Академический Документы

Профессиональный Документы

Культура Документы

IEC-62382 Electrical and Instrumentation Loop Check

Загружено:

FreddyАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

IEC-62382 Electrical and Instrumentation Loop Check

Загружено:

FreddyАвторское право:

Доступные форматы

INTERNATIONAL IEC

STANDARD 62382

First edition

2006-11

Electrical and instrumentation loop check

Reference number

IEC 62382:2006(E)

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

--`,,```,,,,````-`-`,,`,,`,`,,`---

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/searchpub) enables you to

search by a variety of criteria including text searches, technical committees

and date of publication. On-line information is also available on recently issued

publications, withdrawn and replaced publications, as well as corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/online_news/ justpub)

is also available by email. Please contact the Customer Service Centre (see

below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

INTERNATIONAL IEC

STANDARD 62382

First edition

2006-11

Electrical and instrumentation loop check

© IEC 2006 ⎯ Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

--`,,```,,,,````-`-`,,`,,`,`,,`---

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

Com mission Electrotechnique Internationale

International Electrotechnical Com m ission

PRICE CODE R

Международная Электротехническая Комиссия

For price, see current catalogue

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

–2– 62382 © IEC:2006(E)

CONTENTS

FOREWORD...........................................................................................................................3

INTRODUCTION.....................................................................................................................5

--`,,```,,,,````-`-`,,`,,`,`,,`---

1 Scope ...............................................................................................................................6

2 Terms and definitions.........................................................................................................6

3 Abbreviations ...................................................................................................................7

4 The order of loop check and cold commissioning in the project schedule ..........................7

5 Loop-check content ..........................................................................................................8

5.1 Included activities....................................................................................................8

5.2 Excluded activities................................................................................................. 10

6 Loop check procedure .................................................................................................... 10

6.1 Documentation check ............................................................................................ 10

6.2 Visual inspection ................................................................................................... 10

6.3 Function check ...................................................................................................... 11

6.4 Checkout of E&I infrastructure and E&I concepts................................................... 11

6.5 Additional tests – Quality and safety relevant loops ............................................... 12

7 Documents and test sheets ............................................................................................ 12

7.1 Input documents .................................................................................................... 12

7.2 Test sheets ........................................................................................................... 12

7.3 Documents generated upon completion of loop check ........................................... 13

7.4 Loop-check results ................................................................................................ 13

8 Quality assurance........................................................................................................... 13

9 Safety aspects................................................................................................................ 13

Annexe A (informative) Test report for analogue input loop .................................................. 14

Annexe B (informative) Test report for binary input loop....................................................... 15

Annexe C (informative) Test report for analogue output loop................................................ 16

Annexe D (informative) Test report for binary output loop .................................................... 17

Annexe E (informative) Test report for motors and variable frequency drives ....................... 18

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

62382 © IEC:2006(E) –3–

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRICAL AND INSTRUMENTATION LOOP CHECK

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

--`,,```,,,,````-`-`,,`,,`,`,,`---

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62382 has been prepared by IEC technical committee 65:

Industrial-process measurement and control.

This standard cancels and replaces IEC/PAS 62382 published in 2004. This first edition

constitutes a technical revision.

The text of this standard is based on the following documents:

FDIS Report on voting

65/386/FDIS 65/395/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

–4– 62382 © IEC:2006(E)

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

62382 © IEC:2006(E) –5–

INTRODUCTION

The inspection and verification of the individual measurements and controls in conjunction

with the control systems used to monitor these devices (DCS, PLC, etc.) is referred to as loop

check. In industry, numerous methods and philosophies are used to check the instrumentation

and controls after mechanical installation within projects for modified or new facilities.

This standard was created to provide a better understanding of what loop check consists of

and also to provide a standard methodology for executing loop check.

The annexes of this standard contain forms which may be used in the check procedures.

Buyers of this publication may copy these forms for their own purposes only in the required

amount.

For application in the pharmaceutical or other highly specialized industries, additional

guidelines (for example, Good Automated Manufacturing Practice (GAMP)), definitions and

stipulations should apply in accordance with existing standards, for example, for GMP

Compliance 21 CFR (FDA) and the Standard Operating Procedure of the European Medicines

Agency (SOP/INSP/2003).

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

–6– 62382 © IEC:2006(E)

ELECTRICAL AND INSTRUMENTATION LOOP CHECK

1 Scope

This International Standard describes the steps recommended to complete a loop check,

which comprises the activities between the completion of the loop construction (including

installation and point-to-point checks) and the start-up of cold commissioning. This standard

is applicable for the construction of new plants and for expansion/retrofits (i.e. revamping) of

E&I installations in existing plants (including PLC, BAS, DCS, panel-mounted and field

instrumentation). It does not include a detailed checkout of power distribution systems, except

as they relate to the loops being checked (i.e. a motor starter or a power supply to a four-wire

transmitter).

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1

precommissioning

phase, during which the activities of non-operating adjustments, cold alignment checks,

cleaning, and testing of machinery take place.

NOTE Please refer to the enclosed annexes as an example.

2.2

mechanical completion

milestone, which is achieved when the plant, or any part thereof, has been erected and

tested in accordance with drawings, specifications, instructions, and applicable codes and

regulations to the extent necessary to permit cold commissioning

NOTE This includes completion of all necessary electrical and instrumentation work. This is a milestone marking

the end of the precommissioning activities.

2.3

cold commissioning

phase, during which the activities associated with the testing and operation of equipment or

facilities using test media such as water or inert substances prior to introducing any chemical

in the system take place

2.4

start-up

milestone marking the end of cold commissioning.

NOTE At this stage, the operating range of every instrument loop is already adjusted to reflect the actual working

condition.

2.5

hot commissioning

phase, during which the activities associated with the testing and operation of equipment or

facilities using the actual chemical process prior to making an actual production run take

place

2.6

start of production

milestone marking the end of hot commissioning.

NOTE At this stage, the plant is ready for full and continuous operation.

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

62382 © IEC:2006(E) –7–

2.7

performance test

milestone at which time the production plant runs to its design capacity

NOTE This test, carried out by the owner’s personnel with the help and supervision of the contractor, should

demonstrate the contractor’s process performance and consumption guarantees as specified in the contract.

