Академический Документы

Профессиональный Документы

Культура Документы

Washing Equipment Product Handbook - WEB - 06 2016

Загружено:

Lmf DanielОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Washing Equipment Product Handbook - WEB - 06 2016

Загружено:

Lmf DanielАвторское право:

Доступные форматы

washing equipment

PRODUC T HANDBOOK

© 06.2016 / Superior Industries P/1

superior washing equipment

WASH WASHING/CLASSIFYING EQUIPMENT

P/3 Classifying Systems

P/13 Aggredry® Dewatering Washer

P/19 Fine Material Washer

P/25 Coarse Material Washer

P/29 Dewatering Screen

P/33 Blade Mill Washer

P/37 Log Washer

P/41 Aggre-Washer™ Portable Plant

P/47 Rotary Screen

P/49 Aggre-Saver Washout System

P/2 Superior Industries / © 06.2016

Classifying Systems Up to 12’ x 48’

Groundbreaking, user-friendly computer controls blends a higher quality product with highest product output. n

High pressure hydraulics for the fastest control response time. n

Weir to weir measurements equal the largest tank design for the highest capacities in the industry. n

Diverse collection of stationary, semi-portable and portable designs to meet specific application requirements. n

© 06.2016 / Superior Industries P/3

highlights

4

2 3

1/ AR LINED FEEDBOX: High quality, abrasion 4/ HYDRAULIC TANK: Centered along the valve 7/ COLLECTING BLENDING FLUME: High capac-

resistant liners withstand sandblasting like bridge, this high-capacity, water-cooled tank ity, AR lined component allows for creating

pressure of slurry mixture. creates consistent pressure. up to three products. Optional: urethane

liners.

2/ VALVE BRIDGE: An elevated design prevents 5/ RECIRCULATING PUMP: Recycles water from

splashing from deteriorating this valuable tank overflow to supply rising current cells. 8/ RISING CURRENT CELLS: Increases yield by

component. No fresh water required. constantly removing misplaced particles

from the coarse end of tank.

3/ HYDRAULIC TUBING: Stainless steel hydrau- 6/ WEAR PARTS: Urethane valves, seats and dis-

lic lines accommodate highest pressures for charge elbows combine high wear life with

fastest valve response time. effective sealing.

P/4 Superior Industries / © 06.2016

Aggre-Spec Control System

™

AGGRE-SPEC III

¾¾ Three-method calculations consistently deliver 2% (up to

15%) more productivity than single-method programs

¾¾ Re-blends up to two spec products simultaneously

¾¾ Holds tight product specs and reduces out-of-spec material

¾¾ Unlimited mix design storage capacity

¾¾ Microsoft Windows-based control system is familiar and easy to use

¾¾ Collects and reports data, displays and tracks real time fineness

modulus (FM), yield graphs feed and output gradations

¾¾ Stockpile analysis checks finished product against

expected product and input settings

¾¾ Retrofits to other manufacturers’ tanks

¾¾ Programmable automatic tank cleanout

¾¾ Patented dual tank controls

AGGRE-SPEC I AGGRE-SPEC III - COMPUTER INTERFACE

¾¾ Simple intuitive control system

¾¾ 10 recipes of two products for 20 product capacity

¾¾ Ideal for quarry operations

¾¾ Quick start-up

¾¾ Programmable automatic tank cleanout

¾¾ Alarm history

¾¾ Retrofits to other manufacturers’ tanks

AGGRE-SPEC III - INDICATOR PANEL

© 06.2016 / Superior Industries P/5

Stationary Classifiers

FEATURES

¾¾ Single or double tanks

¾¾ AR lined, triple collecting blending flume

¾¾ Valve bridge with railings

¾¾ AR lined feed box

¾¾ Hydraulic power pack

¾¾ Electric motor, 3 phase, 60Hz, 230/460

¾¾ Urethane valves, seats and discharge elbows

¾¾ Access valves from walkway on control bridge

¾¾ Valve and grate allow for a full range of rising current CLASSIFYING TANK WITH STAIRWAY EASILY ACCESS THE VALVES

¾¾ Urethane discharge valves and seats are self-aligning

¾¾ Urethane discharge elbows provide extended life

¾¾ Optional custom-designed support structures and screen tower

URETHANE DIRECTION DISCHARGE BOOTS WITH AR LINED FLUME

VALVE AND GRATE URETHANE DISCHARGE VALVES

P/6 Superior Industries / © 06.2016

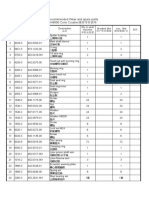

Stationary Classifier Specifications

STATIONARY CLASSIFIER - SINGLE TANK

Tank Size Estimated Tank Weight Estimated Support Structure Weight Estimated Support Structure Weight Estimated Support Structure Weight

Stations

ft (m) lbs (kg) lbs (kg)* lbs (kg)** lbs (kg)***

8’ x 20’ (2 x 6) 6 12,000 (5,443) 7,140 (3,239) 10,540 (4,781) 12,440 (5,643)

8’ x 24’ (2 x 7) 7 14,000 (6,350) 7,540 (3,420) 10,940 (4,962) 12,840 (5,824)

8’ x 28’ (2 x 9) 8 16,000 (7,258) 7,700 (3,493) 11,300 (5,126) 13,000 (5,897)

8’ x 32’ (2 x 10) 9 18,000 (8,165) 8,580 (3,892) 12,860 (5,833) 14,180 (6,432)

10’ x 24’ (3 x 7) 7 18,000 (8,165) 8,500 (3,856) 11,900 (5,398) 13,800 (6,260)

10’ x 28’ (3 x 9) 8 20,000 (9,072) 8,700 (3,946) 12,300 (5,579) 14,000 (6,350)

10’ x 32’ (3 x 10) 9 24,000 (10,886) 9,600 (4,355) 13,700 (6,214) 15,200 (6,895)

10’ x 36’ (3 x 11) 10 28,000 (12,701) 10,600 (4,808) 14,900 (6,759) 16,500 (7,484)

10’ x 40’ (3 x 12) 11 30,000 (13,608) 12,100 (5,489) 16,800 (7,620) 18,000 (8,165)

12’ x 48’ (4 x 15) 11 44,000 (19,958) 16,800 (7,620) 22,000 (9,979) 23,600 (10,705)

*One Chute to Fine Material Washer

** One Chute, Walkway and Ladders

***One Chute, Walkway and Stairs

STATIONARY CLASSIFIER - DOUBLE TANK

Tank Size Estimated Tank Weight Estimated Support Structure Weight Estimated Support Structure Weight Estimated Support Structure Weight

Stations

ft (m) lbs (kg) lbs (kg)* lbs (kg)** lbs (kg)***

10’ x 32’ (3 x 10) 9 48,900 (22,181) 22,500 (10,206) 28,800 (13,064) 30,300 (13,744)

10’ x 36’ (3 x 11) 10 53,000 (24,040) 24,000 (10,886) 31,100 (14,107) 32,700 (14,833)

10’ x 40’ (3 x 12) 11 56,000 (25,401) 26,000 (11,793) 34,000 (15,422) 35,200 (15,967)

12’ x 48’ (4 x 15) 11 86,000 (39,009) 38,000 (17,237) 46,900 (21,274) 48,200 (21,863)

*One Chute to Fine Material Washer

** One Chute, Walkway and Ladders

***One Chute, Walkway and Stairs

© 06.2016 / Superior Industries P/7

Semi-Portable Classifiers

WITH FINE MATERIAL WASHER FEATURES

¾¾ Two individual dewatering screws can produce two

separate products or can be combined to produce

the maximum amount of a primary product

¾¾ Flights are protected with adjustable 1” thick rubber wear shoes

¾¾ Extended shaft and slinger protects lower

bearing from water leakage

¾¾ Plant prewired for easy start-up

¾¾ Flush-back nozzle enhances dewatering efficiency

¾¾ Adjustable weir plates RETRACTABLE VALVE BRIDGE FOR TRAVEL TWIN DEWATERING SCREWS

¾¾ Drain for easy clean out

¾¾ Skid-mounted modular design

WITH AGGRE-DRY DEWATERING WASHER FEATURES

¾¾ Dewatering screen

¾¾ Dual electric vibrators

¾¾ Urethane screen plates and liners

SLINGER PROTECTS LOWER BEARING DUAL ELECTRIC VIBRATORS

URETHANE SCREENS AND LINERS 8% MOISTURE CONTENT

P/8 Superior Industries / © 06.2016

Semi-Portable Classifier Specifications

SEMI-PORTABLE CLASSIFIER WITH FINE MATERIAL WASHER - TRIPLE FLUME

Tank Size Screw Size Capacity Water Capacity - GPM (m3/sec) Estimated Weight

Stations

ft (m) in x ft (mm x m) TPH (MTPH) 100 Mesh 150 Mesh 200 Mesh

lbs (kg)

8’ x 24’ (2 x 7) Twin 36” x 25’ (914 x 7) 7 200 (181) 2,800 (0.17) 1,400 (0.08) N/A 40,000 (18,143)

8’ x 28’ (2 x 8) Twin 36” x 25’ (914 x 7) 8 200 (181) 3,200 (0.20) 1,600 (0.10) N/A 42,000 (19,050)

8’ x 32’ (2 x 10) Twin 36” x 25’ (914 x 7) 9 200 (181) 3,500 (0.22) 1,800 (0.11) N/A 48,500 (21,999)

10’ x 24’ (3 x 7) Twin 36” x 25’ (914 x 7) 7 200 (181) 3,500 (0.22) 1,800 (0.11) N/A 50,000 (22,679)

10’ x 28’ (3 x 8) Twin 36” x 25’ (914 x 7) 8 200 (181) 4,100 (0.25) 2,100 (0.13) N/A 51,000 (23,133)

10’ x 32’ (3 x 10) Twin 36” x 25’ (914 x 7) 9 200 (181) 4,700 (0.29) 2,400 (0.15) 1,250 (0.07) 51,500 (23,360)

10’ x 36’ (3 x 11) Twin 36” x 25’ (914 x 7) 10 200 (181) 5,300 (0.33) 2,700 (0.17) 1,400 (0.08) 58,500 (26,535)

10’ x 40’ (3 x 12) Twin 36” x 25’ (914 x 7) 11 200 (181) 5,900 (0.37) 3,000 (0.18) 1,500 (0.09) 63,000 (28,576)

8’ x 32’ (2 x 10) Twin 44” x 32’ (1,118 x 10) 9 350 (318) 3,500 (0.22) 1,800 (0.11) 950 (0.05) 60,000 (27,216)

10’ x 32’ (3 x 10) Twin 44” x 32’ (1,118 x 10) 9 350 (318) 4,700 (0.29) 2,400 (0.15) 1,250 (0.07) 64,500 (29,257)

10’ x 36’ (3 x 11) Twin 44” x 32’ (1,118 x 10) 10 350 (318) 5,300 (0.33) 2,700 (0.17) 1,400 (0.08) 67,000 (30,391)

10’ x 40’ (3 x 12) Twin 44” x 32’ (1,118 x 10) 11 350 (318) 5,900 (0.37) 3,000 (0.18) 1,500 (0.09) 68,000 (30,844)

