Академический Документы

Профессиональный Документы

Культура Документы

Sequence of Purification Stages

Загружено:

Prakhar Patle0 оценок0% нашли этот документ полезным (0 голосов)

23 просмотров2 страницыpurification stages

Оригинальное название

Sequence of purification stages

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документpurification stages

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

23 просмотров2 страницыSequence of Purification Stages

Загружено:

Prakhar Patlepurification stages

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

Sequence of purification stages:

First purification stage = mechanical waste water treatment

First of all the waste water passes a bar screen which holds back larger solid objects such as paper, bottles,

branches and tins and removes them by means of an automated mechanical rake.

The sewage channel broadens out into the grit chamber, reducing the velocity of the incoming sewage and

thus allowing coarser particles such as gravel and sand, which are heavier than water, to settle at the bottom.

In the primary settlement tank the water is retained for approximately two hours. In this large rectangular or

round settlement tank fine suspended particles can settle as sludge at the bottom. This raw sludge is removed,

thickened (10.) and transferred to a digestion tank (11.). Light particles floating on the water's surface such as fat

and mineral oil are skimmed off and discharged into a separate tank.

The first three stages make up the first purification stage. As it involves purely mechanical treatment of the waste

water it is also referred to as the mechanical treatment stage. This stage removes approximately 30 per cent of

polluting matter from the inflowing raw waste water the plant has to process in total.

back to top

Second purification stage = biological waste water treatment

In the second or biological purification stage a natural process is used by passing the sewage liquor into an

aeration tank. In an activated sludge process oxygen is inserted into the liquor to create favourable conditions for

microorganisms which feed on solved organic particles in the effluent and accumulate the ingested matter.

During this process pollutants such as heavy metals are also ingested.

A large number of microorganisms form colonies which become visible as sludge flocs. These sludge flocs

settle at the bottom of the subsequent secondary settling pond or clarifier and are either returned to the activated

sludge process or pumped into the primary settling pond (3.) for sludge disposal. Hence, the removal of sewage

sludge from the effluent eliminates the bio-degradable pollutants. Smaller sewage treatment plants often use

trickling filters, i.e. round concrete tanks loosely filled with porous rocks which provide a large surface area

needed by the bacteria to settle. They form a continuous film ("biofilm" – similar to the sludge flocs of the

activated sludge process) over which the discharged effluent is passed. The mechanical and biological treatment

stages clean the effluent to a degree of approximately 90 per cent.

back to top

Third purification stage = additional waste water treatment

Today waste water is generally polluted with chemical substances such as nitrogen and phosphate which makes

it necessary to apply additional special processes.

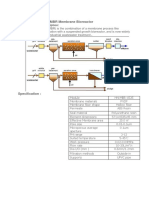

In the example shown in the illustration liquor containing phosphate from the secondary settling pond is

first of all fed into a flocculation tank

In this stage the effluent undergoes vigorous mixing and a dosing pump for precipitants simultaneously

dispenses a chemical solution in the liquor.

This precipitant reacts chemically with the phosphates and forms a water-insoluble compound and the

residual contaminants form flocs which settle in a subsequent clarifier as sludge. This sludge is thickened and

transferred to the digestion tank.

The cleaned waste water can now be discharged into the natural environment.

back to top

Sludge treatment and disposal

The sludge accumulating in stages and has a water content of approximately 98 per cent.

The addition of thickening agents helps to bring this down to 96 per cent, reducing the sludge volume by 50

per cent.

The sludge is subsequently discharged into a digestion tank. In an anaerobic fermentation process a digester

gas is formed at a temperature of 35 ° Celsius which consist of 2/3 of methane and 1/3 of carbon dioxide.

This gas is stored in a separate tank to be used as fuel for heating.

After approximately 4 weeks the digestion process is completed and the then odour-free sludge is discharged

into a sludge drying bed for dewatering.

Вам также может понравиться

- Oscar NiemeyerДокумент19 страницOscar NiemeyerPrakhar PatleОценок пока нет

- Eero SaarinenДокумент26 страницEero SaarinenPrakhar PatleОценок пока нет

- Antoni GaudiДокумент16 страницAntoni GaudiPrakhar PatleОценок пока нет

- Alvar AaltoДокумент25 страницAlvar AaltoPrakhar PatleОценок пока нет

- The Architect As DeveloperДокумент1 страницаThe Architect As DeveloperPrakhar PatleОценок пока нет

- Architect As DeveloperДокумент1 страницаArchitect As DeveloperPrakhar PatleОценок пока нет

- Political Architecture:: Prakhar Patle 0809AR161075Документ2 страницыPolitical Architecture:: Prakhar Patle 0809AR161075Prakhar PatleОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- PID NGOMA+Layout Option 1 & 2-WTP - PRINCIPAL OPTION 2Документ1 страницаPID NGOMA+Layout Option 1 & 2-WTP - PRINCIPAL OPTION 2manzi gratienОценок пока нет

- UNDERGROUND DRAINAGE SYSTEMS Rev 3Документ14 страницUNDERGROUND DRAINAGE SYSTEMS Rev 3Coolwecaleza Chinene100% (1)

