Академический Документы

Профессиональный Документы

Культура Документы

HVAC Calculation Control Bldg. (System-01)

Загружено:

VIREN GOHILИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

HVAC Calculation Control Bldg. (System-01)

Загружено:

VIREN GOHILАвторское право:

Доступные форматы

D

RT'

CE

Saudi Electricity Company الشركـة السعوديـة للكـهرباء

Western Region Branch

APPR'D

CHK'D

MA

HVAC LOAD CALCULATION

HVAC SYSTEM SOW DESCRIPTION:

The construction of Al Adel 380/110/13.8kV BSP Substation is planned in order to meet the

growing power demand of the Area. The Scope of Work in term of “Mechanical (HVAC)”

Providing new and independent HVAC facilities along with all necessary ductwork and

control system for the following Buildings;

IISSUED FOR BASE DESIGN SUBMITTAL

N 1. 380kV GIS Building. 5. Pump Room

O

TI

P

2. 110kV GIS Building. 6. Gate House.

3. Control Building. 7. Cable Tunnels.

RI R.

C NE

OW

S

4. 13.8kV Switchgear Building

ITS

E OF

D T

EN

NS

Air conditioning system for the Al Adel 380/110/13.8kV BSP Substation will be totally CO

EN

independent with 100% Standby facilities. For the 380kV GIS Building, 110kV GIS Building, ITT

WR

Control Building & 13.8kV Switchgear Building packaged type Direct Expansion units (PACU) E

TH

shall be used, as per the Project’s Technical Specification (PTS-11WN355). Each PACU unit

T

OU

is selected at 100% of zone(s) load; therefore, each zone(s) had 100% standby capacity.

TH

WI

That means each unit of the pair runs independently of the other and can fulfill the

NT

ME

concerned zones requirements as per the load demand/variation.

CU

DO

S

THI

OM

For Gate House, 01 No. Ceiling Mounted mini Split Type A/C Unit with 100% capacity will be FR

D

BY C provided. NE

TAI

OB

Ventilation System will be provided for the following zones as per PTS-11WN355;

AJE

BE

ALL

SH

APRIL 2014

RT

DATE 1. Cable Tunnel (Under 380kV Bldg.). PA

IN

OR

2. Outgoing Outdoor Cable Tunnel from 110kV Bldg.). LL

FU

IN

00 NO.

3. Cable Tunnel (Control Bldg. / 380kV Bldg.).

N

TIO

REVISIONS UC

4. Cable Tunnel (Control Bldg. / 110kV Bldg.).

OD

DRAWN

PR

RE

5. Cable Tunnel (110kV Bldg/Power Transformer).

NO

BY: Md. Nayeemullah CO.

Y

DATE: APRIL 2014 CIT

6. Pump Room. TRI

CHECKED

EC

EL

BY: Muhammad Afzal 7. Toilet. UDI

SA

OF

DATE: APRIL 2014 8. Battery Room. TY

ER

OPRG. DEPT

OP

HVAC System design shall comply with the requirement of following Standards.

PR

LE

BY SO

E

DATE:- 1. Project scope of work/Technical specification (PTS-11WN355) TH

E

ENG'G. DEPT.

AR

2. SEC Engineering Standard (TES-K-100.01) N

REI

BY:- HE

DATE:-

3. SEC Construction Standard (TCS-K-100) ED

AIN

NT

CERTIFIED. 4. American Society of Heating, Refrigeration & Air conditioning Engineers (ASHRAE).

CO

N

TIO

BY:-

5. SMACNA for Design & Construction of Low Pressure Ducts.

MA

OR

DATE:-

INF

E

DRAWING TITLE INDEX PLANT DRAWING NO. SHEET NO. REV NO.

TH

THIS DRAWING IS NOT D

TO BE USED FOR

HVAC SYSTEM DESIGN CALCULATION AN

CONSTRUCTION OF

FOR ORDERING CONTROL BUILDING @SYSTEM # 01 A JD526 WE - 254756 Page 1 of 21 00

ING

AW

MATERIALS UNTIL

DR

CERTIFIED AND

AL ADEL 380/110/13.8kV BSP S

JEDDAH SAUDI ARABIA JOB ORDER NO. 4400001340 DWG. CONT. SHT. WE - 254702

THI

DATED

SEC-ERB CAD-E (2002/03)

WORD

D

RT'

CE

Saudi Electricity Company الشركـة السعوديـة للكـهرباء

Western Region Branch

APPR'D

MA SYSTEM DESIGN DESCRIPTION:

CHK'D

System has been designed to provide constant volume application to maintain the required

inside temperature of 77o F (25o C) under all outdoor summer ambient conditions.

For each building, two pairs of Packaged Type A/C units are used. Each pair of two units runs

independently controlled by their concerned zones / areas.

The Packaged A/C units are located outdoor the Substation and zones description are

mentioned below;

IISSUED FOR BASE DESIGN SUBMITTAL

380kV GIS Building:

O

TI

P

As per Tender Layout Drawing # WT - 908465, Due to large size of 380kV GIS

RI R.

C NE

Building 02 set of Air-Conditioning Units shall be provided for 380kV GIS Building.

OW

S

ITS

E OF

D T

1st set of Air Conditioning unit (System # 01 consisting of PACU-1A & PACU-1B) and 2 nd

EN

NS

CO

set of Air Conditioning unit (System # 02 consisting of PACU-2A & PACU-2B) is used for EN

ITT

below mentioned zones; WR

E

•

TH

380kV GIS Room T

OU

TH

WI

• Store Room

NT

ME

CU

DO

Hence the System # 01 & 02 has total 02 separate/independent Zones.

S

THI

OM

FR

D

BY C 110kV GIS Building: NE

TAI

AJE OB

As per Tender Layout Drawing # WT - 908465, Due to large size of 110kV GIS

BE

ALL

Building 02 set of Air-Conditioning Units shall be provided for 110kV GIS Building.

SH

APRIL 2014

RT

PA

DATE IN

1st set of Air Conditioning unit (System # 03 consisting of PACU-3A & PACU-3B) and 2 nd

OR

LL

FU

00 NO. set of Air Conditioning unit (System # 04 consisting of PACU-4A & PACU-4B) is used for IN

N

REVISIONS below mentioned zones; TIO

UC

•

OD

DRAWN 110kV GIS Room PR

RE

NO

BY: Md. Nayeemullah CO.

•

Y

DATE: APRIL 2014 Cable Basement CIT

TRI

CHECKED

EC

EL

• Store Room

UDI

BY: Muhammad Afzal SA

OF

DATE: APRIL 2014 TY

Hence the System # 03 & 04 has total 03 separate/independent Zones.

ER

OPRG. DEPT

OP

PR

Control Building:

LE

BY SO

E

DATE:- TH

As per Tender Layout Drawing # WT - 908465, Due to large size of Control Building

E

ENG'G. DEPT.

AR

02 set of Air-Conditioning Units shall be provided for Control Building.

N

REI

BY:- HE

ED

DATE:-

1st set of Air Conditioning unit (System # 05 consisting of PACU-5A & PACU-5B) is used for

AIN

NT

CERTIFIED.

CO

below mentioned zones; N

TIO

BY:- MA

OR

DATE:-

INF

E

DRAWING TITLE INDEX PLANT DRAWING NO. SHEET NO. REV NO.

TH

THIS DRAWING IS NOT D

TO BE USED FOR

HVAC SYSTEM DESIGN CALCULATION AN

CONSTRUCTION OF

FOR ORDERING CONTROL BUILDING @SYSTEM # 01 A JD526 WE - 254756 Page 2 of 21 00

ING

AW

MATERIALS UNTIL

DR

CERTIFIED AND

AL ADEL 380/110/13.8kV BSP S

JEDDAH SAUDI ARABIA JOB ORDER NO. 4400001340 DWG. CONT. SHT. WE - 254702

THI

DATED

SEC-ERB CAD-E (2002/03)

WORD

D

RT'

CE

Saudi Electricity Company الشركـة السعوديـة للكـهرباء

Western Region Branch

APPR'D

MA • Control & Relay Room & Raised Floor

CHK'D

Hence the System #05 has total 02 separate/independent Zones.

2nd set of Air Conditioning unit (System # 06 consisting of PACU-6A & PACU-6B) is used

for below mentioned zones;

• Associated rooms/ Cable Basement.

Hence the System #06 has total 15 separate/independent Zones.

IISSUED FOR BASE DESIGN SUBMITTAL

N 13.8kV Switchgear Building:

O

As per Tender Layout Drawing # WT - 908465, 01 set of Air-Conditioning Units shall

TI

P

RI

C be provided for 13.8kV Switchgear Building. R.

NE

OW

S

ITS

1st set of Air Conditioning unit (System # 07 consisting of PACU-7A & PACU-7B) is used for

E OF

D T

below mentioned zones;

EN

NS

•

CO

13.8kV Switchgear Building

EN

ITT

WR

E

•

TH

Cable Basement

T

OU

TH

WI

Hence the System #07 has total 02 separate/independent Zones.

NT

ME

CU

DO

S

THI

SYSTEM OPERATION: (NORMAL MODE)

OM

FR

D

NE

BY C TAI

AJE

Each Packaged type air conditioning unit (PACU) is equipped with supply air (MVD), OB

BE

Return/Re-circulated air (MVD) along with Outdoor air (VD) Damper. These Dampers control

ALL

SH

APRIL 2014

and regulate the airflow rates under different load conditions. Separate ducting from each

RT

PA

Unit of the pair combines into one common ducting (sized for 100% of Supply air from single

DATE IN

OR

Unit). The supply air is ducted while the return air is free. The volume damper for supply air

LL

FU

is motorized while the other volume dampers are manually operated. The duct smoke

IN

00 NO. N

detector is mounted on the common supply & return air duct.

TIO

REVISIONS UC

OD

DRAWN

PR

RE

BY: Md. Nayeemullah The Fresh Air or Outdoor Air is supplied through the Sand Trap Louver with Wire Mesh NO

CO.

DATE: APRIL 2014 Screen & Aluminum filter. The Fresh Air intake from the Sand Trap Louver arrangement is Y

CIT

CHECKED

connected to the openings provided in PACU unit. TRI

EC

EL

UDI

BY: Muhammad Afzal

If the PACU Unit is not running i.e. in standby mode, then all the Motorized volume control

SA

OF

DATE: APRIL 2014

dampers (MVD) is in closed position. For the Duty Unit, the Supply Dampers (MVD) is fully

TY

ER

OPRG. DEPT opened; while Return Air damper (MVD) is also operating respectively and Outdoor Air

OP

PR

Damper (MVD) is set at minimum open position. The minimum open position for Outdoor Air

LE

BY SO

E

DATE:- Damper is that which provides the minimum Flow Rate of Outdoor Air required for ventilation TH

E

ENG'G. DEPT. and pressurization of zones and maintains a +ve pressure of 0.2” of W.G. AR

N

REI

BY:- HE

DATE:-

The Duty & standby units will operate on a shift basis. The changeover from duty to standby ED

AIN

unit or vice-versa can be either automatic or manual. NT

CERTIFIED.

