Академический Документы

Профессиональный Документы

Культура Документы

SFDSF PDF

Загружено:

bishnu sahОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SFDSF PDF

Загружено:

bishnu sahАвторское право:

Доступные форматы

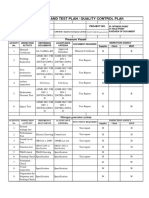

Quality Plan

Project : Q Plan No. KEY: P : Perform

Component : Date of issue W : Witness

R : Review

(P) : Record Maintain

W : Witness

Characteristics to be Extent of Format of Responsibility

SN Operation Type of check Reference document Acceptance norm Record ref. No.

checked check record MD QD Cust.

A] Inspection on receipt

Material identification - Mechanical Properties and Manufacturer's test IS:2062 (Equivalent to IS:2062 (Equivalent to Mill test

1 Sample - R - -

steel Chemical Composition certificate SM 400B) & AISI 304 SM 400B) & AISI 304 certificate

Dimension, Minimum Tensile

Strength, Minimum Manufacturer's test Manufacturer's

2 Seals Sample - R - -

Elongation at Break and certificate test certificate

Durometer Hardness

Electrode AWS A5.4,

Mechanical Properties and Manufacturer's sample test

3 E309 Mo-15 and CO2 Sample ASME II C ASME II C Certificate - R - -

Chemical Composition certificate

welding wire

Catalogue and

4 Paints Date of manufacture Visual 100% Manufacturer's batch Valid expiry date Certificate - R - -

test certificate

B] In-process inspection (Fabrication)

Dimensions (Square,

Sub-assembly, drill holes & diagonal, parallel,

assembly straightness & Flatness)

Fabrication Stage 100%

alignment, welds Approved drawing,

5 Inspection (Gates, Stop Report - P -

Critical dimensions, sub- Measurement plan and

log and Trash rack) Guide frame

assembly and assembly

Critical dimensions, sub-

Rollers / Bushes Sample

assembly and assembly

1) Screw spindle type

Fabrication Stage (manual operation )

Critical dimensions, sub- Approved drawing,

6 Inspection (Hoisting 2) Screw spindle type 100% Approved drawing Report - P -

assembly & assembly Measurement plan

fabricated ) (electric motor with provision

of manual operation )

Visual Defects (porosities,

7 NDT - Weld Visual Weld bead, reinforcement cracks and appearance of 100% ASME Sec V Art 9 Report - P -

welds)

Welds- external defects

NDT- Penetrant 40% of MS/SS

8 Weld bead, reinforcement (cracks, pinholes, ASME Sec V Art 6 Report - P -

(Whenever required) weld joint

porosities)

External defects Surface 20% of MS/SS

9 NDT - Magnetic Test Weld bead, reinforcement ASME Sec V Art 7 Report - P -

cracks weld joint

NDT - Ultrasonic or Welds- internal defects 100% of weld

10 Radiographic Inspection Weld bead, reinforcement (cracks, lack of penetration, joint of skin ASME Sec V Art 5 or 1 Report - P -

(Skin plate Joint) porosities, slag inclusions) plate

Prepared By: Reviewed By: Approved By:

Technical Officer Job In-Charge Quality Manager Customer Approved: Page 1 of 3

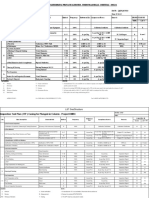

Quality Plan

Project : Q Plan No. KEY: P : Perform

Component : Date of issue W : Witness

R : Review

(P) : Record Maintain

W : Witness

Characteristics to be Extent of Format of Responsibility

SN Operation Type of check Reference document Acceptance norm Record ref. No.

checked check record MD QD Cust.

