Академический Документы

Профессиональный Документы

Культура Документы

34-27-13 AutoBall Charger 301W Operations Maintenance

Загружено:

erik masongОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

34-27-13 AutoBall Charger 301W Operations Maintenance

Загружено:

erik masongАвторское право:

Доступные форматы

AutoCharge 301-W

AutoCharge Operations & Maintenance Manual

Weight-based Automatic Ball Feeder

Version 3.0W

Process Engineering Resources, Inc.

Salt Lake City, Utah, USA

JUNE 2012

Contents

AutoCharge Operations & Maintenance Manual ......................................................................................... 1

1.0 List of Drawings ................................................................................................................................. 3

2.0 Component Data Sheets ................................................................................................................... 4

3.0 System Description ........................................................................................................................... 5

4.0 AUTOCHARGE™ Hopper Door Adjustment ....................................................................................... 7

5.0 Maintenance Schedule ..................................................................................................................... 9

6.0 Recommended Spare Parts............................................................................................................. 11

7.0 Operator Local Control ................................................................................................................... 12

8.0 Remote Operation .......................................................................................................................... 19

9.0 Version History ................................................................................................................................ 27

AUTOCHARGE™ Operations & Maintenance Manual Page 2

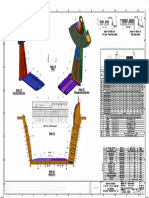

1.0 List of Drawings

Drawing Number Date Title

PER- 1115-R2 11 JUNE 2012 General Assembly

PER- 1121-R1 29 FEB. 2012 Feeder Mounting Detail

PER- 1122-R1 29 FEB. 2012 Safety Guards

PER- 1210-R1 01 MAR. 2012 Ball Counter General Arrangement

PER- 1211-R1 01 MAR. 2012 Ball Counter Detail

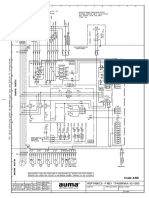

AC-CBPAC-D10-PPC AutoCharge Control Box

AUTOCHARGE™ Operations & Maintenance Manual Page 3

2.0 Component Data Sheets

Component data sheets for the following items are included with this documentation

AutoCharge™ Control Box

• Control Box Wiring Diagram

• Norgren Control Valves

AutoCharge™ Feeder / Counter Equipment:

• Norgren Air Cylinder

• Mettler-Toledo Load Cells

AUTOCHARGE™ Operations & Maintenance Manual Page 4

3.0 System Description

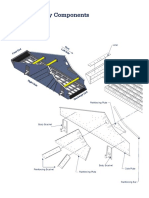

3.1 AUTOCHARGE™ Components

The Process Engineering Resources Inc. AUTOCHARGE™ air-powered automatic grinding ball charging

system consists of the following equipment:

• Ball Feeder

• Discharge Chute Actuator

• Control Box

The Ball Feeder equipment should be assembled and mounted to the storage bin as shown in the site-

specific fabrication drawings. The Discharge Chute Actuator must be mounted below the discharge

chute and allow full travel of the chute without binding according to the site-specific fabrication

drawings.

The Control Box should be mounted in a position close enough to the ball feeder so that an operator can

observe the action of the feeder while adjusting the controls (feedrate, ball count, etc.). Connections to

be completed before proceeding include the following:

1. Electrical connections from the bottom of the control box to the load cell junction box (see

Control Box wiring diagram).

2. Control box air lines from compressed air supply to the box and from the box to the ports on the

Ball Feeder and Discharge Chute Actuator air cylinders (see Control Box wiring diagram).

3. Main electrical connection into the bottom of the control box to the disconnect switch terminal

4. Optionally, an Ethernet 100BaseT (Cat 5/5e/6) connection to the plant control system or

network

3.2 Drawing List

Refer to the drawing list on Page 2 for a complete list of the drawings related to the feeder and

discharge chute general assembly and maintenance.

