatibilityoadipphone7031Оценок пока нет

- All Over India Company DataДокумент32 страницыAll Over India Company DataViren PatelОценок пока нет

- Java SampleExamQuestionsДокумент18 страницJava SampleExamQuestionshmasryОценок пока нет

- Basic Electronics - AC - DC PDFДокумент20 страницBasic Electronics - AC - DC PDFRowena ResurreccionОценок пока нет

- Msi ms-7222 Rev 3.0 SCH PDFДокумент30 страницMsi ms-7222 Rev 3.0 SCH PDFRodney RibeiroОценок пока нет

- Ultrasound Quiz 1Документ9 страницUltrasound Quiz 1saleemut3Оценок пока нет

- Tensile Properties of Ground Coffee Waste Reinforced Polyethylene CompositeДокумент4 страницыTensile Properties of Ground Coffee Waste Reinforced Polyethylene CompositemhmmdzulvaОценок пока нет

- Combustion System Repairs - Industrial Gas Turbines: Industrial Frame Engines - GE, Siemens, Alstom - Including "F" ClassДокумент2 страницыCombustion System Repairs - Industrial Gas Turbines: Industrial Frame Engines - GE, Siemens, Alstom - Including "F" ClassfrdnОценок пока нет

- SFF 8448Документ8 страницSFF 8448eleptonОценок пока нет

- Bends - Route SelectionДокумент6 страницBends - Route SelectionanishsrОценок пока нет

- Software Hardware ListДокумент2 страницыSoftware Hardware ListjackОценок пока нет

- Home,: A Solace To Which A Journey Is Never Too Long..Документ25 страницHome,: A Solace To Which A Journey Is Never Too Long..Duvonto RealtyОценок пока нет

- PPAPДокумент2 страницыPPAPVlad NitaОценок пока нет

- Trouble Codes C32Документ10 страницTrouble Codes C32AliHabes100% (2)

- Powerware 5110 UPS User's ManualДокумент14 страницPowerware 5110 UPS User's ManualjulbfuОценок пока нет

- TDS Tixatrol STДокумент2 страницыTDS Tixatrol STJose E BatistaОценок пока нет

- Exception Handling Notes For Vtu StudentsДокумент42 страницыException Handling Notes For Vtu StudentshelloОценок пока нет

- IA SeriesДокумент20 страницIA Seriessina20795Оценок пока нет

- Physical Pharmacy Answer Key BLUE PACOPДокумент34 страницыPhysical Pharmacy Answer Key BLUE PACOPprincessrhenetteОценок пока нет

- AE Yanmar 6GL UTДокумент151 страницаAE Yanmar 6GL UTMehdi Es-SafiОценок пока нет

- Gsk980Tda Turning Machine CNC System: CharacteristicsДокумент10 страницGsk980Tda Turning Machine CNC System: CharacteristicsPramod YadavОценок пока нет

- ARSTRUCTS Chapter1Документ15 страницARSTRUCTS Chapter1Aila MaeОценок пока нет

- L19 External DiffusionДокумент30 страницL19 External DiffusionEga NabellaОценок пока нет

- TSA Surface Preparation and ApplicationДокумент7 страницTSA Surface Preparation and ApplicationMythri Metallizing Pvt Ltd Projects100% (1)

- EST 2011B v1.0 Configuration 10/28/2018 7:43 AMДокумент2 страницыEST 2011B v1.0 Configuration 10/28/2018 7:43 AMbagusОценок пока нет

- ABB LMU 574 - mcd80Документ12 страницABB LMU 574 - mcd80gadware2011bplОценок пока нет

- Kohler 14 20 RES Parts Manual TP 6806 2016 06Документ76 страницKohler 14 20 RES Parts Manual TP 6806 2016 06peleniusОценок пока нет