Академический Документы

Профессиональный Документы

Культура Документы

Draft NADCA

Загружено:

Pierre MackenzieИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Draft NADCA

Загружено:

Pierre MackenzieАвторское право:

Доступные форматы

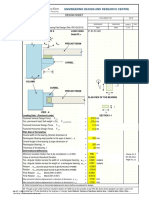

Engineering & Design: Coordinate Dimensioning NADCA

S-4A-7-06

STANDARD

TOLERANCES

Draft Requirements: Standard Tolerances The formula for draft shown

here represents Standard

Tolerance, or normal casting

Draft is the amount of taper or slope given to cores or other parts of the die cavity to permit easy production practice at the

ejection of the casting. most economical level. For

All die cast surfaces which are normally perpendicular to the parting line of the die require Precision Tolerance for draft,

draft (taper) for proper ejection of the casting from the die. This draft requirement, expressed as see the facing page.

an angle, is not constant. It will vary with the type of wall or surface specified, the depth of the

surface and the alloy selected. Note:

Draft values from the equations at right, using the illustration and the table below, provides As the formula indicates,

Standard Draft Tolerances for draft on inside surfaces, outside surfaces and holes, achievable draft, expressed as an

angle, decreases as

under normal production conditions. the depth of the feature

increases. Twice as much

draft is recommended for

Draft Example (Standard Tolerances): inside walls or surfaces as

for outside walls/surfaces.

In the case of an inside surface for an aluminum cast part, for which the constant “C” is 30 (6 This provision is required

mm), the recommended Standard Draft at three depths is: because as the alloy

Calculation Calculation

solidifies it shrinks onto

the die features that form 4A

Depth Draft Draft inside surfaces (usually

for Draft for Draft Angle located in the ejector half)

in. (mm) in. (mm) Degrees ¶ and away from features

0.1 (2.50) 0.010 (0.250) 6° D ´µµ that form outside surfaces

1.0 (25) 0.033 (0.840) 1.9° D= L L¶ ´ (usually located in the

cover half). Note also

5.0 (127) 0.075 (1.890) 0.85° C A= that the resulting draft

0.01746

calculation does not apply

to cast lettering, logotypes

To achieve lesser draft than Where: D= Draft in inches or engraving. Such ele-

normal production allows, L= Depth or height of feature from the parting line ments must be examined

Precision Tolerances maybe individually as to style,

C= Constant, from table S-4A-7, is based on the type of feature size and depth desired.

specified (see opposite page). and the die casting alloy Draft requirements need to

A= Draft angle in degrees Draft be discussed with the die

caster prior to die design

for satisfactory results.

D

Drawing defines draft

L L dimensions for interior

L

PL and exterior surfaces

PL

and total draft for holes

D

A (draft is exaggerated for

B illustration).

NADCA Product Specification Standards for Die Castings / 2006 4A-21

NADCA Engineering & Design: Coordinate Dimensioning

S-4A-7-06

STANDARD

TOLERANCES

Draft Requirements: Standard Tolerances

Table S-4A-7: Draft Constants for Calculating Draft and Draft Angle

Values of Constant "C" by Features and Depth (Standard Tolerances)

Alloy Inside Wall Outside Wall Hole, Total Draft

For Dim. in For Dim. in for Dim. in

inches (mm) inches (mm) inches (mm)

Zinc/ZA 50 (9.90 mm) 100 (19.80 mm) 34 (6.75 mm)

Aluminum 30 (6.00 mm) 60 (12.00 mm) 20 (4.68 mm)

Magnesium 35 (7.00 mm) 70 (14.00 mm) 24 (4.76 mm)

Copper 25 (4.90 mm) 50 (9.90 mm) 17 (3.33 mm)

It is not common practice to specify draft separately for each feature. Draft is normally specified

by a general note with exceptions called out for individual features. The formula should be used to

establish general draft requirements with any exceptions identified.

