Академический Документы

Профессиональный Документы

Культура Документы

WTP (Water Treatment Plant) Design

Загружено:

Pratiksha Pawar100%(1)100% нашли этот документ полезным (1 голос)

599 просмотров3 страницы..

Авторское право

© © All Rights Reserved

Доступные форматы

XLS, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документ..

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLS, PDF, TXT или читайте онлайн в Scribd

100%(1)100% нашли этот документ полезным (1 голос)

599 просмотров3 страницыWTP (Water Treatment Plant) Design

Загружено:

Pratiksha Pawar..

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLS, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

D.Y.

Patil College of Engineering, Akurdi, Pune – 44

Department of Civil Engineering

Assignment No. 2

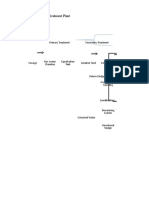

Design of Conventional water Treatment Plant

Note: i) Data in yellow cell to be suitably filled as per requirement

ii) Data in green cell to review the provided value and revise/update if required

Design Flow output from WTP 200 MLD

Design Flow input to WTP, consider 5% losses in WTP 210 MLD

Design flow 8750 cu/hour

Pumping Hours in Raw Water Pumping Station 23 Hours

On the basis of 23 hour pumping, design flow 9130 cu/hour

Consider Inlet channel having width of 2.0 m

Consider Inlet channel having depth of 0.8 m

Over loading capacity 20%

Velocity of flow in channal 1.90 m/sec

Length of channel 40 m

Head loss across manual screen 16 mm

Water supply level at inlet of channal 240.1 m

Top Water Level downstream of screen 240.084 m

Hydraulic Radious of Channal (Area/Perimeter) 0.444 m

Slope Friction loss per 1000 m in Channal 0.00241 m

Losses in Channal 0.09626 m

Water Treatment Plant

Design flow 9130 cu/hour

Inlet chamber detention time 45 Sec

Provide Inlet Chamber of size 3.6*3.6*4.5 m*m*m

Volume provided 58.32 cum

Detention Time provided 22.99 Seconds

No of Flash Mixers and Clariflocullator 2 Nos

Flow in each Flash Mixer 4565.2 cum/hr

Detention Time in flash mixture, range 30-60 seconds 45.0 Sec

Volume required for every flash mixture 57.07 cum

Provide Diameter of Flash mixture 3.25 m

Required depth of Flash mixture 6.88 m

Provide depth of Flash mixture 3.50 m

Clariflocculators

No.s 2 Nos

Flow in every Clariflocculator 4565.2 cum/hour

Detention time in flocculation zone, range 10-40 minutes 30.0 Minutes

Volume reqd. in flocculation zone 2282.6 cum

Provide Water Depth in flocculation zone, range 3-4.5 m 3.75 m

Required Dia of flocculation tank 27.85 m

Provide Dia of flocculation tank 28.00 m

Volume provided 2307.9 cum

Assume surface loading (Range 35-50 m/day) 35 m/day

Surface area required 3130.4 sqm

Area of Flocculation 615.44 sqm

Total Area of Clariflocculator including flocculation 3745.9 sqm

Dia of Clariflocculator 69.08 m

Provide Dia 70.00 m

Detention time (detention time range 1-2 hours), 2.0 hours

Volume required in Clarifying zone 9130.4 cum

Water depth in clarifying zone 3 m

Volume provided in Clarifying zone, 9391.30 cum

Provide outlet launder of , width 0.80 m

Provide outlet launder of , depth 0.80 m

Flow in Launder, for 50% flow lenfth 2282.61 m3/hr

Velocity of flow in launder for design flow 0.99 m/sec

Weir Loading taken 300.00 m3/d/m

Launder Perimeter required 365 m

Provide weir to have inlet from both sides, thus launder 183 m

perimeter required is

Actual launder length provided 221.056 m

Filters

No,s 10 nos

Total output 9130 cum/hour

Rate of Filtration 6 m/hour

Input to each of 10 filters 913.04 cum/hour

Area required for each filter 152.17 sqm

Provide twin bed filters section 3.60m×10.7m*

2 No

Area of each twin filter 77.04 Sqm

Inlet: sluice gate width 350 mm

Inlet: sluice gate depth 350 mm

Velocity 2.07 m/sec

Outlet: Provide Sluice Valve dia 350 mm

Velocity in outlet sluice valve 2.64 m/sec

Wash Water rate 500 lpm/m2

Wash water rate reqd 38.52 cum/minute

Wash water rate reqd 0.642 cum/sec