10’ x 40’ (3 x 12) Twin 54” x 35’ (1,372 x 11) 11 480 (436) 5,900 (0.37) 3,000 (0.18) 1,500 (0.09) 97,000 (43,999)

10’ x 40’ (3 x 12) Twin 66” x 35’ (1,676 x 11) 11 720 (653) 5,900 (0.37) 3,000 (0.18) 1,500 (0.09) 132,000 (59,874)

12’ x 48’ (4 x 15) Twin 44” x 32’ (1,118 x 10) 11 350 (318) 8,100 (0.51) 4,200 (0.26) 2,150 (0.13) 91,000 (41,277)

12’ x 48’ (4 x 15) Twin 54” x 35’ (1,372 x 11) 11 480 (436) 8,100 (0.51) 4,200 (0.26) 2,150 (0.13) 116,000 (52,617)

12’ x 48’ (4 x 15) Twin 66” x 35’ (1,676 x 11) 11 720 (653) 8,100 (0.51) 4,200 (0.26) 2,150 (0.13) 150,000 (68,039)

12’ x 48’ (4 x 15) Twin 72” x 35’ (1,829 x 11) 11 820 (744) 8,100 (0.51) 4,200 (0.26) 2,150 (0.13) 175,000 (79,379)

© 06.2016 / Superior Industries P/9

Semi-Portable Classifiers Specifications (Continued)

SEMI-PORTABLE CLASSIFIER WITH AGGREDRY® DEWATERING WASHER

Tank Size Screw Diameter Capacity Water Capacity - GPM (m3/sec) Estimated Weight

Stations

ft (m) in (mm) TPH (MTPH) 100 Mesh 150 Mesh 200 Mesh

lbs (kg)

8’ x 24’ (2 x 7) Twin 36” (914) 7 200 (181) 2,800 (0.17) 1,400 (0.08) 800 (0.05) 54,000 (24,494)

8’ x 28’ (2 x 9) Twin 36” (914) 8 200 (181) 3,200 (0.20) 1,600 (0.10) 900 (0.05) 56,000 (25,401)

8’ x 32’ (2 x 10) Twin 36” (914) 9 200 (181) 3,500 (0.22) 1,800 (0.11) 950 (0.05) 62,500 (28,350)

10’ x 28’ (3 x 9) Twin 36” (914) 7 200 (181) 4,100 (0.25) 2,100 (0.13) 400 (0.02) 64,000 (29,030)

10’ x 32’ (3 x 10) Twin 36” (914) 8 200 (181) 4,200 (0.26) 2,400 (0.15) 1,250 (0.07) 65,000 (29,483)

10’ x 36’ (3 x 11) Twin 36” (914) 9 200 (181) 5,300 (0.33) 2,700 (0.17) 1,400 (0.08) 65,500 (29,710)

10’ x 40’ (3 x 12) Twin 36” (914) 10 200 (181) 5,900 (0.37) 3,000 (0.18) 1,500 (0.09) 72,500 (32,885)

8’ x 32’ (2 x 10) Twin 48” (1,219) 9 400 (363) 5,300 (0.33) 1,800 (0.11) 950 (0.05) 78,000 (35,380)

10’ x 32’ (3 x 10) Twin 48” (1,219) 9 400 (363) 4,700 (0.29) 2,400 (0.15) 1,250 (0.07) 82,500 (37,421)

10’ x 36’ (3 x 11) Twin 48” (1,219) 10 400 (363) 5,300 (0.33) 2,700 (0.17) 1,400 (0.08) 85,000 (38,555)

10’ x 40’ (3 x 12) Twin 48” (1,219) 11 400 (363) 5,900 (0.37) 3,000 (0.18) 1,500 (0.09) 86,000 (39,009)

10’ x 40’ (3 x 12) Twin 66” (1,676) 11 600 (544) 5,900 (0.37) 3,000 (0.18) 1,500 (0.09) 140,000 (63,503)

12’ x 48’ (4 x 15) Twin 48” (1,219) 11 400 (363) 8,100 (0.51) 4,200 (0.26) 2,150 (0.13) 109,000 (49,442)

12’ x 48’ (4 x 15) Twin 60” (1,524) 11 600 (544) 8,100 (0.51) 4,200 (0.26) 2,150 (0.13) 158,000 (71,668)

P/10 Superior Industries / © 06.2016

Fully Portable Classifier Features And Specifications

FEATURES

¾¾ Air brakes

¾¾ Running lights

¾¾ Hydraulic leveling jacks

¾¾ Fifth wheel hitch

¾¾ Prewired design for easy start-up

NOTE: Classifier must be removed for highway travel QUICK SET-UP AND DISMANTLE

FULLY PORTABLE CLASSIFIER WITH FINE MATERIAL WASHER - TRIPLE FLUME

Tank Size Screw Size Capacity Water Capacity - GPM (m3/sec) Estimated Weight

Stations Axles/Tires

ft (m) inch (mm) TPH (MTPH) 100 Mesh 150 Mesh 200 Mesh

lbs (kg)

8’ x 24’ (2 x 7) Twin 36” (914)* 7 200 (181) 2,800 (0.17) 1,400 (0.08) 800 (0.1) 64,000 (29,030) 2/8 or 3/12

8’ x 28’ (2 x 9) Twin 36” (914)* 8 200 (181) 3,200 (0.20) 1,600 (0.10) 900 (0.05) 65,000 (29,484) 2/8 or 3/12

8’ x 32’ (2 x 10) Twin 36” (914)* 9 200 (181) 3,500 (0.22) 1,800 (0.11) 950 (0.05) 52,000 (23,587) 2/8 or 3/12

8’ x 32’ (2 x 10) Twin 36” (914)* 9 200 (181) 3,500 (0.22) 1,800 (0.11) 950 (0.05) 68,000 (30,844) 2/8 or 3/12

8’ x 32’ (2 x 10) Twin 44” (1,118)* 9 350 (318) 3,500 (0.22) 1,800 (0.11) 950 (0.05) 73,500 (33,339) 3/12

10’ x 28’ (3 x 9) Twin 44” x 32’ (1,118 x 10) 8 350 (318) 4,100 (0.25) 2,100 (0.13) 1,100 (0.06) 81,000 (36,741) 3/12

10’ x 32’ (3 x 10) Twin 44” x 32’ (1,118 x 10) 9 350 (318) 4,700 (0.29) 2,400 (0.15) 1,250 (0.07) 86,000 (39,009) 3/12

10’ x 36’ (3 x 11) Twin 44” x 32’ (1,118 x 10) 10 350 (318) 5,300 (0.33) 2,700 (0.17) 1,400 (0.08) 88,000 (39,916) 3/12

10’ x 40’ (3 x 12) Twin 44” x 32’ (1,118 x 10) 11 350 (318) 5,900 (0.37) 3,000 (0.18) 1,500 (0.09) 95,000 (43,091) 3/12

*Screw length dependant of number of axles required therefore will be 25-ft, 28-ft or 30-ft

© 06.2016 / Superior Industries P/11

Options

RISING CURRENT PUMP WALKWAY TO ACCESS BLENDING FLUME DISCHARGE CHUTE

¾¾ WALKWAY TO ACCESS BLENDING FLUME ¾¾ URETHANE LINED COLLECTION BLENDING FLUME ¾¾ DISCHARGE CHUTE

¾¾ UPPER WALKWAY ¾¾ A532 OR URETHANE WEAR SHOES ¾¾ GUARDING

¾¾ LADDERS ¾¾ METERING BIN CONTROLS ¾¾ RISING CURRENT PUMP

¾¾ STAIRS ¾¾ METERING BINS

in-stock parts

WEAR SLEEVE AND LOWER SEAL VALVES RUBBER WEAR SHOES

¾¾ INPUT OR OUTPUT MODULES ¾¾ HYDRAULIC FILTER ¾¾ WEAR SHOES ¾¾ WEAR SLEEVE ¾¾ VIBRATOR GREASE

¾¾ BINDICATOR ¾¾ VALVES ¾¾ LOWER SEAL ¾¾ DRIVE COMPONENTS

P/12 Superior Industries / © 06.2016

aggredry Dewatering washer

®

Instantly Produce Saleable Sand

Combination of a fine material washer and dewatering screen in a single machine. n

Processed material has 8% moisture, which requires no dry time and is instantly saleable. n

Patented fines recovery system returns fines to screw saving 3% of material from waste pond. n

Dry material is gentler on loader tires and doesn’t stick to conveyor components. n

© 06.2016 / Superior Industries P/13

highlights

7

6

8

5

2 3 4

1/ OVERFLOW WEIR: Allows for leveling of water for 5/ WASH BASIN: Allows initial drainage of silty water. 10/ FINES RECOVERY SYSTEM: Minus quarter millimeter

maximum sand retention. sand collects in an under flume and is reintroduced

6/ DEWATERING SCREEN: Replaceable snap-deck ure-

back into the sand screw via this water jet. The pat-

2/ FEED BOX: High-quality, abrasion-resistant liners thane screens with bolt-on urethane liners.

ented technology saves up to 3% of material from

reduce turbulence for increased yield.

7/ DRIVE SYSTEM: Electrical, 3-phase, 60Hz, 460V motor waste pond.

3/ BAFFLE: Located in load zone to calm water for better with shaft-mounted gear reducer, belts and guarding.

retention of fines.

8/ DUAL VIBRATORS: Electric, linear motion with adjust-

4/ FINE MATERIAL SCREW: Single or twin screws, pro- able g-force.

tected with adjustable 1” thick rubber wear shoes. In

9/ LOWER BEARING: Slinger plate protects lower bear-

sand applications, rubber has 10% longer wear life

ing from water leakage. Standard, robust pillow block

than other wear products.

bearing design.

P/14 Superior Industries / © 06.2016

Technology Comparison

vs. Fine Material Screw vs. Dewatering Screen vs. Hydrocyclone

AGGREDRY WASHER ACHIEVES 8% MOISTURE SAVE FINES FROM WASTE POND CUT OPERATING EXPENSES

¾¾ MOISTURE CONTENT AS HIGH AS 25% ¾¾ DEWATERING SCREEN LOSES UP TO ¾¾ HYDROCYCLONES USE TWICE THE HORSEPOWER

¾¾ EXTRA REAL ESTATE FOR DRYING STOCKPILES 15% OF FINES TO WASTE POND ¾¾ SAVE $4,000 A YEAR IN ENERGY USE

¾¾ WET SAND IS DAMAGING TO ¾¾ AGGRE-DRY WASHER’S FINES ¾¾ BASED ON 1,600 PRODUCTION

TIRES AND COMPONENTS RECOVERY SAVES 3% FROM POND HOURS/YEAR AND 0.071 KWH.