For example, the results at the left indicate that an aluminum casting with most features at least

1.0 in. deep can be covered with a general note indicating 2° minimum draft on inside surfaces

and 1° minimum on outside surfaces (based on outside surfaces requiring half as much draft).

4A-22 NADCA Product Specification Standards for Die Castings / 2006

Engineering & Design: Coordinate Dimensioning NADCA

P-4A-7-06

PRECISION

TOLERANCES

Precision Tolerances for draft

Draft Requirements: Precision Tolerances resulting from the calculations

outlined here involve extra

All cast surfaces normally perpendicular to the parting line of the die require draft (taper) for precision in die construction

and/or special control in

proper ejection of the casting from the die. Minimum precision draft for inside walls is generally production. They should be

recommended at 3/4 degrees per side; with outside walls requiring half as much draft. specified only when necessary.

Draft values from the equation at right, using the illustration and the table below, estimate Draft or the lack of draft can

specific Precision Draft Tolerances for draft on inside surfaces, outside surfaces and holes. greatly affect castability. Early

Precision Draft Tolerances will vary with the type of wall or surface specified, the depth of the die caster consultation will

aid in designing for minimum

wall, and the alloy selected. draft, yet sufficient draft for

castability.

Draft Example (Precision Tolerances):

In the case of an inside surface for an aluminum cast part, for which the constant “C” is 40 (7.80 Note:

mm), the recommended Precision Draft at three depths is: As the formula indicates,

draft, expressed as an angle,

Calculation Calculation decreases as the depth of

Depth Draft Draft the feature increases. See

in. (mm) in. (mm) Degrees

for Draft for Draft Angle graphical representation 4A

¶ on the following pages for

0.1 (2.50) 0.006 (0.150) 3.6°

L x 0.8

µ D ´µ various alloys. Twice as much

1.0 (25) 0.020 (0.510) 1.1° D= ´

L¶ draft is recommended for

2.5 (63.50) 0.032 (1.140) 0.72° C A= inside walls or surfaces as

0.01746

To achieve lesser draft than for outside walls/surfaces.

normal production allows, This provision is required

Where: D= Draft in inches because as the alloy

Precision Tolerances maybe L= Depth or height of feature from the parting line solidifies it shrinks onto the

specified (see opposite page). C= Constant, from table S-4A-7, is based on the type of die features that form inside

feature and the die casting alloy surfaces (usually located in

the ejector half) and away

A= Draft angle in degrees Draft

from features that form

outside surfaces (usually

located in the cover half).

Note also that the resulting

D draft calculation does not

apply to die cast lettering,

Drawing defines draft logotypes or engraving.

L Such elements must be

L dimensions for interior examined individually as to

L and exterior surfaces style, size and depth desired.

PL PL and total draft for holes Draft requirements need to

D (draft is exaggerated for be discussed with the die

A caster prior to die design for

B illustration).

satisfactory results.

NADCA Product Specification Standards for Die Castings / 2006 4A-23

NADCA Engineering & Design: Coordinate Dimensioning

P-4A-7-06

PRECISION

TOLERANCES

Draft Requirements: Precision Tolerances

Table P-4A-7: Draft Constants for Calculating Draft and Draft Angle

Values of Constant "C" by Features and Depth (Precision Tolerances)

Alloy Inside Wall Outside Wall Hole, Total Draft

For Dim. in For Dim. in For Dim. in

inches (mm) inches (mm) inches (mm)

Zinc/ZA 60 (12.00 mm) 120 (24.00 mm) 40 (7.80 mm)

Al/Mg/Cu 40 (7.80 mm) 80 (15.60 mm) 28 (5.30 mm)

It is not common practice to specify draft separately for each feature. Draft is normally speci-

fied by a general note with exceptions called out for individual features. The formula should be

used to establish general draft requirements with any exceptions identified.

For example, the results at the left indicate that an aluminum casting with most features at least 1.0

in. deep can be covered with a general note indicating 1° minimum draft on inside surfaces and 0.5°

minimum on outside surfaces (based on outside surfaces requiring half as much draft).