2.8

acceptance of plant

milestone at which the formal turn over of the plant from the contractor to the owner is carried

out

2.9

basic software

software which, at a minimum, contains the graphic faceplates, base-level alarms and switch

points, basic interlocking and analogue control. In the case of safety loops, any safety switch

point should be included if it is not in the basic database

3 Abbreviations

BAS Building automation systems

C&E Cause and effect diagram

DCS Distributed control system

E&I Electrical and instrumentation and control systems

ESD Emergency shut-down system

FAT Factory acceptance testing

FBD Functional block diagram

FUP Function plan

HMI Human machine interface

HW Hardware

MC Mechanical completion

PDS Project design specifications

PFS Project functional specification

PLC Programmable logic controller

SAT Site acceptance test

SIT Site integration test

SW Software

4 The order of loop check and cold commissioning in the project schedule

The loop checks will ideally occur in the precommissioning phase of the schedule shown in

Figure 1.

However, normal occurrence is that the loop checks begin when any specific loop is

completed and turned over to the checkout crew even if it is during the "construction" phase.

The loop check could substantially overlap the "construction" phase.

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

–8– 62382 © IEC:2006(E)

Acceptance

of plant

PHASES

Construction Precommissioning Commissioning Production

Cold Hot

Completion of Mechanical Start-up Start of

MILESTONES

erection completion production Performance

test

--`,,```,,,,````-`-`,,`,,`,`,,`---

IEC 2057/06

Note – Construction and Precommissioning activities could be overlapping.

Figure 1 – Definition of phases and milestones

The loop check

• follows the E&I construction phase and FAT of the DCS in a project;

• is the last systematic check before mechanical completion to assure that

– all E&I documents (loop sheets, etc.) are available and correspond to their latest

revision;

– all instrumentation and equipment is delivered according to the design specifications;

– installation has occurred in accordance to engineering documents, applicable codes

and local regulations;

– loop functionality is correct.

This provides

• in a project, the quality check for E&I engineering, procurement and installation;

• the base for the commissioning phase which consists of

a) cold commissioning

phase during which functional testing of equipment and facilities, using test media

such as water or inert substances, takes place;

b) hot commissioning (chemical start-up)

phase during which activities associated with the testing and operation of equipment

using the actual process chemicals (initial start-up of process) are performed.

The main activities in the cold and hot commissioning phases are system verification

tuning of loops and instruments and control schemes.

5 Loop check content

5.1 Included activities

The loop check includes the following elements of a "single loop" (sensor and/or actuator).

• Hardware components:

– the installed instruments or components in the field or their final destination;

– the equipment in E&I rooms;

– hard wired functionality between sensor and actuator loops (if applicable);

– the input and output (if applicable) cards of process control systems.

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

62382 © IEC:2006(E) –9–

• The basic software components (including the graphic faceplates, base level alarms and

switch points, basic interlocking and basic analogue control) to test the field devices. The

loop check uses the basic graphics/faceplates of the control system (see Figure 2). Note

that primary inputs and outputs may be connected not only to DCS but also to ESD, PLC,

unit controllers and other subsystems. They all are visualized on DCS.

In the case of safety loops, all safety switch points should be included if they are not in the

basic database.

--`,,```,,,,````-`-`,,`,,`,`,,`---

The actual loop check involves three phases.

a) Documentation checkout

Check for the completeness and consistency of loop documents, including any documents

from the installation or FAT.

b) Visual inspection of loop devices for correct installation and tagging.

c) Function check

A testing device is used to exercise all the components of the loop (including hardware,

wiring and software). It checks that all the components function correctly and that the DCS

or panel readouts are accurate.

IEC 2058/06

1)

Check of "Operational configuration" is completed during "Cold Commissioning" or "Hot Commissioning"

Figure 2 – Loop check

There are three types of deficiencies that can be found during the loop check.

a) Installation failures

Installation failures are discrepancies with the specified hardware or the method of

installation (wrong installation, wrong instruments, etc.). The construction contractor

should fix these problems.

b) Configuration failures

Configuration failures are discrepancies with the original software specification. The

programming contractor or E&I engineering should fix these problems.

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

– 10 – 62382 © IEC:2006(E)

c) E&I engineering failures

Engineering failures are to be suspected when, despite good installation of the right

instruments, the desired functionality cannot be realized (for example, fault in wiring

diagram; wrong measurement principle has been chosen, etc.) These problems should be

corrected by E&I engineering.

Additional deficiencies might be in the process design, but this can only be determined after

process start-up.

--`,,```,,,,````-`-`,,`,,`,`,,`---

5.2 Activities excluded

The loop check does not consist of

• test activities possible without construction being completed:

– software testing using simulation tools;

– other factory acceptance tests performed at the contractor or vendor’s factories;

• other software checkout activities (FAT,etc.);

• detailed construction and mechanical inspections performed during the construction

phase:

– cable testing during construction (Hipot, Meggering et al.);

– point-to-point wiring checks;

• the testing of the internal workings of package units (i.e. process subunits, machinery,

complex analysers, etc.) is excluded; only the I/O testing of this equipment is included in

the loop check;

• activities belonging to the commissioning phase: tuning of loops, instruments and control

schemes (for example, calibrating of level transmitters by filling tanks; verification of

complex control schemes; tuning of continuous control schemes; etc.).

6 Loop check procedure

6.1 Documentation check

– The checkout of the loop should first establish that all documentation pertaining to that

loop is available, consistent and correctly labelled if the loop is a safety, quality or

environmental loop.

– The pertinent documentation must, as a minimum, contain a wiring diagram of the loop

and a specification containing all calibration and functional data necessary to verify the

correct operation of the loop.

6.2 Visual inspection

– The installation should be visually checked against the documents to ensure that the

correct instruments were installed and that the installation is in accordance with the

hardware specifications and circuit diagrams.

–- Valves and flowmeters are checked for correct installation with the direction of flow.

– Can local instrumentation be easily read?

– Are all the elements of the loop available, accessible, labelled and installed in a clean and

neat manner (including junction boxes, panels, cabinets, racks)?