3.3 Functional Description

The grinding balls gravity feed from the storage bin into the AUTOCHARGE™, where they accumulate on

the feeder table. An air cylinder (5”-bore, 4.75”-stroke) powers primary and secondary rotating feed

wheels. Each extension of the cylinder indexes the primary feed wheel 1/8 turn, controlled by a one-

way clutch and brake arrangement. As the feed wheel turns, it picks up a number of balls in the flight of

AUTOCHARGE™ Operations & Maintenance Manual Page 5

the wheel. As the balls pass top center of the wheel, they roll off the wheel into the discharge chute.

The balls are held momentarily in the discharge chute while the chute assembly is weighed by the load

cells integrated into the discharge chute actuator. The discharge chute then lowers, releasing the balls

onto the mill feed conveyor belt or feed stream.

3.4 Stop/Start

The feeder stop/start, feed rate and operating parameters may be controlled locally at the

AUTOCHARGE™ control box or from the plant distributed control system.

3.5 Weighing

Balls drop into the discharge chute where they are weighed by the integrated load cells. The weights

are accumulated by the AUTOCHARGE™ controller generating both total weight and feed rate of balls to

the mill.

3.6 Power & Air Requirements

The AUTOCHARGE™ ball feeder and counting system accommodates all electrical power and requires 90

psi compressed air with an approximate flow rate of 1 cfm.

AUTOCHARGE™ Operations & Maintenance Manual Page 6

4.0 AUTOCHARGE™ Hopper Door Adjustment

4.1 Safety Precautions

All plant SAFETY rules must be strictly followed. The minimum personal protection equipment

required for this operation: Hardhat, Safety glasses, Steel-toed safety boots, and Work gloves.

The EXTEND / RETRACT motion of the air cylinder must be stopped while adjusting the hopper door.

Note: Stop the feeder by following the stop procedure described in the Local Control section of this

manual. Never dump grinding balls into the storage bin while adjusting the door.

4.2 Door Adjustment

The hopper door adjustment feature of the AUTOCHARGE™ is provided for two reasons:

1. To close the opening from the storage hopper to the feeder while filling an empty hopper with

grinding balls. Failure to close the hopper gate may result in damage to the feeding and counting

equipment.

2. To provide the optimum opening for the smooth flow of balls out of the hopper into the ball

feeder.

4.3 Proper Door Height

The optimum flow of balls through the opening can be regulated by the height the door is raised.

Typically, this is approximately 80% of two ball diameters. Out-of-round grinding balls, debris

accumulating in the hopper, and other obstacles should be removed that may impede ball flow out of

the hopper into the feeder. There should be a single layer of balls on the feeder table when the hopper

door opening is properly set.

4.4 Torque Limiter

The door is held in position by a torque limiter keyed to the door adjustment shaft. The torque limiter

will be adjusted at the initial installation to hold the door in any opening height from 0" to 16", while

allowing the operator to turn the shaft with a wrench.

4.5 Positioning Hopper Door

To position the door, use a 1-1/4" box end wrench at least 18" long. Turning the shaft clockwise raises

the door; turning counter clockwise lowers the door.

AUTOCHARGE™ Operations & Maintenance Manual Page 7

4.6 Positioning Procedure

Initially set the door to position the bottom of the door approximately 1.6 ball diameters distance from

the feeder bottom plate. Start the feeder system (see the Local Control section of this manual) from the

control panel; observe the operation of the feeder and the flow of balls out of the hopper for

approximately five minutes. If further adjustment is required, stop the feeder, adjust the opening up or

down about 1-1/2'', then restart the feeder and observe until a smooth operation is achieved. There

should be a single layer of balls on the feeder table when the hopper door opening is properly set.

AUTOCHARGE™ Operations & Maintenance Manual Page 8

5.0 Maintenance Schedule

5.1 Safety Precautions

All maintenance must be conducted while following all plant SAFETY rules. Never perform maintenance

while dumping balls into the storage hopper or while the ball feeder is operating; always shut down the

feeder, disconnect electrical power, and shut off compressed air before attempting any maintenance or

adjustments. The minimum personal protection equipment required: Hardhat, Safety glasses, Steel-

toed work boots, and Work gloves.