CO

N

TIO

BY:- MA

OR

DATE:-

INF

E

DRAWING TITLE INDEX PLANT DRAWING NO. SHEET NO. REV NO.

TH

THIS DRAWING IS NOT D

TO BE USED FOR

HVAC SYSTEM DESIGN CALCULATION AN

CONSTRUCTION OF

FOR ORDERING CONTROL BUILDING @SYSTEM # 01 A JD526 WE - 254756 Page 3 of 21 00

ING

AW

MATERIALS UNTIL

DR

CERTIFIED AND

AL ADEL 380/110/13.8kV BSP S

JEDDAH SAUDI ARABIA JOB ORDER NO. 4400001340 DWG. CONT. SHT. WE - 254702

THI

DATED

SEC-ERB CAD-E (2002/03)

WORD

D

RT'

CE

Saudi Electricity Company الشركـة السعوديـة للكـهرباء

Western Region Branch

APPR'D

MA In “Automatic” mode, the Changeover from duty to Standby unit is either on the Time Basis

CHK'D

or due to failure of running unit. The time Basis changeover can be set from one day to one

week, as required. The 7-day per week – 24 hour per day timer shall take care of scheduling

the operation of the two units in order to make sure that the two Units works equally. Also in

case of failure of the running PACU unit due to any reason, then the operation shall be

transferred automatically to the standby PACU unit. “Manually” the changeover can be

activated any time from the HVAC Control Panel.

The temperature controller (or Thermostat) will decide whether cooling or heating is required

or not, by comparing the set-point with actual space temperature, If cooling is required then

IISSUED FOR BASE DESIGN SUBMITTAL

N DX cooling stages have to be activated/deactivated based on the cooling demand to meet

O

TI the set-point, which is adjustable from the controller display. If heating is required then the

P

RI

duct mounted electric heater is activated. R.

C NE

The Temperature controls shall be provided as part of the AC unit by the Control Panel

OW

S

ITS

E OF

D

Supplier/Installer. The Thermostat shall be cooling and heating type with a minimum of 2 T

EN

stages of Mechanical Cooling / Heating. The Thermostat shall be mounted on the return air NS

CO

stream @ 1.5M above F.F.L. The Thermostat shall be provided with lockable transparent EN

ITT

cover. WR

E

TH

T

OU

TH

SMOKE PURGE MODE:

WI

NT

ME

CU

DO

In case the Smoke Detector installed at the common Supply and Return air Ducts detects

S

THI

smoke or the FACP sends a signal indicating smoke presence, then the Duty Packaged unit

OM

FR

shall be automatically de-energized and all temperature control function shall stop. At such

D

NE

condition, an indication shall be sent to the HVAC control Panel also.

BY C TAI

AJE OB

BE

ALL

During the Smoke purge operation all PACU’s (Duty and standby) dampers (Supply and

SH

APRIL 2014

RT

PA

DATE

Return air) will be closed and smoke purge / exhaust damper and Return Opening MF/SD IN

OR

will be opened fully to clear the smoke and product of combustion from the concerned zone. LL

FU

00 NO. Smoke Purge Fan operates during smoke purging operation i.e. to exhaust smoke from the IN

N

REVISIONS zones in the event of fire or heavy smoke conditions. It should be possible to manually run TIO

UC

the Smoke Purge Fan either from the HVAC Control Panel or from Smoke Purge Fan

OD

DRAWN

PR

isolating switch or from Remote Selector Switch located outside near the main door of

RE

NO

BY: Md. Nayeemullah

Control Room.

CO.

Y

DATE: APRIL 2014 CIT

TRI

CHECKED

After the smoke purging operation ends, it would only be possible to re-start the Air

EC

EL

UDI

BY: Muhammad Afzal Conditioning units by re-setting the HVAC Control Panel. SA

OF

DATE: APRIL 2014 TY

ER

OPRG. DEPT

OP

PR

SYSTEM DESIGN CRITERIA:

LE

BY SO

E

DATE:- TH

E

ENG'G. DEPT. For calculating air-conditioning load of Al Adel 380/110/13.8kV BSP Substation, reference is AR

N

BY:- taken from Project Technical Specification (PTS-11WN355) and other inputs / data are REI

HE

DATE:-

adopted from ASHRAE standards or SEC Engineering Standards. ED

AIN

NT

CERTIFIED.

CO

N

TIO

BY:- MA

OR

DATE:-

INF

E

DRAWING TITLE INDEX PLANT DRAWING NO. SHEET NO. REV NO.

TH

THIS DRAWING IS NOT D

TO BE USED FOR

HVAC SYSTEM DESIGN CALCULATION AN

CONSTRUCTION OF

FOR ORDERING CONTROL BUILDING @SYSTEM # 01 A JD526 WE - 254756 Page 4 of 21 00

ING

AW

MATERIALS UNTIL

DR

CERTIFIED AND

AL ADEL 380/110/13.8kV BSP S

JEDDAH SAUDI ARABIA JOB ORDER NO. 4400001340 DWG. CONT. SHT. WE - 254702

THI

DATED

SEC-ERB CAD-E (2002/03)

WORD

D

RT'

CE

Saudi Electricity Company الشركـة السعوديـة للكـهرباء

Western Region Branch

APPR'D

MA

CHK'D

DESIGN PSYCHROMETRIC CONDITIONS:

SEASON OUTDOOR CONDITION INDOOR CONDITION

48 C or 118 F Dry bulb

IISSUED FOR BASE DESIGN SUBMITTAL

Summer Electrical Equipments Rooms

O

TI temperature & 27C or 81F Wet

P

RI

C bulb temperature. 25 C or 77.0 F Dry bulb R.

NE

OW

S

temperature & 50 % RH for all

ITS

E

14 C or 57 F Dry bulb

OF

D T

Winter zones.

EN

NS

temperature CO

EN

ITT

WR

E

Refer Attachment: “1” for the “Cooling Design Conditions” for Jeddah. We had taken the

TH

T

ambient dry bulb condition & ambient wet bulb condition as per PTS-11WN355.

OU

TH

WI

NT

ME

CU

DO

SITE INFORMATION: S

THI

OM

FR

The site conditions adopted for Load calculation are given below;

D

NE

BY C TAI

AJE OB

BE

ALL

SITE DATA VALUE

SH

APRIL 2014

RT

PA

DATE IN

Location Jeddah

OR

LL

FU

21.51 (North)

IN

00 NO.

Latitude N

TIO

REVISIONS UC

Longitude 39.13 (East) OD

DRAWN

PR

RE

BY: Md. Nayeemullah Altitude 7m (26ft)

NO

CO.

Y

DATE: APRIL 2014

Mean daily range 27F

CIT

TRI

CHECKED

EC

Max wind velocity 22 kph (14 mph)

EL

UDI

BY: Muhammad Afzal SA

Wind Direction

OF

DATE: APRIL 2014 North TY

ER

OPRG. DEPT

Required building pressurization

OP

+ve Pressurization of 50 Pa (0.2” W.G) in all PR

LE

BY SO

DATE:-

zone except Battery Room, which is to be E

TH

E

ENG'G. DEPT. Neutrally pressurized.

AR

N

REI

BY:- HE

ED

DATE:- Refer Attachment: “1” for the “Site Conditions” for Jeddah. We had taken the site data from AIN

NT

CERTIFIED. Geological Survey from Internet. CO

N

TIO

BY:- MA

OR

DATE:-

INF

E

DRAWING TITLE INDEX PLANT DRAWING NO. SHEET NO. REV NO.

TH

THIS DRAWING IS NOT D

TO BE USED FOR

HVAC SYSTEM DESIGN CALCULATION AN

CONSTRUCTION OF

FOR ORDERING CONTROL BUILDING @SYSTEM # 01 A JD526 WE - 254756 Page 5 of 21 00

ING

AW

MATERIALS UNTIL

DR

CERTIFIED AND

AL ADEL 380/110/13.8kV BSP S

JEDDAH SAUDI ARABIA JOB ORDER NO. 4400001340 DWG. CONT. SHT. WE - 254702

THI

DATED

SEC-ERB CAD-E (2002/03)

WORD

D

RT'

CE

Saudi Electricity Company الشركـة السعوديـة للكـهرباء

Western Region Branch

APPR'D

MA

CHK'D

ZONE WISE LOAD DATA:

The HVAC load is calculated on the “zone basis” .The variable load inputs for each zone is

described below:

IISSUED FOR BASE DESIGN SUBMITTAL

N BUILDING WALL & FLOOR AREAS:

O

TI

P The zone’s areas are calculated using the Substation building plan. Refer Civil &

Architectural drawings for S/S building plan showing the room’s dimensions / area and their

RI R.

C NE

orientation.

OW

S

ITS

E OF

D T

BUILDING MATERIAL’S U-VALUES:

EN

NS

CO

EN

ITT

The U-Value is calculated based on the actual material used. All values for “R” (Resistance) WR

E

are extracted from ASHRAE GRP 158, cooling and heating load calculation manual, Table TH

T

3.1A unless otherwise noted. For detail U-value calculation, refer Attachment: “A” (Co- OU

TH

WI

Overall “U” Values ASHRAE NT

Building Element ME

(Btu / Hr. (Ft²) (ºF) Reference CU

DO

S

THI

Exposed Roof (Double T Slab w/ False Ceiling) 0.043 12 #

OM

FR

D

Pre-cast Wall 0.08 B

NE

BY C TAI

AJE OB

Internal Concrete Wall 0.31 B

BE

ALL

SH

APRIL 2014

RT

DATE Metal Door 0.14 G PA

IN

OR

LL

efficient of Heat Transmission Calculation: 7 pages). The U-Values adopted for different FU

IN

00 NO.

Architectural elements of Al Adel 380/110/13.8kV BSP Substation is summarized below.

N

TIO

REVISIONS UC

OD

DRAWN

PR

RE

NO

BY: Md. Nayeemullah CO.