Randomly

checking 10-12

11 Painting Inspection DFT DFT meter, Visual points each on Report P (P) -

gate and guide

frame

Packing, Loading, all stage Challan / Packing

12 Release for dispatch Review all reports 100% - - - P - R

reports list

C] In-process inspection (Installation)

Gate and Guide frame

Inspection during Critical dimensions, sub-

13 100% Report - P -

Erection Stage assembly and assembly

Hoisting and Steel Support

Preliminary Test:

1) Inspection of sealing and

measurement of seals gap

2) Setting of limit switch,

EPI and control equipment

3) Inspection of satisfactory

installation of all

components

Testing & commissioning Operation Test:

of gates (After completion Gate leaf, Guide frame & 1) Measurements of

14 100% Report - Project In-Charge

of installation work at Hoisting operation speeds

site) 2) Accuracy of EPI

3) Manual operation of

hoist

5) Leakage during closed

condition of gate

6) Satisfactory operation

under dry and available

maximum water level

conditions

D] Final inspection

15 Review all reports Records Review 100% Review Review Report Review - P -

Handover to the

Project Manager / Project In-

16 Employer after testing & Review all reports Review all reports 100% Official Letter -

Charge

commissioning

Prepared By: Reviewed By: Approved By:

Technical Officer Job In-Charge Quality Manager Customer Approved: Page 2 of 3

Quality Plan

Project : Q Plan No. KEY: P : Perform

Component : Date of issue W : Witness

R : Review

(P) : Record Maintain

W : Witness

Characteristics to be Extent of Format of Responsibility

SN Operation Type of check Reference document Acceptance norm Record ref. No.

checked check record MD QD Cust.

Abbreviations

ASME American Society of Mechanical Engineering NDT Non Destructive Test Cust Customer

Sec Section DFT Dry Film Thickness Customer Employer / Client

Art Article MD Mechanical Division,

Gr Grade QD Quality Division,

Prepared By: Reviewed By: Approved By:

Technical Officer Job In-Charge Quality Manager Customer Approved: Page 3 of 3

Вам также может понравиться

- Qap ReactorДокумент6 страницQap ReactorPARMAR MUKESHОценок пока нет

- Sample QAPДокумент3 страницыSample QAPArjun ChouhanОценок пока нет

- QAP N2 Generator & N2 VesselДокумент2 страницыQAP N2 Generator & N2 VesselVijay - Spantech EngineersОценок пока нет

- Shop Inspection and Test Plan for FRP Water TroughДокумент29 страницShop Inspection and Test Plan for FRP Water TroughEljo AndsОценок пока нет

- SEW Quality Assurance Plan for Tube Bundle IDE-111 ADДокумент2 страницыSEW Quality Assurance Plan for Tube Bundle IDE-111 ADSANGEETHAОценок пока нет

- Qap - Structural Mechanical FabricationДокумент8 страницQap - Structural Mechanical Fabricationbharathi_pmОценок пока нет

- ITP Structural SteelДокумент4 страницыITP Structural SteelfranОценок пока нет

- ITP Low Tempt Test - RevДокумент6 страницITP Low Tempt Test - RevAgus GunawanОценок пока нет

- Quality Assurance Plan For Austenitic Stainless Steel Welded Pipe AS PER ASTM A 312, Latest Edtion Vendor: Jindal Quality Tubular LimitedДокумент2 страницыQuality Assurance Plan For Austenitic Stainless Steel Welded Pipe AS PER ASTM A 312, Latest Edtion Vendor: Jindal Quality Tubular Limitedamit rajputОценок пока нет

- Simple LOS QAP FormatДокумент1 страницаSimple LOS QAP Formatmechdesign2k23Оценок пока нет

- QAP1Документ2 страницыQAP1akshaymehra2354Оценок пока нет

- M/s-PINAX STEEL ITP for Fabricated DUCT & HOPPERSДокумент1 страницаM/s-PINAX STEEL ITP for Fabricated DUCT & HOPPERSStructures ProductionОценок пока нет

- Quality Control in Fabricaton 1 Quality Assurance Plan 2 Inspection Report 3 NDT Report 4Документ13 страницQuality Control in Fabricaton 1 Quality Assurance Plan 2 Inspection Report 3 NDT Report 4Varun MalhotraОценок пока нет

- Inspection Test Plan PV Nozzle Modification/AlterationДокумент4 страницыInspection Test Plan PV Nozzle Modification/AlterationMohd Shafuaaz KassimОценок пока нет