4A-24 NADCA Product Specification Standards for Die Castings / 2006

Engineering & Design: Coordinate Dimensioning NADCA

S/P-4A-7-06

STANDARD/PRECISION

TOLERANCES

Aluminum Draft

0.2

Standard Inside Wall

0.18 Standard Outside Wall

0.16 Precision Inside Wall

Precision Outside Wall

0.14 Standard Hole

Draft in Inches

0.12 Precision Hole

0.1

0.08

0.06

0.04

0.02

4A

0

)

)

)

4)

8)

2)

.0

.4

.8

.6

.0

.4

.8

.2

.6

5.

0.

6.

54

79

04

01

27

52

77

03

28

(2

(5

(7

(2

(2

(3

(1

(1

(1

(1

(2

(2

1

10

11

12

4

9

Length from Parting Line in Inches (mm)

Aluminum Draft Angle

3.5

Standard Inside Wall

3 Standard Outside Wall

Draft Angle in Degrees

Precision Inside Wall

2.5

Precision Outside Wall

Standard Hole

2

Precision Hole

1.5

0.5

0

)

)

4)

8)

2)

.6

.0

.4

.8

.2

.6

.0

.4

.8

5.

0.

6.

01

27

52

77

03

28

54

79

04

(2

(5

(7

(1

(1

(1

(1

(2

(2

(2

(2

(3

1

10

11

12

4

Length from Parting Line in Inches (mm)

NADCA Product Specification Standards for Die Castings / 2006 4A-25

NADCA Engineering & Design: Coordinate Dimensioning

S/P-4A-7-06

STANDARD/PRECISION

TOLERANCES

Copper Draft

0.25

Standard Inside Wall

Standard Outside Wall

0.2 Precision Inside Wall

Precision Outside Wall

Draft in Inches

Standard Hole

0.15

Precision Hole

0.1

0.05

)

)

)

4)

8)

2)

.0

.4

.8

.6

.0

.4

.8

.2

.6

5.

0.

6.

54

79

04

01

27

52

77

03

28

(2

(5

(7

(2

(2

(3

(1

(1

(1

(1

(2

(2

1

10

11

12

4

9

Length from Parting Line in Inches (mm)

Copper Draft Angle

4

Standard Inside Wall

3.5

Standard Outside Wall

Draft Angle in Degrees

3 Precision Inside Wall

Precision Outside Wall

2.5

Standard Hole

2 Precision Hole

1.5

0.5

0

)

)

)

)

4)

8)

2)

.0

.4

.8

.6

.0

.4

.8

.2

.6

5.

0.

6.

54

79

04

01

27

52

77

03

28

(2

(5

(7

(2

(2

(3

(1

(1

(1

(1

(2

(2

1

10

11

12

4

Length from Parting Line in Inches (mm)

4A-26 NADCA Product Specification Standards for Die Castings / 2006

Engineering & Design: Coordinate Dimensioning NADCA

S/P-4A-7-06

STANDARD/PRECISION

TOLERANCES

Magnesium Draft

0.16

Standard Inside Wall

0.14 Standard Outside Wall

Precision Inside Wall

0.12 Precision Outside Wall

Standard Hole

Draft in Inches

0.1 Precision Hole

0.08

0.06

0.04

0.02 4A

0

)

)

)

4)

8)

2)

.0

.4

.8

.6

.0

.4

.8

.2

.6

5.

0.

6.

54

79

04

01

27

52

77

03

28

(2

(5

(7

(2

(2

(3

(1

(1

(1

(1

(2

(2

1

10

11

12

4

Length from Parting Line in Inches (mm) 9

Magnesium Draft Angle

3

Standard Inside Wall

2.5 Standard Outside Wall

Draft Angle in Degrees

Precision Inside Wall

2 Precision Outside Wall

Standard Hole

1.5 Precision Hole

0.5

0

)

)

)

)

4)

8)

2)

.0

.4

.8

.6

.0

.4

.8

.2

.6

5.