Y

DATE: APRIL 2014 CIT

TRI

CHECKED

EC

EL

UDI

BY: Muhammad Afzal SA

OF

DATE: APRIL 2014 TY

ER

OPRG. DEPT

OP

PR

LE

BY SO

E

DATE:- TH

E

ENG'G. DEPT. (Based on the actual Insulation U-Value and SEC Approved R-Value data)

AR

N

REI

BY:- HE

Please note that only Control Room, Communication Room, Conference Room, Relay Test

ED

DATE:-

AIN

NT

CERTIFIED. Room, Office, Fire Fighting Room, Corridor & Toilet are provided with False Ceiling while CO

N

TIO

BY:- MA

OR

DATE:-

INF

E

DRAWING TITLE INDEX PLANT DRAWING NO. SHEET NO. REV NO.

TH

THIS DRAWING IS NOT D

TO BE USED FOR

HVAC SYSTEM DESIGN CALCULATION AN

CONSTRUCTION OF

FOR ORDERING CONTROL BUILDING @SYSTEM # 01 A JD526 WE - 254756 Page 6 of 21 00

ING

AW

MATERIALS UNTIL

DR

CERTIFIED AND

AL ADEL 380/110/13.8kV BSP S

JEDDAH SAUDI ARABIA JOB ORDER NO. 4400001340 DWG. CONT. SHT. WE - 254702

THI

DATED

SEC-ERB CAD-E (2002/03)

WORD

D

RT'

CE

Saudi Electricity Company الشركـة السعوديـة للكـهرباء

Western Region Branch

APPR'D

MA 380kV GIS Room, 110kV GIS Room, 13.8kV Switchgear Room, Auxiliary Room, Store

CHK'D

Room’s, Cable Basement & Battery Room are without False Ceiling.

AIR CONDITIONED ZONES:

Keeping with the Technical specification and SEC requirements the complete building is to

be Air-conditioned, under this SOW.

For determining the HVAC load, the Building is divided into 02 separate zones, keeping in

IISSUED FOR BASE DESIGN SUBMITTAL

N

O

view its orientation, purpose, and load profile.

TI

The operation hours for the A/C zones are 24 Hours. Therefore, equipment is to be run

P

RI R.

continuously.

C NE

OW

S

ITS

E OF

D

OCCUPANCY LOAD:

T

EN

NS

CO

EN

The Substation is of unmanned type; but occupancy is considered in Control Room. This can ITT

WR

be considered as “office space”. As per ASHRAE’s Table for “Rates of Heat gain from E

TH

occupants of conditioned spaces”, for standing; light work, walking, rate of heat gain are;

T

OU

TH

WI

Adjusted Sensible heat gain = 73 Watts = 250 Btu / Hr

NT

ME

CU

Adjusted Latent heat gain = 59 Watts = 200 Btu / Hr

DO

S

THI

OM

(Refer Attachment: “B”) FR

D

NE

BY C TAI

AJE

Hence, for determining the occupant heat load, we will use following equation; OB

BE

ALL

SH

APRIL 2014

QPS = NP x 250

RT

PA

DATE IN

QPL = NP x 200

OR

LL

FU

Where

IN

00 NO. N

QPS = Occupant’s Sensible Heat Gain

TIO

REVISIONS UC

OD

DRAWN

PR

QPL = Occupant’s Latent Heat Gain RE

NO

BY: Md. Nayeemullah CO.

DATE: APRIL 2014 NP = No. of person / occupant in the zone Y

CIT

TRI

CHECKED

EC

EL

For occupancy in different zones, following estimates are used;

UDI

BY: Muhammad Afzal SA

OF

DATE: APRIL 2014 TY

ER

OPRG. DEPT

OP

PR

BY

Sr. No. Zone / Room Occupancy LE

SO

E

DATE:- TH

E

ENG'G. DEPT. 1 Control & Relay Room 06

AR

N

REI

BY:-

2 Control & Relay Room (Raised Floor)

HE

01 ED

DATE:-

AIN

3 ENT lobby (Staircase # 02)

NT

CERTIFIED. Nil CO

N

TIO

BY:- MA

OR

DATE:-

INF

E

DRAWING TITLE INDEX PLANT DRAWING NO. SHEET NO. REV NO.

TH

THIS DRAWING IS NOT D

TO BE USED FOR

HVAC SYSTEM DESIGN CALCULATION AN

CONSTRUCTION OF

FOR ORDERING CONTROL BUILDING @SYSTEM # 01 A JD526 WE - 254756 Page 7 of 21 00

ING

AW

MATERIALS UNTIL

DR

CERTIFIED AND

AL ADEL 380/110/13.8kV BSP S

JEDDAH SAUDI ARABIA JOB ORDER NO. 4400001340 DWG. CONT. SHT. WE - 254702

THI

DATED

SEC-ERB CAD-E (2002/03)

WORD

D

RT'

CE

Saudi Electricity Company الشركـة السعوديـة للكـهرباء

Western Region Branch

APPR'D

MA

CHK'D LIGHTING LOAD:

The Lightings load in each air-conditioned room is taken from actual Lighting Calculation, as

adopted in the Detail Electrical Design.

The following equation will be used to calculate the heat dissipation from Light Fixtures in

individual rooms / zones;

QLIG. = 3.41 X W X FU X FS

(Refer ASHRAE Fundamental 1997)

IISSUED FOR BASE DESIGN SUBMITTAL

N Where;

QLIG. = Sensible Heat Gain from Light Fixtures (Btu/Hr)

O

TI

P

RI

C W = Total Wattage of Light Fixtures R.

NE

OW

S

FU = Light Fixtures Usage Factor = 1.0

ITS

E OF

D T

FS = Ballast Factor Allowance

EN

NS

CO

We have;

EN

ITT

WR

Ballast Factor for Fluorescent Lamps = 1.20

E

TH

T

OU

Ballast Factor for Incandescent Lamps = 1.00 TH

WI

NT

ME

CU

The heat dissipation due to the lighting load is summarized below; DO

S

THI

OM

FR

Lighting Heat D

NE

Sr. No. Zone / Room Dissipation

BY C TAI

AJE OB

(Watts)

BE

ALL

SH

APRIL 2014

1 Control & Relay Room

RT

DATE 12,715 PA

IN

2 Control & Relay Room (Raised Floor)

OR

Nil

LL

FU

IN

00 NO.

3 ENT lobby (Staircase # 02) 500

N

TIO

REVISIONS UC

OD

DRAWN For lighting load in each room, refer Table: “Heat Dissipation Detail” (Refer Attachment: “C”). PR

RE

NO

BY: Md. Nayeemullah CO.

EQUIPMENT LOAD:

Y

DATE: APRIL 2014 CIT

TRI

CHECKED

EC

For Equipment Heat Dissipation, the reference is taken from “Equipment Layout”. Equipment

EL

UDI

BY: Muhammad Afzal SA

DATE: APRIL 2014

heat dissipation is based on either data provided by the Manufacturer or Supplier or else OF

TY

data is adopted for similar type of panels, distribution board etc from other similar size ER

OPRG. DEPT

OP

projects. In either case the reference is provided for the data adopted for Equipment’s heat PR

LE

BY

dissipation. Refer Attachment: “D“, for Heat dissipation data adopted with panel details. SO

E

DATE:- TH

E

ENG'G. DEPT. Following values are taken for equipment heat dissipation in different rooms. AR

N

REI

BY:- HE

ED

DATE:- Equipment Heat AIN

Sr. No. Zone / Room NT

CERTIFIED. Dissipation (Watts)

CO

N

TIO

BY:-

1 Control & Relay Room

MA

51,512

OR

DATE:-

INF

2 Control & Relay Room (Raised Floor)

E

DRAWING TITLE INDEX PLANT 10,000

DRAWING NO. SHEET NO. REV NO.

TH

THIS DRAWING IS NOT D

TO BE USED FOR

HVAC SYSTEM DESIGN CALCULATION AN

CONSTRUCTION OF

FOR ORDERING

3 ENT lobby (Staircase # 02)

CONTROL BUILDING @SYSTEM # 01 A JD526 WE - 254756

Nil Page 8 of 21 00

ING

AW

MATERIALS UNTIL

DR

CERTIFIED AND

AL ADEL 380/110/13.8kV BSP S

JEDDAH SAUDI ARABIA JOB ORDER NO. 4400001340 DWG. CONT. SHT. WE - 254702

THI

DATED

SEC-ERB CAD-E (2002/03)

WORD

D

RT'

CE

Saudi Electricity Company الشركـة السعوديـة للكـهرباء

Western Region Branch

APPR'D

MA

CHK'D

“Heat Dissipation Data” (Refer Attachment: “D”)

OUTDOOR AIR LOAD:

IISSUED FOR BASE DESIGN SUBMITTAL

N

O

TI As per SEC Standard, it is necessary to provide a slight positive internal pressure for

keeping the outdoor dust borne air out and also for proper zone pressurization. For

P

RI R.

calculating the Outdoor or Fresh air quantity, we need to calculate the Exhaust,

C NE

OW

S

Pressurization and Ex-filtration air quantity respectively and then we will calculate the total

ITS

E OF

D

outdoor air quantity based on the criteria set by SEC Standards.

T

EN

NS

For calculating the Building pressurization / ex-filtration air quantity, we have; CO

EN

Site max outdoor temperature = 49ºC = 120ºF ITT

WR

Outdoor wind velocity = 37 kph = 23 mph E

TH

(Refer Attachment: “1” sht. 1 of 2) T

OU

Prevailing wind direction = North of East

TH

WI

Building Pressurization = 0.2 inch of W.G. = 50 Pa

NT

ME

(As per TES-P-119)

CU

DO

S

THI

OM

FR

A.) Wind Pressurization:

D

NE

BY C TAI

AJE OB

BE

The Wind Pressure (or velocity head), caused by the moving air is given by; ALL

SH

APRIL 2014

RT

PA

Pw = C 1 C p V2

DATE IN

OR

2

LL

FU

(Refer ASHRAE Fundamentals 1997, Chap: 25 – Equ. #25)

IN

00 NO. N

Where;

TIO

REVISIONS UC

Pw = Wind surface pressure relative to Static pr. in

OD

DRAWN

PR

RE

BY: Md. Nayeemullah undisturbed flow (inch of W.G.) NO

CO.

DATE: APRIL 2014 C1 = Unit conversion factor = 0.0129 Y

CIT

Cp = Wind surface pr. coefficient. (Dimensionless) TRI

CHECKED

EC

= Air density (lbm / ft3) = 0.06 lbm / ft3

EL

UDI

BY: Muhammad Afzal

V = Wind speed (mph) = 23 mph (Specification)

SA

OF

DATE: APRIL 2014 TY

ER

OPRG. DEPT Cp is a function of location on building envelope and wind direction. For undisturbed surface

OP

PR

its value is taken as unity. Putting the values;

LE

BY SO

E

DATE:- TH

E

ENG'G. DEPT.