¾¾ CALCULATE THE ADDITIONAL PROFIT AT

SUPERIOR-IND.COM/PRODUCTS/AGGRE-DRY

Photo Gallery

© 06.2016 / Superior Industries P/15

Fines recovery profit calculation

Patented Fines

Recovery System

Imput values matching your plants specific data to calculate additonal annual profit from fines recovery.

x 3% = x x =

Tons Per Day of Wet Saved From Additional Saleable Cost Per Ton Production Days Additional Annual

Sand Production Waste Pond Tons in a Year Profit

If you would like to use our online calculator,

visit www.superior-ind.com/products/aggre-dry

P/16 Superior Industries / © 06.2016

features

SINGLE SCREW TWIN SCREW LOAD ZONE BAFFLE SETTLES FINES

CURVED BELLY PAN SLINGER PLATE PROTECTS LOWER BEARING FLUSH-BACK NOZZLE

DUAL ELECTRIC VIBRATORS SCREEN URETHANE SIDE WALLS 8% MOISTURE CONTENT

© 06.2016 / Superior Industries P/17

Options in-stock Parts

DISCHARGE CHUTE PROTECTIVE GUARDING SPECIAL GREASE FOR VIBRATORS

¾¾ DISCHARGE CHUTE ¾¾ A532 AND URETHANE WEAR SHOES ¾¾ STAINLESS STEEL WEAR SLEEVE

¾¾ HYDRAULIC DRIVE ¾¾ GUARDING ¾¾ HEAVY-DUTY RUBBER LOWER SEAL

¾¾ CLEAN-OUT DOORS FOR BELLY PAN ¾¾ RUBBER WEAR SHOES

¾¾ VIBRATOR GREASE

specifications

AGGREDRY® DEWATERING WASHER – SINGLE SCREW

Screw Size Capacity Screw Speed Max. Material Size Auger Motor Size Vibrating Motor Size Water Capacity - GPM (m3/sec)

inch (mm) TPH (MTPH) RPM inch (mm) HP (kw) HP (kw) 100 Mesh 150 Mesh 200 Mesh

36” (914) 100 (90) 20 3/8” (0.9) 15 (11.0) two 8.05 (6.0) 1,700 (0.10) 850 (0.05) 450 (0.02)

48” (1,219) 200 (181) 16 3/8” (0.9) 25 (19.0) two 11.40 (8.5) 2,200 (0.13) 1,050 (0.06) 600 (0.03)

60” (1,524) 300 (272) 13 3/8” (0.9) 30 (22.0) two 12.61 (9.5) 2,400 (0.15) 1,200 (0.07) 650 (0.04)

AGGREDRY® DEWATERING WASHER – TWIN SCREW

Screw Size Capacity Screw Speed Max. Material Size Auger Motor Size Vibrating Motor Size Water Capacity - GPM (m3/sec)

inch (mm) TPH (MTPH) RPM inch (mm) HP (kw) HP (kw) 100 Mesh 150 Mesh 200 Mesh

48” (1,219) 400 (362) 16 3/8” (0.9) two 25 (18.0) four 17.2 (13.0) 3,700 (0.23) 1,800 (0.11) 975 (0.06)

60” (1,524) 600 (540) 16 3/8” (0.9) two 30 (22.0) four 17.2 (13.0) 4,000 (0.25) 2,000 (0.12) 1,200 (0.07)

P/18 Superior Industries / © 06.2016

fine material washer Up to 1,110 TPH

Industry’s largest range of sizes allows us to match equipment to specific requirements. n

Market’s only dewatering screw capable of handling material as large as 3/4”. n

Heavy-duty skid frame allows for crane-free installation into existing footprints. n

One machine for dewatering, classifying and washing materials. n

© 06.2016 / Superior Industries P/19

Features

SINGLE OR TWIN SCREWS SLINGER PROTECTS LOWER BEARING CURVED BELLY PAN

GUARDED DRIVE SYSTEM FLUSH-BACK NOZZLE LOAD ZONE BAFFLE SETTLES FINES

DEWATERING SCREW DRIVE SYSTEM ¾¾ Adjustable weir plates level overflow water,

¾¾ Single or twin models ¾¾ Electrical 3-phase, 60Hz, 460V motor maximizing retention of desirable fines

¾¾ Flights are protected with adjustable ¾¾ Off-the-shelf, shaft-mounted gear reducer ¾¾ Baffle, located behind load zone, calms

1” thick rubber wear shoes ¾¾ Belt and guarding water for better retention of fines

¾¾ Extended shaft and slinger protects WASH BASIN ¾¾ Heavy-duty skid frame

lower bearing from water leakage ¾¾ Flush-back nozzle promotes efficient dewatering ¾¾ Lifting points

by removing stagnant sand near discharge ¾¾ Drain for easy clean out

¾¾ Support legs

P/20 Superior Industries / © 06.2016

options

DISCHARGE CHUTE A532 WEAR SHOES PERSONAL SAFETY COVERS AND GUARDING

¾¾ DISCHARGE CHUTE ¾¾ A532 WEAR SHOES ¾¾ PERSONAL SAFETY COVERS ¾¾ FOLDING WING WALLS

¾¾ HYDRAULIC DRIVE ¾¾ URETHANE WEAR SHOES ¾¾ GUARDING

in-stock parts

WEAR SLEEVE AND LOWER SEAL DRIVE COMPONENTS RUBBER WEAR SHOES

¾¾ STAINLESS STEEL WEAR SLEEVE ¾¾ RUBBER WEAR SHOES ¾¾ LOWER BEARING RETROFIT KITS FOR ¾¾ ELECTRIC OR HYDRAULIC

¾¾ HEAVY-DUTY RUBBER LOWER SEAL ¾¾ A532 AND URETHANE WEAR SHOES OTHER MANUFACTURERS’ WASHERS DRIVE COMPONENTS

¾¾ HEAVY WALLED STEEL PIPE SHAFTS ¾¾ BELLY PANS

© 06.2016 / Superior Industries P/21

Specifications

FINE MATERIAL WASHER – SINGLE SCREW

Screw Size Capacity Peripheral Screw Speed Screw Speed Motor Size Water Capacity - GPM (m3/sec) Discharge Chute Weight Estimated Empty Weight

in x ft (mm x m) TPH (MTPH) FPM (MPS) RPM HP (kw) 100 Mesh 150 Mesh 200 Mesh

lbs (kg) lbs (kg)

20 (18) 120 (0.6) 40 3 (2.0)

12” x 14’ 15 (13) 90 (0.4) 30 3 (2.0) 150 (0.009) 100 (0.006) 50 (0.003) 80 (36) 3,000 (1,360)

(304 x 4) 10 (9) 60 (0.3) 20 3 (2.0)

5 (4) 30 (0.1) 10

50 (45) 200 (1.0) 32 7.5 (5.5)

24” x 24’

38 (34) 150 (0.8) 24 5 (3.5) 500 (0.03) 225 (0.01) 125 (0.007) 120 (54) 6,500 (2,948)

(609 x 7)

25 (22) 100 (0.5) 16 5 (3.5)

75 (68) 200 (1.0) 25 15 (11.0)

30” x 24’

60 (54) 150 (0.8) 19 10 (7.5) 575 (0.03) 275 (0.01) 160 (0.01) 140 (64) 8,300 (3,765)

(762 x 7)

50 (45) 100 (0.5) 13 7.5 (5.5)

100 (90) 200 (1.0) 20 15 (11.0)

36”x 25’

75 (68) 150 (0.8) 15 10 (7.5) 700 (0.04) 330 (0.02) 180 (0.01) 150 (68) 10,600 (4,808)

(914 x 7)

50 (45) 100 (0.5) 12 7.5 (5.5)

175 (159) 200 (1.0) 17 20 (15.0)

44” x 32’ *

130 (118) 150 (0.8) 14 15 (11.0) 1,600 (0.10) 750 (0.04) 425 (0.02) 240 (109) 16,340 (7,412)

(1,118 x 10)

85 (77) 100 (0.5) 9 10 (7.5)

200 (181) 200 (1.0) 16 30 (22.0)

48” x 35’

150 (136) 150 (0.8) 12 25 (18.5) 1,700 (0.10) 850 (0.05) 450 (0.02) 350 (159) 25,000 (11,340)

(1,219 x 11)

100 (91) 100 (0.5) 8 20 (15.0)

275 (249) 200 (1.0) 15 25 (18.5)

54” x 35

210 (191) 150 (0.8) 12 20 (15.0) 1,900 (0.11) 950 (0.05) 575 (0.03) 240 (109) 18,400 (8,346)

(1,372 x 11)

140 (127) 100 (0.5) 8 15 (11.0)

340 (308) 200 (1.0) 14 40 (29.5)

60”x 35’

255 (231) 150 (0.8) 9 30 (22.0) 2,200 (0.13) 1,050 (0.06) 600 (0.03) 350 (159) 27,500 (12,474)

(1,524 x 11)

170 (154) 100 (0.5) 7 25 (18.5)

400 (363) 200 (1.0) 13 50 (37.0)

66” x 35’

300 (272) 150 (0.8) 11 40 (29.5) 2,400 (0.15) 1,200 (0.07) 650 (0.04) 350 (159) 29,160 (13,227)

(1,676 x 11)

200 (181) 100 (0.5) 7 30 (22.0)

475 (431) 235 (1.2) 13 60 (44.0)

72” x 38’

360 (327) 180 (0.9) 10 50 (37.0) 2,600 (0.16) 1,300 (0.08) 700 (0.04) 450 (204) 31,880 (14,461)

(1,829 x 12)

240 (218) 126 (0.6) 7 40 (29.5)

600 (544) 260 (1.3) 11 75 (55.0)

84” x 38’

450 (408) 160 (0.8) 8 60 (44.0) 3,100 (0.19) 1,600 (0.10) 850 (0.05) 550 (227) 43,000 (19,504)

(2,134 x 12)

300 (272) 110 (0.6) 5 50 (37.0)

*Optional hinged folding wing walls allow for quick transition from transport to operation modes.

P/22 Superior Industries / © 06.2016

Specifications

FINE MATERIAL WASHER – TWIN SCREW

Screw Size Capacity Peripheral Screw Speed Screw Speed Motor Size Water Capacity - GPM (m3/sec) Discharge Chute Weight Estimated Empty Weight

in x ft (mm x m) TPH (MTPH) FPM (MPS) RPM HP (kw) lbs (kg) lbs (kg)

100 Mesh 150 Mesh 200 Mesh

100 (90) 200 (1.0) 32 (2) 7.5 (5.5)

24” x 24’

75 (68) 150 (0.8) 24 (2) 5 (3.5) 890 (0.05) 420 (0.02) 235 (0.01) 240 (109) 14,800 (6,713)

(609 x 7)

50 (45) 100 (0.5) 16 (2) 5 (3.5)

150 (136) 200 (1.0) 25 (2) 15 (11.0)

30” x 24’

120 (108) 150 (0.8) 19 (2) 10 (7.5) 1,000 (0.06) 490 (0.03) 280 (0.02) 270 (122) 15,700 (7,121)

(762 x 7)

100 (91) 100 (0.5) 13 (2) 7.5 (5.5)

200 (181) 200 (1.0) 20 (2) 15 (11.0)

36”x 25’

150 (136) 150 (0.8) 15 (2) 10 (7.5) 1,250 (0.07) 620 (0.04) 340 (0.02) 280 (127) 17,000 (7,711)

(914 x 7)

100 (91) 100 (0.5) 10 (2) 7.5 (5.5)

350 (318) 200 (1.0) 17 (2) 20 (15.0)

44”x 32’ *

260 (236) 150 (0.8) 14 (2) 15 (11.0) 2,800 (0.17) 1,400 (0.08) 675 (0.04) 350 (159) 30,000 (13,608)

(1,118 x 10)

