Академический Документы

Профессиональный Документы

Культура Документы

Structured Cabling

Загружено:

Anandu AshokanАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Structured Cabling

Загружено:

Anandu AshokanАвторское право:

Доступные форматы

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Method Statement and Risk Assessment for

Installation and Testing of Structured Cabling, at

AMC Connectivity Corridors & Concourse Bridge

Project, Maryah island,

ABUDHABI

Project No-M- 1467

Document Ref No: MCL-ME-A-MST-MSS-003 (to be obtained from McLaren DC)

Method Statement Title Installation and Testing of Structured Doc Ref No: MCL-ME-A-MST-MSS-003

Cabling

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 01

Prepared By Frasat Ahmed Approved By Revision Date: 19-02-2019

SAF-098 (UAE) 09/16 Rev G 1 of 20 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Project name AMC Connectivity Corridors & Concourse Bridge Project Project No M1467

Main Contractor McLaren Construction Ltd. Document No MCL-ME-A-MST-MSS-003

Title/Task Structured Cabling Revision No 01

Document

Date of issue 19/02/2019 Prepared By

Frasat Ahmed

Duration of

Proposed start date 12/04/2019 task 1 Month

Contents

Section A Register of Revisions

Section B Scope of Works to be undertaken:

Section C Location of the Project

Section D Location of the Works to be Undertaken with the Project

Section E Site Access/Egress and Access to the Work Zone

Section F Emergency Contacts Details and Procedures:

Section G McLaren Site Specific HSE Safety Induction:

Section H Welfare facilities:

Section I Personal Protective Equipment

Section J Plant/Equipment and tools to be Used

Section K Materials To be used.

Section L Communication/Toolbox Talks/Training Requirements:

Section M Works Permits

Section N Environmental and Waste Management:

Section O Programme for the Works:

Section P Housekeeping and Storage:

Section Q Hygiene and cleanliness

Section R Working At Height

Section S Occupational Health

Section T Sequence of Works/Activities

Appendices

Appendix A Site Logistic Plans and Other Design Information Relative to the Works

Appendix B Crisis/Emergency Plan

Appendix C COSHH Assessments and Material Data Sheets (to be provided by Subcontractor)

Appendix D Risk Assessments (to be provided by Subcontractor)

Appendix E Technical Information (to be provided by the Subcontractor)

Appendix F Risk Assessment

Method Statement Title Installation and Testing of Structured Doc Ref No: MCL-ME-A-MST-MSS-003

Cabling

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 01

Prepared By Frasat Ahmed Approved By Revision Date: 19-02-2019

SAF-098 (UAE) 09/16 Rev G 2 of 20 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Section A - Register of Revisions

Revision Date Reason for Amendment Amended By Signature Has this amendment been briefed

No (Name) to the operatives involved and have

the operatives signed the register.

00 11/02/ Mixed with ESCF Project Requirements Frasat

2019

00 11/02/ How the work to be carried at or working Frasat

2019 platform used not being Identified

00 11/02/ Risk Assessment to match the sequence of work Frasat

2019 and the activity being carried out.

This method statement has been prepared in conjunction with the following documents;

1. OSHAD regulation and requirements

2. OHSAD- Code of Practices, HSE Regulations, Technical Guidelines, Mechanisms

3. GR HSE Guidelines and Requirements

4. Federal Environmental Authority Law No 24/1999 and its supplements.

5. Federal Labour Law No 8

6. Articles (3,4,5,7) Local Law No 21/2005 (Waste Management)

7. McLaren SHE Procedures

8. McLaren’s site specific SHEQ Plan (including TMMS, SWMP, EPP).

9. McLaren’s Integrated Management System Policy Statement (IMS) .

Section B- Scope of Works to be undertaken:

The work Describes Installation and Testing of Structured Cabling for AMC Connectivity Corridors & Concourse

Bridge Project, Abu Dhabi-UAE.

The following Critical Hazards have been identified during the preparation of the scope of works, please refer to

the Risk Assessments within Appendix D.

1. Manual Handling Injuries

2. Slip Trips and Falls

3. Fall from Height

4. electrical Hazard

5. Struck by Objects

6. Use of ladders

7.Falling objects

8. Sharp Edges

9. Injury to body parts

Method Statement Title Installation and Testing of Structured Doc Ref No: MCL-ME-A-MST-MSS-003

Cabling

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 01

Prepared By Frasat Ahmed Approved By Revision Date: 19-02-2019

SAF-098 (UAE) 09/16 Rev G 3 of 20 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Section C- Location of the Project

Location of the Project;

Our project is located AMC Connectivity Corridors & Concourse Bridge in between Almaryha and Galleria Mall as

marked below.

