Академический Документы

Профессиональный Документы

Культура Документы

WPS 856110 016 Rev 3 PDF

Загружено:

Prashant KumarОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

WPS 856110 016 Rev 3 PDF

Загружено:

Prashant KumarАвторское право:

Доступные форматы

WELDING PROCEDURE SPECIFICATION WPS 856110.

016

Intermare Sarda SPECIFICA PROCEDIMENTO SALDATURA

According to AWS D1.1:2006 + TOTAL GS EP STR 301 rev. 5

Project: Usan TA&BA

Sheet 1/1

SUPPORTING Verbale di procedura di saldatura: WPQR 91-2009

WELDING PROCESS(ES) AND TYPE: GTAW + FCAW Structural steel work

Procedimento di saldatura e tipo

Manual + Semiautomatic All NDT classes

BASE MATERIAL

Materiale Item A / Item B

Spec. & type: EN 10225 S 355G15+N / ASTM A694 F52

JOINTS AWS D1.1:2006 Gr. No. 2 / Gr. No. 2

POSITION

Smussi Steel Mill & Delivery condition:ITEM A:Vallourec&Mannesmann / Normalized Posizione

Groove design: See sketch ITEM B: Icarus / Forged + Q&T Groove position: ALL

Tipo Posizione di cianfrino

Backing: YES for FCAW Impact Test Quality: KL-40 & KT -50 / KL-29 & KT-29 Weld progr.: UPHILL FOR

Supporto Thickness mm: 9.53 ÷ 28.58 Deposited metal: Avanzamento VERTICAL

Spessore Mat. Depositato

Backing mat: Weld metal (FCAW) Fillet position: N.A.

Mat. Supporto Diameter mm: 60.3 ÷ 323.8 Posizione d’ angolo

Diametro

ITEM A: C≤0,15% Ceq≤0,45% Pcm≤0,25%

ITEM B: C≤0,11% Ceq≤0,41% Pcm≤0,21%

GAS PREHEAT HEAT TREATMENTS

Preriscaldo Trattamenti termici

Shielding gas: Argon for GTAW;

Gas di protezione Mixture Ar-CO2 for FCAW Temp. °C 47 Type/ Tipo : NO

Composition: 99.99% Argon for GTAW; Maintenance: UP TO WELD COMPLETION Holding temp.°C

Mantenimento Temperatura

/ /

Composizione 80% Ar ÷ 20%CO2 (±2%nom) for FCAW

Flow rate (l/min.): 10÷14 for GTAW Holding time h

Method: PROPANE BURNERS / /

Consumo 18÷20 for FCAW Mantenimento

Gas Backing: N.A. Interpass °C: 242 Heating rate °C/h / /

Gas di supporto Gradiente di Salita

Trailing shielding gas compos.: N.A. Cooling rate °C/h / /

Gradiente di Discesa

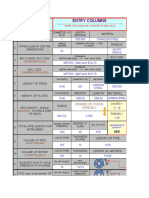

TECNIQUE FILLER METALS AND WELDING PARAMETERS

Tecnica Materiali d'apporto e parametri di saldatura

String or weave bead: STRING Process GTAW (1) GTAW (2) FCAW (1) FCAW(2)

Passata larga o stretta Procedimento

Oscillation: N.A. Filler type OK 13.23 OK 13.23 OK 15.17 OK 15.17

Oscillazione Mat. d'apporto

Initial interpass cleaning: BRUSHING / GRINDING Supplier ESAB ESAB ESAB ESAB

Pulizia Fornitore

Method of back gouging: N.A. Size mm 2.4 2.4 1.2 1.2

Metodo di ripresa Diametro mm

Orifice or gas cup size: 10 mm for GTAW; 14÷20 mm for FCAW EN Class. / / / /

Contact tube to work distance: 15÷25 mm for FCAW SFA N° 5.28 5.28 5.29 5.29

Multipass or single: MULTIPASS AWS Class. ER 80S Ni1 ER 80S Ni1 E81T1-Ni1 E81T1-Ni1

Single or multiple electrode: SINGLE F N° 6 6 / /

Power Source: CV output for FCAW A N° 10 10 / /

NOTE : Current DIRECT DIRECT DIRECT DIRECT

Corrente

Consumable control procedure: 856110-7006-INS-WI-QUAL-015 Amps 130 ÷ 140 142 ÷ 154 170 ÷ 210 182 ÷ 205

Welding Repair: according to WPS 856110.016R Volts 11.6 ÷ 12.5 12.5 ÷ 13.5 22 ÷ 25.4 23.5 ÷ 26

ROL cm N.A. N.A. N.A. N.A.