170 (154) 100 (0.5) 9 (2) 10 (7.5)

400 (363) 200 (1.0) 16 (2) 25 (18.5)

48”x 35’

300 (272) 150 (0.8) 12 (2) 20 (15.0) 3,000 (0.18) 1,450 (0.09) 750 (0.04) 380 (172) 40,000 (18,144)

(1,219 x 11)

200 (181) 100 (0.5) 8 (2) 15 (11.0)

550 (499) 200 (1.0) 15 (2) 30 (22.0)

54”x 35’

420 (381) 150 (0.8) 12 (2) 25 (18.5) 3,500 (0.22) 1,750 (0.11) 950 (0.05) 480 (218) 48,000 (21,772)

(1,372 x 11)

280 (254) 100 (0.5) 8 (2) 15 (11.0)

680 (617) 200 (1.0) 14 (2) 40 (29.5)

60”x 35’

510 (463) 150 (0.8) 9 (2) 30 (22.0) 3,700 (0.23) 1,800 (0.11) 975 (0.06) 580 (263) 60,000 (27,216)

(1,524 x 11)

340 (308) 100 (0.5) 7 (2) 25 (18.5)

800 (726) 200 (1.0) 13 (2) 50 (37.0)

66”x 35’

600 (544) 150 (0.8) 11 (2) 40 (29.5) 4,000 (0.25) 2,000 (0.12) 1,200 (0.07) 650 (295) 62,000 (28,123)

(1,676 x 11)

400 (363) 100 (0.5) 7 (2) 30 (22.0)

950 (862) 235 (1.2) 13 (2) 60 (44.0)

72”x 38’

710 (644) 180 (0.9) 10 (2) 50 (37.0) 4,500 (0.28) 2,200 (0.13) 1,250 (0.07) 750 (340) 64,500 (29,257)

(1,829 x 12)

475 (431) 126 (0.6) 7 (2) 40 (29.5)

1,100 (998) 224 (1.1) 12 (2) 75 (55.0)

84”x 38’

825 (748) 180 (0.9) 9 (2) 60 (44.0) 4,800 (0.30) 2,500 (0.15) 1,350 (0.08) 850 (386) 70,500 (31,978)

(2,134 x 12)

550 (499) 120 (0.6) 6 (2) 50 (37.0)

*Optional hinged folding wing walls allow for quick transition from transport to operation modes.

© 06.2016 / Superior Industries P/23

photo gallery

P/24 Superior Industries / © 06.2016

Coarse Material Washer Up to 550 TPH

Adjustable screw shaft design allows producers to process a wider range of material sizes. n

Heavy-duty angle iron skid frame is stronger than formed plate designs and installs without e xpensive cranes. n

Broadest group of product designs in the industry for very application-specific offerings. n

Motors, drive parts and pillow block bearings are standard, off-the-shelf components for easy replacement. n

© 06.2016 / Superior Industries P/25

features

A532 WEAR SHOES AND PADDLES ADJUSTABLE OVERFLOW GATE SLINGER PROTECTS LOWER BEARING

GEAR REDUCER CURVED BELLY PAN FLUSH-BACK NOZZLE

WASHING SCREW DRIVE SYSTEM WASH BASIN

¾¾ Single or twin models ¾¾ Electrical 3-phase, 60Hz, 460V motor; ¾¾ Flush-back nozzle enhances dewatering efficiency

¾¾ Combination of flights and paddles can also be configured to match local ¾¾ Adjustable overflow gates

dependent on scrubbing requirements power requirements, if necessary ¾¾ Heavy-duty skid frame

¾¾ Flights and paddle bases are protected with ¾¾ Shaft-mounted gear reducer ¾¾ Lifting points

replaceable A532 wear shoes and paddles ¾¾ Belt and guarding ¾¾ Drain for easy clean out

¾¾ Extended shaft and slinger protects ¾¾ Support legs for 15°

lower bearing from water leakage

P/26 Superior Industries / © 06.2016

options

DISCHARGE CHUTE PROTECTIVE GUARDING BOLT ON PADDLES INCREASE SCRUBBING

¾¾ DISCHARGE CHUTE ¾¾ PERSONAL SAFETY COVERS ¾¾ URETHANE WEAR SHOES

¾¾ HYDRAULIC DRIVE ¾¾ GUARDING ¾¾ BOLT ON PADDLES

in-stock parts

WEAR SLEEVE AND LOWER SEAL MOTORS SHAFT AND WEAR SHOES

¾¾ STAINLESS STEEL WEAR SLEEVE ¾¾ HEAVY WALLED STEEL PIPE SHAFTS ¾¾ LOWER BEARING RETROFIT KITS FOR ¾¾ ELECTRIC OR HYDRAULIC

¾¾ HEAVY-DUTY RUBBER LOWER SEAL ¾¾ BEARINGS OTHER MANUFACTURERS’ WASHERS DRIVE COMPONENTS

¾¾ RUBBER WEAR SHOES ¾¾ BELLY PANS

© 06.2016 / Superior Industries P/27

Specifications

COARSE MATERIAL WASHER - SINGLE SCREW

Screw Size Estimated Capacity Screw Speed Motor Size Max. Material Size Estimated Empty Weight Discharge Chutes Weight

in x ft (mm x m) TPH (MTPH) RPM HP (kw) inch (mm) lbs (kg) lbs (kg)

24” x 18’ (610 x 5) 60 - 75 (50 - 60) 40 15 (11.0) 1.5” (40) 8,000 (3,600) 120 (50)

30” x 18’ (760 x 5) 100 - 125 (90 - 110) 35 20 (15.0) 2.0” (50) 9,000 (4,000) 140 (60)

30” x 24’ (760 x 7) 100 - 125 (90 - 110) 35 25 (18.5) 2.0” (50) 10,700 (4,800) 140 (60)

36” x 18’ (915 x 5) 150 - 175 (135 - 160) 30 25 (18.5) 3.0” (75) 11,300 (5,100) 150 (70)

36” x 28’ (915 x 10) 150 - 175 (135 - 160) 30 30 (22.0) 3.0” (75) 14,400 (6,500) 150 (70)

44” x 20’ (1,100 x 6) 200 - 250 (180 - 230) 26 30 (22.0) 3.0” (75) 15,000 (6,700) 240 (100)

44” x 32’ (1,100 x 10) 200 - 250 (180 - 230) 26 50 (37.0) 3.0” (75) 19,100 (8,700) 240 (100)

48” x 24’ (1,200 x 7) 220 - 275 (200 - 250) 24 40 (29.5) 3.5” (90) 21,500 (9,800) 280 (130)

48” x 32’ (1,200 x 10) 220 - 275 (200 - 250) 24 50 (37.0) 3.5” (90) 25,500 (11,600) 280 (130)

COARSE MATERIAL WASHER - TWIN SCREW

Screw Size Estimated Capacity Screw Speed Motor Size Max. Material Size Estimated Empty Weight Discharge Chutes Weight

in x ft (mm x m) TPH (MTPH) RPM HP (kw) inch (mm) lbs (kg) lbs (kg)

30” x 18’ (760 x 5) 200 -250 (180 - 230) 35 (2) 20 (15.0) 1.5” (40) 13,700 (6,200) 280 (130)

30” x 24’ (760 x 7) 200 - 250 (180 - 230) 35 (2) 25 (18.5) 2.0” (50) 19,300 (8,700) 280 (130)

36” x 18’ (915 x 5) 250 - 300 (230 - 270) 30 (2) 25 (18.5) 3.0” (75) 16,800 (7,600) 280 (130)

36” x 28’ (915 x 10) 250 - 300 (230 - 270) 30 (2) 30 (22.0) 3.0” (75) 23,000 (10,500) 280 (130)

44” x 20’ (1,100 x 6) 450 - 500 (400 - 450) 26 (2) 30 (22.0) 3.0” (75) 28,400 (12,900) 350 (160)

44” x 32’ (1,100 x 10) 450 - 500 (400 - 450) 26 (2) 50 (37.0) 3.0” (75) 36,600 (16,600) 350 (160)

48” x 24’ (1,200 x 7) 450 - 550 (400 - 500) 24 (2) 40 (29.5) 3.5” (90) 39,600 (18,000) 450 (200)

48” x 32’ (1,200 x 10) 450 - 550 (400 - 500) 24 (2) 50 (37.0) 3.5” (90) 42,500 (19,300) 450 (200)

P/28 Superior Industries / © 06.2016

dewatering screen Up to 300 TPH

Achieve moisture content as low as 8% for a saleable product in less than a day. n

Deeper bed depth allows screens to remove more moisture and retain highest percentage of saleable product. n

Aggressive throw allows for higher feed tonnage and faster drying cycles. n

Urethane screen sidewalls allow for additional dewatering along the sides of the bed. n

© 06.2016 / Superior Industries P/29

Features

SCREEN URETHANE SIDE WALLS DUAL ELECTRICAL VIBRATORS WATER DISCHARGE

RECYCLE WATER LINE STEEL COMPRESSION SPRINGS 8% MOISTURE CONTENT

DRIVE SCREEN DECK STANDARD

¾¾ Electric vibrators (adjustable counterweights) ¾¾ Bed angle: -5° to +5° ¾¾ Steel compression springs

¾¾ Adjustable high g-forces ¾¾ Replaceable snap-deck urethane screens ¾¾ 1” steel motor mount

¾¾ Unbalanced motors ¾¾ Bolt-on urethane screen liners ¾¾ Rigid 1/2” A36 steel welded frame

¾¾ Centrifugal force ¾¾ Stationary frame

¾¾ Side liners with screen openings allows

for larger surface for drainage

P/30 Superior Industries / © 06.2016

options

PORTABLE PACKAGING SPRAY NOZZLE FOR DISCHARGE CLEANOUT DISCHARGE CHUTE

¾¾ DISCHARGE CHUTE ¾¾ SUPPORT LEGS ¾¾ PORTABLE PACKAGE: TIRES, HITCH,

¾¾ SPRAY BARS ¾¾ FEED BOX LINING LANDING GEAR AND BREAKAWAY

in-stock parts

SCREEN PLATES AND LINERS COMPRESSION SPRINGS SPECIAL GREASE FOR VIBRATORS

¾¾ VIBRATOR GREASE ¾¾ SCREEN LINERS ¾¾ COMPRESSION SPRINGS

¾¾ SCREEN PLATES ¾¾ SPRAY BARS

© 06.2016 / Superior Industries P/31

specifications

DEWATERING SCREEN

Dewatering Screen Size Capacity Motor Size Weight

Screen in x ft (mm x m) TPH (MTPH) HP (kw) lbs (kg)

DS-488 48” x 8’ (1,220 x 2.4) 100 (90.0) two 8.05 (6.0) 4,500 (2,041)

DS-6010 60” x 10’ (1,525 x 3.0) 200 (180.0) two 11.40 (8.5) 6,500 (2,948)

DS-7212 72” x 12’ (1,828 x 3.6) 300 (270.0) two 12.61 (9.5) 9,500 (4,309)

photo gallery

STATIONARY

PORTABLE FINE MATERIAL WASHER TO A DEWATERING SCREEN

P/32 Superior Industries / © 06.2016

blade mill Washer Up to 720 TPH

Long and short tub lengths allows for additional scrubbing and more effective conditioning of clay and conglomerates. n