Section D- Location of the Works to be Undertaken within the Project

Method Statement Title Installation and Testing of Structured Doc Ref No: MCL-ME-A-MST-MSS-003

Cabling

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 01

Prepared By Frasat Ahmed Approved By Revision Date: 19-02-2019

SAF-098 (UAE) 09/16 Rev G 4 of 20 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Add full sketch of the project and mark up your areas of work (logistics plan to be updated)

Section E- Site Access/Egress and Access to the Work Zone

Entrance to the Site will be from Gate no 1 as per attached drawing.

(logistics plan to be attached)

Method Statement Title Installation and Testing of Structured Doc Ref No: MCL-ME-A-MST-MSS-003

Cabling

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 01

Prepared By Frasat Ahmed Approved By Revision Date: 19-02-2019

SAF-098 (UAE) 09/16 Rev G 5 of 20 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Section F- Emergency Contacts Details and Procedures:

The following staff from both McLaren and will be on site during the execution of the works and will be

responsible for managing the works;

Name Position Company Contact Details

Paul Carlin Operations Director McLaren 056-1054691

Luke Watson Project manager McLaren 052-1022402

Prabhu Srinivasulu Construction Manager McLaren 050-9709963

Joby John HSE Manager (First Aider) McLaren 050-6372060

Evangeline Huerto First Aider McLaren 056-1852727

Jijo Mathew Safety Advisor/First Aider McLaren 055-2152903

Ramil Magano QA/QC Engineer(Fire marshal) McLaren 050-2923058

Biju MEP Engineer McLaren 056-8059139

Syed Faisal Ahmed Project Manager Genfocus 056-5465814

Anu Baby Project Engineer Genfocus 0565465807

Prabir Kumar Safety Manager Genfocus 0558179965

Prabir Kumar First Aider Genfocus 0558179965

In case of an Emergency/fire Alarm, all operatives, Staff and Visitors are required to report to the Assembly Point,

which is indicated on the site logistics drawing, as indicated by the symbol below. Where the registers will be

checked to ensure that no one is un-accounted. No one will be allowed to leave the assembly point until the

Emergency response Controller confirms that it is safe to do so.

1 Assembly Point No-01 (TBA)

2 Assembly Point No-02 (TBA)

Please refer to the attached Crisis/Emergency Plan, (Appendix B) which is to be implemented where the need

arises.

The Qualified First Aiders for the Project are listed below, and the first Aid Boxes will be available either in the

Induction/First Aid Room or in the Main Office.

McLaren: (details of First Aiders ) Subcontractors(Details of First Aiders )

Joby John- 050-6372060 Syed Faisal Ahmed 056-5465814

Jijo Mathew 055-2152903 Prabir Kumar 056-5465847

Please see below the Emergency contact details

Authority/Company Contact Telephone No.

McLaren Construction Ltd 04-3417964

Police 999

Ambulance 997

GR Emergency No 058-2864950

AMC Emergency No 056-7459621

Section G- McLaren Site Specific HSE Safety Induction:

Method Statement Title Installation and Testing of Structured Doc Ref No: MCL-ME-A-MST-MSS-003

Cabling

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 01

Prepared By Frasat Ahmed Approved By Revision Date: 19-02-2019

SAF-098 (UAE) 09/16 Rev G 6 of 20 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Prior to any works taking place, all Operatives arriving at AMC project will be required to undergo a

Multiplex/Gulf Related safety induction followed by McLaren Site Safety induction, which will be held in the

induction room, by McLaren’s HSE Representative or other designated person. Once the operatives have received

the site specific safety induction, they then will be briefed on the contents of this RAMS, by their respective Site

Supervisor, from which they will then be required a sign a RAMS Briefing Register (SAF019 UAE) confirming that

they have been briefed and that they fully understand the RAMS and what is expected from them during the

execution of the site works. The Operatives will also be briefed on the Emergency and Security Procedures for the

project, which is also a part of site safety induction programme.

Any operative who will be operating any plant and equipment will be required to produce a copy of their

competency certificate/card carried out by an OSHAD approved third party training provider, to enable McLaren

to issue them with the Plant Operators Authorisation (SAF023 UAE).

Section H- Welfare facilities:

Drinking Water-

Clean drinking water will be provided on site (as per approved Logistics plan) and all operatives are to ensure they

take on enough fluids throughout the day .

Comply with Summer Working Requirements .

Rest areas and toilet-

Rest area and toilets are being provided at site and located as per AMC logistics layout plan

Section I- Personal Protective Equipment (PPE)

The Following Personal Protective Equipment must be worn/be available during the execution of the works

activities

Type of PPE Required Yes No

Safety Helmet (as per standards) Yes

Safety Footwear (as per standards) Yes

Eye protection (as per standards) Yes

Gloves (as per standards) Yes

Hi- viz Vests Yes

Overalls (for operatives only) Yes

Ear protection Yes

Face Respirator No

Body Harness Yes

Respiratory masks Yes

Others (other specific requirements)

Please ensure that any specific precautions for PPE as identified within MSDS/COSHH assessment or any

specific requirements by supplier/manufacturer are to be complied and adhered to.