– Is the tagging clear and unambiguous (no danger of false interpretation)?

Are the field elements adequately protected from mechanical or environmental damage?

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

62382 © IEC:2006(E) – 11 –

6.3 Function check

The function checks are ideally performed in well-defined blocks. (Related technical blocks

like process units or related racks in E&I rooms.) The actual method and order of checkout

should be defined by the project team prior to starting the loop check.

The purpose of the function check is to exercise all the components of a loop during one test

and measure their accuracy. Checking out a loop in pieces does not qualify as a function

check and shall not substitute for the function check.

The actual check involves connecting a testing device to the transmitter and increasing the

signal, in increments, to full span to insure that the DCS or panel readout follows the input.

Also, if the loop has an output, the actuator should be observed to verify that it follows the

incremental output changes within a specified tolerance. In the final element (actuator) a

failure should be enforced or simulated to verify the correct failure reaction. The test results

(P = Pass, PR = Pass after repair, F = Fail) can be recorded either on the loop diagram and

signed and dated, or signed and dated on a separate form. This information shall be kept with

--`,,```,,,,````-`-`,,`,,`,`,,`---

the checkout package and filed with the project files to be kept for record.

Motor loops should be checked for correct operation and overload protection before coupling

the motor to the driven device. Note that the grounding checks (meggering) should be done

as part of the construction phase, though this may be repeated in the checkout phase.

Check of inter-loop functionality (like analogue control loops or interlock functions) is

preferably carried out for integrated units after a successful checkout of the separate sensor

and actuator loop. This is most effectively completed during cold commissioning.

Safety, quality and environmental loops

– For these loops, the function check should be as close to the actual function as possible

(i.e. putting pressure on the transmitter diaphragm while it is hooked up to its loop wiring

or introducing a sample gas to an analyser). The test should check the actuation of the

safety or major plant interlock to ensure proper function, in addition to the loop’s other

functions. If the actual measurement cannot be simulated (as in a flowmeter), the test

should be completed during cold commissioning.

– Flowmeters shall be specifically checked either by testing at a plant flow lab or by flowing

water through them in their field location to a calibrated weighing vessel and timed for flow

rate. If this is impractical, the meter should be specified to be separately tested by the

manufacturer and the test report included with meter. Also, if a tank has a secondary level

switch that is deemed to be a safety device, the tank level should be increased to trip the

switch as installed. If this is not practical, a test method should be devised to ensure that

the device functions correctly as installed. In particular, that it actuates at the correct level

to prevent overflow.

– For safety systems and systems with major plant shutdown implications, it is mandatory

that the functionality of the entire E&I measure as a whole be verified (sensor loop +

binary control loop/or/interlock + actuator loop).

– Quality and environmental loops may also require added special testing and

documentation as defined by the project team.

IMPORTANT: A recheck is required for E&I loops that have been modified or disconnected

after successful checkout has been completed.

6.4 Checkout of E&I Infrastructure and E&I concepts

Prior to, or during, loop checkout, E&I infrastructure should be checked for mechanical

completion and full functionality. This covers a checklist on the overall condition of E&I rooms,

field installations, energy supplies, grounding systems and cabinet equipment.

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

– 12 – 62382 © IEC:2006(E)

During the function check of loops, it is good practice to checkout E&I fundamentals and

concepts.

• Check of loop reaction during a failure or malfunction

– Check of the "fail-safe" action – does the loop go to a safe state when a component

malfunctions?

– What happens when the span limits are exceeded – do the readings and alarms

conform to manufacturers specifications?

– If the DCS malfunctions, do the final element’s actions conform to the specifications?

• Check of the function of redundant controls or power supplies

– Does the redundancy function works as specified during the failure of the primary

element? Does it switch back correctly?

The loop-related concept checkout results are to be recorded on the loop test report. Loop-

related concept checkout is performed for each loop typical and for all safety and quality

loops. For non-safety loops, these tests are performed only frequently enough that each

concept is checked.

Results of infrastructure concept checkout are recorded on the E&I general infrastructure test

report.

6.5 Additional tests – Quality and safety relevant loops

– All quality-relevant and safety-measure-relevant tags are to be rechecked after successful

completion of the loop check.

– For safety measures it is important that the functionality of the entire E&I measurement as

a whole is verified (sensor loop + binary control loop/or/interlock + actuator loop).

– These specific additional checks are to be verified by a second E&I checkout crew or

specifically tested during cold commissioning.

7 Documents and test sheets

7.1 Input documents

The prepared documentation set according to the process unit contains

a) E&I index;

b) specification sheets (hardware and software);

c) loop wiring diagrams;

d) list of spans, alarms and switches;

e) test reports;

f) calculation and documents (i.e., intrinsic safety);

g) if any certificates (i.e., motor megger checks or point-to-point checks) from the

construction phase are available, they should also be included as part of the

documentation package.

NOTE All project, safety, code, local regulations/law-related documents as required by the specific project should

be available

7.2 Test sheets

The following annexes or PC tools (Excel files) contain examples of test reports per loop type.

– Test report for analogue input loop Annex A

– Test report for binary input loop Annex B

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

62382 © IEC:2006(E) – 13 –

– Test report for analogue output loop (control valve) Annex C

– Test report for binary output loop (on/off valve) Annex D

– Test report for motors and variable frequency drives Annex E

7.3 Documents generated upon completion of loop check

– Marked-up E&I documentation to reflect as-built condition.

– Loop test report: signed and completed with loop check results.

7.4 Loop check results

The results of the loop checks shall be indicated as follows.

P = Pass (correct when checked)

F = Fail (not passed when checked; shall include a clear problem description; may

require engineering involvement)

PR = Pass after repair (repair action by checkout/repair crew required)

8 Quality assurance

The test reports are drafted in such a way that all relevant items are covered at least once.

Quality is guaranteed by the following measures.

– The loop check is always performed in the same manner (independent of the particular

tester).

– Test reports are updated with the latest information.

– The testers confirm with their signature that a complete loop check agrees with the test

procedures.

9 Safety aspects

For safety installations, extra checklists and working plans are set up in addition to the normal

loop-check procedure. These documents typically describe a very detailed check procedure

and are periodically repeated after production start-up.