Provide SV dia for wash water 800 mm φ

Velocity 1.28 m/sec

Wash out; Provide gate / width 0.75 m

Wash out; Provide gate / depth 0.75 m

Velocity 1.1413 m/sec

Air – inlet required rate 750 lpm/m2

Air flow rate 57.78 cum/minute

Air flow rate 0.963 cum/sec

sluice valve for Air inlet, dia for each filter bed 250 mm

Velocity 19.63 m/sec

Wash water Pump 2311.2 m³/hr

Capacity required

Provide 3 Submerssible pump sets (2W+1S), working 2 no working

pumps=

Capacity of each pump 1155.6 cum/hr

Capacity of each pump 19260 LPS

Air blower

Air capacity reqd. 3466.8 cum/hour

Provide two blowers (1W + 1S) of capacity 3500 cum/hour

Chemical House

Consider an average of dose of alum at 50 ppm

strength solution 10 %

Solution required for 8 hrs 36521.74 litres

Solution required for 8 hrs 36.52 cum

Provide 3 tanks each of 3.25×2.8×2.2 m*m*m

Alum required for 90 days 986087 Kg

Taking alum density 1300 kg/m3

Volume of alum 758.53 cum

Taking stake height as , 2 m

Area required for alum storage 379.26 sqm

Taking provision for movement and putting weighing scale 20% %

etc., Provide additional storage area for Alum

Additional area for movement, weight scale 75.85 sqm

Total Area required 455.12 sqm

Total Area required 460.00 sqm

Seat No.

Name:

Class & Division:

Вам также может понравиться

- WTP - Hydraulic CalculationДокумент4 страницыWTP - Hydraulic Calculationabhishek5810Оценок пока нет

- Design of Sewage Pumping StationДокумент23 страницыDesign of Sewage Pumping StationForam ParekhОценок пока нет

- Annexure 15 - Tool For Water Treatment Plant DesignДокумент3 страницыAnnexure 15 - Tool For Water Treatment Plant DesignMicheal Jackson100% (2)

- WTP Hydraulic CalculationДокумент4 страницыWTP Hydraulic Calculationabhishek581050% (2)

- Design of STP Sewage Treatment PlantДокумент12 страницDesign of STP Sewage Treatment Plantyoyo100% (1)

- Annex 30 Tool - Design - Waste Stabilization PondsДокумент9 страницAnnex 30 Tool - Design - Waste Stabilization PondsAly AnisОценок пока нет

- 35 MLD WTP EstimateДокумент78 страниц35 MLD WTP EstimateaneeshmeloottuОценок пока нет

- STP Design (With Aeration Tank)Документ16 страницSTP Design (With Aeration Tank)Sagar Patel.Оценок пока нет

- Extended AerationДокумент5 страницExtended Aerationgautam guptaОценок пока нет

- Activated Sludge System PlanningДокумент63 страницыActivated Sludge System PlanningSung Woong MoonОценок пока нет

- Design Sheet STPДокумент17 страницDesign Sheet STPBhagyashree Rath0% (1)

- Residential water design optimizationДокумент6 страницResidential water design optimizationIbrahem Hamdy Naeem100% (4)

- WTP Design 3.12 MLDДокумент21 страницаWTP Design 3.12 MLDSandeep VaishnavОценок пока нет

- STP DesignДокумент20 страницSTP DesignmukhleshОценок пока нет

- Aerating Tank Process and Sludge Drying Bed DesignДокумент14 страницAerating Tank Process and Sludge Drying Bed DesignDavid Lambert100% (2)

- Design 2 MLDДокумент9 страницDesign 2 MLDANIL KUMAR H CОценок пока нет

- Design Spread Sheet For W&WWДокумент18 страницDesign Spread Sheet For W&WWsuinsas75% (8)

- Water Demand Calculation and System DesignДокумент27 страницWater Demand Calculation and System DesignMario Sajulga Dela Cuadra100% (8)

- Annex 30 Tool - Design - Waste Stabilization PondsДокумент8 страницAnnex 30 Tool - Design - Waste Stabilization Pondsmurkeking100% (1)

- STP CalculationДокумент10 страницSTP CalculationYe Myat Thu100% (1)

- STP - MBBR Design Sheet For Conventional/Biox - MBBR Media Description CapacityДокумент12 страницSTP - MBBR Design Sheet For Conventional/Biox - MBBR Media Description CapacitySindhuja RaghunathanОценок пока нет

- Clariflocculator CalculationsДокумент4 страницыClariflocculator Calculationssanu80% (5)

- Clarifier Recirculation2Документ23 страницыClarifier Recirculation2PavithiranОценок пока нет

- Water Treatment Design Sample CalculationДокумент21 страницаWater Treatment Design Sample CalculationOladunni Afolabi100% (2)