0.

6.

54

79

04

01

27

52

77

03

28

(2

(5

(7

(2

(2

(3

(1

(1

(1

(1

(2

(2

1

10

11

12

4

Length from Parting Line in Inches (mm)

NADCA Product Specification Standards for Die Castings / 2006 4A-27

NADCA Engineering & Design: Coordinate Dimensioning

S/P-4A-7-06

STANDARD/PRECISION

TOLERANCES

Zinc Draft

0.12

Standard Inside Wall

Standard Outside Wall

0.1 Precision Inside Wall

Precision Outside Wall

Standard Hole

0.08

Draft in Inches

Precision Hole

0.06

0.04

0.02

)

)

)

4)

8)

2)

.0

.4

.8

.6

.0

.4

.8

.2

.6

5.

0.

6.

54

79

04

01

27

52

77

03

28

(2

(5

(7

(2

(2

(3

(1

(1

(1

(1

(2

(2

1

10

11

12

4

9

Length from Parting Line in Inches (mm)

Zinc Draft Angle

1.8

Standard Inside Wall

1.6

Standard Outside Wall

1.4

Draft Angle in Degrees

Precision Inside Wall

1.2 Precision Outside Wall

Standard Hole

1

Precision Hole

0.8

0.6

0.4

0.2

0

)

)

)

)

4)

8)

2)

.0

.4

.8

.6

.0

.4

.8

.2

.6

5.

0.

6.

54

79

04

01

27

52

77

03

28

(2

(5

(7

(2

(2

(3

(1

(1

(1

(1

(2

(2

1

10

11

12

4

Length from Parting Line in Inches (mm)

4A-28 NADCA Product Specification Standards for Die Castings / 2006

Вам также может понравиться

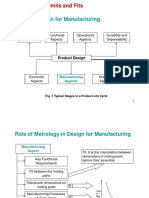

- 1-Tolerances and FitsДокумент45 страниц1-Tolerances and FitsTt OwnsqqОценок пока нет

- Saej1459v004 PDFДокумент9 страницSaej1459v004 PDFvishalОценок пока нет

- Integrity and Bar Cut OffДокумент10 страницIntegrity and Bar Cut OffAseel NajibОценок пока нет

- Tolerances and Fits: Min MaxДокумент24 страницыTolerances and Fits: Min MaxIrfan MuhammadОценок пока нет

- Design Sheet: View A Load Case= Nodal ID = α F F F Precast BeamДокумент5 страницDesign Sheet: View A Load Case= Nodal ID = α F F F Precast BeamGanesh PrabuОценок пока нет

- Boundary Dimensions and Bearing Number Codes NTNДокумент6 страницBoundary Dimensions and Bearing Number Codes NTNtrunghieutcОценок пока нет

- Basic Machine Processes: Identify The Basic Concepts of The Manufacturing ProcessesДокумент34 страницыBasic Machine Processes: Identify The Basic Concepts of The Manufacturing ProcessestnchsgОценок пока нет

- Bearing NumbersДокумент6 страницBearing NumbersonlineojОценок пока нет

- Sand and Permanent Mold Casting Errata WatermarkДокумент7 страницSand and Permanent Mold Casting Errata Watermarkprakashp111Оценок пока нет

- DA Directional Ceiling DiffuserДокумент4 страницыDA Directional Ceiling DiffuserJf OngОценок пока нет

- Square Diffuser CatДокумент4 страницыSquare Diffuser CatRobert JonesОценок пока нет

- Visual and Dimension Inspection Tolerance RevДокумент8 страницVisual and Dimension Inspection Tolerance RevJorgeОценок пока нет

- Diaphragm Design PDFДокумент50 страницDiaphragm Design PDFManoj JaiswalОценок пока нет