Bolt-on, heavy-duty A532 shoes can be adjusted for years of additional service life. n

Motors, drive parts and pillow block bearings are standard, off-the-shelf components for easy replacement. n

Increases screening efficiency by up to 15%. n

© 06.2016 / Superior Industries P/33

features

A532 PADDLES ADJUSTABLE OVERFLOW GATE HEAVY-DUTY FRAME W/LIFT POINTS

SLINGER PROTECTS LOWER BEARING EASY ACCESS TO DRAIN AND FILL GUARDED DRIVE SYSTEM

DEWATERING SCREW DRIVE SYSTEM WASH BASIN

¾¾ Single or twin models ¾¾ Electrical 3-phase, 60Hz, 460V motor; ¾¾ Adjustable overflow gates

¾¾ Heavy-duty paddle design for maximum scrubbing can also be configured to match local ¾¾ Heavy-duty skid frame

¾¾ Flights and paddle bases are protected with power requirements, if necessary ¾¾ Lifting points

adjustable A532 wear shoes and paddles ¾¾ Shaft-mounted gear reducer ¾¾ Drain for easy clean out

¾¾ Extended shaft and slinger protects ¾¾ Belt and guarding

lower bearing from water leakage

P/34 Superior Industries / © 06.2016

options

OVERFLOW TROUGH ADJUSTABLE SUPPORT LEGS PROTECTIVE GUARDING

¾¾ DISCHARGE CHUTE ¾¾ DISCHARGE SCREEN ¾¾ CLEAN-OUT DOORS FOR BELLY PAN ¾¾ ADJUSTABLE SUPPORT LEGS

¾¾ OVERFLOW TROUGH ¾¾ HYDRAULIC DRIVE ¾¾ SUPPORT LEGS FROM 2°-10° ¾¾ GUARDING

in-stock parts

WEAR SLEEVE AND LOWER SEAL DRIVE COMPONENTS A532 PADDLES AND WEAR SHOES

¾¾ STAINLESS STEEL WEAR SLEEVE ¾¾ RUBBER WEAR SHOES ¾¾ ELECTRIC OR HYDRAULIC ¾¾ LOWER BEARING RETROFIT KITS FOR

¾¾ HEAVY-DUTY RUBBER LOWER SEAL ¾¾ PADDLES DRIVE COMPONENTS OTHER MANUFACTURERS’ WASHERS

¾¾ HEAVY-WALLED STEEL PIPE SHAFTS ¾¾ BELLY PANS

© 06.2016 / Superior Industries P/35

Specifications

BLADE MILL - SINGLE SHAFT

Screw Size Estimated Capacity Operating Angle Screw Speed Motor Size Max. Material Size Estimated Empty Weight

in x ft (mm x m) TPH (MTPH) degrees RPM HP (kw) inch (mm) lbs (kg)

24” x 18’ (610 x 5) 60 - 110 (55 - 100) 0°- 8° 35 15 (11.0) 1.5” (40) 7,000 (3,200)

24” x 24’ (610 x 5) 60 - 110 (55 - 100) 0°- 8° 35 20 (15.0) 1.5” (40) 7,800 (3,500)

30” x 18’ (760 x 5) 100 - 165 (90 - 150) 0°- 8° 30 20 (15.0) 2.0” (50) 9,500 (4,300)

30” x 24’ (760 x 5) 100 - 165 (90 - 150) 0°- 8° 30 25 (18.5) 2.0” (50) 10,600 (4,800)

36” x 18’ (915 x 5) 150 - 250 (135 - 225) 0°- 8° 30 25 (18.5) 3.0” (75) 11,000 (5,000)

36” x 28’ (915 x 10) 150 - 250 (135 - 225) 0°- 8° 30 30 (22.0) 3.0” (75) 14,000 (6,400)

44” x 20’ (1,120 x 5) 200 - 335 (180 - 300) 0°- 8° 26 30 (22.0) 3.5” (90) 15,000 (6,800)

44” x 32’ (1,120 x 10) 200 - 335 (180 - 300) 0°- 8° 26 50 (37.0) 3.5” (90) 19,500 (8,800)

48” x 24’ (1,220 x 5) 220 - 360 (200 - 325) 0°- 8° 24 50 (37.0) 3.5” (90) 21,500 (9,800)

BLADE MILL - TWIN SHAFT

Screw Size Estimated Capacity Operating Angle Screw Speed Motor Size Max. Material Size Estimated Empty Weight

in x ft (mm x m) TPH (MTPH) degrees RPM HP (kw) inch (mm) lbs (kg)

30” x 18’ (760 x 5) 120 - 220 (110 - 200) 0°- 8° 30 (2) 25 (18.5) 2.0” (50) 14,000 (6,400)

30” x 24’ (760 x 5) 120 - 220 (110 - 200) 0°- 8° 30 (2) 20 (15.0) 2.0” (50) 19,300 (8,800)

36” x 18’ (915 x 5) 200 - 330 (180 - 300) 0°- 8° 30 (2) 25 (18.5) 3.0” (75) 17,000 (7,700)

36” x 28’ (915 x 10) 200 - 330 (180 - 300) 0°- 8° 30 (2) 30 (22.0) 3.0” (75) 23,100 (10,500)

44” x 20’ (1,120 x 5) 400 - 670 (360 - 610) 0°- 8° 26 (2) 30 (22.0) 3.5” (90) 28,000 (12,700)

44” x 32’ (1,120 x 10) 400 - 670 (360 - 610) 0°- 8° 26 (2) 50 (37.0) 3.5” (90) 36,700 (16,650)

48” x 24’ (1,220 x 5) 440 - 720 (400 - 650) 0°- 8° 24 (2) 50 (37.0) 3.5” (90) 45,000 (20,400)

P/36 Superior Industries / © 06.2016

Log Washers Up to 190 TPH

Integrity of shafts and drivetrain enhanced by a rigid, heavy-duty skid frame. n

Spiral paddle design reduces impact loading on paddles and increases throughput. n

Bottom clean-out doors allow for convenient maintenance versus digging out material by hand. n

Motor, drive parts and pillow block bearings are standard, off-the-shelf components for easy replacement. n

© 06.2016 / Superior Industries P/37

Features

A532 PADDLES ADJUSTABLE OVERFLOW GATE SLINGER PROTECTS LOWER BEARING

EASY ACCESS TO DRAIN AND FILL SPIRAL PADDLES FOR CONTINUOUS AGITATION GUARDED DRIVE SYSTEM

LOG SHAFT DRIVE SYSTEM WASH BASIN

¾¾ Twin shafts with paddles ¾¾ Electrical 3-phase, 60Hz, 460V motor ¾¾ Adjustable overflow gates

¾¾ Paddle bases are protected with ¾¾ Gear reducer ¾¾ Heavy-duty skid frame

adjustable A532 wear paddles ¾¾ Belt and guarding ¾¾ Lifting points

¾¾ Extended shaft and slinger protects ¾¾ Drain for easy clean out

lower bearing from water leakage

P/38 Superior Industries / © 06.2016

options

CLEAN OUT DOORS FOR BELLY PAN OVERFLOW TROUGH PROTECTIVE GUARDING

¾¾ DISCHARGE CHUTE ¾¾ HYDRAULIC DRIVE ¾¾ SUPPORT LEGS FROM 2°-10° ¾¾ PERSONAL SAFETY COVERS

¾¾ OVERFLOW TROUGH ¾¾ CLEAN OUT DOORS FOR BELLY PAN ¾¾ ADJUSTABLE SUPPORT LEGS ¾¾ GUARDING

in-stock parts

WEAR SLEEVE AND LOWER SEAL BELLY PAN A532 PADDLES AND WEAR SHOES

¾¾ STAINLESS STEEL WEAR SLEEVE ¾¾ RUBBER WEAR SHOES ¾¾ ELECTRIC OR HYDRAULIC ¾¾ LOWER BEARING RETROFIT KITS FOR

¾¾ HEAVY-DUTY RUBBER LOWER SEAL ¾¾ PADDLES DRIVE COMPONENTS OTHER MANUFACTURERS’ WASHERS

¾¾ HEAVY-WALLED STEEL PIPE SHAFTS ¾¾ BELLY PANS

© 06.2016 / Superior Industries P/39

Specifications

LOG WASHER

Screw Size Screw Diameter Max. Material Size Speed Motor Size Capacity Estimated Empty Weight

in x ft (mm x m) inch (mm) inch (mm) RPM HP (kw) TPH (MTPH) lbs (kg)

24” x 20’ (610 x 6) 24” (610) 2” (51) 40 40 (29.5) 30 - 60 (26 -53) 30,000 (13,608)

36” x 25’ (914 x 8) 36” (914) 3” (76) 33 75 (55.0) 50 - 125 (44 - 111) 33,500 (15,195)

36” x 30’ (914 x 9) 36” (914) 3” (76) 33 100 (73.5) 50 - 125 (44 - 111) 38,500 (17,463)

36” x 35’ (914 x 11) 36” (914) 3” (76) 33 150 (110.5) 50 - 125 (44 - 111) 48,000 (21,772)

38” x 30’ (965 x 9) 38” (965) 2.5” (64) 33 150 (110.5) 60 - 140 (53 - 125) 41,000 (18,597)

38” x 35’ (965 x 11) 38” (965) 2.5” (64) 33 150 (110.5) 60 - 140 (53 - 125) 49,000 (22,226)

44” x 25’ (1,118 x 8) 44” (1,118) 4” (102) 26 125 (92.0) 75 - 175 (67 - 156) 53,500 (24,267)

44” x 30’ (1,118 x 9) 44” (1,118) 4” (102) 26 150 (110.5) 75 - 175 (67 - 156) 57,000 (25,855)

44” x 35’ (1,118 x 11) 44” (1,118) 4” (102) 26 200 (147.0) 75 - 175 (67 - 156) 71,000 (32,205)

46” x 30’ (1,168 x 9) 46” (1,168) 3.5” (89) 24 200 (147.0) 100 - 190 (90 - 170) 61,000 (27,669)

46” x 35’ (1,168 x 11) 46” (1,168) 3.5” (89) 24 200 (147.0) 100 - 190 (90 - 170) 74,000 (33,566)

photo gallery

P/40 Superior Industries / © 06.2016

Aggre-Washer Portable Plant ™

Washing and Screening

Simply fold the feed hopper and remove blocking for a quick transition from operation to transport mode. n

Large, water system equipped feed hopper ensures maximum production to the screen. n

Spray bars on each deck ensure maximum material washing. n

Flexible to design and manufacture units for custom performance. n

© 06.2016 / Superior Industries P/41

Features

PORTABLE WASH PLANT SEMI-PORTABLE WASH PLANT

FINE MATERIAL WASHER WORK PLATFORM

¾¾ Single or twin models ¾¾ Large, safe area to change screen cloth,

¾¾ Flights are protected with adjustable adjust spray bars and monitor operation

1” thick rubber wear shoes WIRED FOR IMMEDIATE PRODUCTION

¾¾ Extended shaft and slinger protects ¾¾ Simply plug into electrical source and switch on

lower bearing from water leakage WASH BASIN

PROCESSING SCREEN ¾¾ Minimal clearance between belly pan and screw

¾¾ Customer screen brand preference shaft to accommodate smaller size aggregate

¾¾ Drive motor ¾¾ Flush-back nozzle promotes efficient dewatering SINGLE OR TWIN SHAFT