- Quotation Mediambbr BDFДокумент8 страницQuotation Mediambbr BDFcitramuaraОценок пока нет

- How To Tackle Water Contamination and Diseases in India - Ideas From Gandhi Medical College, HyderabadДокумент13 страницHow To Tackle Water Contamination and Diseases in India - Ideas From Gandhi Medical College, HyderabaddrswetharanisavalaОценок пока нет

- Sewage Treatment Plants and DesignДокумент72 страницыSewage Treatment Plants and Designsatishkumarkolluru9809100% (1)

- Definition of Biochemical Oxygen Demand (BOD)Документ3 страницыDefinition of Biochemical Oxygen Demand (BOD)Firdaus DausОценок пока нет

- 2512 Tutorial Sheet 01Документ2 страницы2512 Tutorial Sheet 01aggrey noahОценок пока нет

- Module - 1 Introduction Design of Sanitary SewersДокумент32 страницыModule - 1 Introduction Design of Sanitary SewersFaran Masood FASTNUОценок пока нет

- Sistem Pengolahan Air Udara Limbah PadatДокумент52 страницыSistem Pengolahan Air Udara Limbah PadatMochammadBayuPraharaОценок пока нет

- Lecture 19 Coagulation Flocculation B 2014Документ49 страницLecture 19 Coagulation Flocculation B 2014ProsperОценок пока нет

- Description of Jambi City: 1. General Overview 1.1 LocationДокумент3 страницыDescription of Jambi City: 1. General Overview 1.1 LocationDini AryantiОценок пока нет

- Application of Low Fouling RO Membrane Elements For Reclamation of Municipal WastewaterДокумент17 страницApplication of Low Fouling RO Membrane Elements For Reclamation of Municipal Wastewaterzerocool86Оценок пока нет

- Wastewater Story QsДокумент6 страницWastewater Story QsTUSHAR DASHОценок пока нет

- (Satterfield, 2005) - (Satterfield, 2005) (Satterfield, 2005)Документ2 страницы(Satterfield, 2005) - (Satterfield, 2005) (Satterfield, 2005)abrar al mahmoodОценок пока нет

- Tutorial Sheet - Water PollutionДокумент8 страницTutorial Sheet - Water PollutionAbdoo YasserОценок пока нет

- Preliminary Treatment Primary Treatment Secondary Treatment Tertiary TreatmentДокумент22 страницыPreliminary Treatment Primary Treatment Secondary Treatment Tertiary Treatmentbefkadu ayalkieОценок пока нет

- WWT - Thai AnhДокумент88 страницWWT - Thai AnhHoàng Ngọc PhượngОценок пока нет

- Daily Report Analysis Sea Water Reverse Osmosis & Log Sheet: Month TrainДокумент10 страницDaily Report Analysis Sea Water Reverse Osmosis & Log Sheet: Month Trainmahesa34Оценок пока нет

- Green Nova Waste WaterДокумент2 страницыGreen Nova Waste WaterJeffrey YeeОценок пока нет

- Bdwbu: Cwi Ek ImvqbДокумент58 страницBdwbu: Cwi Ek ImvqbScientia Online CareОценок пока нет

- DENR Pollution Control Officer - List of RequirementsДокумент3 страницыDENR Pollution Control Officer - List of RequirementsMiguel Pillas0% (1)

- Wastewater and Excreta DisposalДокумент95 страницWastewater and Excreta DisposalRyeanKRumanoОценок пока нет

- Sources of Water Supply and Wastewater GenerationДокумент2 страницыSources of Water Supply and Wastewater GenerationRowel GanzonОценок пока нет

- Sanitary Engineering Chapter 7Документ82 страницыSanitary Engineering Chapter 7nisha chimariyaОценок пока нет

- Activated Sludge Combined With Powdered Activated Carbon (PACT Process) For The Petroleum Industry Wastewater Treatment: A ReviewДокумент10 страницActivated Sludge Combined With Powdered Activated Carbon (PACT Process) For The Petroleum Industry Wastewater Treatment: A ReviewAmmr MahmoodОценок пока нет

- New Techniques of Waste Water ManagementДокумент25 страницNew Techniques of Waste Water ManagementAbhishek AnandОценок пока нет

- Decentralized Wastewater Treatment Systems (Dewats) For Domestic SewageДокумент41 страницаDecentralized Wastewater Treatment Systems (Dewats) For Domestic SewageSudeept MaitiОценок пока нет

- EN8592 UNIT 2 Grey Water HarvestingДокумент14 страницEN8592 UNIT 2 Grey Water Harvesting2CIVIL3045 SONIYA AОценок пока нет

- SARIGUMBA - Summit One Vs Pollution Adjudication BoardДокумент2 страницыSARIGUMBA - Summit One Vs Pollution Adjudication BoardMiguel Louie Sarigumba III75% (4)

- MBR Membrane BioreactorДокумент10 страницMBR Membrane BioreactordeddyОценок пока нет