AR

N

BY:- Pw = 0.0129 x 1.0 x 0.06 x (23)2 REI

HE

DATE:-

2 ED

AIN

NT

CERTIFIED. = 0.2 inches of W.G.

CO

N

TIO

BY:- MA

OR

DATE:-

INF

E

DRAWING TITLE INDEX PLANT DRAWING NO. SHEET NO. REV NO.

TH

THIS DRAWING IS NOT D

TO BE USED FOR

HVAC SYSTEM DESIGN CALCULATION AN

CONSTRUCTION OF

FOR ORDERING CONTROL BUILDING @SYSTEM # 01 A JD526 WE - 254756 Page 9 of 21 00

ING

AW

MATERIALS UNTIL

DR

CERTIFIED AND

AL ADEL 380/110/13.8kV BSP S

JEDDAH SAUDI ARABIA JOB ORDER NO. 4400001340 DWG. CONT. SHT. WE - 254702

THI

DATED

SEC-ERB CAD-E (2002/03)

WORD

D

RT'

CE

Saudi Electricity Company الشركـة السعوديـة للكـهرباء

Western Region Branch

APPR'D

MA B.) Make-up (Outside) Air Required to Pressurized the conditioned Space:

CHK'D

Using;

QP = Qexh + P0 Qexh + P0 Q x + Qx (B)

PI PI

Where;

QP = Amount of Ventilation (outdoor) air for required space

Pressurization to the design static pressure (Cfm)

Qexh = Exhaust air (Cfm) from conditioned Zone

IISSUED FOR BASE DESIGN SUBMITTAL

N Qx = Ex-filtration air (Cfm) from conditioned zone

O

TI PO = Outside static pressure on building wall (inches of W.G.)

P

RI

PI = Inside static pressure on building space (inches of W.G.) R.

C NE

S

E

Now, OW

ITS

OF

D T

PI = PS PO

EN

+ NS

Where;

CO

EN

ITT

WR

Ps = Required space pressurization (inches of W.G.)

E

TH

T

PS = 0.2 in of W.G (as req. by specification) OU

TH

PO= Pw = 0.2 in of W.G (as calculated previously) WI

NT

ME

CU

Therefore; DO

S

THI

OM

PI = 0.2// + 0.2//

FR

D

= 0.4// of W.G

NE

BY C TAI

AJE OB

BE

Hence inside required pressure on the building is 0.4// of W.G ALL

SH

APRIL 2014

RT

PA

DATE IN

C.) Ex-filtration Air from Conditioned Space

OR

LL

FU

IN

00 NO.

Using;

N

TIO

REVISIONS UC

OD

DRAWN

PR

RE

NO

BY: Md. Nayeemullah CO.

Y

DATE: APRIL 2014

=

CIT

Qx (Cs x t) + (Cw x V2)

TRI

CHECKED

EC

EL

BY: Muhammad Afzal Where; UDI

SA

OF

DATE: APRIL 2014

Cs = Stack Co-efficient (Cfm2 / in4.0F)

TY

AL

ER

OPRG. DEPT

= (Ref: ASHRAE

0.0150 Cfm2Fundamental;

/ in4.0F Chap: 25) OP

PR

LE

BY (Refer ASHRAE Fundamentals 2009, Ch. 16, Table: 4) SO

E

DATE:- Cw = Wind Co-efficient (Cfm2 / in4. Mph2)

TH

E

ENG'G. DEPT. Cw = 0.0119 Cfm2 / in4. Mph2

AR

N

REI

BY:- (Refer ASHRAE Fundamentals 2009*, Ch. 16, Table: 5) HE

ED

DATE:- t = Average temperature difference between

AIN

NT

CERTIFIED. Indoor – outdoor space. (0F)

CO

N

TIO

BY:-

t = Tspace – Toutdoor

MA

OR

DATE:-

INF

E

DRAWING TITLE INDEX PLANT DRAWING NO. SHEET NO. REV NO.

TH

THIS DRAWING IS NOT D

TO BE USED FOR

HVAC SYSTEM DESIGN CALCULATION AN

CONSTRUCTION OF

FOR ORDERING CONTROL BUILDING @SYSTEM # 01 A JD526 WE - 254756 Page 10 of 21 00

ING

AW

MATERIALS UNTIL

DR

CERTIFIED AND

AL ADEL 380/110/13.8kV BSP S

JEDDAH SAUDI ARABIA JOB ORDER NO. 4400001340 DWG. CONT. SHT. WE - 254702

THI

DATED

SEC-ERB CAD-E (2002/03)

WORD

D

RT'

CE

Saudi Electricity Company الشركـة السعوديـة للكـهرباء

Western Region Branch

APPR'D

MA = 77.0 – 120 = - 43 0F

CHK'D V = Average wind velocity = 23 mph

Putting the values;

Qx = [0.0150 x (-43)] + [0.0119 x (23)2]

AL

Qx = 2.377 Cfm / in2

AL

Or

IISSUED FOR BASE DESIGN SUBMITTAL

N

O

Qx = 2.377 X AL (Cfm)

TI

P

RI R.

Where;

C NE

OW

S

ITS

AL = Effective Air leakage area, (in2 / ft 2)

E OF

D T

Air leakage can take place through doors, windows, crawl space etc; for the Control & Relay EN

NS

Building air leakage can only take place through the doors opening outside the building. CO

EN

ITT

WR

Using;

E

TH

AL = AD1 x DL1 + AD2 x DL2 + ..........+ ADN x DLN

T

OU

TH

WI

Where;

NT

ME

CU

AL = Effective Air leakage area. DO

S

AD = Area of door opening outside. THI

OM

DL = Air leakage through door FR

D

BY C N = No: of Doors of each type NE

TAI

AJE OB

BE

D.) Zone Ex-filtration Air :

ALL

SH

APRIL 2014

RT

For the zones / rooms in the HVAC system, the outdoors is located in the Control & Relay

PA

DATE IN

Room.

OR

LL

FU

IN

00 NO. N

REVISIONS

For Substation building different sizes of outward doors used the detail of which are as TIO

UC

follows; OD

DRAWN

PR

RE

NO

BY: Md. Nayeemullah

Since there is no door directly exposed to ambient for Control & Relay Room, the Ex- CO.

Y

DATE: APRIL 2014

Filtration Air for this zone will be considered as nil.

CIT

TRI

CHECKED

EC

EL

UDI

BY: Muhammad Afzal

Qx = 0 Cfm SA

OF

DATE: APRIL 2014 TY

ER

OPRG. DEPT

OP

PR

E.) Zone Exhaust Air :

LE

BY SO

E

DATE:- TH

From Air conditioned spaces Al Adel Control & Relay Room have no any exhaust air.

E

ENG'G. DEPT.

AR

N

REI

BY:-

HE

Qexh = 0 Cfm ED

DATE:-

AIN

NT

CERTIFIED.

CO

F.) Zone Pressurization Air : N

TIO

BY:- MA

OR

DATE:-

INF

E

DRAWING TITLE INDEX PLANT DRAWING NO. SHEET NO. REV NO.

TH

THIS DRAWING IS NOT D

TO BE USED FOR

HVAC SYSTEM DESIGN CALCULATION AN

CONSTRUCTION OF

FOR ORDERING CONTROL BUILDING @SYSTEM # 01 A JD526 WE - 254756 Page 11 of 21 00

ING

AW

MATERIALS UNTIL

DR

CERTIFIED AND

AL ADEL 380/110/13.8kV BSP S

JEDDAH SAUDI ARABIA JOB ORDER NO. 4400001340 DWG. CONT. SHT. WE - 254702

THI

DATED

SEC-ERB CAD-E (2002/03)

WORD

D

RT'

CE

Saudi Electricity Company الشركـة السعوديـة للكـهرباء

Western Region Branch

APPR'D

MA Now

CHK'D (B) QP = 0 + (0.1/0.3)0+ (0.1/0.3) 0 + 0

= 0+0+0+0

Taking;

QP = 0 Cfm

IISSUED FOR BASE DESIGN SUBMITTAL

N

O

TI

P

RI R.

C NE

OW

S

ITS

E OF

D T

EN

NS

G.) Estimating Outdoor Air Quantity Air : CO

EN

ITT

WR

1. As per TES-K-100.01 P-51 of 89 (sec. 10-1-b) in substations, control room E

TH

and other duct sensitive facility, it is mandatory to provide 10% of supply air

T

OU

fresh air make up. Therefore 10% of the supply air for the fresh air make up

TH

WI

is 1,643 CFM (For supply air quantity Refer cooling Load (CHVAC) Output

NT

ME

sheets; section: C)

CU

DO

S

THI

2. As per TES-K-100.00 P-51 of 89 (sec. 10.2) the maximum amount of outside

OM

FR

D

BY C air shall equal the greater of 5% of supply air in excess of all exhaust air. NE

TAI

AJE Therefore 5% of total supply air is 822 CFM plus exhaust and ex-filtration air, OB

BE

i.e. 822 + 0 + 0 CFM. Total makeup air is 822 CFM. ALL

SH

APRIL 2014

RT

PA

Comparing the values, the higher value of 1,643 CFM is considered as per Section10.2

DATE IN

OR

LL

FU

Hence;

IN

00 NO. N

TIO

REVISIONS UC

Outdoor Air Quantity = 1,643 CFM

OD

DRAWN

PR

RE

NO

BY: Md. Nayeemullah CO.

Y

DATE: APRIL 2014 CIT

TRI

CHECKED

EC

EL

UDI

BY: Muhammad Afzal SA

OF

DATE: APRIL 2014 TY

ER

OPRG. DEPT

OP

PR

LE

BY SO

E

DATE:- TH

E

ENG'G. DEPT.

AR

N

REI

BY:- HE

ED

DATE:-

AIN

NT

CERTIFIED.

CO

N

TIO

BY:- MA

OR

DATE:-

INF

E

DRAWING TITLE INDEX PLANT DRAWING NO. SHEET NO. REV NO.

TH

THIS DRAWING IS NOT D

TO BE USED FOR

HVAC SYSTEM DESIGN CALCULATION AN

CONSTRUCTION OF

FOR ORDERING CONTROL BUILDING @SYSTEM # 01 A JD526 WE - 254756 Page 12 of 21 00

ING

AW

MATERIALS UNTIL

DR

CERTIFIED AND

AL ADEL 380/110/13.8kV BSP S

JEDDAH SAUDI ARABIA JOB ORDER NO. 4400001340 DWG. CONT. SHT. WE - 254702

THI

DATED

SEC-ERB CAD-E (2002/03)

WORD

D

RT'

CE

Saudi Electricity Company الشركـة السعوديـة للكـهرباء

Western Region Branch

APPR'D

MA

CHK'D

IISSUED FOR BASE DESIGN SUBMITTAL

N

O

TI

P

RI R.