- 809-WS-ASME VIII Div 2 - Ellipsoidal Head Design - Rev0Документ2 страницы809-WS-ASME VIII Div 2 - Ellipsoidal Head Design - Rev0Sebastiano OrofinoОценок пока нет

- STAAD Design ParametersДокумент8 страницSTAAD Design Parametersbobmarley20161934Оценок пока нет

- Staad Pro DFF, DJ1 and DJ2Документ10 страницStaad Pro DFF, DJ1 and DJ2syed AffanОценок пока нет

- Compression 1 1 PDFДокумент57 страницCompression 1 1 PDFrahimi mohamadОценок пока нет

- Ancon Shearfix Punching Shear Reinforcement - Guidance For Completion of BS EN 1992 (EC2) Design SheetДокумент2 страницыAncon Shearfix Punching Shear Reinforcement - Guidance For Completion of BS EN 1992 (EC2) Design SheetАлександар Але СтојановићОценок пока нет

- Appendix: 4.2 Types of Line and Their ApplicationsДокумент4 страницыAppendix: 4.2 Types of Line and Their ApplicationsAbiyyu Thorif ArkanОценок пока нет

- DrawstandДокумент7 страницDrawstandMacedo S OliveiraОценок пока нет

- 11 Threadings UpdДокумент33 страницы11 Threadings UpdMarco RicardОценок пока нет

- Gear Design CalcДокумент2 страницыGear Design Calcomprakashd4196Оценок пока нет

- Shaft Rings: Alternate Design (Manufacturer's Option)Документ2 страницыShaft Rings: Alternate Design (Manufacturer's Option)Dadang Edy Kurniawan, S.TОценок пока нет

- Fits and TolerancesДокумент115 страницFits and TolerancesSachidhanandam MОценок пока нет

- Tolerances FitsДокумент25 страницTolerances FitsAnonymous E2oSW7Оценок пока нет

- Engineering Drawing StandardДокумент59 страницEngineering Drawing StandardYuva Raj AnandОценок пока нет

- Ship Rule 2000 ExtractДокумент5 страницShip Rule 2000 ExtractKamaraj ChinnaduraiОценок пока нет

- Aisc 360 - Staad Design ParamДокумент4 страницыAisc 360 - Staad Design Paramamraja2001Оценок пока нет

- EML2322L-GD&T Drawing ExplainedДокумент52 страницыEML2322L-GD&T Drawing Explainedyusrizal mohd yusofОценок пока нет

- Metric Screw Threads: Nissan Engineering StandardДокумент90 страницMetric Screw Threads: Nissan Engineering StandardBea RiveraОценок пока нет

- 013 - Strut and Tie Method (2014 11 09)Документ58 страниц013 - Strut and Tie Method (2014 11 09)Ming Shann LokОценок пока нет

- General Dimensional Tolerance For Parts Formed by Press Working From Sheet MetalДокумент2 страницыGeneral Dimensional Tolerance For Parts Formed by Press Working From Sheet MetalRicardo F.A.100% (3)

- Limits Fits & ToleranceДокумент30 страницLimits Fits & ToleranceSrikanth SrikeeОценок пока нет

- Structural Bolts CatalogueДокумент3 страницыStructural Bolts CatalogueTom CaineОценок пока нет

- Fundamentals of Limits and Fits: Notes Prepared by Dr. Suhas S. Joshi, Department of Mechanical Engineering, IndianДокумент35 страницFundamentals of Limits and Fits: Notes Prepared by Dr. Suhas S. Joshi, Department of Mechanical Engineering, Indianyair Enrique Romero OspinoОценок пока нет

- E PlansДокумент14 страницE PlanseduardoОценок пока нет

- Inflection Points and Bar Cut OffДокумент8 страницInflection Points and Bar Cut Offjohn sorianoОценок пока нет