Section J- Plant and Equipment to be Used

Method Statement Title Installation and Testing of Structured Doc Ref No: MCL-ME-A-MST-MSS-003

Cabling

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 01

Prepared By Frasat Ahmed Approved By Revision Date: 19-02-2019

SAF-098 (UAE) 09/16 Rev G 7 of 20 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

It is anticipated that the following Plant and Equipment will be used during the execution of the works; other

items will also be identified on the schedule below;

Generator

Distribution Boards

110V Transformers

Fork lif

Ladder (Only for Congested Area)

Scaffolding

*Note: All relevant competency certificates (as per OHSAD /GR requirements) to be submitted to HSE

Manager/Eng./Advisor prior to start of any activity.

(Below schedule to be completed by subcontractor)

Type of Plant/Equipment to be Used Yes No Type of Plant/Equipment to be Used Yes No

Lifing Yes Cradle No

Mechanical hoist No Excavation shoring No

Mobile elevating working platform No Hand tools Yes

Ladder Yes Electrical tools No

Hoist No CAT & Gen Set Yes

Test Equipment No Ventilation/Extraction Equip No

Task Lighting No Pump No

Scaffolding Tubular Yes Lifing slings/chains No

Mobile scaffolds No Mechanical plant No

Podium Scaffold No Others:

Section K- Materials To be used.

Method Statement Title Installation and Testing of Structured Doc Ref No: MCL-ME-A-MST-MSS-003

Cabling

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 01

Prepared By Frasat Ahmed Approved By Revision Date: 19-02-2019

SAF-098 (UAE) 09/16 Rev G 8 of 20 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

The following Materials will be utilised during the execution of the works, the Material Data sheets being

provided, which will allow the relevant COSHH assessments to be carried out; (See Appendix C)

Item Material Description Has MSDS been Has the COSHH

provided and Assessment sheet been

attached? completed and attached?

1 Cat-6 Cable, Fiber Optic Cable, Data Socket, N/A N/A

Patch Panels, Racks

Section L- Communication/Tool Box Talks/Training Requirements:

Once the RAMS has been briefed to the workforce, we will also hold Tool Box Talk relative to the work activities

being carried out, these will be conducted by the HSE team, in conjunction with the relevant site supervisors, this

will ensure that the message gets across to the workforce, in their own language, thus avoiding any

misinterpretation of the RAMS/Toolbox Talk.

During the Preparation of this RAMS the following training for the staff and operatives has been identified;

Item Description Of Training Has the Training been If not, when will be

completed? (Yes/No) completed(Date)

1 3rd party training for operative of plant and N/A

equipment

2 3rd party competency card for operators No 1/3/2019

3 Riggers, Banksman No 1/3/2019

4 First aid training N/A

5 Scaffolding inspection and erection No 1/3/2019

*Note: All relevant certificates will be submitted prior to works commencing or during induction. Where the

training has not been carried out, it must do so prior to the works/activities commencing.

Section M- Works Permits

Method Statement Title Installation and Testing of Structured Doc Ref No: MCL-ME-A-MST-MSS-003

Cabling

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 01

Prepared By Frasat Ahmed Approved By Revision Date: 19-02-2019

SAF-098 (UAE) 09/16 Rev G 9 of 20 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

The following works permits will be required during the execution of the Works;

Item Description of the Work Permit Permit Issued By Tick only applicable

1 Permit to Enter Confined Space McLaren

2 Permit for Lifing Operations. McLaren

3 Permit to Dig McLaren

4 Permit to work Hot cutting or Welding McLaren

5 Permit to Work in Ceiling Void McLaren

6 Permit for Roof Access McLaren

7 Permit to Work with Ladders, steps McLaren

8 Permit to Work at Height McLaren

9 Permit To Work – Electrical above 110V McLaren

10 Permit To Work with COSHH Items McLaren

11 Permit To Work At External Face of The Building McLaren

12 Permit For Removal of Existing Fall Protections McLaren

Any other permits if required to be added

Section N- Environmental and Waste Management:

During the execution of the project, waste will accumulate. Skips will be provided by McLaren and will be

required to put all waste in the skips provided. All waste will be segregated for recycling as per below sequence

1. Metal

2. Plastic

3. General waste

4. Concrete waste

5. Food waste

6. Hazardous waste

7. Wood Waste

Due to the nature of the works and the actual conditions of the present site, airborne dust will be minimal,

however where necessary the area affected by the installation of the temporary works, the dust will be

suppressed by spraying water.