- Jash Engineering LTD.: Quality Assurance PlanДокумент3 страницыJash Engineering LTD.: Quality Assurance PlanShree ConstructionОценок пока нет

- Field Quality Plan: KSK Power Company LimitedДокумент6 страницField Quality Plan: KSK Power Company LimitedGayatree RathoreОценок пока нет

- Quality Assurance PlanДокумент3 страницыQuality Assurance PlanVicky Gautam100% (1)

- Inspection & Test Plan Revision: 0 Project: Owner: Location: Contract/PO No.: Engineer(s) : QA/QC Phase: Structural SteelДокумент2 страницыInspection & Test Plan Revision: 0 Project: Owner: Location: Contract/PO No.: Engineer(s) : QA/QC Phase: Structural SteelmetroroadОценок пока нет

- GM 1927-16b Exhaust Pipe Bending Process AuditДокумент4 страницыGM 1927-16b Exhaust Pipe Bending Process AuditJOHNОценок пока нет

- Natural Gas Transportation Development Project - Siak Riau: Inspection Test Plan (Itp) at ShopДокумент3 страницыNatural Gas Transportation Development Project - Siak Riau: Inspection Test Plan (Itp) at Shopanang_priОценок пока нет

- PROJECT Site Record Acceptance Norms RefДокумент6 страницPROJECT Site Record Acceptance Norms Refvanchai sapaОценок пока нет

- Quality Assurance Plan for Metallic Expansion Joint ManufacturingДокумент1 страницаQuality Assurance Plan for Metallic Expansion Joint Manufacturingdemas100% (1)

- Quality Management - Inspection and Test Plan for Gold Pump ModelДокумент1 страницаQuality Management - Inspection and Test Plan for Gold Pump ModelVIKASH RAIОценок пока нет

- Manufacturing Inspection Test Plan: 1. Fabrication & Pre RequisitesДокумент1 страницаManufacturing Inspection Test Plan: 1. Fabrication & Pre RequisitesAlesol EquipmentОценок пока нет

- Quality Assurance PlanДокумент3 страницыQuality Assurance PlanNESTOR YUMULОценок пока нет

- ITP For PipingДокумент5 страницITP For PipingAldeline SungahidОценок пока нет

- Inspection & Test Plan Mechanical (ITP)Документ6 страницInspection & Test Plan Mechanical (ITP)hari banggaОценок пока нет

- FQP For Brick WorkДокумент1 страницаFQP For Brick WorkHimanshu ChaudharyОценок пока нет

- QAP New Customer Nov23Документ1 страницаQAP New Customer Nov23RND DRAWОценок пока нет

- ITP For Boiler ErectionДокумент6 страницITP For Boiler ErectionUmair Awan100% (2)

- Final - Pump - QAP - 5P0312ABCD - Antico - Code 4 PDFДокумент1 страницаFinal - Pump - QAP - 5P0312ABCD - Antico - Code 4 PDFRishabh VermaОценок пока нет

- ITP Valves PDFДокумент4 страницыITP Valves PDFric leonisoОценок пока нет

- Standard Inspection and Test Plan For Api6D Valves: A GSL Company - Quality EndorsedДокумент4 страницыStandard Inspection and Test Plan For Api6D Valves: A GSL Company - Quality EndorsednithyaОценок пока нет

- API6DValvesInspectionTestPlan PDFДокумент4 страницыAPI6DValvesInspectionTestPlan PDFkeertiraj09Оценок пока нет

- Attach-2 ITP For Building WaterДокумент29 страницAttach-2 ITP For Building WaterSukalyan BasuОценок пока нет

- ITP (Can Gas)Документ1 страницаITP (Can Gas)Kemas Muhandis MancapaniОценок пока нет

- Item 4 and 5 DatasheetДокумент5 страницItem 4 and 5 DatasheetAJNAZ PACIFICОценок пока нет

- Inspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak RiauДокумент10 страницInspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak Riauanang_priОценок пока нет