C NE

OW

S

ITS

E OF

D T

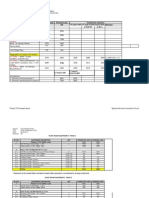

H.) SUMMARY: EN

NS

CO

EN

Total ITT

Total Total Ex- WR

Outside Exhaust Pressure E

supply Return filtration % % TH

Area Air Air Air T

Airflow Airflow Air O.A Press. OU

Req. (Cfm) (Cfm) TH

(Cfm) (Cfm)

WI

(Cfm) (Cfm)

NT

ME

CU

DO

Control & Relay

S

16,433 14,790 1,643 ----- 1,643 --- 10 10

THI

OM

Room FR

D

NE

BY C TAI

AJE OB

Using;

BE

ALL

% O.A = Outside Air x 100

SH

APRIL 2014

RT

Supply air

PA

DATE IN

OR

And; LL

FU

00 NO. % Press = Outside Air – Exhaust Air x 100 IN

N

REVISIONS Supply Air TIO

UC

DRAWN

Or OD

PR

% Press = Ex-filtration Air + Pressure Air x 100

RE

NO

BY: Md. Nayeemullah

Supply Air

CO.

Y

DATE: APRIL 2014

HVAC LOAD CALCULATION:

CIT

TRI

CHECKED

EC

EL

The load calculations is performed using HVAC software (Elite CHVAC SOFTWARE Ver.

UDI

BY: Muhammad Afzal SA

6.03.6 (window based) commercial HVAC Program) which employees ASHRAE CLTD / CLF

OF

DATE: APRIL 2014 TY

calculation’s method / guidelines. For calculating the Sub station’s cooling and heating load,

ER

OPRG. DEPT

OP

the building is divided into separate zone, keeping in view its orientation, purpose and load

PR

LE

BY SO

profiles. The load inputs (i.e. area, orientation, occupancy, equipment and light load etc.) are E

DATE:- TH

described in the “Zone Wise Data Sheets”. E

ENG'G. DEPT.

AR

N

BY:- The Calculation was performed using the above data on proportion supply Cfm basis. The REI

HE

DATE:-

load summary is given below. Detailed computer load output is attached. ED

AIN

NT

CERTIFIED. HVAC LOAD SUMMARY:

CO

N

TIO

BY:-

As per the load calculation, (Refer HVAC Load output sheets; Section: C)

MA

OR

DATE:-

INF

E

DRAWING TITLE INDEX PLANT DRAWING NO. SHEET NO. REV NO.

TH

THIS DRAWING IS NOT D

TO BE USED FOR

HVAC SYSTEM DESIGN CALCULATION AN

CONSTRUCTION OF

FOR ORDERING CONTROL BUILDING @SYSTEM # 01 A JD526 WE - 254756 Page 13 of 21 00

ING

AW

MATERIALS UNTIL

DR

CERTIFIED AND

AL ADEL 380/110/13.8kV BSP S

JEDDAH SAUDI ARABIA JOB ORDER NO. 4400001340 DWG. CONT. SHT. WE - 254702

THI

DATED

SEC-ERB CAD-E (2002/03)

WORD

D

RT'

CE

Saudi Electricity Company الشركـة السعوديـة للكـهرباء

Western Region Branch

APPR'D

MA No. of Zones : 03

Safety factor : 10% (for both Latent & Sensible and Heating)

CHK'D

System type : Constant Volume

Load Peak Time : June @ 5PM

Supply Air Qty. : 16,433 Cfm

Outdoor Air Qty. : 1,643 Cfm

Total Cooling Load : 471,119 BTUH or 39.26 Tons

IISSUED FOR BASE DESIGN SUBMITTAL

N

O

TI

Total Sensible Load : 424,077 BTUH or 35.34 Tons

Total Heating Load : 58,087 BTUH or 17.02 kW

P

RI R.

C NE

Detailed computer load output is attached.

OW

S

ITS

E OF

D

HVAC EQUIPMENT SCHEDULE: T

EN

NS

CO

As per latest project Specification, each A/C’s Equipment should be selected 100% for the

EN

ITT

WR

maximum required capacity. One A/C unit shall be duty and other standby. E

TH

T

OU

Therefore each equipments Configuration is detailed below; (Refer HVAC Load output TH

WI

sheets; Section: C) NT

ME

CU

DO

For System No.1 (PACU-5A & PACU-5B)

S

THI

OM

FR

No. of Unit = 02 (01 Duty & 01 Standby)

D

NE

BY C TAI

Type of Unit = Packaged Type

AJE OB

BE

ALL

SH

Supply Air Qty. = 16,433 Cfm

APRIL 2014

RT

PA

DATE IN

Outdoor Air Qty. = 1,643 Cfm OR

LL

FU

00 NO. Entering D.B. = 80.72 °F IN

N

TIO

REVISIONS

Entering W.B. = 66.25 °F

UC

OD

DRAWN

PR

Leaving D.B. = 57.00 °F

RE

NO

BY: Md. Nayeemullah CO.

Leaving W.B. = 56.94 °F

Y

DATE: APRIL 2014 CIT

TRI

CHECKED

EC

Cooling Load = 39.36 Tr. (471,119 Btuh) EL

UDI

BY: Muhammad Afzal SA

DATE: APRIL 2014

Sensible Load = 35.34 Tr. (424,077 Btuh) OF

TY

ER

OPRG. DEPT Heating Load = 17.02 kW (58,087 Btuh) OP

PR

LE

BY SO

E

DATE:- TH

ENG'G. DEPT.

AIR BALANCING: E

AR

N

REI

BY:- HE

ED

DATE:-

AIN

NT

CERTIFIED.

CO

N

TIO

BY:- MA

OR

DATE:-

INF

E

DRAWING TITLE INDEX PLANT DRAWING NO. SHEET NO. REV NO.

TH

THIS DRAWING IS NOT D

TO BE USED FOR

HVAC SYSTEM DESIGN CALCULATION AN

CONSTRUCTION OF

FOR ORDERING CONTROL BUILDING @SYSTEM # 01 A JD526 WE - 254756 Page 14 of 21 00

ING

AW

MATERIALS UNTIL

DR

CERTIFIED AND

AL ADEL 380/110/13.8kV BSP S

JEDDAH SAUDI ARABIA JOB ORDER NO. 4400001340 DWG. CONT. SHT. WE - 254702

THI

DATED

SEC-ERB CAD-E (2002/03)

WORD

D

RT'

CE

Saudi Electricity Company الشركـة السعوديـة للكـهرباء

Western Region Branch

APPR'D

MA

Sr. Supply Return Exhaust Press. Air Ex-filtration Room

Zone Description

CHK'D

No. Air Cfm Air Cfm Air Cfm Cfm Air Cfm Press.

1 Control & Relay Room 14,318 12,886 -- 1,432 -- +ve

Control & Relay Room

2 1,894 1,705 -- 189 -- +ve

(raised floor)

IISSUED FOR BASE DESIGN SUBMITTAL

N

O

TI ENT Lobby

3 220 198 -- 22 -- +ve

(Staircase # 02)

P

RI R.

C NE

OW

S

ITS

E OF

D

Total 16,433 14970 -- 1,643 --

T

EN

NS

CO

EN

ITT

WR

E

TH

Result Verification:

T

OU

TH

WI

NT

We have;

ME

CU

DO

Supply Air = 16,433 CFM

S

THI

OM

FR

Return Air = 14,970 CFM D

NE

BY C TAI

AJE

Exhaust Air = 0 CFM OB

BE

ALL

Pressure Air = 1,643 CFM

SH

APRIL 2014

RT

PA

Ex-filtration = 0 CFM

DATE IN

OR

LL

Now,

FU

IN

00 NO. N

Outdoor Air = Exhaust Air + Pressure Air + Ex-filtration

TIO

REVISIONS UC

OD

DRAWN

PR

RE

NO

BY: Md. Nayeemullah CO.

DATE: APRIL 2014 = 0 + 1,643 + 0 = 1,643 CFM Y

CIT

TRI

CHECKED

EC

EL

UDI

BY: Muhammad Afzal

Return Air = Supply Air – Outdoor Air

SA

OF

DATE: APRIL 2014 TY

ER

OPRG. DEPT

OP

PR

= 16,433 - 1,643 = 14,790 CFM

LE

BY SO

E

DATE:-

O.K

TH

E

ENG'G. DEPT.

AR

N

REI

BY:-

FRESH AIR INTAKE (SAND TRAP LOUVER) SIZE:

HE

ED

DATE:-

AIN

NT

CERTIFIED.

CO

As per project HVAC Load calculation:

N

TIO

BY:- MA

OR

DATE:-

INF

E

DRAWING TITLE INDEX PLANT DRAWING NO. SHEET NO. REV NO.

TH

THIS DRAWING IS NOT D

TO BE USED FOR

HVAC SYSTEM DESIGN CALCULATION AN

CONSTRUCTION OF

FOR ORDERING CONTROL BUILDING @SYSTEM # 01 A JD526 WE - 254756 Page 15 of 21 00

ING

AW

MATERIALS UNTIL

DR

CERTIFIED AND

AL ADEL 380/110/13.8kV BSP S

JEDDAH SAUDI ARABIA JOB ORDER NO. 4400001340 DWG. CONT. SHT. WE - 254702

THI

DATED

SEC-ERB CAD-E (2002/03)

WORD

D

RT'

CE

Saudi Electricity Company الشركـة السعوديـة للكـهرباء

Western Region Branch

APPR'D

MA Total Outside Air Quantity (Q) = 1,643 Cfm

CHK'D Qty of Sand trap louver = 01 No.

As per SEC Standard, the recommended velocity is 300 FPM

A = Q

V

= 1,643

IISSUED FOR BASE DESIGN SUBMITTAL

N

300

O

= 5.48 ft²

TI

P

RI R.

C NE

From the manufacturer’s catalogue, the sand trap louver of size 48” in height by 54” wide

OW

S

ITS

gives a net free area of 5.54 ft². [Refer Attachment “E’]

E OF

D T

EN

Sand trap Louver Size = 48 inch x 54 inch (H x W)

NS

CO

EN

ITT

Qty of S.T.L = 01 No. per System WR

E

TH

T

Actual Sand Trap Louver Velocity = 1,643ft³/m

OU

TH

5.54ft²

WI

NT

ME

= 297 ft/m

CU

DO

S

Sand Trap Louver Efficiency = 38% (Refer Attachment “E”)

THI

OM

FR

D

BY C Sand Trap Louver Pressure Drop = 0.7” of W.G. (Refer Attachment “E”) NE

TAI

AJE OB

BE

Note: Selection of S.T.L is tentative based on the projects PTS, however final selection of ALL

SH

APRIL 2014

S.T.L shall be made by Equipment Manufacturer/Supplier and shall be included with RT

PA

the packaged unit material submittal.