Drip trays to be placed under plant and generator to catch any excess oil. Approved Waste Collection Contractor

will then remove excess oil from site in oil containers and sent back to store for collection.

Section O- Programme for the Works.

Method Statement Title Installation and Testing of Structured Doc Ref No: MCL-ME-A-MST-MSS-003

Cabling

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 01

Prepared By Frasat Ahmed Approved By Revision Date: 19-02-2019

SAF-098 (UAE) 09/16 Rev G 10 of 20 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

The works will commence on 4/03/2019 For a duration of 4 Month, as the works are scheduled to take place

during day light hours, there will be no requirement for any additional lighting

However if Night shif starts, adequate task lighting to be provided by the Genfocus

Section P- Housekeeping and Storage:

Housekeeping will be carried out as and when required and storage of materials will be in an agreed location ( as

per approved site logistics plan) within the segregated area and as agreed in subcontractor prestart meeting. The

subcontractor will remove from site.

Section Q- Hygiene and cleanliness:

Hygiene and cleanliness are the upmost requirements for the project. All works carried out within the catering

facility should comply with Etihad’s catering Hygiene Procedures and requirements. Compliance of PPE pertaining

to Hygiene and cleanliness to be strictly complied.

Section R- Working at Height

During the preparation of the RAMS, the following activities for working at height have been identified and have

been addressed within the risk assessments within Appendix D. ( to be filled if applicable to your works)

Item Activity Risk Assessment Reference

1 Installation and Testing of Structured Refer attached risk assessment

Cabling

Section S- Occupational Health

During the preparation of the RAMS, the following Occupational Health items have been reviewed and addressed

within this Method Statement.

Item Description of OH Item Preventative Measures, (see also within the Risk Assessments)

1 Bad Back/sprain due to improper All Operatives will be briefed on correct lifing techniques and

Manual handling avoid heavy lifing altogether

2 Hand/Arm Vibration N/A

3 Construction dust N/A

4 Noise To be Controlled

5 Sun Operatives will be required to wear long sleeve and pants to

avoid direct sunlight UV rays and drink plenty of water to avoid

dehydration

6 Skin Coveralls and gloves required at all times

Section T- Sequence of Works/Activities

The works will be carried out in the following sequences; (Subcontractor to detail out the sequence of work, from offloading the

Method Statement Title Installation and Testing of Structured Doc Ref No: MCL-ME-A-MST-MSS-003

Cabling

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 01

Prepared By Frasat Ahmed Approved By Revision Date: 19-02-2019

SAF-098 (UAE) 09/16 Rev G 11 of 20 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

materials at site to final fix including safety precautions taken during the sequence of works )

1 RAMS to be briefed to all the operatives involved in the work.

2 STARRT card to be prepared by assessing the area of work prior starting the work.

3 Supervisor to ensure all operatives have received a Multiplex and McLaren site basic induction

4 Supervisor to ensure all operatives have adequate PPE for the job including Full body harness (If required).

5 Supervisor to ensure that all operatives entering the facility have adequate disposable PPE (coverall, hand

gloves).

6 Supervisor to ensure that the site is clean and ready to start the work

7 Supervisor to ensure adequate tools are provided and should be visibly clean and tidy. Advise Site manager

if more tools are needed.

8 Supervisor to ensure that all materials taken into the facility are covered and equipment’s to be used are

clean.

9 Supervisor to ensure proper working platforms such as ladders and scaffoldings are been used and make

sure that all the working platforms are having permit to work.

10 Any damage or irregularity in the supply noted on unpacking will inform to the proper authorities as per

the standard practice.

11 Installation inspection will be carrying out as per specification

12 Site QC Inspector in coordination will conduct inspection with Engineer/Employer Representative prior to

submitting Inspection and/or Test Request to the Engineer/Employer Representative.

13 Inspection for the Engineer/Employer Representative shall be arranged accordingly.

14 Procedure of CAT-6 Installation: CAT-6 cable run will not exceed a maximum installed length of 90 meters,

and when routing shielded cabling or sitting RJ-45 outlets a minimum separation distance will be

maintained, from possible sources of EMI (Electro Magnetic Interference).

15 CAT-6 Cables are to be installed to locations specified using the provided cable trunking in the ceiling voids

in the corridors

16 The CAT-6 cables are to be pulled in manually ensuring that the pulling tension does not exceed the

manufacturers recommended guidelines.

17 Once cables are installed and to point they shall be cut to length and terminated to an RJ45 jack

terminating within the provided trunking.

18 Before pulling the CAT-6 cable the conduits will be checked with the fish tape inside to be assured that

there are no blockages in the route.

19 Connect the strength member of the cable to the pull line. Unless cables are designed for such use, basket

grips and similar methods of attachment should not be used.