- Itp S8 CivilДокумент12 страницItp S8 CivilAnonymous G3jRndEbVОценок пока нет

- Tanhov Industrial Co.,Ltd: ITP (Inspection and Test Plan) FOR PRVДокумент2 страницыTanhov Industrial Co.,Ltd: ITP (Inspection and Test Plan) FOR PRVUmair AwanОценок пока нет

- Scan 27 Sep 2020 (4)Документ2 страницыScan 27 Sep 2020 (4)SURAJ PRSADОценок пока нет

- 5 ITP Block WorkДокумент2 страницы5 ITP Block Workahmsami91Оценок пока нет

- Inspection Testing Plan (ITP)Документ1 страницаInspection Testing Plan (ITP)Kdown 99100% (1)

- 149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Документ58 страниц149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Muhammad Fitransyah Syamsuar PutraОценок пока нет

- L&T GeoStructure casing inspection planДокумент2 страницыL&T GeoStructure casing inspection plansanil50% (2)

- QAP FormatДокумент3 страницыQAP FormatSaravana Kumar100% (2)

- Inspection Test Plan (Itp) at Shop: Remark No DescriptionДокумент2 страницыInspection Test Plan (Itp) at Shop: Remark No Descriptionanang_pri100% (1)

- 415 - Dexler - QAP - 800V,2200AДокумент4 страницы415 - Dexler - QAP - 800V,2200Asriram.5230Оценок пока нет

- QAP - Invest Energy Group (10.0 TPH)Документ3 страницыQAP - Invest Energy Group (10.0 TPH)chanjunkaiОценок пока нет

- QIP of Boiler For ErectionДокумент6 страницQIP of Boiler For ErectionUmair Awan100% (2)

- Quality Assurance Plan SummaryДокумент4 страницыQuality Assurance Plan SummaryDeepak UpadhyayОценок пока нет

- Inspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak RiauДокумент4 страницыInspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak Riauanang_priОценок пока нет

- ITP For Fabrication & Installation of Tensile Fabric ShadesДокумент1 страницаITP For Fabrication & Installation of Tensile Fabric ShadesSun ShadeОценок пока нет

- Rai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksДокумент4 страницыRai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksVijaya Barani100% (1)

- QAP For Bitumen JobДокумент2 страницыQAP For Bitumen JobSasanka SekharОценок пока нет

- Water Tank Fabrication QAPДокумент2 страницыWater Tank Fabrication QAPYOGESHОценок пока нет

- Inspection and Test Plan: Order No.: Client: Project: Purchaser: Scope of Supply: Safety Relief Valve Doc No.Документ2 страницыInspection and Test Plan: Order No.: Client: Project: Purchaser: Scope of Supply: Safety Relief Valve Doc No.jayendrapatilОценок пока нет

- QAP CondenserДокумент3 страницыQAP CondenserisaacОценок пока нет

- Itp For Ug PipelineДокумент3 страницыItp For Ug PipelineJustin Alwar100% (1)

- ABC SoilДокумент5 страницABC SoilAlliah MendozaОценок пока нет

- Stability Analysis of Geocell Reinforced Slopes by Considering Bending EffectДокумент13 страницStability Analysis of Geocell Reinforced Slopes by Considering Bending EffectRakesh KapoorОценок пока нет

- LPSR Based Paper - Optik JournalДокумент12 страницLPSR Based Paper - Optik JournalSK ChaulyaОценок пока нет

- Comparison Between Different Heat Sources Types in Thin-Plate Welding Simulation-Hashemzadeh-2014Документ8 страницComparison Between Different Heat Sources Types in Thin-Plate Welding Simulation-Hashemzadeh-2014DonatasОценок пока нет

- Aroma Chemistry Smell of BooksДокумент1 страницаAroma Chemistry Smell of BooksEstefanía Gómez RodríguezОценок пока нет

- The Influence of Hydrogen On Tension-Compression and Rolling Contact Fatigue Properties of Bearing SteelДокумент8 страницThe Influence of Hydrogen On Tension-Compression and Rolling Contact Fatigue Properties of Bearing Steelmp87_ingОценок пока нет