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

– 14 – 62382 © IEC:2006(E)

Annex A

(informative)

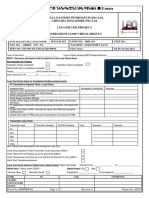

Test report for analogue input loop

--`,,```,,,,````-`-`,,`,,`,`,,`---

Function Purpose Phase Temp. PA001

TIAS Loop check after installation Precommissioning

Remark: This check is performed/documented after successful point-t-point wiring check and base software implementation.

Changes in installation or software functionality require recheck.

Irrelevant boxes are crossed out or filled in with N/A (not applicable).

Instrument type:

Results

1. Documentation check (Italics denote: normally not present)

Loop documentation complete? Cable test - point-to-point connection test complete P PR F

Date

PCS specification HW present Wiring diagram present Name

Instrument certificates present Test sheet SW-FAT present Signature

Release of construction present PCS Specification SW present

2. Visual inspection

Are the elements of the loop complete, coded, installed in a clean and neat manner? P PR F

Cable glands and connections tight? Construction/flow direction OK Date

All cards and nests installed and properly labeled? Name

Do the instruments conform to the circuit diagrams (loop diagram) and specification sheets? Signature

Individual configuration of cards, transmitters, etc. complete (e.g. dip switches properly set)?

3. Function check

Function of PCS loop successful? P PR F

Date

Fuses placed in system Name

Cards, nests and instruments operational? Signature

Accept. error of span %

Accept. error of meas. % 1,5 Span -30 200 gradC

Calibration Value Accepted Indicator

device error Field /PU DCS Panel Rec./other Results

3,5 mA False measurement

4 mA -30 0,45

12 mA 85 1,5

20 mA 200 3

22 mA False measurement

Open circuit

Span and units on read out OK?

SW/Spec: alarm and switch levels OK? No check due to operational reasons?

Loop brought back ready for commissioning?

Explanation:

Description

Remarks: of failure (use other side) P Pass

PR Pass after repair

F Fail

Status: Date

Issued to checkout crew

Issued to repair crew

Description of repair (use other side)

Issued to constr. for repair

Issued to progr. for repair

Issued to engineering

Loop filed and complete

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

62382 © IEC:2006(E) – 15 –

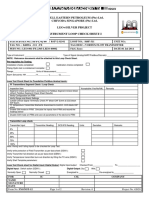

Annex B

(informative)

Test report for binary input loop

Test report for binary input loop January 2002

Complex Process area Subprocess Techn. item Business unit Building xyz-coord L0001

ANTPCS6 V401 TA10 KU 80 317 Tag-description

Function Purpose Phase Min. Level BA001

LSA Loop check after installation Precommissioning

Remark: This check is performed/documented after successful point-to-point wiring check and base software implementation.

Changes in installation or software functionality require recheck.

Irrelevant boxes are crossed out or filled in with N/A (not pplicable).

Instrument type: Liquiphant

Results

1. Documentation check (Italics denote: normally not present)

Loop documentation complete? Cable test - point to point connection test complete P PR F

Date

PCS specification HW present Wiring diagram present Name

Instrument certificates present Test sheet SW-FAT present Signature

Release of construction present PCS specification SW present

2. Visual inspection

Are the elements of the loop complete, coded, installed in a clean and neat manner? P PR F

Cable glands and connections tight? Construction/flow direction OK Date

All cards & nests installed and properly labeled? Name

Do the instruments conform to the circuit diagrams (loop diagram) and specification sheets? Signature

Individual configuration of cards, transmitters, etc. complete (e.g. dip switches properly set)?

3. Function check

Function of PCS loop successful? P PR F

Date

Fuses placed in system Name

Cards, nests and instruments operational? Signature

Calibration Value Indicator

device Field /PU DCS Panel Rec./other Result

0/0 V

1/24 V

Device alarm No check due to operational reasons?

Open circuit

--`,,```,,,,````-`-`,,`,,`,`,,`---

Explanation:

SW/Spec: alarm and switch levels OK? P Pass

PR Pass after repair

Loop brought back ready for commissioning? F Fail

Description

Remarks: of failure (use other side)

Status: Date

Issued to checkout rew

Issued to repair crew

Issued to constr. for repair

Issued to progr. for repair

Description of repair (use other side)

Issued to engineering

Loop filed and complete

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

– 16 – 62382 © IEC:2006(E)

--`,,```,,,,````-`-`,,`,,`,`,,`---

Annex C

(informative)

Test report for analogue output loop

Test report for analogue output loop (control valve) Janaury 2002

Complex Process area Subprocess Techn. item Business unit Building xyz-coord Y0001

ANTPCS6 V401 TA10 KU 80 115.2 Tag-description

Function Purpose Phase Product out BA001

YCOS Loop check after installation Precommissioning

Remark: This check is performed/documented after successful point-to-point wiring check and base software implementation.

Changes in installation or software functionality require recheck.

Irrelevant boxes are crossed out or filled in with N/A (not applicable).

Instrument type: Control membranevalve CT

Results

1. Documentation check (Italics denote: normally not present)

Loop documentation complete? Cable test - point-to-point connection test complete P PR F

Date

PCS specification HW present Wiring diagram present Name

Instrument certificates present PCS specification SW present Signature

Release of construction present Test sheet SW-FAT present

2. Visual inspection

Are the elements of the loop complete, coded, installed in a clean and neat manner? P PR F

Cable glands and connections tight? Construction/flow direction OK Date

All cards and nests installed and properly labelled? Name

Do the instruments conform to the circuit diagrams (loop diagram) and specification sheets? Signature

Individual configuration of cards, transmitters, etc. complete (e.g. dip switches properly set)?

3. Function check

Function of PCS loop successful? P PR F

Fuses placed in system Date

Instrument air open Name

Cards, nests and instruments operational? Signature

Indication limit switches

Setpoint Field /PU DCS Panel Recorder/other Results

OPEN

CLOSE

Setpoint Analog output Indication analog output

device Air to open Air to close Field /PU DCS Panel Recorder/other Results

3,5 mA False value

0% 4,0 mA 20,0 mA

10% 5,6 mA 18,4 mA

50% 12,0 mA 12,0 mA

100% 20,0 mA 4,0 mA

22 mA False value

SW/Spec: control functions OK? SW/Spec: interlock functions OK?