20 Use lots of large pull boxes and divide pulls in half or even thirds at corners or pull boxes. A pulling

operation must be stopped if pulling tensions reach the cable's limit. The discontinued pull will have to be

aborted, the cable pulled back out and replaced on the reel, and the pull started again using shorter runs.

The cable may be reused if the pull or extraction has not damaged it.

21 Identify exact terminating locations in advance, keeping in mind that the cable must be pulled all the way

to where it will be terminated, not just into the room. This obvious though ofen overlooked step can lead

to costly mistakes if forgotten.

22 Carefully measure the cable's path before the conduit pull to avoid the need for splices. Not only do splices

Method Statement Title Installation and Testing of Structured Doc Ref No: MCL-ME-A-MST-MSS-003

Cabling

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 01

Prepared By Frasat Ahmed Approved By Revision Date: 19-02-2019

SAF-098 (UAE) 09/16 Rev G 12 of 20 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

cost time and money, but they also cause loss in both signal quality and strength. In fact, most designers

specify point-to-point or device-to-device runs to avoid needless signal loss from splices.

Pull the pull tape into the conduit, or along the cable path, for an initial measurement, and add to that

extra length for terminations, and future access coils, if specified.

23 Procedure for Termination of CAT-6 Cable in Outlet & Patch Panel: The CAT-6 Cable will be prepared and

dressed up to the Panel and the cable will be taken inside the Panel and outlet.

Splicing of all CAT-6 cable shall be carried out by means of a punch down tool.

All data/voice jacks shall be terminated using the “T568B" wiring scheme.

24 Fluke Testing for CAT-6 Cable: Upon completion of the installation, testing to all outlets will take place

using a Fluke copper cable Tester. Testing will comprise of the following elements - Headroom, Wire Map,

NEXT and ELFEXT, Length, Propagation Delay, Delay Skew, Impedance, Attenuation, Resistance, ACR, Return

Loss, Power Sum NEXT, Power Sum ELFEXT and Power Sum ACR.

25 Installation of Fiber Optic Cable: Identify exact terminating locations in advance, keeping in mind that the

cable must be pulled all the way to where it will be terminated, not just into the room. This obvious though

ofen overlooked step can lead to costly mistakes if forgotten.

26 Carefully measure the cable's path before the conduit pull to avoid the need for splices. Not only do splices

cost time and money, but they also cause loss in both signal quality and strength. In fact, most designers

specify point-to-point or device-to-device runs to avoid needless signal loss from splices.

27 Pull the pull tape into the conduit, or along the cable path, for an initial measurement, and add to that

extra length for splices, terminations, and future access coils, if specified. The amount of additional cable

needed for splicing depends on site conditions, splicing method used, and long-range plans for cable usage.

28 Choose crews based on the length of the pull, total degrees of bend, tail loading (force required to pull

cable off feed reel). In most cases, two- or three-person crews are ideal. That way, one person pays the

cable off the reel and into the duct, while one or two others pull at the other end.

29 Procedure for Termination of FOC in Patch Panel: The FOC will be prepared and dressed up to the Panel

and the cable will be taken inside the Panel.

Splicing of all FOC shall be carried out by means of a fusion-splicing machine & optical fibre cleaver.

30 The SC Pigtail (1.5m long) based will be spliced on the individual fibers & will be terminated on the splice

tray in the patch panel.

The theoretical splice loss readings, which are displayed on the fusion splice machine, shall be kept to a

maximum of 0.10 dB to reduce the number of re-splicing. The minimum splice loss shall be 0.5dB.

31 The actual splice loss of each individual splice shall be equal to or less than the stated splice loss in the

contractual specification.

If the average splice loss is greater than 0.5 dB on any two fiber spliced, then the splice shall be remade.

Maximum attempts to re-splice a particular high fiber shall be made to bring the actual splice loss within

the 0.5 dB.

32 Procedure for Fiber Optic Cable Testing:

Testing using OTDR:

An OTDR measurement shall be made on every fiber from fiber

Optic Patch Panel (origin end) to fiber optic Patch Panel (remote

End) to measure the attenuation per kilometre, afer testing all

fibers record the results. These results will give the optical length

of the link. The test will be carried out in both wavelengths 1310nm

Method Statement Title Installation and Testing of Structured Doc Ref No: MCL-ME-A-MST-MSS-003

Cabling

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 01

Prepared By Frasat Ahmed Approved By Revision Date: 19-02-2019

SAF-098 (UAE) 09/16 Rev G 13 of 20 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

& 1550nm for single mode in both directions.

33 The OTDR test result will be provided in the hard copy form in labeled ring binder with signature of witness

to verify execution of all tests.

The documentation package will consist of the following:

a) Calibration Certificate

b) OTDR test in both direction @ 1310nm & 1550nm with OTDR.