5.2 Daily Maintenance

Every 24 hours of operation. Observe the operation of each piece of equipment in the grinding ball

transfer/count system from storage hopper to mill entry. Watch for loose or broken parts, erratic or

unusual operating conditions, compressed air leaks, loose electrical connections, and damaged electrical

insulation. Shut down the equipment to make any required repairs.

5.3 Storage Bin Maintenance

If the storage bin contains 24 hours supply of grinding balls, once each 24 hours run the storage bin

empty and sweep out or remove all dust, accumulated debris, and ball chips or halves. If the storage bin

has a larger capacity, schedule this maintenance operation to coincide with the bin capacity.

5.4 Weekly Maintenance

Every 168 hours of operating time, check the adjustment of the AUTOCHARGE hopper door torque

limiter. Check the torque of the 44 cap screws holding the chain to the hopper door. Check the

operation of the discharge chute and load cell inputs. The load cell inputs can be read directly from the

“Manual” operation screen, check that the signal responds according to no-load and loaded conditions

(maximum 100 lbs load). Check the cylinder clevis rod to make sure it has not loosened.

5.5 Yearly Maintenance

Every 8760 hours of operating time. Replace the Feed Wheel Torque Limiter Friction Disc and check the

Hopper Door Torque Limiter Friction Disc for wear. Check all mating parts for scoring or wear. Check the

hopper door for damage. Check the door guides for wear or damage. Check the torque on all mounting

bolts, cap screws and setscrews. Replace the rod and piston seals in the air cylinder and check the rod

and clevis pins for wear. Disassemble the feeder one-way clutch following the manufacturer’s

instructions; replace any worn parts and reassemble. Check all electrical wiring for loose or damaged

connections. Check all air piping and hoses for damage or leaks.

AUTOCHARGE™ Operations & Maintenance Manual Page 9

5.6 Safety Guards

Always replace safety guards that have been removed for maintenance, before restoring electrical

power or air pressure.

AUTOCHARGE™ Operations & Maintenance Manual Page 10

6.0 Recommended Spare Parts

6.1 Recommended Parts per Installation

Recommended AUTOCHARGE™ wear parts and capital spare parts per installed unit are listed in the

tables below. Items designated with an asterisk (*) are capital spare parts with only one item required

per two installed units.

6.2 Wear Part (One Year)

Part Name/Number Manufacturer Drawing Quantity

Torque Limiter Friction Disk (700A) Morse PER-1115-R2 1

Cylinder Repair Kit (rod & piston) Norgren PER-1115-R2 1

6.3 Capital Spare Parts

Part Name/Number Manufacturer Drawing Quantity

*A-1233C1-P(3/8B)-5X4.75 Norgren PER-1115-R2 0.5

Air Cylinder Seal Kit (SWK-35) Norgren PER-1115-R2 1

Air Cylinder Piston Seal Kit (AJK-503) Norgren PER-1115-R2 1

Torque Limiter Friction Disk (700A) Morse PER-1115-R2 2

*P-16A-LH Cam Clutch Morse PER-1115-R2 0.5

Unisphere Bearing (048034) Dodge PER-1115-R2 4

*ASA#8012-Tooth Sprocket Utah Fabrication PER-1115-R2 0.5

*ASA#8014-Tooth Sprocket Utah Fabrication PER-1115-R2 0.5

AUTOCHARGE™ Operations & Maintenance Manual Page 11

7.0 Operator Local Control

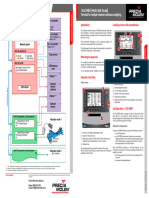

7.1 Local Operator Interface

The AUTOCHARGE™ control box incorporates a panel mounted touchscreen PC for local control and

configuration of the feeder system. The computer is configured to boot and automatically launch the

controller interface when power is applied from the disconnect switch located on the right side of the

control box.