Speed cm/min 6.3 7 6.8 7.3 24 ÷ 26.3 23 ÷ 26.5

Velocità

Maximum thickness of buttering shall be 12 mm

Heat input 1.29 1.67 1.46 1.83 0.85 1.33 0.97 1.39

Buttering is allowed to correct root openings not greater than twice the thk of KJ/mm

thinner part or 20mm, whichever is less Polarity

Polarità

STRAIGHT STRAIGHT REVERSE REVERSE

Arc time N.A. N.A. N.A. N.A.

Sec.

SKETCH: WELDING SEQUENCE (Sequenza di saldatura)

(Schizzo) Single Side and Buttering layers on ITEM A or B

Root pass by GTAW(1); Hot pass by GTAW(2); Fill by FCAW(1); Cap by FCAW(2)

+5°

-0°

Double Side

Root pass by GTAW(1); Hot pass by GTAW(2); Fill by FCAW(1); Cap by FCAW(2)

15° +5° Backgoug up to sound metal;Back passes (min 2) by GTAW(2)

37, -0°

5°

0.7-1.5

ITEM A ITEM B

+1

3 -0

3 15/12/2010 S. Musso M. Mihai

2 01/07/2010 O. Fois / S. Musso

Rev. Date IMS, welding eng Reviewed by Saipem Third Party Certification Approval by Total

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- RECORD NFT 201 7FA2407S 3193930 EN 1529933557 SmallДокумент1 страницаRECORD NFT 201 7FA2407S 3193930 EN 1529933557 SmallPrashant KumarОценок пока нет

- Tankfabrication Pos Eng WebДокумент12 страницTankfabrication Pos Eng WebPrashant KumarОценок пока нет

- Obiukwu Osita, Udeani Henry, Ubani ProgressДокумент12 страницObiukwu Osita, Udeani Henry, Ubani ProgressPrashant KumarОценок пока нет

- Maxflux SAF-8 (LS) : Agglomerated Basic Flux For Submerged Arc WeldingДокумент1 страницаMaxflux SAF-8 (LS) : Agglomerated Basic Flux For Submerged Arc WeldingPrashant KumarОценок пока нет

- Yahoo Mail Document - Passport & PhotoДокумент1 страницаYahoo Mail Document - Passport & PhotoPrashant KumarОценок пока нет

- Goibibo DocumentДокумент2 страницыGoibibo DocumentPrashant KumarОценок пока нет

- Duqm Refinery Project EPC Package OneДокумент22 страницыDuqm Refinery Project EPC Package OnePrashant KumarОценок пока нет

- Capa PDFДокумент2 страницыCapa PDFPrashant KumarОценок пока нет

- ASME Sec IXДокумент5 страницASME Sec IXPrashant KumarОценок пока нет

- Curriculum Vitae: Career ObjectiveДокумент4 страницыCurriculum Vitae: Career ObjectivePrashant KumarОценок пока нет

- Washersf436 PDFДокумент1 страницаWashersf436 PDFPrashant KumarОценок пока нет

- Technical Specifications For PRZДокумент17 страницTechnical Specifications For PRZPrashant KumarОценок пока нет

- Tata Aig Network Hospitals ListДокумент1 553 страницыTata Aig Network Hospitals ListPrashant KumarОценок пока нет

- 1561013458uptet P-2 17Документ34 страницы1561013458uptet P-2 17Prashant KumarОценок пока нет

- Appoinment LetterДокумент3 страницыAppoinment LetterPrashant KumarОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- API 570 DAY 3 BOOK (1 To 108) (PP)Документ106 страницAPI 570 DAY 3 BOOK (1 To 108) (PP)melvinОценок пока нет