¾¾ Screen subframe by removing stagnant sand near discharge

SCREEN DISCHARGE CHUTE ¾¾ Baffle, located behind load zone, calms

¾¾ AR plate steel liners water for better retention of fines

¾¾ Maintenance-free service life ¾¾ Drain for easy clean out

¾¾ Discharge directly onto conveyor

SPRAY BARS

¾¾ Installed on each deck for maximum washing

¾¾ Valve regulated water flow rate

CURVED BELLY PAN

P/42 Superior Industries / © 06.2016

options

AR LINED STEEL CHUTE TRIPLE AXLES ON 16’ AND LARGER ROBUST, LONG-LASTING CONSTRUCTION

¾¾ SINGLE OR TWIN SCREW CLASSIFIERS ¾¾ TRIPLE AXLE ASSEMBLY ¾¾ ROLLAWAY DISCHARGE CHUTES

¾¾ HORIZONTAL OR INCLINE SCREENS ¾¾ OVERSIZE MATERIAL BLENDING GATE ¾¾ 30 AMP MALE PIN AND SLEEVE PLUGS

¾¾ 24” - 30” REVERSIBLE CROSS CONVEYOR ¾¾ URETHANE OR A532 WEAR SHOES ¾¾ ADDITIONAL NO. 2 STARTER/START-STOP SWITCH

¾¾ VALVE REGULATED WATER FLOW RATE ¾¾ HYDRAULIC LEVELING JACKS ¾¾ OFF PLANT CONVEYORS

in-stock parts

WEAR SLEEVE AND LOWER SEAL DRIVE COMPONENTS RUBBER WEAR SHOES

¾¾ STAINLESS STEEL WEAR SLEEVE ¾¾ RUBBER WEAR SHOES ¾¾ LOWER BEARING RETROFIT KITS FOR ¾¾ ELECTRIC OR HYDRAULIC

¾¾ HEAVY-DUTY RUBBER LOWER SEAL ¾¾ A532 AND URETHANE WEAR SHOES OTHER MANUFACTURERS’ WASHERS DRIVE COMPONENTS

¾¾ HEAVY-WALLED STEEL PIPE SHAFTS ¾¾ BELLY PANS

© 06.2016 / Superior Industries P/43

Specifications

AGGRE-WASHER™ PORTABLE PLANT – SINGLE SCREW

Screw Size Capacity Peripheral Screw Speed Speed Max. Material Size Motor Size Water Capacity - GPM (m3/sec)

in x ft (mm x m) TPH (MTPH) FPM (MPS) RPM inch (mm) HP (kw) 100 Mesh 150 Mesh 200 Mesh

100 (90) 100 (0.5) 20 15 (11.0)

36” x 25’

75 (68) 75 (0.3) 15 3/8” (9.5) 10 (7.5) 700 (0.04) 330 (0.02) 650 (0.04)

(914 x 7)

50 (45) 50 (0.2) 10 7.5 (5.5)

100 (90) 100 (0.5) 20 15 (11.0)

36” x 28’

75 (68) 75 (0.3) 15 3/8” (9.5) 10 (7.5) 700 (0.04) 330 (0.02) 150 (0.01)

(914 x 8)

50 (45) 50 (0.2) 10 7.5 (5.5)

175 (159) 100 (0.5) 17 20 (15.0)

44” x 32’

130 (118) 75 (0.3) 14 3/8” (9.5) 15 (11.0) 1,600 (0.10) 750 (0.04) 425 (0.02)

(1,117 x 9)

85 (77) 50 (0.2) 10 10 (7.5)

200 (181) 100 (0.5) 16 25 (18.5)

48”x 32’

150 (136) 75 (0.3) 12 3/8” (9.5) 20 (15.0) 1,700 (0.10) 850 (0.05) 450 (0.02)

(1,219 x 9)

100 (90) 50 (0.2) 8 15 (11.0)

275 (249) 100 (0.5) 16 30 (22.0)

54” x 35’

210 (190) 75 (0.3) 12 3/8” (9.5) 25 (18.5) 1,800 (0.11) 950 (0.05) 525 (0.03)

(1,371 x 10)

140 (127) 50 (0.2) 8 20 (15.0)

AGGRE-WASHER™ PORTABLE PLANT – TWIN SCREW

Screw Size Capacity Peripheral Screw Speed Speed Max. Material Size Motor Size Water Capacity - GPM (m3/sec)

in x ft (mm x m) TPH (MTPH) FPM (MPS) RPM inch (mm) HP(MT) 100 Mesh 150 Mesh 200 Mesh

200 (181) 100 (0.5) 20 (2) 15 (11.0)

36” x 25’

150 (136) 75 (0.3) 15 3/8” (9.5) (2) 10 (7.5) 1,250 (0.07) 620 (0.03) 340 (0.02)

(914 x 7)

100 (90) 50 (0.2) 10 (2) 7.5 (5.5)

200 (181) 100 (0.5) 20 (2) 15 (11.0)

36” x 28’

150 (136) 75 (0.3) 15 3/8” (9.5) (2) 10 (7.5) 1,250 (0.07) 620 (0.03) 340 (0.02)

(914 x 8)

100 (90) 50 (0.2) 10 (2) 7.5 (5.5)

350 (317) 100 (0.5) 18 (2) 20 (15.0)

44” x 32’

260 (235) 75 (0.3) 14 3/8” (9.5) (2) 15 (11.0) 2,800 (0.17) 1,400 (0.08) 675 (0.04)

(1,117 x 9)

170 (154) 50 (0.2) 10 (2) 10 (7.5)

P/44 Superior Industries / © 06.2016

Specifications

AGGRE-WASHER™ PORTABLE PLANT – HORIZONTAL SCREENS

Screw Diameter Screen Length Peripheral Screw Speed Speed Max. Material Size Motor Size Water Capacity - GPM (m3/sec)

inch (mm) ft. (m) FPM (MPS) RPM inch (mm) HP (kw) 100 Mesh 150 Mesh 200 Mesh

36” (914)* 12’ (3.6) 200 (1.0) 20 3/4” (19) 15 (11.0) 700 (0.04) 330 (0.02) 160 (0.01)

36” (914)* 16’ (4.8) 200 (1.0) 20 3/4” (19) 15 (11.0) 700 (0.04) 330 (0.02) 160 (0.01)

36” (914)** 20’ (6.0) 200 (1.0) 20 3/4” (19) 15 (11.0) 700 (0.04) 330 (0.02) 160 (0.01)

44” (1,117) 16’ (4.8) 200 (1.0) 17 3/4” (19) 20 (15.0) 1,600 (0.10) 750 (0.04) 425 (0.02)

(2) 36” (914) 16’ (4.8) 200 (1.0) 20 3/4” (19) (2) 15 (11.0) 1,250 (0.07) 620 (0.03) 340 (0.02)

(2) 36” (914) 20’ (6.0) 200 (1.0) 20 3/4” (19) (2) 15 (11.0) 1,250 (0.07) 620 (0.03) 340 (0.02)

(2) 44” (1,117) 16’ (4.8) 200 (1.0) 17 3/4” (19) (2) 20 (15.0) 2,800 (0.17) 1,400 (0.08) 675 (0.04)

(2) 44” (1,117) 20’ (6.0) 200 (1.0) 17 3/4” (19) (2) 20 (15.0) 2,800 (0.17) 1,400 (0.08) 675 (0.04)

AGGRE-DRY® PORTABLE PLANT – HORIZONTAL SCREENS

Screw Diameter Screen Length Peripheral Screw Speed Speed Max. Material Size Motor Size Water Capacity - GPM (m3/sec)

inch (mm) ft. (m) FPM (MPS) RPM inch (mm) HP (kw) 100 Mesh 150 Mesh 200 Mesh

36” (914) 12’ (3.6) 200 (1.0) 20 3/4” (19) 15 (11.0) 700 (0.04) 330 (0.02) 160 (0.01)

36” (914) 16’ (4.8) 200 (1.0) 20 3/4” (19) 15 (11.0) 700 (0.04) 330 (0.02) 160 (0.01)

36” (914) 20’ (6.0) 200 (1.0) 20 3/4” (19) 15 (11.0) 700 (0.04) 330 (0.02) 160 (0.01)

48” (1,219) 16’ (4.8) 200 (1.0) 16 3/4” (19) 25 (18.5) 1,700 (0.10) 850 (0.05) 450 (0.02)

48” (1,219) 20’ (6.0) 200 (1.0) 16 3/4” (19) 25 (18.5) 1,700 (0.10) 850 (0.05) 450 (0.02)

60” (1,524) 20’ (6.0) 200 (1.0) 13 3/4” (19) 40 (30.0) 2,200 (0.13) 1,050 (0.06) 600 (0.03)

*Screw length = 25-ft

** Screw length = 28-ft

© 06.2016 / Superior Industries P/45

Specifications

SKID MOUNTED AGGRE-WASHER™ – HORIZONTAL OR INCLINE SCREENS

Screw Diameter Screen Length Peripheral Screw Speed Speed Max. Material Size Motor Size Water Capacity - GPM (m3/sec)

inch (mm) ft. (m) FPM (MPS) RPM inch (mm) HP (kw) 100 Mesh 150 Mesh 200 Mesh

36” (914) 12’ (3.6) 200 (1.0) 20 3/4” (19) 15 (11.0) 700 (0.04) 330 (0.02) 160 (0.01)

36” (914) 16’ (4.8) 200 (1.0) 20 3/4” (19) 15 (11.0) 700 (0.04) 330 (0.02) 160 (0.01)

(2) 36” (914) 16’ (4.8) 200 (1.0) 20 3/4” (19) (2) 15 (11.0) 1,250 (0.07) 620 (0.03) 340 (0.02)

44” (1,117) 12’ (3.6) 200 (1.0) 17 3/4” (19) 20 (15.0) 1,600 (0.10) 750 (0.04) 425 (0.02)

44” (1,117) 16’ (4.8) 200 (1.0) 17 3/4” (19) 20 (15.0) 1,600 (0.10) 750 (0.04) 425 (0.02)

(2) 44” (1,117) 16’ (4.8) 200 (1.0) 17 3/4” (19) (2) 20 (15.0) 2,800 (0.17) 1,400 (0.08) 675 (0.04)

44” (1,117) 20’ (6.0) 200 (1.0) 17 3/4” (19) 20 (15.0) 2,800 (0.17) 1,400 (0.08) 675 (0.04)

(2) 44” (1,117) 20’ (6.0) 200 (1.0) 17 3/4” (19) (2) 20 (15.0) 2,800 (0.17) 1,400 (0.08) 675 (0.04)

(2) 48” (1,219) 16’ (4.8) 200 (1.0) 16 3/4” (19) (2) 25 (18.5) 1,700 (0.10) 850 (0.05) 450 (0.02)

(2) 48” (1,219) 20’ (6.0) 200 (1.0) 16 3/4” (19) (2) 25 (18.5) 1,700 (0.10) 850 (0.05) 450 (0.02)

48” (1,219) 16’ (4.8) 200 (1.0) 16 3/4” (19) 25 (18.5) 1,700 (0.10) 850 (0.05) 450 (0.02)