Solenoid forced? Valve operation as specified?

Air fail position CLOSE of valve OK? No check due to operational reasons?

DCS malfunctioning: action final element (valve) conform to specification?

Loop brought back ready for commissioning?

Description

Remarks: of Failure (use other side) Explanation:

P Pass

PR Pass after repair

F Fail

Status: Date

Issued to checkout crew

Description of Repair (use other side)

Issued to repair crew

Issued to constr. for repair

Issued to progr. for repair

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

62382 © IEC:2006(E) – 17 –

Annex D

(informative)

Test report for binary output loop

Complex Process area Subprocess Techn. item Business unit Building xyz-coord Y0029

ANTPCS6 V401 TA10 KU 80 Tag-description

Function Purpose Phase Input to BA001

YOS Loop check after installation Precommissioning

Remark: This check is performed/documented after successful point-to-point wiring check and base software implementation.

Changes in installation or software functionality require recheck.

Irrelevant boxes are crossed out or filled in with N/A (not applicable).

Instrument type: Ball valve

Results

1. Documentation check (Italics denote: normally not present)

Loop documentation complete? Cable test - point-to-point connection test complete P PR F

Date

PCS specification HW present Wiring diagram present Name

Instrument certificates present PCS specification SW present Signature

Release of construction present Test sheet SW-FAT present

2. Visual inspection

Are the elements of the loop complete, coded, installed in a clean and neat manner? P PR F

Cable glands and connections tight? Construction/flow direction OK Date

All cards and nests installed and properly labelled? Name

Do the instruments conform to the circuit diagrams (loop diagram) and specification sheets? Signature

Individual configuration of cards, transmitters, etc. complete (e.g. dip switches properly set)?

3. Function check

Function of PCS loop successful? P PR F

Date

Fuses placed in system Name

Instrument air open Signature

Cards, nests and instruments operational?

Set on Indication limit switches

DCS Field /PU DCS Panel Rec./other Results

OPEN

CLOSE

Air fail position CLOSE of valve OK?

SW/Spec: interlock functions OK? No check due to operational reasons?

DCS malfunctioning: action final element (valve) conform to specification?

Explanation:

P Pass

Loop brought back ready for commissioning? PR Pass after repair

F Fail

Description of failure (use other side)

Remarks:

Status: Date

Issued to checkout crew

Issued to repair crew

Issued to constr. for repair

Issued to progr. for repair

Description of Repair (use other side)

Issued to engineering

Loop filed and complete

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

– 18 – 62382 © IEC:2006(E)

Annex E

(informative)

Test report for motors and variable frequency drives

--`,,```,,,,````-`-`,,`,,`,`,,`---

Test report for motor var. freq. drive January 2002

Complex Process area Subprocess Techn. item Business unit Building xyz-coord M0001

ANTPCS6 V401 TA10 KU 80 Tag-description

Function Purpose Phase Mixer BA001

MCOS Loop check after installation Precommissioning

Remark: This check is performed/documented after successful point-to-point wiring check and base software implementation.

Changes in installation or software functionality require recheck.

Irrelevant boxes are crossed out or filled in with N/A (not applicable).

Instrument type: F&G CD100L1/4

Results

1. Documentation check (Italics denote: normally not present)

Loop documentation complete? Cable test - point-to-point connection test complete P PR F

Date

PCS specification HW present Wiring diagram present Name

Instrument certificates present PCS specification SW present Signature

Release of construction present Test sheet SW-FAT present

2. Visual inspection

Are the elements of the loop complete, coded, installed in a clean and neat manner? P PR F

Cable glands and connections tight? Construction/flow direction OK Date

All cards and nests installed and properly labeled? Name

Do the instruments conform to the circuit diagrams (loop diagram) and specification sheets? Signature

Individual configuration of cards, transmitters, etc. complete (e.g. dip switches properly set)?

3. Function check

Power fuses removed Function of PCS loop successful? P PR F

Control fuses installed Date

Cards, nests and instruments operational Name

Field repair disconnect - closed Signature

Operation/ Field PU DCS Panel Other Result

indication at

Mode Manual/Auto Manual/Auto Manual/Auto Manual/Auto Manual/Auto

Operation / / / AUTO / /

On / / / / /

Off / / / / /

Disturbance / / / / /

Setpoint Setpoint Analogue Indication at var. freq. drive Result

device RPM output S313 K706 E01.1

0% 0 4 mA

50% 710 12 mA

100% 1420 20 mA

Overtemp. Thermal overloads

Run dry prot. Power monitor Overload lockout

Repair disc.

SW/spec: control functions OK? Span and units on readout OK? No check due to operational reasons?

SW/spec: interlock functions OK?

DCS malfunctioning: action final element (motor) conform to specification?

Loop brought back ready for commissioning?

Description

Remarks: of Failure (use other side) Explanation:

P Pass

PR Pass after repair

F Fail

Status: Date

Issued to checkout crew

Description of Repair (use other side)

Issued to repair crew

Issued to constr. for repair

Issued to progr. for repair

___________

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

Standards Survey

The IEC would like to offer you the best quality standards possible. To make sure that we

continue to meet your needs, your feedback is essential. Would you please take a minute

to answer the questions overleaf and fax them to us at +41 22 919 03 00 or mail them to

the address below. Thank you!

Customer Service Centre (CSC)

International Electrotechnical Commission

3, rue de Varembé

1211 Genève 20

Switzerland

or

--`,,```,,,,````-`-`,,`,,`,`,,`---

Fax to: IEC/CSC at +41 22 919 03 00

Thank you for your contribution to the standards-making process.

Nicht frankieren

Ne pas affranchir

A Prioritaire

Non affrancare

No stamp required

RÉPONSE PAYÉE

SUISSE

Customer Service Centre (CSC)

International Electrotechnical Commission

3, rue de Varembé

1211 GENEVA 20

Switzerland

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

Q1 Please report on ONE STANDARD and Q6 If you ticked NOT AT ALL in Question 5

ONE STANDARD ONLY. Enter the exact the reason is: (tick all that apply)

number of the standard: (e.g. 60601-1-1)

.............................................................

standard is out of date R

standard is incomplete R

standard is too academic R

Q2 Please tell us in what capacity(ies) you standard is too superficial R

bought the standard (tick all that apply).