- PDFДокумент8 страницPDFOnkar NaikОценок пока нет

- DME Microproject-1Документ11 страницDME Microproject-1omkar digamabar sonone100% (1)

- Saudi Aramco Engineering Standard PDF WeldingДокумент2 страницыSaudi Aramco Engineering Standard PDF WeldingMohammed ZameerОценок пока нет

- Lincoln Ranger 225Документ6 страницLincoln Ranger 225fdpc1987Оценок пока нет

- Datasheet Sandvik 2re69 enДокумент9 страницDatasheet Sandvik 2re69 enMuzammilОценок пока нет

- ASTM Welding Procedures A36 To A930Документ5 страницASTM Welding Procedures A36 To A930solrac4371Оценок пока нет

- Soldamatic Educational 2012 User GuideДокумент29 страницSoldamatic Educational 2012 User GuideRoberto Carlos Berdeja ZambranaОценок пока нет

- Aws C5.5 (2003) Rp-GtawДокумент131 страницаAws C5.5 (2003) Rp-GtawIsmail Karmana100% (2)

- Contents (Continued) : Chapter 4. Metal Structure, Welding, and BrazingДокумент4 страницыContents (Continued) : Chapter 4. Metal Structure, Welding, and BrazingrobinyОценок пока нет

- English/Metric Tensile Strength/Yield Strength Conversion ChartДокумент1 страницаEnglish/Metric Tensile Strength/Yield Strength Conversion ChartTAMILОценок пока нет

- MinaIJPVP20 03 PDFДокумент10 страницMinaIJPVP20 03 PDFricardo sabinoОценок пока нет

- HW-6 Chap 9 Dan 10: ProblemsДокумент6 страницHW-6 Chap 9 Dan 10: ProblemsRifda Muthia AlvianaОценок пока нет

- Api 577Документ6 страницApi 577Mohammed YoussefОценок пока нет

- Welding of Ferritic Cryogenic SteelsДокумент2 страницыWelding of Ferritic Cryogenic SteelsMuhammed SulfeekОценок пока нет

- Job Description-VietnamДокумент4 страницыJob Description-Vietnama_Vijayakumar77Оценок пока нет

- Armstrong Svoemmervandudladere Katalog PDFДокумент22 страницыArmstrong Svoemmervandudladere Katalog PDFShaheryar Akram Kang100% (1)

- HAZ Liquation Cracking in Austenitic and Duplex S.S. - J.C. Lippold PDFДокумент14 страницHAZ Liquation Cracking in Austenitic and Duplex S.S. - J.C. Lippold PDFHagen_of_TronjeОценок пока нет

- W Section 1 Mma Welding Saf Fro General Catalogue68475045296859596Документ8 страницW Section 1 Mma Welding Saf Fro General Catalogue68475045296859596sarahrouОценок пока нет

- Exotic Metal Base Metal & Filler GuideДокумент1 страницаExotic Metal Base Metal & Filler GuideJuan RodriguezОценок пока нет

- Astralloy Catalog enДокумент42 страницыAstralloy Catalog enHector Galvan LopezОценок пока нет

- Entry Columns: DescriptionДокумент21 страницаEntry Columns: Descriptiondilema_pgОценок пока нет

- WeldДокумент165 страницWeldHayleyОценок пока нет

- Syllabus: Craft Instructors Training Scheme (Cits)Документ21 страницаSyllabus: Craft Instructors Training Scheme (Cits)Abdul MalikОценок пока нет

- Build Up A BikeДокумент5 страницBuild Up A BikeNhel OclinariaОценок пока нет

- Broch PC-2 EN PDFДокумент4 страницыBroch PC-2 EN PDFSgk ManikandanОценок пока нет

- GSI SLV Duisburg - International Welding Engineer-2015Документ2 485 страницGSI SLV Duisburg - International Welding Engineer-2015yutwelding83% (12)

- Standard Description View ImageДокумент32 страницыStandard Description View ImageRakesh ParaОценок пока нет

- BOC Smootharc Tig 200 ACDC ManualДокумент19 страницBOC Smootharc Tig 200 ACDC Manualeddo200675% (4)

- Creep-Resistant Steels - TWIДокумент6 страницCreep-Resistant Steels - TWIJlkKumarОценок пока нет