DATE IN

OR

LL

FU

IN

00 NO. N

ELECTRIC DUCT HEATER SIZE:

TIO

REVISIONS UC

OD

DRAWN

PR

RE

BY: Md. Nayeemullah As per project HVAC Load calculation: NO

CO.

Y

DATE: APRIL 2014 CIT

Total Supply Air Quantity = 16,433 Cfm

TRI

CHECKED

EC

(From HVAC Load Calculation)

EL

UDI

BY: Muhammad Afzal SA

OF

DATE: APRIL 2014

Total Heating Calculated = 58,087 Btuh

TY

ER

OPRG. DEPT

(From HVAC Load Calculation)

OP

PR

LE

BY SO

E

DATE:- Hence the Heating Capacity in kW shall be; TH

E

ENG'G. DEPT. = Total Heating Req. in Btuh AR

N

3413 Btu/ Hr. /kW

REI

BY:- HE

ED

DATE:-

AIN

= 58,087

NT

CERTIFIED.

CO

3413

N

TIO

BY:- MA

OR

DATE:-

INF

E

DRAWING TITLE INDEX PLANT DRAWING NO. SHEET NO. REV NO.

TH

THIS DRAWING IS NOT D

TO BE USED FOR

HVAC SYSTEM DESIGN CALCULATION AN

CONSTRUCTION OF

FOR ORDERING CONTROL BUILDING @SYSTEM # 01 A JD526 WE - 254756 Page 16 of 21 00

ING

AW

MATERIALS UNTIL

DR

CERTIFIED AND

AL ADEL 380/110/13.8kV BSP S

JEDDAH SAUDI ARABIA JOB ORDER NO. 4400001340 DWG. CONT. SHT. WE - 254702

THI

DATED

SEC-ERB CAD-E (2002/03)

WORD

D

RT'

CE

Saudi Electricity Company الشركـة السعوديـة للكـهرباء

Western Region Branch

APPR'D

MA

CHK'D

= 17.02 kW

Duct Size; on location of E.D.H. is 1400mm X 650mm; hence the net free area available for

heater installation is;

Supply Duct Area = 1400mm X 650mm

= 56” X 26”

= 10.11 ft

IISSUED FOR BASE DESIGN SUBMITTAL

N

O Hence;

TI

P

kW / ft Ratio of EDH = 17.02 / 10.11

= 1.68 kW / ft

RI R.

C NE

OW

S

Therefore the recommended Duct Mounted Electric Heater rating shall be;

ITS

E OF

D T

EN

NS

CO

E.D.H. Recommended Size = 17.02 kW

EN

ITT

WR

Qty. of E.D.H = 01 No.

E

TH

T

OU

TH

ELECTRIC DATA OF DUCT MOUNTED HEATER: WI

NT

ME

CU

From the manufacturer’s catalogue DO

S

THI

The required line current for 3 phase = Wattage/ (Voltage x 1.73)

OM

FR

D

= 17,020/ (400 x 1.73)

NE

BY C TAI

AJE OB

= 24.60 Amps

BE

ALL

SH

APRIL 2014

Considered number of step control = 02 Nos.

RT

PA

DATE IN

OR

The ampere per step = 12.30 Amps LL

FU

IN

00 NO.

Hence, N

TIO

REVISIONS UC

DRAWN

EDH Criteria for Control & Relay Room Shall be; OD

PR

RE

NO

BY: Md. Nayeemullah

Total Wattage of E.D.H = 17.02 kW CO.

Y

DATE: APRIL 2014

No. of Steps = 02

CIT

TRI

CHECKED

No. Ampere/Step = 12.30 Amps

EC

EL

UDI

BY: Muhammad Afzal SA

OF

DATE: APRIL 2014 TY

ER

OPRG. DEPT BELL MOUTH OPENING SIZING: OP

PR

LE

BY

For sizing of Bell Mouth Opening, we take the maximum & minimum duct velocities as

SO

E

DATE:-

mentioned in Table-5.0 TES-K-100.01.

TH

E

ENG'G. DEPT.

AR

N

REI

BY:- 1) For BMO-1; HE

ED

DATE:-

AIN

NT

CERTIFIED. As per HVAC Load Calculation: CO

N

TIO

BY:-

Return Air Qty. for System # 01 in Control & Relay Room = 14,790 CFM

MA

OR

DATE:-

INF

E

DRAWING TITLE INDEX PLANT DRAWING NO. SHEET NO. REV NO.

TH

THIS DRAWING IS NOT D

TO BE USED FOR

HVAC SYSTEM DESIGN CALCULATION AN

CONSTRUCTION OF

FOR ORDERING CONTROL BUILDING @SYSTEM # 01 A JD526 WE - 254756 Page 17 of 21 00

ING

AW

MATERIALS UNTIL

DR

CERTIFIED AND

AL ADEL 380/110/13.8kV BSP S

JEDDAH SAUDI ARABIA JOB ORDER NO. 4400001340 DWG. CONT. SHT. WE - 254702

THI

DATED

SEC-ERB CAD-E (2002/03)

WORD

D

RT'

CE

Saudi Electricity Company الشركـة السعوديـة للكـهرباء

Western Region Branch

APPR'D

MA

CHK'D

As per TES-K-100.01 the minimum velocity for main duct is 900 FPM.

Therefore;

A = Q

V

= 14,790

900

= 16.43 ft²

IISSUED FOR BASE DESIGN SUBMITTAL

N

The required size of Bell Mouth Opening the area is 16.43 ft².

O

TI

P

The provided size of BMO is 1900 X 800mm (76” X 32”).

RI

A = LxH

R.

C NE

OW

S

ITS

E

D = 76” x 32” OF

T

= 2,432 inch²

EN

NS

CO

EN

= 16.88 ft² [

ITT

WR

Comparing the value of BMO size, the provided size is bigger than to required size. It means the

E

TH

size of BMO provided is suitable.

T

OU

TH

2) For BMO-2; WI

NT

ME

CU

As per HVAC Load Calculation: DO

S

THI

Supply Air Qty. for System # 01 in Control & Relay Room = 1,894 CFM OM

FR

(Raised Floor)

D

NE

BY C TAI

AJE OB

As per TES-K-100.01 the minimum velocity for Branch duct is 600 FPM.

BE

ALL

SH

Therefore;

APRIL 2014

RT

PA

A = Q

DATE IN

OR

V LL

FU

IN

00 NO. N

REVISIONS = 1,894 TIO

UC

600 OD

DRAWN

PR

RE

NO

BY: Md. Nayeemullah

= 3.15 ft² CO.

Y

DATE: APRIL 2014

The required size of Bell Mouth Opening the area is 3.15 ft². CIT

TRI

CHECKED

EC

The provided size of BMO is 450 X 850mm (18 X 34”).

EL

UDI

BY: Muhammad Afzal SA

OF

DATE: APRIL 2014 A = LxH TY

ER

OPRG. DEPT

OP

= 18 x 34” PR

LE

BY SO

= 612 inch² E

DATE:- TH

E

ENG'G. DEPT. = 4.25 ft² [

AR

N

REI

BY:- Comparing the value of BMO size, the provided size is bigger than to required size. It means the HE

ED

DATE:- size of BMO provided is suitable. AIN

NT

CERTIFIED.

CO

N

TIO

BY:- MA

OR

DATE:-

INF

E

DRAWING TITLE INDEX PLANT DRAWING NO. SHEET NO. REV NO.

TH

THIS DRAWING IS NOT D

TO BE USED FOR

HVAC SYSTEM DESIGN CALCULATION AN

CONSTRUCTION OF

FOR ORDERING CONTROL BUILDING @SYSTEM # 01 A JD526 WE - 254756 Page 18 of 21 00

ING

AW

MATERIALS UNTIL

DR

CERTIFIED AND

AL ADEL 380/110/13.8kV BSP S

JEDDAH SAUDI ARABIA JOB ORDER NO. 4400001340 DWG. CONT. SHT. WE - 254702

THI

DATED

SEC-ERB CAD-E (2002/03)

WORD

D

RT'

CE

Saudi Electricity Company الشركـة السعوديـة للكـهرباء

Western Region Branch

APPR'D

MA

CHK'D

IISSUED FOR BASE DESIGN SUBMITTAL

N

O

TI

P

RI R.

C NE

OW

S

ITS

E OF

D T

EN

NS

CO

EN

ITT

WR

E

TH

T

OU

TH

WI

SMOKE PURGE FAN SIZING: NT

ME

CU

For sizing of Smoke Purge Fan, we take the building air change to be 6 so that smoke laden air

DO

S

without any draught can be exhausted. For each packaged unit, separate smoke purge fans are

THI

OM

provided.

FR

D

NE

BY C TAI

1) Control & Relay Room:

AJE OB

BE

ALL

SH

APRIL 2014

RT

DATE Room dimensions are as follows; PA

IN

OR

LL

Length = l = 50.85 m FU

IN

00 NO.

Width = b = 23.23 m N

TIO

REVISIONS

Height = h = 3.70 m

UC

OD

DRAWN

Therefore;

PR

RE

NO

BY: Md. Nayeemullah CO.

Volume of conditioned space = 50.85 m x 23.23 m x 3.70 m

Y

DATE: APRIL 2014 CIT

TRI

CHECKED

= 4,371 m³ = 154,360 ft³

EC

EL

UDI

BY: Muhammad Afzal

No. of Air changes required = 6 Air change / Hr

SA

OF

DATE: APRIL 2014 TY

ER

OPRG. DEPT As per PTS Page no.62 (Refer Attachment: “F”) OP

PR

LE

BY Hence using; SO

E

DATE:- TH

E

ENG'G. DEPT. Exhaust Air = Volume of Space x Air Change / Hr AR

N

BY:-

60 REI

HE

= 154,360 x 6 ED

DATE:-

AIN

60 NT

CERTIFIED.

CO

N

TIO

BY:- = 15,436 CFM MA

OR

DATE:-

INF

E

DRAWING TITLE INDEX PLANT DRAWING NO. SHEET NO. REV NO.