54” (1,371) 16’ (4.8) 200 (1.0) 15 3/4” (19) 30 (22.0) 1,900 (0.11) 950 (0.05) 575 (0.03)

(2) 54” (1,371) 20’ (6.0) 200 (1.0) 15 3/4” (19) (2) 30 (22.0) 1,900 (0.11) 950 (0.05) 575 (0.03)

60” (1,524) 16’ (4.8) 200 (1.0) 13 3/4” (19) 40 (30.0) 2,200 (0.13) 1,050 (0.06) 600 (0.03)

60” (1,524) 20’ (6.0) 200 (1.0) 13 3/4” (19) 40 (30.0) 2,200 (0.13) 1,050 (0.06) 600 (0.03)

P/46 Superior Industries / © 06.2016

Rotary Screen 66” x 42’ - 96” x 66’

Heavy-duty truss frame allows operation of an inner scalping screen. n

Produce up to three products from a single rotary screen. n

Planetary type gear reduction allows screen speed adjustment to meet specific production requirements. n

Dual wheel drive ensures reliable, accurate rotation of the screen drum. n

© 06.2016 / Superior Industries P/47

Specifications

ROTARY SCREEN

Outer Drum Diameter Inner Drum Length Drum Length

Model Number

inch (mm) inch (mm) ft (m)

TF 66-16 66” (1,675) 42” (1,065) 16’ (5.0)

TF 96-16 96” (2,440) 66” (1,675) 16’ (5.0)

TF 96-20 96” (2,440) 66” (1,675) 20’ (6.0)

OPTIONS

¾¾ WALKWAY AND HAND RAILING

¾¾ RECEIVING HOPPERS

¾¾ RUBBER-LINED PUMP BOXES

¾¾ DISCHARGE CHUTES

¾¾ HOPPERS

¾¾ SUPPORT STRUCTURE

P/48 Superior Industries / © 06.2016

Aggre-Saver washout system Up to 2.2 yards per minute

Recover aggregate material from ready-mix trucks and avoid wasteful material disposal. n

Eliminate truck washdown time, end-of-shift overtime hours and costly trips to disposal site. n

Unique receiving hopper allows two ready-mix trucks to discharge at the same time. n

Bolt-on, heavy-duty shoes can be adjusted for years of additional service life. n

© 06.2016 / Superior Industries P/49

features

SINGLE DECK VIBRATING SCREEN UNLOAD TWO READY-MIX TRUCKS AT ONCE RECEIVING HOPPER

options

RECEIVING HOPPER WITH SPRAY SYSTEM DRIVE SYSTEM

¾¾ Allows two ready-mix trucks to ¾¾ Electrical 3-phase, 60Hz, 460V motor

discharge at one time. ¾¾ Shaft-mounted gear reducer ¾¾ SINGLE DECK VIBRATING SCREEN MOUNTED

¾¾ Equipped spray system for fast, easy clean up. ¾¾ Belt and guarding AT FEED OR DISCHARGE POINT

FINE MATERIAL SCREW TANK ¾¾ FOUR TRUCK WASHOUT HOPPER

¾¾ More clearance between belly pan and screw ¾¾ Skid frame ¾¾ AUTOMATIC CONTROL SYSTEM FOR WASHOUT

shaft to accommodate larger size aggregate. ¾¾ Lifting points ¾¾ 4” WATER PUMP

¾¾ Flights are protected with adjustable ¾¾ Support legs ¾¾ TRUCK WASHOUT SYSTEM

1” thick rubber wear shoes. ¾¾ Drain for easy clean out ¾¾ CLEAN-OUT DOORS FOR BELLY PAN

¾¾ Adjustable weir plate keeps water ¾¾ Flush-back nozzle enhances dewatering efficiency ¾¾ SPRAY SYSTEM

at optimum operating level. ¾¾ A532 AND URETHANE WEAR SHOES

¾¾ Extended shaft and slinger protects ¾¾ GUARDING

lower bearing from water leakage.

Specifications

AGGRE-SAVER

Screw Size Screw Diameter Processing Time Length Speed Motor Size Estimated Empty Weight

in x ft (mm x m) inch (mm) yrd/min (m/m) ft (m) RPM HP (kw) lbs (kg)

36” x 25’ (915 x 8) 36” (915) 1.2 (1.0) 25’ (8.0) 20 15 (11.0) 10,800 (4,900)

44” x 32’ (1,120 x 10) 44” (1,120) 2.2 (2.0) 32’ (10.0) 17 20 (15.0) 16,800 (7,620)

P/50 Superior Industries / © 06.2016

© 06.2016 / Superior Industries P/51

SUPERIOR-IND.COM

P/52 Superior Industries / © 06.2016

Вам также может понравиться

- KEESTRACK Productoverview - 5.17 - Eng - Web - 11Документ43 страницыKEESTRACK Productoverview - 5.17 - Eng - Web - 11Антон ЛазаровОценок пока нет

- Search Requests and Query My Hidden VideosДокумент26 страницSearch Requests and Query My Hidden VideosEMILY BASSОценок пока нет

- Lesson 4.2 - Greatest Common FactorДокумент23 страницыLesson 4.2 - Greatest Common FactorehystadОценок пока нет

- Smash Up RulebookДокумент12 страницSmash Up RulebookRobert MilesОценок пока нет

- Bogvik Pattern List 19 - KleДокумент19 страницBogvik Pattern List 19 - KleShanghai Bogvik Wear Material Co., LtdОценок пока нет

- Hydrocyclone HarmonyДокумент2 страницыHydrocyclone HarmonyPv RohithОценок пока нет

- Cone CrushersДокумент18 страницCone CrushersRodrigo GarcíaОценок пока нет

- Pinion Rebuild 42-65Документ19 страницPinion Rebuild 42-65Oscar Aragon TejadaОценок пока нет

- PresentationДокумент46 страницPresentationDanielSantosОценок пока нет

- Hewitt, Vibrex Manual PDFДокумент98 страницHewitt, Vibrex Manual PDFCarlos anderson Sossa ChaverraОценок пока нет

- Part 3-FLUENCY FOR IELTS SPEAKINGДокумент14 страницPart 3-FLUENCY FOR IELTS SPEAKINGMỹ Tiên100% (1)

- TBK 80 (Ø850) Rock-On-Rock Vsi Crusher Operation and Maintenance ManualДокумент44 страницыTBK 80 (Ø850) Rock-On-Rock Vsi Crusher Operation and Maintenance ManualIruna HupaloОценок пока нет

- CV115-129 01 OM S226.030 01.en PDFДокумент128 страницCV115-129 01 OM S226.030 01.en PDFLmf DanielОценок пока нет

- Vertical Shaft Impactor - Sand Making MachineДокумент37 страницVertical Shaft Impactor - Sand Making Machineaaronshakti100% (1)

- 05.CH660-04 Installation Instructions S223.1257-04 enДокумент78 страниц05.CH660-04 Installation Instructions S223.1257-04 enMichael adu-boahen100% (1)

- Hazemag Hpi-H EngДокумент16 страницHazemag Hpi-H Engekrem0867Оценок пока нет

- Multotec Rubber Screening Brochure PDFДокумент6 страницMultotec Rubber Screening Brochure PDFNilton Inca TitoОценок пока нет

- Newitem 148 Stone Crusher ReportДокумент142 страницыNewitem 148 Stone Crusher ReportSaurabh Singh100% (3)

- Crusher Backing Compound EstimatorДокумент1 страницаCrusher Backing Compound Estimatorlandago100% (1)

- Hydrocone Manual - S223.360.01.en PDFДокумент291 страницаHydrocone Manual - S223.360.01.en PDFLmf Daniel100% (2)

- MPS Rebuild 42-65Документ20 страницMPS Rebuild 42-65Oscar Aragon TejadaОценок пока нет

- Cobra 230 Tech SpecДокумент28 страницCobra 230 Tech SpecJP BlancaОценок пока нет

- Washing and Classifying Brochure EnglishДокумент24 страницыWashing and Classifying Brochure EnglishMohammed Alshami GeologistОценок пока нет

- Deepak Project On Jaw CrusherДокумент96 страницDeepak Project On Jaw CrusherAnil Kumar KnОценок пока нет

- Rocksledger: Primary Jaw CrushersДокумент2 страницыRocksledger: Primary Jaw CrushersMechanical department100% (2)

- Z ScoresДокумент27 страницZ ScoresSoma San JoseОценок пока нет

- JW I Filter Press ManualДокумент23 страницыJW I Filter Press ManualSarangОценок пока нет

- Sci.10 Lesson Plan Electricity and MagnetismДокумент5 страницSci.10 Lesson Plan Electricity and MagnetismJeiril Divino100% (3)

- Size Control: - Screening Using A Geometrical Pattern For Size ControlДокумент5 страницSize Control: - Screening Using A Geometrical Pattern For Size ControlSergei DumrovaОценок пока нет

- Aggregate ScreeningДокумент38 страницAggregate Screeningssmith2007Оценок пока нет

- Bulletin 1047Документ2 страницыBulletin 1047Cesar Casachagua DavilaОценок пока нет

- 6000 Spa PDFДокумент51 страница6000 Spa PDFLmf DanielОценок пока нет

- Mesda Crukings Product ManualДокумент26 страницMesda Crukings Product ManualJake HuangОценок пока нет

- Airpods Pro QSGДокумент2 страницыAirpods Pro QSGAndrés M. Argüelles LandínezОценок пока нет

- Hewitt (Nordberg) Gyrex ScreenДокумент36 страницHewitt (Nordberg) Gyrex ScreenCarlos anderson Sossa ChaverraОценок пока нет

- Wmd0976 Trio Tc66 Series Cone Crusher Spec SheetДокумент2 страницыWmd0976 Trio Tc66 Series Cone Crusher Spec SheetYang Wan100% (1)

- Replacement PartsДокумент19 страницReplacement PartsVladimirОценок пока нет

- Trio Materials Washers.Документ3 страницыTrio Materials Washers.SinaiОценок пока нет

- Cerro Verde Production Unit Expansion: Ludowici Vibrating Screens Installation Sequence Document No. SN-100462-MD18Документ5 страницCerro Verde Production Unit Expansion: Ludowici Vibrating Screens Installation Sequence Document No. SN-100462-MD18jhonОценок пока нет

- VibratingEquipmentBrochure PDFДокумент10 страницVibratingEquipmentBrochure PDFมนต์ชัย บุญธนลาภОценок пока нет

- Cedarapids Overview BrochureДокумент28 страницCedarapids Overview BrochureJuan Marcos RodriguezОценок пока нет

- JW Series Jaw Crushers: Terex Minerals Processing SystemsДокумент16 страницJW Series Jaw Crushers: Terex Minerals Processing SystemsKarin Anderson100% (1)

- Basics RELEASE DATE: 3-12-03Документ15 страницBasics RELEASE DATE: 3-12-03Victor Ivan BarriosОценок пока нет

- 8r77r-Cybas I ConeДокумент6 страниц8r77r-Cybas I Coneturkishdjem100% (1)

- Screw Washer A 01Документ15 страницScrew Washer A 01joule357Оценок пока нет

- Vibratory Feeders and Conveyors PDFДокумент14 страницVibratory Feeders and Conveyors PDFArnaldo BenitezОценок пока нет