- GD&T Symbols, Definitions ASME Y14.5-2009 Training - ISO G&T Symbols 1101 Definitions - GD&T Trainers - Engineers EdgeДокумент8 страницGD&T Symbols, Definitions ASME Y14.5-2009 Training - ISO G&T Symbols 1101 Definitions - GD&T Trainers - Engineers Edgevenkata gopi nadhОценок пока нет

- 4 Wire DrawingДокумент9 страниц4 Wire DrawingPratik GhoshОценок пока нет

- GD&TДокумент21 страницаGD&TJochelle Mae PecsonОценок пока нет

- Specification For Circlips: Indian StandardДокумент12 страницSpecification For Circlips: Indian StandardkrixotОценок пока нет

- Keys Couplings Seals Tolerances and Fits HandoutДокумент53 страницыKeys Couplings Seals Tolerances and Fits HandoutMijhael Anatholi Romero MamaniОценок пока нет

- Mitsu Turning Tools 1 PDFДокумент110 страницMitsu Turning Tools 1 PDFMax NovaxОценок пока нет

- PH-3500 Tools Technical BookДокумент6 страницPH-3500 Tools Technical BookJustformedia JustformediaОценок пока нет

- Staad Pro British ExampleДокумент104 страницыStaad Pro British ExampleCt NaSihahОценок пока нет

- Dumped RiprapДокумент13 страницDumped RipraprasangaОценок пока нет

- IntroductionДокумент24 страницыIntroductionVictor PirvulescuОценок пока нет

- Knuckle Joint: Design Procedure, Problems and QuestionsДокумент11 страницKnuckle Joint: Design Procedure, Problems and QuestionscaveshgmailcomОценок пока нет

- Engineering Drawing Notes BДокумент50 страницEngineering Drawing Notes BMuhammad AsimОценок пока нет

- Designing "Slab Type" Raft / Footing For Bending Moment and One-Way ShearДокумент8 страницDesigning "Slab Type" Raft / Footing For Bending Moment and One-Way ShearMuhammad HasanОценок пока нет

- SMEA1304Документ164 страницыSMEA1304y2k405 kaosОценок пока нет

- JDN 200 PDFДокумент14 страницJDN 200 PDFX800XLОценок пока нет

- Reinforced Concrete Design: (CIVL 3320)Документ24 страницыReinforced Concrete Design: (CIVL 3320)taiman chanОценок пока нет

- Lecture 6 Wire DrawingДокумент45 страницLecture 6 Wire Drawingisrael100% (2)

- Design by First PrincipleДокумент47 страницDesign by First Principlesaam456100% (2)

- GD 2Документ18 страницGD 2surapanenipraneetha08Оценок пока нет

- Field Notching and Drilling of Glued Laminated Timber Beams: Technical NoteДокумент8 страницField Notching and Drilling of Glued Laminated Timber Beams: Technical NoteEnrique LineroОценок пока нет

- Design Parameters - Concrete Is 456Документ5 страницDesign Parameters - Concrete Is 456Uttam Kumar GhoshОценок пока нет

- Tolerances. Section 8 ANSI H35.2Документ55 страницTolerances. Section 8 ANSI H35.2Bá Lộc NguyễnОценок пока нет

- Engineering Drawing: Unlocking Visual Perception in Engineering DrawingОт EverandEngineering Drawing: Unlocking Visual Perception in Engineering DrawingОценок пока нет

- Milling Manual ProgДокумент668 страницMilling Manual ProgPierre MackenzieОценок пока нет

- Tempeff Catalogue 2019Документ72 страницыTempeff Catalogue 2019Pierre MackenzieОценок пока нет

- Technical Drawing - Rev3Документ140 страницTechnical Drawing - Rev3Xds100% (20)

- Smoothon CatalogДокумент48 страницSmoothon CatalogPierre MackenzieОценок пока нет

- Metal CastingДокумент154 страницыMetal CastingPierre Mackenzie100% (1)

- Casting Solidification Analysis by Modulus Vector Method: B. Ravi and M. N. SrinivasantДокумент7 страницCasting Solidification Analysis by Modulus Vector Method: B. Ravi and M. N. SrinivasantSudhir KumarОценок пока нет