TH

THIS DRAWING IS NOT D

TO BE USED FOR

HVAC SYSTEM DESIGN CALCULATION AN

CONSTRUCTION OF

FOR ORDERING CONTROL BUILDING @SYSTEM # 01 A JD526 WE - 254756 Page 19 of 21 00

ING

AW

MATERIALS UNTIL

DR

CERTIFIED AND

AL ADEL 380/110/13.8kV BSP S

JEDDAH SAUDI ARABIA JOB ORDER NO. 4400001340 DWG. CONT. SHT. WE - 254702

THI

DATED

SEC-ERB CAD-E (2002/03)

WORD

D

RT'

CE

Saudi Electricity Company الشركـة السعوديـة للكـهرباء

Western Region Branch

APPR'D

MA

CHK'D

2) Control Relay (raised floor):

Room dimensions are as follows;

Length = l = 50.85 m

Width = b = 23.23 m

Height = h = 0.9 m

Therefore;

IISSUED FOR BASE DESIGN SUBMITTAL

N Volume of conditioned space = 50.85 m x 23.23 m x 0.9 m

O

TI = 1063 m³ = 37,539 ft³

P

RI

C No. of Air changes required = 6 Air change / Hr R.

NE

OW

S

ITS

E OF

D T

As per PTS Page no.62 (Refer Attachment: “F”) EN

NS

CO

Hence using; EN

ITT

WR

E

Exhaust Air = Volume of Space x Air Change / Hr TH

T

60 OU

TH

= 37,539 x 6 WI

NT

60 ME

CU

DO

S

= 3,754 CFM THI

OM

FR

D

3) ENT Lobby (Staircase # 02):

NE

BY C TAI

AJE OB

BE

Room dimensions are as follows;

ALL

SH

APRIL 2014

RT

PA

Length = l = 10.77 m

DATE IN

OR

Width = b = 4.20 m

LL

FU

IN

00 NO.

Height = h = 3.70 m N

TIO

REVISIONS Therefore; UC

OD

DRAWN

PR

RE

BY: Md. Nayeemullah Volume of conditioned space = 10.77 m x 4.20 m x 3.70 m NO

CO.

Y

DATE: APRIL 2014

= 167.36 m³ = 5,910 ft³ CIT

TRI

CHECKED

EC

No. of Air changes required = 6 Air change / Hr EL

UDI

BY: Muhammad Afzal SA

OF

DATE: APRIL 2014 TY

ER

OPRG. DEPT As per PTS Page no.62 (Refer Attachment: “F”) OP

PR

LE

BY

Hence using; SO

E

DATE:- TH

E

ENG'G. DEPT. Exhaust Air = Volume of Space x Air Change / Hr AR

N

BY:- 60 REI

HE

ED

DATE:-

AIN

= 5,910 x 6 NT

CERTIFIED.

CO

60 N

TIO

BY:- MA

OR

DATE:-

INF

E

DRAWING TITLE INDEX PLANT DRAWING NO. SHEET NO. REV NO.

TH

THIS DRAWING IS NOT D

TO BE USED FOR

HVAC SYSTEM DESIGN CALCULATION AN

CONSTRUCTION OF

FOR ORDERING CONTROL BUILDING @SYSTEM # 01 A JD526 WE - 254756 Page 20 of 21 00

ING

AW

MATERIALS UNTIL

DR

CERTIFIED AND

AL ADEL 380/110/13.8kV BSP S

JEDDAH SAUDI ARABIA JOB ORDER NO. 4400001340 DWG. CONT. SHT. WE - 254702

THI

DATED

SEC-ERB CAD-E (2002/03)

WORD

D

RT'

CE

Saudi Electricity Company الشركـة السعوديـة للكـهرباء

Western Region Branch

APPR'D

MA = 591 CFM

CHK'D

Total Exhaust Air CFM = 15,436 + 3,574 + 591

= 19,601 CFM

As per Smoke Purge Fan calculation:

IISSUED FOR BASE DESIGN SUBMITTAL

Taking;

O

TI

P

RI R.

C NE

S Smoke Purge Exhaust Air = 19,601 CFM OW

ITS

E OF

Qty. of Smoke Purge Fan = 01 No.

D T

EN

NS

CO

EN

ITT

WR

E

TH

T

OU

TH

WI

NT

ME

CU

DO

S

THI

OM

FR

D

NE

BY C TAI

AJE OB

BE

ALL

SH

APRIL 2014

RT

PA

DATE IN

OR

LL

FU

IN

00 NO. N

TIO

REVISIONS UC

OD

DRAWN

PR

RE

NO

BY: Md. Nayeemullah CO.

Y

DATE: APRIL 2014 CIT

TRI

CHECKED

EC

EL

UDI

BY: Muhammad Afzal SA

OF

DATE: APRIL 2014 TY

ER

OPRG. DEPT

OP

PR

LE

BY SO

E

DATE:- TH

E

ENG'G. DEPT.

AR

N

REI

BY:- HE

ED

DATE:-

AIN

NT

CERTIFIED.

CO

N

TIO

BY:- MA

OR

DATE:-

INF

E

DRAWING TITLE INDEX PLANT DRAWING NO. SHEET NO. REV NO.

TH

THIS DRAWING IS NOT D

TO BE USED FOR

HVAC SYSTEM DESIGN CALCULATION AN

CONSTRUCTION OF

FOR ORDERING CONTROL BUILDING @SYSTEM # 01 A JD526 WE - 254756 Page 21 of 21 00

ING

AW

MATERIALS UNTIL

DR

CERTIFIED AND

AL ADEL 380/110/13.8kV BSP S

JEDDAH SAUDI ARABIA JOB ORDER NO. 4400001340 DWG. CONT. SHT. WE - 254702

THI

DATED

SEC-ERB CAD-E (2002/03)

WORD

Вам также может понравиться

- HvacДокумент22 страницыHvacMudassar Idris Raut100% (1)

- Electrical Load Calculation and Energy Consumption (22.8.12) .Документ274 страницыElectrical Load Calculation and Energy Consumption (22.8.12) .Gandhi Ono100% (1)

- Electrical Thumb RuleДокумент3 страницыElectrical Thumb RuleRadhaОценок пока нет

- AN-NAJAH HOSPITAL MECHANICAL SYSTEMSДокумент32 страницыAN-NAJAH HOSPITAL MECHANICAL SYSTEMSAzher MemonОценок пока нет

- GOA AIRPORT LOADДокумент13 страницGOA AIRPORT LOADSaurabh DwivediОценок пока нет

- Electrical Thumb Rules (Part 3)Документ4 страницыElectrical Thumb Rules (Part 3)Manish TiwariОценок пока нет

- Condensate Drain Calculation Lab AHU PDFДокумент1 страницаCondensate Drain Calculation Lab AHU PDFAri RizaldiОценок пока нет

- Elania Residential Apartment, at Changanassery, KeralaДокумент18 страницElania Residential Apartment, at Changanassery, KeralaAnkur ChowdharyОценок пока нет

- Load CalculationДокумент8 страницLoad Calculationlastwarning100% (1)

- Substation Design Guideliness PDFДокумент40 страницSubstation Design Guideliness PDFLimuel EspirituОценок пока нет

- Chiller Selection Report - 210TR Nominal - 193.6TR Rated - Twin Circuit - Air Cooled Flooded Screw - BSL - 29.12.17Документ1 страницаChiller Selection Report - 210TR Nominal - 193.6TR Rated - Twin Circuit - Air Cooled Flooded Screw - BSL - 29.12.17Gaurav KadamОценок пока нет

- Vol 4 DBR EPC AIIMS GKPR - 21.01.2018Документ234 страницыVol 4 DBR EPC AIIMS GKPR - 21.01.2018Shyam SinghОценок пока нет

- LOAD CALCULATION SHEET FOR KHAZANA JEWELLERY PROJECTДокумент25 страницLOAD CALCULATION SHEET FOR KHAZANA JEWELLERY PROJECTSatheesh Kumar NatarajanОценок пока нет

- Transformer CalcДокумент1 страницаTransformer CalcSumit Kumar DattaОценок пока нет

- RTCC panel cable scheduleДокумент11 страницRTCC panel cable schedulearafinОценок пока нет

- Calculate Exhaust Fan Size (1.1.19)Документ6 страницCalculate Exhaust Fan Size (1.1.19)jiguparmar1516Оценок пока нет

- DESIGN DATA FOR COOLING AND HEATING LOAD ESTIMATIONДокумент5 страницDESIGN DATA FOR COOLING AND HEATING LOAD ESTIMATIONFarzin ShahabОценок пока нет

- Data Entry: 3.5 Sq. Meter Room CFM CalculationДокумент38 страницData Entry: 3.5 Sq. Meter Room CFM Calculationehtesham314Оценок пока нет

- Electrical Clearance Standards for SubstationsДокумент11 страницElectrical Clearance Standards for SubstationsAashutosh ThakurОценок пока нет

- Pipe Size Guide To GPMДокумент2 страницыPipe Size Guide To GPMengomar76100% (1)

- Electrical Thumb Rules - 7Документ4 страницыElectrical Thumb Rules - 7Jeya KannanОценок пока нет

- APERFECTHEATLOADДокумент1 страницаAPERFECTHEATLOADselva.uae8207Оценок пока нет

- Automatic Duct SizingДокумент4 страницыAutomatic Duct SizingSudhir KulkarniОценок пока нет

- Annexure E2 - Electrical Load Details-R3 - (09!09!2011)Документ10 страницAnnexure E2 - Electrical Load Details-R3 - (09!09!2011)vinesh_viswanathan_3Оценок пока нет

- Technology Park Development Project, Islamabad Electrical Load Estimation (Phase-1-1)Документ2 страницыTechnology Park Development Project, Islamabad Electrical Load Estimation (Phase-1-1)Asad KhanОценок пока нет

- Electrical Thumb Rules - 4Документ4 страницыElectrical Thumb Rules - 4Jeya KannanОценок пока нет

- Cable Size Calculation for 125 KW LT and 350 KW HT MotorsДокумент5 страницCable Size Calculation for 125 KW LT and 350 KW HT MotorsJay Rameshbhai ParikhОценок пока нет

- DBR For HVACДокумент15 страницDBR For HVACdhanu_lagwankar50% (2)

- Electrical thumb rules guideДокумент5 страницElectrical thumb rules guideAshwin NarayanОценок пока нет

- Fan Static Head Calculation SheetДокумент1 страницаFan Static Head Calculation SheetAqil KhanОценок пока нет

- Modification & Repair of Gantry Control Room: Doc No. 2838-CAL-001 Revision No. 0 Calculation For Room PressurizationДокумент1 страницаModification & Repair of Gantry Control Room: Doc No. 2838-CAL-001 Revision No. 0 Calculation For Room Pressurizationazhar islamОценок пока нет