- Biofuge Contifuge Stratos 120 200 208 240V DualДокумент103 страницыBiofuge Contifuge Stratos 120 200 208 240V DualAndrew Holmes50% (2)

- Poliuretano - Mallas WS85Документ32 страницыPoliuretano - Mallas WS85Oscar C SotomayorОценок пока нет

- Cone Ranger: Mobile Cone Crushing UnitsДокумент2 страницыCone Ranger: Mobile Cone Crushing UnitsYousef AlipourОценок пока нет

- Optitooth Jaw Plates - Customer Testimonial Data - 2017Документ8 страницOptitooth Jaw Plates - Customer Testimonial Data - 2017danielОценок пока нет

- Systems: WashingДокумент6 страницSystems: WashingVinОценок пока нет

- Mobile Jaw Crusher PDFДокумент7 страницMobile Jaw Crusher PDFNguyễn LinhОценок пока нет

- Project Case - CT4254 JAW PLATESДокумент4 страницыProject Case - CT4254 JAW PLATESNicole WuОценок пока нет

- Clarifier Thickener BrochureДокумент1 страницаClarifier Thickener BrochureKartika Pratama SyafitriОценок пока нет

- Uranium Corporation of India Limited P.O: Jaduguda Mines, Jharkhand - 832102Документ4 страницыUranium Corporation of India Limited P.O: Jaduguda Mines, Jharkhand - 832102arsanioseОценок пока нет

- Sandvik Ud211 Wheeled Processing Unit: Technical SpecificationДокумент2 страницыSandvik Ud211 Wheeled Processing Unit: Technical Specificationpmf engineering limited100% (1)

- Mvi Vertical ShaftДокумент4 страницыMvi Vertical ShaftMarcel BaqueОценок пока нет

- RAPTOR Cone CrusherДокумент4 страницыRAPTOR Cone CrusherLuis Miguel La TorreОценок пока нет

- WO 2014/075722 Al: International BureauДокумент17 страницWO 2014/075722 Al: International BureauneusonОценок пока нет

- Smalis Radial Stacker ManualДокумент61 страницаSmalis Radial Stacker Manualmacross086100% (1)

- Flip Flow ScreenДокумент6 страницFlip Flow Screenani1985Оценок пока нет

- CEDARAPIDS (2015) - Quality Paving Guide BookДокумент96 страницCEDARAPIDS (2015) - Quality Paving Guide BookRodrigo DíazОценок пока нет

- Kreiselbrecher enДокумент7 страницKreiselbrecher enDiegoAlvarezHuguezОценок пока нет

- UH320 ClassicДокумент2 страницыUH320 ClassicRicardo E Andrea RachelОценок пока нет

- FLSmidth TS GyratoryCrusher Brochure Email2015 PDFДокумент8 страницFLSmidth TS GyratoryCrusher Brochure Email2015 PDFAlex JonatanОценок пока нет

- Terex Simplicity Vibrating Feeders: Terex Minerals Processing SystemsДокумент6 страницTerex Simplicity Vibrating Feeders: Terex Minerals Processing SystemsestramilsolutionОценок пока нет

- fm60c 0Документ8 страницfm60c 0Srinivas NandikantiОценок пока нет

- A1753037 48 Conveyor Parts Manual CON 203 1 J1349Документ19 страницA1753037 48 Conveyor Parts Manual CON 203 1 J1349waltergvОценок пока нет

- Trio - Group Washers LogДокумент4 страницыTrio - Group Washers LogCemYurtseverОценок пока нет

- RazerTail Truck UnloaderДокумент4 страницыRazerTail Truck UnloaderRAUL PEREZ NEGREIROSОценок пока нет

- Series Pds Pms H2o FPT EngДокумент2 страницыSeries Pds Pms H2o FPT EngtongaiОценок пока нет

- 36BV9H002, Bleed Valves - Pressures To 36,000 Psi: SpecificationsДокумент3 страницы36BV9H002, Bleed Valves - Pressures To 36,000 Psi: SpecificationssatyendraОценок пока нет

- Henywell Control ManualДокумент4 страницыHenywell Control ManualLmf DanielОценок пока нет

- Brochure Spares Wears 3000 en LowresДокумент8 страницBrochure Spares Wears 3000 en Lowresneo shagrathОценок пока нет

- LAC - Air Oil Cooler With AC Motor For Industrial Use - HY10-6001.UKДокумент12 страницLAC - Air Oil Cooler With AC Motor For Industrial Use - HY10-6001.UKSandeep_Bellap_5543Оценок пока нет

- 5JTANordberg Cone ReplacementДокумент32 страницы5JTANordberg Cone ReplacementLmf DanielОценок пока нет

- Oil Burner Installtion PDFДокумент62 страницыOil Burner Installtion PDFLmf DanielОценок пока нет

- 150 103 Burner Control For Gas and Oil Burners Flame Sensor: D-GF D-LeДокумент6 страниц150 103 Burner Control For Gas and Oil Burners Flame Sensor: D-GF D-LeLmf DanielОценок пока нет

- Warm Air Heater ManualДокумент32 страницыWarm Air Heater ManualLmf DanielОценок пока нет

- Sandvik Cs550 Cone Crusher: Technical SpecificationДокумент8 страницSandvik Cs550 Cone Crusher: Technical SpecificationLmf DanielОценок пока нет

- 708 05 Fenner CouplingsДокумент18 страниц708 05 Fenner CouplingsLmf Daniel100% (1)

- 2 Burners ControlДокумент2 страницы2 Burners ControlLmf DanielОценок пока нет

- Anly Two Digi Timer RelayДокумент2 страницыAnly Two Digi Timer RelayLmf DanielОценок пока нет

- TrilogiДокумент78 страницTrilogiWanda PowellОценок пока нет

- sj-9 Hauck BurnerДокумент52 страницыsj-9 Hauck BurnerLmf DanielОценок пока нет

- Consolidator: Multi-Channel ControllerДокумент56 страницConsolidator: Multi-Channel ControllerMf LuiОценок пока нет

- UK Tutorial MarkingAndLabelling PDFДокумент40 страницUK Tutorial MarkingAndLabelling PDFreinaldomdОценок пока нет

- Cs840i Specification Sheet EnglishДокумент2 страницыCs840i Specification Sheet EnglishLmf DanielОценок пока нет

- Recommended Wear and spare parts H8800 Cone Crusher推荐零件清单Документ3 страницыRecommended Wear and spare parts H8800 Cone Crusher推荐零件清单Lmf DanielОценок пока нет

- QS331 Cone Crusher: Features & BenefitsДокумент34 страницыQS331 Cone Crusher: Features & BenefitsLmf DanielОценок пока нет

- 800i Connected Cone Crusher Brochure EnglishДокумент5 страниц800i Connected Cone Crusher Brochure EnglishLmf DanielОценок пока нет

- cs550 Specification Sheet EnglishДокумент5 страницcs550 Specification Sheet EnglishLmf DanielОценок пока нет

- 13 Hamid Manouchehri Sandvik Eco-Efficiency in ComminutionДокумент10 страниц13 Hamid Manouchehri Sandvik Eco-Efficiency in ComminutionLmf DanielОценок пока нет

- S226.027.en - Vibration SwitchДокумент6 страницS226.027.en - Vibration SwitchLmf DanielОценок пока нет

- CV115-129 01 Interlock S226.037 01Документ22 страницыCV115-129 01 Interlock S226.037 01Lmf DanielОценок пока нет

- R226.076 CV115-CV129Документ8 страницR226.076 CV115-CV129Lmf DanielОценок пока нет

- S226-049.00 Daily Log - enДокумент10 страницS226-049.00 Daily Log - enLmf DanielОценок пока нет

- Analysis and Design Principles of Microwave Antennas - Unit 1 - How To Access The PortalДокумент4 страницыAnalysis and Design Principles of Microwave Antennas - Unit 1 - How To Access The Portalchinnujan24100% (1)

- Syllabus Part Ii - Course Content HINT 730 Information Management in Healthcare Course DescriptionДокумент14 страницSyllabus Part Ii - Course Content HINT 730 Information Management in Healthcare Course DescriptionSarybell Del ValleОценок пока нет

- Associative Learning PresentationДокумент9 страницAssociative Learning PresentationMairos Kunze BongaОценок пока нет

- Edc PDFДокумент7 страницEdc PDFKarim SamhyОценок пока нет

- Neration of Various SignalsДокумент5 страницNeration of Various SignalsPREMKUMAR JOHNОценок пока нет

- 1) Oracle Administrator Question & AnswersДокумент8 страниц1) Oracle Administrator Question & Answersmanideep thatikondaОценок пока нет

- Incorporation CertificateДокумент1 страницаIncorporation Certificatesnehal bhosaleОценок пока нет

- A Model Curriculum For K-12 Computer ScienceДокумент45 страницA Model Curriculum For K-12 Computer ScienceRini SandeepОценок пока нет

- Applet SlidesДокумент15 страницApplet SlidesankitaОценок пока нет

- Oracle Advisor Webcast: What's New in Financial Reporting 11.1.2.4.900Документ33 страницыOracle Advisor Webcast: What's New in Financial Reporting 11.1.2.4.900huyhnОценок пока нет

- Rules of Procedure - NPCДокумент27 страницRules of Procedure - NPCMark VernonОценок пока нет

- Testing of Transmitter & SwitchesДокумент4 страницыTesting of Transmitter & SwitchesJoost1982Оценок пока нет

- Please Cite This Paper Rather Than This Web Page If You Use The Macro in Research You Are PublishingДокумент3 страницыPlease Cite This Paper Rather Than This Web Page If You Use The Macro in Research You Are PublishingVic KeyОценок пока нет

- ION 2008 An Analysis of MMOG Subscription GrowthДокумент30 страницION 2008 An Analysis of MMOG Subscription Growthdigitalbridgemedia100% (2)

- Important Characterstics of 555 Timer IC: Circuits Based On 5555 ICДокумент6 страницImportant Characterstics of 555 Timer IC: Circuits Based On 5555 ICManohar PotnuruОценок пока нет

- Java ManualДокумент59 страницJava ManualThirupathi Reddy. Bandi1620Оценок пока нет

- (##) Solar Thermoelectric RefrigerationДокумент87 страниц(##) Solar Thermoelectric RefrigerationJohn Bernard ShaОценок пока нет

- Coursera - Data Analytics - Course 1Документ8 страницCoursera - Data Analytics - Course 1UtjaleОценок пока нет

- Animal Robot Mini Cheetah: Department of Mechanical EngineeringДокумент10 страницAnimal Robot Mini Cheetah: Department of Mechanical EngineeringMRINAL MAGARОценок пока нет

- Weekly Home Learning Plan: Empowerment Technologies S.Y 2020-2021 1 SemesterДокумент4 страницыWeekly Home Learning Plan: Empowerment Technologies S.Y 2020-2021 1 SemesterGlenzchie Taguibao90% (10)

- Discrete Mathematics: (COMP2121B)Документ20 страницDiscrete Mathematics: (COMP2121B)Brandon TayОценок пока нет

- Automated Billing SystemДокумент24 страницыAutomated Billing SystemjamesОценок пока нет