Pass criteria for each fiber:

Maximum loss Requirement: Optical Cable Loss < or = 0.4000 dB/km [1310nm]

Maximum loss Requirement: Optical Cable Loss < or = 0.400 dB/km [1550nm]

Method Statement Title Installation and Testing of Structured Doc Ref No: MCL-ME-A-MST-MSS-003

Cabling

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 01

Prepared By Frasat Ahmed Approved By Revision Date: 19-02-2019

SAF-098 (UAE) 09/16 Rev G 14 of 20 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

APPENDIX A

Site Logistics Plan

APPENDIX B

CRISIS PLAN

Method Statement Title Installation and Testing of Structured Doc Ref No: MCL-ME-A-MST-MSS-003

Cabling

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 01

Prepared By Frasat Ahmed Approved By Revision Date: 19-02-2019

SAF-098 (UAE) 09/16 Rev G 15 of 20 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

CRISIS PLAN

1. Upon an incident, being discovered the first member of McLaren’s staff or the site operative

discovering the incident shall inform the Project Manager and Site HSE team through AMC Project

emergency Contact No-056-7459621.

2. Both the HSE Engineer/advisor and the First Aider are to attend the scene with their mobile. The

project Manager or authorised person waits in office ready to contact relevant emergency

services.

3. Both the HSE Engineer/advisor and the first Aider are to assess the situation and put in place the

relevant systems to end/deal with the emergency.

4. Both the HSE Engineer/advisor and the first Aider are to ensure all trades are gathered at the

assembly point and liaise with supervisor to account for all operatives - no person should leave

site.

5. Either the HSE Engineer/advisor or the first Aider phones the project Manager or site receptionist

and informs him/her of which emergency services are required.

6. The Project Manager calls all relevant McLaren staff.

7. Both the HSE Engineer/advisor and the first Aider waits for the emergency services at scene.

8. Once emergency services arrive, The Project Manager will telephone the relevant authorities, i.e.

the HSE/Client’s Safety Advisor/QHSE Manager/McLaren’s operations Director.

9. Both the HSE Engineer/advisor and the first Aider keep trades informed of the situation and

releases trades to return to work or leave site only when emergency services or The Project

Manager instruct that it is safe to do so, and all names of witnesses are recorded.

10. Project Manager or Construction Manager are to arrange for photographs of the scene to be

taken, and if necessary the area to be cordoned.

A full investigation of the Incident is to be carried out, with a written report being submitted the

SHEQ Director, as soon as practicably possible afer the incident, including all witness statements,

11. photos of the scene, induction and method statement records, recommendation to prevent a re-

occurrence and what action has been taken since the incident taking place.

Method Statement Title Installation and Testing of Structured Doc Ref No: MCL-ME-A-MST-MSS-003

Cabling

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 01

Prepared By Frasat Ahmed Approved By Revision Date: 19-02-2019

SAF-098 (UAE) 09/16 Rev G 16 of 20 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

APPENDIX C

COSHH ASSESSMENTS AND MSDS

(Not Applicable)

Method Statement Title Installation and Testing of Structured Doc Ref No: MCL-ME-A-MST-MSS-003

Cabling

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 01

Prepared By Frasat Ahmed Approved By Revision Date: 19-02-2019

SAF-098 (UAE) 09/16 Rev G 17 of 20 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

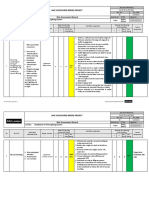

APPENDIX- D

RISK ASSESSMENTS

Method Statement Title Installation and Testing of Structured Doc Ref No: MCL-ME-A-MST-MSS-003

Cabling

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 01

Prepared By Frasat Ahmed Approved By Revision Date: 19-02-2019

SAF-098 (UAE) 09/16 Rev G 18 of 20 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

APPENDIX-E

TECHNICAL INFORMATION

Method Statement Title Installation and Testing of Structured Doc Ref No: MCL-ME-A-MST-MSS-003

Cabling

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 01

Prepared By Frasat Ahmed Approved By Revision Date: 19-02-2019

SAF-098 (UAE) 09/16 Rev G 19 of 20 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Method Statement Title Installation and Testing of Structured Doc Ref No: MCL-ME-A-MST-MSS-003

Cabling

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 01

Prepared By Frasat Ahmed Approved By Revision Date: 19-02-2019

SAF-098 (UAE) 09/16 Rev G 20 of 20 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Risk Assessment For Installation of Drainage PipesДокумент17 страницRisk Assessment For Installation of Drainage PipesAnandu Ashokan97% (34)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Risk Assessment For Installation of Fire Fighting SystemДокумент20 страницRisk Assessment For Installation of Fire Fighting SystemAnandu Ashokan93% (30)

- Risk Assessment For Installation of Water Supply PipeДокумент18 страницRisk Assessment For Installation of Water Supply PipeAnandu Ashokan89% (27)