- Cal Mep Pressurization CalculationДокумент10 страницCal Mep Pressurization CalculationArif MohammedОценок пока нет

- Demand Factor-Diversity Factor-Utilization Factor-Load Factor - EEPДокумент15 страницDemand Factor-Diversity Factor-Utilization Factor-Load Factor - EEPMahesh MadasОценок пока нет

- CFD Report For BasementДокумент31 страницаCFD Report For Basementrajarathnam.k100% (1)

- Ahu Coil SelectionДокумент6 страницAhu Coil SelectionpsjjoshiОценок пока нет

- Hvac Boq-07082014Документ18 страницHvac Boq-07082014Kohilan NahivОценок пока нет

- Design Document RequirementДокумент5 страницDesign Document RequirementAnupam01030% (1)

- C110-M410.01 - Rev. C - System Design Calculation - Accommodation - 08052015Документ2 страницыC110-M410.01 - Rev. C - System Design Calculation - Accommodation - 08052015kokocdfОценок пока нет

- Design Basis ReportДокумент9 страницDesign Basis ReportRadhika KhandelwalОценок пока нет

- Paradip Refinery Water Supply ProjectДокумент23 страницыParadip Refinery Water Supply ProjectTeja GajjarОценок пока нет

- CABLE SIZING CALCULATION REv1Документ4 страницыCABLE SIZING CALCULATION REv1jack jala0% (1)

- Load ScheduleДокумент202 страницыLoad Scheduleshivvaram-1100% (1)

- Electrical CalculationДокумент1 страницаElectrical Calculationengrwaqas_11Оценок пока нет

- Hvac Schedule Site P PDFДокумент3 страницыHvac Schedule Site P PDFSureshbabuОценок пока нет

- Cooling Tower (Genius)Документ7 страницCooling Tower (Genius)JeghiОценок пока нет

- Fan Sizing VENTILATIONДокумент1 страницаFan Sizing VENTILATIONArun KumarОценок пока нет

- Design Basis Report PDFДокумент27 страницDesign Basis Report PDFStephen BridgesОценок пока нет

- Electrical Load Estimation r1 29.01.2013Документ9 страницElectrical Load Estimation r1 29.01.2013PrasadОценок пока нет

- SES Menu and Standards UpdatedДокумент4 страницыSES Menu and Standards UpdatedTori SmallОценок пока нет

- Cable Tray Size CalculationДокумент3 страницыCable Tray Size Calculationtsraj10Оценок пока нет

- Power Calculation (r1)Документ21 страницаPower Calculation (r1)gopaltryОценок пока нет

- The Growing Ecosystem For Egan Fet Power Conversion: PrologueДокумент6 страницThe Growing Ecosystem For Egan Fet Power Conversion: PrologueoszemОценок пока нет

- 6 - Baterry&charger17-12-2013Документ38 страниц6 - Baterry&charger17-12-2013Thi Huyen Trang VuОценок пока нет

- APPROVED WITH COMMENTS DRAWING FOR COAL FIRED POWER PLANTДокумент6 страницAPPROVED WITH COMMENTS DRAWING FOR COAL FIRED POWER PLANTDevy MangimbaОценок пока нет

- GaN Based HEMT High Voltage PDFДокумент16 страницGaN Based HEMT High Voltage PDFATman VaghamshiОценок пока нет

- 1MRG009835 en Application Note 87T For Step-Up Transformer Consisting of Three Single-Phase Units PDFДокумент5 страниц1MRG009835 en Application Note 87T For Step-Up Transformer Consisting of Three Single-Phase Units PDFrajeshОценок пока нет

- Comment Sheet: TT-ELДокумент4 страницыComment Sheet: TT-ELmidhunvarОценок пока нет

- 010 OktoberДокумент36 страниц010 OktoberTri ananda putraОценок пока нет

- 4100-0061 BMS Network CardДокумент2 страницы4100-0061 BMS Network CardNafis TyagiОценок пока нет

- SLS-T Allgemein VMT - JMДокумент65 страницSLS-T Allgemein VMT - JMjmtexla680% (1)

- HDFC MF SwitchingДокумент1 страницаHDFC MF SwitchingVIREN GOHILОценок пока нет

- RF Firehose Friction RevisedДокумент94 страницыRF Firehose Friction RevisedOnur SürücüОценок пока нет

- E1801 SH Ut MG 00503Документ1 страницаE1801 SH Ut MG 00503VIREN GOHILОценок пока нет

- PPF Nri 2018Документ1 страницаPPF Nri 2018VIREN GOHILОценок пока нет

- Scheme Name Plan Category NameДокумент3 страницыScheme Name Plan Category NameVIREN GOHILОценок пока нет

- Mathematics Worksheet: Basic LevelДокумент4 страницыMathematics Worksheet: Basic LevelVIREN GOHILОценок пока нет

- Annual Returns - Sectoralthematic, Sectoralthematic Fund Performance Tracker Mutual Funds With Highest ReturnsДокумент9 страницAnnual Returns - Sectoralthematic, Sectoralthematic Fund Performance Tracker Mutual Funds With Highest ReturnsVIREN GOHILОценок пока нет

- PPF Nri 2018Документ1 страницаPPF Nri 2018VIREN GOHILОценок пока нет

- High Earnings Growth Portfolio StocksДокумент21 страницаHigh Earnings Growth Portfolio StocksVIREN GOHILОценок пока нет

- MF DoneДокумент10 страницMF DoneVIREN GOHILОценок пока нет

- Upt-V-00-215z-101-015-A General Specification - Fire Detect - Fire Alarm SystemДокумент10 страницUpt-V-00-215z-101-015-A General Specification - Fire Detect - Fire Alarm SystemVIREN GOHILОценок пока нет

- Aegis Installation ManualДокумент90 страницAegis Installation ManualRicardo MercadoОценок пока нет

- (21353) Winter Assignment - Grade 3 - 2016Документ7 страниц(21353) Winter Assignment - Grade 3 - 2016VIREN GOHILОценок пока нет

- (Bin) (124109) Light and Shadow NotesДокумент2 страницы(Bin) (124109) Light and Shadow NotesVIREN GOHILОценок пока нет

- 02 Saudi Qurayyah IPP1 QU-J-RJ-RFQ-001 DCS R3 - Signed SizeДокумент57 страниц02 Saudi Qurayyah IPP1 QU-J-RJ-RFQ-001 DCS R3 - Signed SizeVIREN GOHILОценок пока нет

- High-Performance VAV Systems PDFДокумент11 страницHigh-Performance VAV Systems PDFTonyChuangОценок пока нет

- Scheme Name Plan Category NameДокумент3 страницыScheme Name Plan Category NameVIREN GOHILОценок пока нет

- (13467) HALF YEARLY Worksheet 2018.PDF KДокумент5 страниц(13467) HALF YEARLY Worksheet 2018.PDF KVIREN GOHILОценок пока нет

- ARB CPR Complying With USP 797Документ7 страницARB CPR Complying With USP 797virtechОценок пока нет

- BJP Manifesto 2019Документ45 страницBJP Manifesto 2019The Wire100% (4)

- AFAA SmokeДокумент63 страницыAFAA SmokeAloke RoyОценок пока нет

- 11 VESDA-E VEP-A00 Product Guide A4 IE Lores PDFДокумент112 страниц11 VESDA-E VEP-A00 Product Guide A4 IE Lores PDFfernandoОценок пока нет

- Aegis Installation ManualДокумент90 страницAegis Installation ManualRicardo MercadoОценок пока нет

- MF SIP Reckoner May To July 2019Документ7 страницMF SIP Reckoner May To July 2019VIREN GOHILОценок пока нет

- Pros ND Cons of VRFДокумент4 страницыPros ND Cons of VRFTahir Raza100% (1)

- Samvat 2076 Rashi Bhavishya SandeshДокумент15 страницSamvat 2076 Rashi Bhavishya SandeshVIREN GOHILОценок пока нет

- RF Firehose Friction RevisedДокумент94 страницыRF Firehose Friction RevisedOnur SürücüОценок пока нет

- Guidelines For The Design of Cable Stayed BridgesДокумент69 страницGuidelines For The Design of Cable Stayed BridgesDiego Alejandro Sequera100% (1)

- Settlement Part DДокумент7 страницSettlement Part DHardik GajjarОценок пока нет

- Spring Development GuidelinesДокумент4 страницыSpring Development GuidelinesIyaadanОценок пока нет

- UHPFRC Bridges - Presentation Dated 07052022 - 221007 - 074633Документ58 страницUHPFRC Bridges - Presentation Dated 07052022 - 221007 - 074633VISHWAJITОценок пока нет

- Trackbed Drainage: and TrackДокумент20 страницTrackbed Drainage: and TrackCezary P.Оценок пока нет

- All Verco Decking DataSheetsДокумент200 страницAll Verco Decking DataSheetsRuihao ZhuОценок пока нет

- Wind Lecture NotesДокумент15 страницWind Lecture NotesPeter Jean-jacquesОценок пока нет

- BREB Tendr ListДокумент2 страницыBREB Tendr ListLorem53Оценок пока нет

- Quantity Shuttering: Tower-A B2 (Lower)Документ4 страницыQuantity Shuttering: Tower-A B2 (Lower)vikasОценок пока нет

- Centrifugal Pump System Curves ExplainedДокумент5 страницCentrifugal Pump System Curves ExplainedPTC Phils.Оценок пока нет

- Isolated Footing Design Example and Excel Sheet PDFДокумент8 страницIsolated Footing Design Example and Excel Sheet PDFPrabhakar Reddy33% (3)

- Engineering Materials GuideДокумент142 страницыEngineering Materials Guidesri kiranОценок пока нет

- Machine Design Lesson on Buckling of Slender ColumnsДокумент10 страницMachine Design Lesson on Buckling of Slender ColumnsCarl JavierОценок пока нет

- Coastal Process StructureДокумент49 страницCoastal Process Structureshakirhamid6687Оценок пока нет

- Advantages of Bladder Surge TanksДокумент8 страницAdvantages of Bladder Surge TanksChrisHogbenОценок пока нет

- FMDS0122Документ11 страницFMDS0122Soumyadip RoyОценок пока нет

- AE-84 Improvement of Lal Bahadur Shastri RoadДокумент34 страницыAE-84 Improvement of Lal Bahadur Shastri RoadSandeep Ardale100% (1)

- Steam Blowing BASICSДокумент14 страницSteam Blowing BASICSadarsh_gangradeОценок пока нет

- 60 M.bow String Girder-10411-4-RДокумент1 страница60 M.bow String Girder-10411-4-RkesharinareshОценок пока нет