- DesignДокумент76 страницDesignsanibkoolОценок пока нет

- SAFF reactor design and specificationsДокумент4 страницыSAFF reactor design and specificationsRakesh Verma100% (2)

- SBR DesignДокумент2 страницыSBR DesignHRK65100% (6)

- STP Design (With MBBR)Документ9 страницSTP Design (With MBBR)Sagar Patel.100% (1)

- Spreadsheet For Activated Sludge ProcessДокумент31 страницаSpreadsheet For Activated Sludge ProcessHemantk8731100% (8)

- MBR STP flow sheet for 50 KLD sewage treatmentДокумент13 страницMBR STP flow sheet for 50 KLD sewage treatmentDhanraj Bn100% (1)

- 0.90 MLD MechanicalДокумент8 страниц0.90 MLD Mechanicalkiran raghukiranОценок пока нет

- Aeration Tank and Clarifier DesignДокумент6 страницAeration Tank and Clarifier DesignRajesh NareОценок пока нет

- S.T.P DesignДокумент70 страницS.T.P DesignAmit Bhamre75% (12)

- Grit Removal DesignДокумент5 страницGrit Removal Designnassif75Оценок пока нет

- Etp - 30 KLDДокумент18 страницEtp - 30 KLDsubramanyam kumarОценок пока нет

- Process Design Calculation3 - NDДокумент14 страницProcess Design Calculation3 - NDabhishek5810Оценок пока нет

- Proceess .FileДокумент10 страницProceess .Filekiran raghukiranОценок пока нет

- Power plant water requirement and effluent analysisДокумент6 страницPower plant water requirement and effluent analysisSyed Mehboob60% (5)

- MBBR OM Manual-250Документ42 страницыMBBR OM Manual-250senthil2002100% (3)

- Design of Slow Sand Filter FinalДокумент11 страницDesign of Slow Sand Filter FinalHemant SonawadekarОценок пока нет

- Rapid Sand FilterДокумент30 страницRapid Sand Filtersachinambekar100% (1)

- Annex 31 Tool Design Extended AerationДокумент5 страницAnnex 31 Tool Design Extended AerationAnonymous QiMB2lBCJLОценок пока нет

- Septic Tank Design (50 Users)Документ3 страницыSeptic Tank Design (50 Users)rammohan100% (6)

- 0.18MGD RSFPДокумент3 страницы0.18MGD RSFPEr Shoiab MubarakОценок пока нет

- Fan and Duct Size for Cement Mill Static SeparatorДокумент9 страницFan and Duct Size for Cement Mill Static SeparatorbipinagarwalОценок пока нет

- Ips-6 at Bulandshahr CityДокумент2 страницыIps-6 at Bulandshahr Cityankur yadavОценок пока нет

- Annexure 15 - Tool For Water Treatment Plant DesignДокумент6 страницAnnexure 15 - Tool For Water Treatment Plant DesignPremKumarОценок пока нет

- Sprinkler Design TemplateДокумент18 страницSprinkler Design TemplateketemaОценок пока нет

- Design of Pro. WTP (6.8 MLD) For BasavkalyanДокумент27 страницDesign of Pro. WTP (6.8 MLD) For BasavkalyanPradeep Kumar SharmaОценок пока нет

- YKK DesignДокумент10 страницYKK Designbasu_soumen2011Оценок пока нет

- Design of slow sand filter for water treatment plantДокумент2 страницыDesign of slow sand filter for water treatment plantmajeedctОценок пока нет

- Aerobic Calculation WWTP TataДокумент1 страницаAerobic Calculation WWTP TataAchmad Rizky Hardi AdhariОценок пока нет

- Hydraulic CalculationsДокумент16 страницHydraulic CalculationsForam ParekhОценок пока нет

- Cable Channel Rainwater Drain Pump - Data Sheet and SizingДокумент1 страницаCable Channel Rainwater Drain Pump - Data Sheet and SizingMate JamesОценок пока нет

- 6000 M3/D STP Process Design & Unit SizingДокумент8 страниц6000 M3/D STP Process Design & Unit SizingMinakshi SinghОценок пока нет

- Depyrogenation Tunnel Belt Speed CalculationДокумент4 страницыDepyrogenation Tunnel Belt Speed CalculationPalash Das50% (2)

- Fire Tank Recirculation Pump SizingДокумент1 страницаFire Tank Recirculation Pump SizingAkhil VijaiОценок пока нет

- Peripheral Launder HydraulicsДокумент2 страницыPeripheral Launder HydraulicsahmadОценок пока нет

- Master Blaster Pool CalculationДокумент62 страницыMaster Blaster Pool CalculationwanroyОценок пока нет