I am the/a:

title is misleading R

I made the wrong choice R

purchasing agent R other ....................................................

librarian R

researcher R

design engineer R Q7 Please assess the standard in the

safety engineer R following categories, using

testing engineer R the numbers:

marketing specialist R (1) unacceptable,

(2) below average,

other.....................................................

(3) average,

(4) above average,

(5) exceptional,

Q3 I work for/in/as a:

(6) not applicable

(tick all that apply)

manufacturing R timeliness .............................................

consultant R quality of writing....................................

technical contents.................................

R

--`,,```,,,,````-`-`,,`,,`,`,,`---

government

logic of arrangement of contents ..........

test/certification facility R tables, charts, graphs, figures ...............

public utility R other ....................................................

education R

military R

other.....................................................

Q8 I read/use the: (tick one)

Q4 This standard will be used for: French text only R

(tick all that apply) English text only R

general reference R both English and French texts R

product research R

product design/development R

specifications R Q9 Please share any comment on any

tenders R aspect of the IEC that you would like

quality assessment R us to know:

certification R ............................................................

technical documentation R ............................................................

thesis R ............................................................

manufacturing R ............................................................

other..................................................... ............................................................

............................................................

............................................................

Q5 This standard meets my needs:

(tick one) ............................................................

............................................................

not at all R ............................................................

nearly R ............................................................

fairly well R ............................................................

exactly R

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

--`,,```,,,,````-`-`,,`,,`,`,,`---

ISBN 2-8318-8889-1

-:HSMINB=] ] ^\:

ICS 25.040.01

Typeset and printed by the IEC Central Office

GENEVA, SWITZERLAND

Copyright International Electrotechnical Commission

Provided by IHS under license with IEC

No reproduction or networking permitted without license from IHS Not for Resale

Вам также может понравиться

- IEC - 62381 - 2006 - EN-FAT y SATДокумент11 страницIEC - 62381 - 2006 - EN-FAT y SATandres mauricio galeano ospinaОценок пока нет

- Loop Checking and Field Instrument Testing ProcedureДокумент7 страницLoop Checking and Field Instrument Testing Procedurecharzree0% (1)

- Instrument Loop Testing ProcedureДокумент9 страницInstrument Loop Testing ProcedureSusanto Pausinugroho100% (1)

- Loop Checking Procedure IdeasДокумент2 страницыLoop Checking Procedure IdeasJonatas13Оценок пока нет

- Instrument Commissioning ChecklistДокумент13 страницInstrument Commissioning Checklistrajeshkumarab100% (9)

- (EMERSON) Loop CheckingДокумент29 страниц(EMERSON) Loop CheckingDavid Chagas80% (5)

- ICSS Loop Test Presentation UpdatedДокумент31 страницаICSS Loop Test Presentation UpdatedHashemAliHashem50% (2)

- Loop Check Procedure PDFДокумент8 страницLoop Check Procedure PDFImran Nawaz Mehthal75% (4)

- FAT Procedure of PLC PanelДокумент25 страницFAT Procedure of PLC PanelDipti Bhanja83% (6)

- Loop Checking GuideДокумент66 страницLoop Checking Guidefazilpaf100% (5)

- 1.1 Scope 1.2: Shell Pakistan Limited (SPL) Petrochemical Engineering Consultants (PEC)Документ21 страница1.1 Scope 1.2: Shell Pakistan Limited (SPL) Petrochemical Engineering Consultants (PEC)Muhammad Ibad AlamОценок пока нет

- Check List For Instrumentation DesignДокумент22 страницыCheck List For Instrumentation Designmanjunath8685100% (4)

- Isa-S5 3Документ22 страницыIsa-S5 3Shin Bo100% (2)

- Loop Test ReportДокумент7 страницLoop Test ReportAldeline Sungahid100% (1)

- MQDP4 instrument loop checkДокумент2 страницыMQDP4 instrument loop checkshanks263100% (1)

- Standard Specifications - Part GДокумент52 страницыStandard Specifications - Part GBrijesh SharmaОценок пока нет

- Loop Test Procedure 71259C-0100-PP-941 - OpenДокумент40 страницLoop Test Procedure 71259C-0100-PP-941 - Opensaid250009250Оценок пока нет

- Isa-98.00.02 Skill Standards For Control Systems TechniciansДокумент22 страницыIsa-98.00.02 Skill Standards For Control Systems TechniciansDalamagas KwnstantinosОценок пока нет

- ESD System OperationДокумент53 страницыESD System Operationsalic2013100% (1)

- F-NC-174 (Elephant) Field Development Project - GOSP: Inspection and Test Plan (Itp)Документ5 страницF-NC-174 (Elephant) Field Development Project - GOSP: Inspection and Test Plan (Itp)bhct1987100% (1)

- Loop check procedure E1Документ3 страницыLoop check procedure E1mc_prayer50% (2)

- ISA-20.00.03-2001 Specification Forms. Part 3Документ30 страницISA-20.00.03-2001 Specification Forms. Part 3Максим ХилоОценок пока нет

- Site Acceptance Test PlanДокумент12 страницSite Acceptance Test PlanUmar Adamu83% (6)

- Factory Acceptance Test New Sample ReportДокумент13 страницFactory Acceptance Test New Sample ReportJafarov VuqarОценок пока нет

- FAT Procedure Rev.1Документ9 страницFAT Procedure Rev.1Rahul Deva100% (1)

- Loop Check Sheet TransmitterДокумент2 страницыLoop Check Sheet Transmittershanks263100% (1)

- Internal document guides field instrumentation projectДокумент102 страницыInternal document guides field instrumentation projectCandice Williams100% (2)

- ISA RP60.6 Nameplates, Labels, and Tags For Control CentersДокумент44 страницыISA RP60.6 Nameplates, Labels, and Tags For Control CentersfmnguestОценок пока нет