- MNIT Jaipur Tender for Construction of Academic Lecture TheatresДокумент102 страницыMNIT Jaipur Tender for Construction of Academic Lecture Theatresdrjonesg19585102Оценок пока нет

- TUV Approved Solar DC Cables GuideДокумент5 страницTUV Approved Solar DC Cables Guide1382aceОценок пока нет

- Text Book: "Advanced Mechanics of Materials"Документ22 страницыText Book: "Advanced Mechanics of Materials"developmental biologyОценок пока нет

- PulpДокумент382 страницыPulpBeerBie100% (1)

- Dayu 12Документ3 страницыDayu 12Wayan SukerayasaОценок пока нет

- 3353 - Alloys Task Sheet - Final Check CompleteДокумент15 страниц3353 - Alloys Task Sheet - Final Check CompleteAref DahabrahОценок пока нет

- Bro-0008.7 Hvofsolutions enДокумент16 страницBro-0008.7 Hvofsolutions enIzziОценок пока нет

- WeldingДокумент3 страницыWeldingGregor SamsaОценок пока нет

- Design For Hot Dip GalvanisingДокумент9 страницDesign For Hot Dip GalvanisingSreedhar Patnaik.MОценок пока нет

- Introduction To GFRCДокумент13 страницIntroduction To GFRCibrahim alshaerОценок пока нет

- Resistivity Log: Well Logging (Pe413)Документ9 страницResistivity Log: Well Logging (Pe413)Ramy MaamounОценок пока нет

- Rizvi New Unit Shed-3 - 68'X111'Документ7 страницRizvi New Unit Shed-3 - 68'X111'shohugОценок пока нет

- Study The Different Types of Pattern and Their CharacteristicsДокумент5 страницStudy The Different Types of Pattern and Their CharacteristicsUsman RazaОценок пока нет

- NORSOK Recommended-Guidelines-For-Water-Based-Firefighting-SystemsДокумент17 страницNORSOK Recommended-Guidelines-For-Water-Based-Firefighting-SystemsG0% (1)

- Candidates Are Required To Give Their Answer in Their Own Words As Far As Practicable. The Figure in The Margin Indicates Full MarksДокумент3 страницыCandidates Are Required To Give Their Answer in Their Own Words As Far As Practicable. The Figure in The Margin Indicates Full MarksShankar KhanalОценок пока нет

- Rheology Book PDFДокумент268 страницRheology Book PDFPaulo SouzaОценок пока нет

- Belclene 400 Technical Data Sheet IWT 8.5x11Документ2 страницыBelclene 400 Technical Data Sheet IWT 8.5x11Buenaventura Jose Huamani TalaveranoОценок пока нет

- PETRONAS Distributor Price List - W.E.F 10-10-23Документ2 страницыPETRONAS Distributor Price List - W.E.F 10-10-23Mujeeb SiddiqueОценок пока нет

- Effects of Heat Treatments On Steels For Bearing ApplicationsДокумент7 страницEffects of Heat Treatments On Steels For Bearing ApplicationsAshwani KansaraОценок пока нет

- Hydrometallurgical Process: Analysis of Free, Total & WAD Cyanide in Gold Leach Slurry & WastewaterДокумент1 страницаHydrometallurgical Process: Analysis of Free, Total & WAD Cyanide in Gold Leach Slurry & WastewaterJUNIORОценок пока нет

- Factors Affecting Resistance in a Wire Multiple ChoiceДокумент8 страницFactors Affecting Resistance in a Wire Multiple ChoiceGeeja EdgerОценок пока нет

- Bulletin ASTM C 920Документ1 страницаBulletin ASTM C 920carlosОценок пока нет

- Rigid PavementДокумент2 страницыRigid Pavementanatoink2Оценок пока нет

- Lithos: Lan-Chun Huang, Shao-Yong JiangДокумент20 страницLithos: Lan-Chun Huang, Shao-Yong JiangNguyen tiendungОценок пока нет