- Risk Assessment For Installation of Ducts and AccessoriesДокумент17 страницRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan83% (12)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Method Statement For Structured Cabling System InstallationДокумент9 страницMethod Statement For Structured Cabling System InstallationAnandu Ashokan50% (2)

- Risk Assessment For Installation of Grill, Diffuser and LouversДокумент13 страницRisk Assessment For Installation of Grill, Diffuser and LouversAnandu Ashokan100% (7)

- Visual AnalysisДокумент4 страницыVisual Analysisapi-35602981850% (2)

- Risk Assessment For Installation of Sanitary WaresДокумент14 страницRisk Assessment For Installation of Sanitary WaresAnandu Ashokan67% (6)

- Risk Assessment For Installation of Toilet Exhaust FanДокумент11 страницRisk Assessment For Installation of Toilet Exhaust FanAnandu Ashokan67% (3)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Method Statement For Cable Tray and Truncking InstallationДокумент9 страницMethod Statement For Cable Tray and Truncking InstallationAnandu AshokanОценок пока нет

- Method Statement For Water Heaters InstallationДокумент9 страницMethod Statement For Water Heaters InstallationAnandu Ashokan100% (1)

- Doulci Activator For IOS 9Документ2 страницыDoulci Activator For IOS 9Syafiq Aiman100% (2)

- RAMS EvaluationДокумент3 страницыRAMS EvaluationAnandu AshokanОценок пока нет

- Method Statement LV Distribution Boards InstallationДокумент9 страницMethod Statement LV Distribution Boards InstallationAnandu Ashokan100% (1)

- Method Statement For Drainage Pipes InstallationДокумент11 страницMethod Statement For Drainage Pipes InstallationAnandu Ashokan100% (4)

- Method Statement For Earthing and Lightning ProtectionДокумент12 страницMethod Statement For Earthing and Lightning ProtectionAnandu Ashokan100% (1)

- Method Statement For LV Cables, Wiring For Lighting and Power InstallationДокумент11 страницMethod Statement For LV Cables, Wiring For Lighting and Power InstallationAnandu Ashokan50% (2)

- Method Statement For Wiring Accessories InstallationДокумент9 страницMethod Statement For Wiring Accessories InstallationAnandu AshokanОценок пока нет

- MS For Installation of Grills, Diffuser & LouversДокумент21 страницаMS For Installation of Grills, Diffuser & LouversAnandu AshokanОценок пока нет

- Marcos & Sumulong Highway, Rizal Applicant'S Information Sheet (Non-Academic)Документ2 страницыMarcos & Sumulong Highway, Rizal Applicant'S Information Sheet (Non-Academic)dummy testerОценок пока нет

- The Magnificent 10 For Men by MrLocario-1Документ31 страницаThe Magnificent 10 For Men by MrLocario-1Mauricio Cesar Molina Arteta100% (1)

- Present Tense Exercises. Polish A1Документ6 страницPresent Tense Exercises. Polish A1Pilar Moreno DíezОценок пока нет

- MS Comments SheetДокумент1 страницаMS Comments SheetAnandu AshokanОценок пока нет

- Method Statement For GI Conduits InstallationДокумент9 страницMethod Statement For GI Conduits InstallationAnandu AshokanОценок пока нет

- Method Statement For PPR Pipes and Fittings InstallationДокумент9 страницMethod Statement For PPR Pipes and Fittings InstallationAnandu AshokanОценок пока нет

- Method Statement For Fire Alarm and Emergency System InstallationДокумент9 страницMethod Statement For Fire Alarm and Emergency System InstallationAnandu Ashokan100% (1)

- MS For Installation of Sanitary WaresДокумент22 страницыMS For Installation of Sanitary WaresAnandu AshokanОценок пока нет

- Method Statement For PEX Pipes and Fittings InstallationДокумент9 страницMethod Statement For PEX Pipes and Fittings InstallationAnandu AshokanОценок пока нет

- Method Statement For PVC Conduits InstallationДокумент9 страницMethod Statement For PVC Conduits InstallationAnandu AshokanОценок пока нет

- MS Cover SheetДокумент1 страницаMS Cover SheetAnandu AshokanОценок пока нет

- MS For Installation of Toilet Exhaust FanДокумент20 страницMS For Installation of Toilet Exhaust FanAnandu AshokanОценок пока нет

- MS For Installation of Drainage PipesДокумент20 страницMS For Installation of Drainage PipesAnandu Ashokan100% (1)

- MS For Installation of Duct & AccessariesДокумент21 страницаMS For Installation of Duct & AccessariesAnandu Ashokan100% (1)

- MS - Installation of Water Supply PipeДокумент20 страницMS - Installation of Water Supply PipeAnandu Ashokan100% (1)