- Instrument Index and Io List Worksheet1Документ5 страницInstrument Index and Io List Worksheet1arietilang100% (2)

- Loop Checking Technicians GuideДокумент151 страницаLoop Checking Technicians GuideVipin Nair89% (19)

- ITP (Instrumentation)Документ9 страницITP (Instrumentation)Yaser A. Al-Bustanji100% (1)

- ISA Standards Committees ListДокумент8 страницISA Standards Committees ListAnonymous a19X9GHZОценок пока нет

- Instrument Installation RequirementsДокумент98 страницInstrument Installation Requirementszelda1022100% (3)

- 639-2017 - Forms (ITP)Документ9 страниц639-2017 - Forms (ITP)george stanley paceteОценок пока нет

- How To Do Loop Checks During Plant Pre-CommissioningДокумент18 страницHow To Do Loop Checks During Plant Pre-Commissioningtom2626Оценок пока нет

- IT for Grounding and Cadwelding SystemsДокумент3 страницыIT for Grounding and Cadwelding SystemsGanga DaranОценок пока нет

- Loop Checking A Technicians GuideДокумент24 страницыLoop Checking A Technicians GuideJ Mohamed UvaisОценок пока нет

- Instrument ITPДокумент4 страницыInstrument ITPVictor Biacolo100% (2)

- SIS Proof Testing by ABBДокумент74 страницыSIS Proof Testing by ABBDio MaseraОценок пока нет

- Positioners - Isa - 751301 - SPBДокумент48 страницPositioners - Isa - 751301 - SPBIsa Blue100% (2)

- Control System Specification Energy Equity KeeraДокумент42 страницыControl System Specification Energy Equity KeeraIkhtiander IkhtianderОценок пока нет

- Loop Test Procedure of Each InstrumentДокумент2 страницыLoop Test Procedure of Each InstrumentMohamed Rafih100% (1)

- Factory Acceptance Test Procedure for Turbine Meter SkidДокумент25 страницFactory Acceptance Test Procedure for Turbine Meter SkidGeo Thaliath100% (1)

- Hookup LibraryДокумент221 страницаHookup Librarykapilarora123100% (6)

- ITP For Instrumentation ControlДокумент9 страницITP For Instrumentation Controlsugeng wahyudiОценок пока нет

- What An Instrument Engineer Should KnowДокумент2 страницыWhat An Instrument Engineer Should KnowHutama Putra Wibawa75% (4)

- 006 Field Instrument InstallationДокумент8 страниц006 Field Instrument InstallationMohamed KasemОценок пока нет

- Loop Check PresentationДокумент39 страницLoop Check Presentationsaqib javaid100% (5)

- General Specification of InstrumentationДокумент41 страницаGeneral Specification of InstrumentationMaulani CandraОценок пока нет

- 02 Control System FAT TestДокумент12 страниц02 Control System FAT TestHashemAliHashemОценок пока нет

- LIMA Power and Safety System UpgradeДокумент25 страницLIMA Power and Safety System UpgradeIkhtiander Ikhtiander100% (2)

- Instrument Commissioning Checklist PDFДокумент9 страницInstrument Commissioning Checklist PDFBrijesh Srivastav100% (1)

- Junction Box and Local Control Panel Quality Control and Inspection Report FormДокумент1 страницаJunction Box and Local Control Panel Quality Control and Inspection Report FormJpa YudiОценок пока нет

- Successful Instrumentation and Control Systems Design, Second EditionОт EverandSuccessful Instrumentation and Control Systems Design, Second EditionРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Human-Machine Interface Design for Process Control ApplicationsОт EverandHuman-Machine Interface Design for Process Control ApplicationsРейтинг: 4 из 5 звезд4/5 (2)

- Certified Automation Professional A Complete Guide - 2020 EditionОт EverandCertified Automation Professional A Complete Guide - 2020 EditionОценок пока нет

- Condensed Handbook of Measurement and Control, 3rd EditionОт EverandCondensed Handbook of Measurement and Control, 3rd EditionРейтинг: 4 из 5 звезд4/5 (6)

- Ieee C57.135 (2001)Документ50 страницIeee C57.135 (2001)Daniel PaniaguaОценок пока нет

- Areas of Application of Standards 0713 eДокумент1 страницаAreas of Application of Standards 0713 eFreddyОценок пока нет

- PSEE HVAC InteractiveДокумент21 страницаPSEE HVAC InteractiveFreddyОценок пока нет

- PB CT Hvac4Документ15 страницPB CT Hvac4FreddyОценок пока нет

- Snip Gost List CivilДокумент1 страницаSnip Gost List CivilFreddyОценок пока нет

- Digame Usted Digame Usted Digame Usted Digame Usted: Bb7 Eb9Документ2 страницыDigame Usted Digame Usted Digame Usted Digame Usted: Bb7 Eb9FreddyОценок пока нет

- Hydrogen Sensor - Honeywell-XNX-Data-SheetДокумент5 страницHydrogen Sensor - Honeywell-XNX-Data-SheetFreddyОценок пока нет

- Experion Turbomachinery Hydro TurbineДокумент4 страницыExperion Turbomachinery Hydro TurbineFreddyОценок пока нет

- Soviet Union State Standards: Official PublicationДокумент22 страницыSoviet Union State Standards: Official PublicationFreddyОценок пока нет

- Snip Gost List MechДокумент1 страницаSnip Gost List MechFreddyОценок пока нет

- Digame Usted Digame Usted Digame Usted Digame Usted: D.C. y Sigue D.C. y Sigue D.C. y Sigue D.C. y SigueДокумент2 страницыDigame Usted Digame Usted Digame Usted Digame Usted: D.C. y Sigue D.C. y Sigue D.C. y Sigue D.C. y SigueFreddyОценок пока нет

- s71500 Di 32x24vdc HF Manual en-US en-USДокумент52 страницыs71500 Di 32x24vdc HF Manual en-US en-USpjl112008Оценок пока нет

- Synchrophasor Measurement Standard - IEEE C37.118.1Документ29 страницSynchrophasor Measurement Standard - IEEE C37.118.1FreddyОценок пока нет