- MSS SP-55Документ25 страницMSS SP-55Christian Perez100% (1)

- Design For Manufacturing Questions and AnswersДокумент18 страницDesign For Manufacturing Questions and Answersyeswanth100% (2)

- Figure 49.2 Schematic of Equipment Used in Profile ExtrusionДокумент8 страницFigure 49.2 Schematic of Equipment Used in Profile ExtrusionSamson GabrielОценок пока нет

- Denure Base ResinДокумент94 страницыDenure Base ResinVishnu S Pattath100% (1)

- Design of Gravity Die CastingsДокумент25 страницDesign of Gravity Die CastingsM PraveenОценок пока нет

- Case Study On MdisДокумент16 страницCase Study On MdisDing HangОценок пока нет

- 0s Aaap. SummeeeshhДокумент95 страниц0s Aaap. SummeeeshhPious T JoseОценок пока нет

- Mod 03Документ50 страницMod 03Anuj DubeyОценок пока нет

- Results of Cooling of Dies With Water Mist: of Achievements in Materials and Manufacturing EngineeringДокумент6 страницResults of Cooling of Dies With Water Mist: of Achievements in Materials and Manufacturing Engineeringmehrdad abdolahhiОценок пока нет

- What Are Long Fiber CompositesДокумент1 страницаWhat Are Long Fiber CompositesSanket BansalОценок пока нет

- Jet Cooling English Presentationv2Документ21 страницаJet Cooling English Presentationv2susu22200050% (2)

- Decomposition and Reaction of Thermal-Formed Alumina in Aluminum Alloy CastingsДокумент9 страницDecomposition and Reaction of Thermal-Formed Alumina in Aluminum Alloy CastingskarthikkandaОценок пока нет

- Soling Materials GuideДокумент1 страницаSoling Materials GuideVivek RainaОценок пока нет

- Dycote : ManualДокумент30 страницDycote : ManualG Alex QSОценок пока нет

- Semi Solid Metal CastingДокумент2 страницыSemi Solid Metal CastingSuresh KumarОценок пока нет

- Evaluation of Methods For Metal Cleanliness AssessДокумент6 страницEvaluation of Methods For Metal Cleanliness AssessMohit pathakОценок пока нет

- Fundamentos de Manufactura Philip Rufe 2 EdДокумент70 страницFundamentos de Manufactura Philip Rufe 2 EdChilly Spices100% (1)

- MPs Lesson PlanДокумент2 страницыMPs Lesson PlanHareesha N GОценок пока нет

- Assignment4 CastingДокумент2 страницыAssignment4 CastingAkashkumar PrajapatiОценок пока нет

- Electrical Distribution Equipment, Questions & Answers, Part IIДокумент91 страницаElectrical Distribution Equipment, Questions & Answers, Part IIهانى خير100% (3)

- Renderoc LaxtraДокумент2 страницыRenderoc LaxtraBalasubramanian AnanthОценок пока нет

- Macrosegregation PDFДокумент6 страницMacrosegregation PDFZakaria AguezzarОценок пока нет

- TotalBoat Cast N Turn Clear Urethane Casting Resin KitДокумент11 страницTotalBoat Cast N Turn Clear Urethane Casting Resin KitTihomir MarkovicОценок пока нет

- Metallurgical EngineeringДокумент3 страницыMetallurgical EngineeringAPPI NAIDUОценок пока нет

- Heat Transfer CalculationsДокумент727 страницHeat Transfer CalculationsPhu NguyenОценок пока нет

- Dupont Compounds UL 1446Документ20 страницDupont Compounds UL 1446alex696Оценок пока нет

- Gost 1583-93Документ53 страницыGost 1583-93KannanОценок пока нет

- Multiple QueuesДокумент3 страницыMultiple Queuestuberose_13847748Оценок пока нет