- MS For Installation of FF Pipes FittingsДокумент23 страницыMS For Installation of FF Pipes FittingsAnandu Ashokan100% (1)

- Guerrero vs Benitez tenancy disputeДокумент1 страницаGuerrero vs Benitez tenancy disputeAb CastilОценок пока нет

- 04 - JTC Template On Project ProposalДокумент10 страниц04 - JTC Template On Project Proposalbakelm alqamisОценок пока нет

- Journal of Electronic MaterialsДокумент10 страницJournal of Electronic MaterialsSanjib BaglariОценок пока нет

- Vmware Vsphere Professional 8 Exam Dumps PDF (VCP DCV)Документ158 страницVmware Vsphere Professional 8 Exam Dumps PDF (VCP DCV)romal ghulamОценок пока нет

- Trends, Networks, and Critical Thinking in The 21st CenturyДокумент22 страницыTrends, Networks, and Critical Thinking in The 21st CenturyGabrelle Ogayon100% (1)

- Cek List in House BakeryДокумент20 страницCek List in House BakeryAhmad MujahidОценок пока нет

- Callaghan Innovation Annual Report 2018Документ108 страницCallaghan Innovation Annual Report 2018Kerjasama P2BiotekОценок пока нет

- Molly C. Dwyer Clerk of CourtДокумент3 страницыMolly C. Dwyer Clerk of CourtL. A. PatersonОценок пока нет

- HOTC 1 TheFoundingoftheChurchandtheEarlyChristians PPPДокумент42 страницыHOTC 1 TheFoundingoftheChurchandtheEarlyChristians PPPSuma HashmiОценок пока нет

- The Ramayana and The Sacred Palm Trees of Sumeria, Mesopotamia, Assyria and PhoeniciaДокумент7 страницThe Ramayana and The Sacred Palm Trees of Sumeria, Mesopotamia, Assyria and PhoeniciaNeeta RainaОценок пока нет

- Study of Storm and Sewer Drains For Rajarhat (Ward No 4) in West Bengal Using Sewergems SoftwareДокумент47 страницStudy of Storm and Sewer Drains For Rajarhat (Ward No 4) in West Bengal Using Sewergems SoftwareRuben Dario Posada BОценок пока нет

- WritingSubmission OET20 SUMMARIZE SUBTEST WRITING ASSESSMENT 726787 40065 PDFДокумент6 страницWritingSubmission OET20 SUMMARIZE SUBTEST WRITING ASSESSMENT 726787 40065 PDFLeannaОценок пока нет

- The Basic Philosophical and Theological Notions of Saint Augustine - John C. Cooper PDFДокумент21 страницаThe Basic Philosophical and Theological Notions of Saint Augustine - John C. Cooper PDFjusrmyrОценок пока нет

- MCQ CH 5-Electricity and Magnetism SL Level: (30 Marks)Документ11 страницMCQ CH 5-Electricity and Magnetism SL Level: (30 Marks)Hiya ShahОценок пока нет

- EDUC 5240 - Creating Positive Classroom EnvironmentsДокумент5 страницEDUC 5240 - Creating Positive Classroom EnvironmentsMay Phyo ThuОценок пока нет

- Lecture Notes - Design of RC Structure - Day 5Документ6 страницLecture Notes - Design of RC Structure - Day 5Tapabrata2013Оценок пока нет

- Compilation of Activities UBCVДокумент13 страницCompilation of Activities UBCVRenell Vincent RamosОценок пока нет

- Safety Data Sheet Highlights Key Hazards and ProtectionsДокумент7 страницSafety Data Sheet Highlights Key Hazards and ProtectionsOm Prakash RajОценок пока нет

- AIESEC - Exchange Participant (EP) GuidebookДокумент24 страницыAIESEC - Exchange Participant (EP) GuidebookAnonymous aoQ8gc1Оценок пока нет

- A Model For Blockchain-Based Distributed Electronic Health Records - 2016Документ14 страницA Model For Blockchain-Based Distributed Electronic Health Records - 2016Asif KhalidОценок пока нет

- APEC ArchitectДокумент6 страницAPEC Architectsarah joy CastromayorОценок пока нет

- Fundamentals of Analytics in Practice /TITLEДокумент43 страницыFundamentals of Analytics in Practice /TITLEAcad ProgrammerОценок пока нет

- Bioassay Techniques For Drug Development by Atta-Ur RahmanДокумент214 страницBioassay Techniques For Drug Development by Atta-Ur RahmanEmpress_MaripossaОценок пока нет

- Credit Suisse AI ResearchДокумент38 страницCredit Suisse AI ResearchGianca DevinaОценок пока нет

- College Management System Micro-ProjectДокумент27 страницCollege Management System Micro-ProjectNatashaОценок пока нет