- Caledonian Cables IEC60502-1 Low Voltage CablesДокумент56 страницCaledonian Cables IEC60502-1 Low Voltage CablesFreddy100% (1)

- Cable Tray SelectionДокумент8 страницCable Tray SelectionrumioyОценок пока нет

- Cerabar T PMC131, PMP131, PMP135: Technical InformationДокумент28 страницCerabar T PMC131, PMP131, PMP135: Technical InformationFreddyОценок пока нет

- ENG EC-BOS-2 SeriesДокумент3 страницыENG EC-BOS-2 SeriesFreddyОценок пока нет

- Cable Tray Manual PDFДокумент53 страницыCable Tray Manual PDFkevinbovoОценок пока нет

- Module 1 Ethernet and VLAN: Lab 1-1 Ethernet Interface and Link Configuration Learning ObjectivesДокумент15 страницModule 1 Ethernet and VLAN: Lab 1-1 Ethernet Interface and Link Configuration Learning ObjectivesChaima BelhediОценок пока нет

- Worry-Free Services Suites: Trend MicroДокумент4 страницыWorry-Free Services Suites: Trend MicroFaisal SharifОценок пока нет

- Moe-Llava: Mixture of Experts For Large Vision-Language ModelsДокумент22 страницыMoe-Llava: Mixture of Experts For Large Vision-Language Models2136 SANTHOSHIОценок пока нет

- 2022 ELA125A Practical Guide v11Документ16 страниц2022 ELA125A Practical Guide v11Ouch ZeroSlackОценок пока нет

- SEO-OPTIMIZED TITLE FOR BYJU'S EXAM PREP DIRECTIONAL WORD AND NUMBER ARRANGEMENT MACHINE PROBLEMSДокумент27 страницSEO-OPTIMIZED TITLE FOR BYJU'S EXAM PREP DIRECTIONAL WORD AND NUMBER ARRANGEMENT MACHINE PROBLEMSVineetha GopalakrishnanОценок пока нет

- (Non-QU) Linear Algebra by DR - Gabriel Nagy PDFДокумент362 страницы(Non-QU) Linear Algebra by DR - Gabriel Nagy PDFamrОценок пока нет

- High-Level Data Link Control: (HDLC)Документ8 страницHigh-Level Data Link Control: (HDLC)Scaria AlexОценок пока нет

- Procedure to Repair Samsung LCD/LED Panel without External Gate COFДокумент70 страницProcedure to Repair Samsung LCD/LED Panel without External Gate COFDiego Correa100% (2)

- 1 Page PDF .PDF - SearchДокумент6 страниц1 Page PDF .PDF - Search001srvnОценок пока нет

- Validating The Integrity of Computing DevicesДокумент239 страницValidating The Integrity of Computing DevicesNhat NguyenОценок пока нет

- Solving The Large-Scale TSP Problem in 1h: Santa Claus Challenge 2020Документ20 страницSolving The Large-Scale TSP Problem in 1h: Santa Claus Challenge 2020Isabella IsaОценок пока нет

- General European OMCL Network (GEON) Quality Management DocumentДокумент10 страницGeneral European OMCL Network (GEON) Quality Management Documentmr2704Оценок пока нет

- Contingency Ranking and Analysis of IEEE 14-Bus System Using PSATДокумент5 страницContingency Ranking and Analysis of IEEE 14-Bus System Using PSATVenkatesh PeruthambiОценок пока нет

- Synopsis of Railway ReservationДокумент14 страницSynopsis of Railway ReservationBhojRaj Yadav100% (1)

- TreeSize Professional - Folder Contents of - CДокумент1 страницаTreeSize Professional - Folder Contents of - CHenrique GilОценок пока нет

- PVTsim Hands-On Webinar Handout - Introduction To EoS ModelingДокумент22 страницыPVTsim Hands-On Webinar Handout - Introduction To EoS ModelingsabrineОценок пока нет

- Husky Preform Manufacturing SolutionsДокумент8 страницHusky Preform Manufacturing Solutionseeit_nizamОценок пока нет

- Cooper Industries PPAP Quick ReferenceДокумент1 страницаCooper Industries PPAP Quick ReferenceMoraru CiprianОценок пока нет

- Ingepac Da pt4 pt5 Fy50iptt01 FДокумент2 страницыIngepac Da pt4 pt5 Fy50iptt01 FRafael Hoffmann PaludoОценок пока нет

- IDPSДокумент12 страницIDPSمطيع برهومОценок пока нет

- An Integrated Marketing Communication Project Report On IMC Strategies of Vodafone and IdeaДокумент14 страницAn Integrated Marketing Communication Project Report On IMC Strategies of Vodafone and IdeaHarshal MehtaОценок пока нет

- Using Payables Invoice To PayДокумент514 страницUsing Payables Invoice To PayErika100% (1)

- Teldat SD Wan Features Description April 2018 180413Документ35 страницTeldat SD Wan Features Description April 2018 180413casinaroОценок пока нет

- Trina Solar - Installation ManualДокумент13 страницTrina Solar - Installation ManualJuan HolandaОценок пока нет

- A Detailed Investigation and Analysis of Using Machine Learning Techniques For Intrusion DetectionДокумент43 страницыA Detailed Investigation and Analysis of Using Machine Learning Techniques For Intrusion DetectionSalmaanCadeXaajiОценок пока нет

- An Efficient and Robust Access Method For Points and RectanglesДокумент38 страницAn Efficient and Robust Access Method For Points and RectanglesAlok YadavОценок пока нет

- QB SetДокумент30 страницQB SetAhyyaОценок пока нет

- Receiver: Service ManualДокумент49 страницReceiver: Service ManualheladiomontesdeocaОценок пока нет

- Feederless-SFP-DC Cables-Flexi Multiradio Base Station Installation Site Requirements PDFДокумент15 страницFeederless-SFP-DC Cables-Flexi Multiradio Base Station Installation Site Requirements PDFFlorin StanОценок пока нет

- EV-H-A1R 54C - M - EN - 2014 - D - Heat Detector SalwicoДокумент2 страницыEV-H-A1R 54C - M - EN - 2014 - D - Heat Detector SalwicoCarolinaОценок пока нет