- Fire Water Demand Calculation for 36.8m Storage TankДокумент68 страницFire Water Demand Calculation for 36.8m Storage TankZakyAlFatony100% (1)

- Euro FirefighterДокумент2 страницыEuro FirefighterGustavo VydraОценок пока нет

- CalibrationДокумент7 страницCalibrationstolen mechieducОценок пока нет

- NFPA 20 Pump CharactaristicsДокумент1 страницаNFPA 20 Pump Charactaristicsmohammad awedОценок пока нет

- Purwoko Arie Sujadi: ExperienceДокумент4 страницыPurwoko Arie Sujadi: Experienceeriant014Оценок пока нет

- Profile Summary:: Curriculum VitaeДокумент3 страницыProfile Summary:: Curriculum Vitaepritam banerjeeОценок пока нет

- Caterpillar Cat 320d 320dl Excavator Parts ManualДокумент34 страницыCaterpillar Cat 320d 320dl Excavator Parts ManualSara Sarmiento Echeverry100% (1)

- Line Follower NXTДокумент21 страницаLine Follower NXTKen LeОценок пока нет

- Tufail MaboodДокумент3 страницыTufail MaboodMickey DalbeheraОценок пока нет

- Checklist for Training Cleaning StaffДокумент1 страницаChecklist for Training Cleaning StaffharrydrivesucrazyОценок пока нет

- Statement of PurposeДокумент2 страницыStatement of PurposeAan DaisyОценок пока нет

- School Data Management System ReportДокумент122 страницыSchool Data Management System ReportshekharyadawОценок пока нет

- Lean & Environment ToolkitДокумент96 страницLean & Environment Toolkittinyplankton100% (7)

- The Autolisp TutorialsДокумент285 страницThe Autolisp Tutorialsmynareshk100% (7)

- Chapter 01 - JAVA ProgrammingДокумент29 страницChapter 01 - JAVA ProgrammingsunnyxmОценок пока нет

- Estimate of Cycle Stand Extension Situated at Bhagat Singh College Jaora, Dist. RatlamДокумент5 страницEstimate of Cycle Stand Extension Situated at Bhagat Singh College Jaora, Dist. RatlamaasifahОценок пока нет

- Project 1 Fettuccini Truss Bridge ReportДокумент23 страницыProject 1 Fettuccini Truss Bridge ReportKah LeongОценок пока нет

- Catalogue 12V Ilss For Polis Bantuan Vehicles (Petronas)Документ7 страницCatalogue 12V Ilss For Polis Bantuan Vehicles (Petronas)Afiq Muizz SallehhoudinОценок пока нет

- Schott Ky DiodesДокумент3 страницыSchott Ky DiodesAmarnath M DamodaranОценок пока нет

- Bwts Gloen Patrol Technical Description XXX 250m3Документ13 страницBwts Gloen Patrol Technical Description XXX 250m3aloordominicОценок пока нет

- BTS3900 GSM Site Maintenance Terminal User Guide - (V300R008 - 06)Документ160 страницBTS3900 GSM Site Maintenance Terminal User Guide - (V300R008 - 06)engrvinzzОценок пока нет

- Pembentukan Dan Karakterisasi Dispersi Padat Efavirenzs-CrospovidoneДокумент7 страницPembentukan Dan Karakterisasi Dispersi Padat Efavirenzs-CrospovidoneanggiberОценок пока нет

- Fabricación de Insertos de Carburo de TungstenoДокумент5 страницFabricación de Insertos de Carburo de TungstenoRolando Nuñez MonrroyОценок пока нет

- Hex Head AVD 780 Installation Manual WEB PDFДокумент77 страницHex Head AVD 780 Installation Manual WEB PDFdasdsaОценок пока нет

- ABH-2 Pile - RamДокумент5 страницABH-2 Pile - RamGaneshalingam Ramprasanna2Оценок пока нет

- PHD Thesis BentzДокумент320 страницPHD Thesis Bentzcrusanu50% (2)

- Installation Manual: Automatic TWIN Greasing SystemДокумент62 страницыInstallation Manual: Automatic TWIN Greasing SystemWill FrontОценок пока нет

- Advance Diploma For CivilДокумент4 страницыAdvance Diploma For CivilAung Naing Latt AungОценок пока нет

- 253 MA Austenitic - High - Temperature - Grades - Datasheet PDFДокумент12 страниц253 MA Austenitic - High - Temperature - Grades - Datasheet PDFAbdulОценок пока нет

- Canon Ir3245 Series-PcДокумент154 страницыCanon Ir3245 Series-PcPetrescu CezarОценок пока нет

- Morgan Parts Catalog 44p LRДокумент27 страницMorgan Parts Catalog 44p LRArturo Zavala UrquidesОценок пока нет