When the computer boots and the operator interface starts the screen in Figure 1 is shown for 60

seconds or until the Continue button is clicked after about 5 seconds.

Figure 1 AUTOCHARGE™ startup screen

7.2 Local Data Entry

Since the AUTOCHARGE™ control box does not have a keyboard, all information is entered through the

touchscreen using and on-screen keyboard or on-screen numeric keypad. To edit a value, click on an

editable value and the computer will show the appropriate keypad (numeric or alpha-numeric) as shown

in Figure 2. To enter a new value, type the value using the on-screen buttons and click OK. For numeric

values, the minimum and maximum allowable values are shown. The keypad will not accept values

outside this range.

AUTOCHARGE™ Operations & Maintenance Manual Page 12

Figure 2 On-screen numeric keypad

7.3 Local and Remote Modes

The AUTOCHARGE™ may be operated from the local display or from a remote network connection.

Initially, when the AUTOCHARGE™ starts, it enters LOCAL mode. The mode is indicated in the upper

right corner of the screen as shown in Figure 3 and Figure 4. The mode can be toggled by clicking either

the “REMOTE” or “LOCAL” button.

Figure 3 Main screen, local operation

For safety reasons, the local/remote operating mode can only be set from the local display.

AUTOCHARGE™ Operations & Maintenance Manual Page 13

Figure 4 Main screen, remote operation

7.4 Initial Configuration

When the AUTOCHARGE™ is shipped, it does not contain any configuration information and must be

configured prior to first use. Attempting to start the AUTOCHARGE™ with missing configuration

parameters will generate a configuration error.

To enter the configuration settings, use the “Setup” button located on the main LOCAL screen. This will

open the setup screen shown in Figure 5. Each of the configuration parameters is described below.

Figure 5 AUTOCHARGE™ Setup screen

AUTOCHARGE™ Operations & Maintenance Manual Page 14

Ball Weight Units – defines the units used for the nominal ball weight (typically lb or kg).

Weight Scale Factor – applies a scaling factor to the load cell input signal. By default, the load cell input

is in kilograms. Enter the conversion factor here for other ball weight units of measure.

Cylinder Extend Time – is the amount of time (in seconds) required for the air cylinder to fully extend.

This value depends on supplied air pressure, but is typically 1 – 3 seconds.

Cylinder Retract Time – is the amount of time (in seconds) required for the air cylinder to fully retract.

This value depends on supplied air pressure, but is typically 1 – 3 seconds.

Settling Time – is the time (in milliseconds) the AUTOCHARGE™ will delay after the cylinder retracts and

before it attempts to measure the weight of the discharge chute.

Feed Zero Count Limit – the AUTOCHARGE™ counts the number of feed attempts for which there are no

balls counted across all channels. If the value exceeds this limit, the controller will indicate a “ball jam or

bin empty” condition. This condition must be reset by an operator before the AUTOCHARGE™ will

continue.

Chute Discharge Time – is the time (in seconds) for the discharge chute to lower. This value depends on

supplied air pressure, but is typically 1-3 seconds.

Auto-Tare – when this box is checked, the AUTOCHARGE™ will weigh the empty discharge chute

between each discharge. If this box is unchecked, the AUTOCHARGE™ will weigh the empty discharge

chute only once when the mode is set to RUN.

Español – click this button to display the user screen in Spanish.

In addition to the configuration parameters, the feed rate must be set for the AUTOCHARGE™ to start

feeding balls. The feed rate is set in the ball weight units per hour and is adjustable from the main local

display (or remotely).

7.5 Remote Operation Network Setup

For remote operation, the AUTOCHARGE™ controller must be connected to the local network and have

its IP address set accordingly. The AUTOCHARGE™ controller has two network ports, Ethernet 1 and

Ethernet 2, located on the top of the controller inside the control box. Ethernet 1 is used internally to

connect the controller to the panel PC. Ethernet 2 is available for connection to the plant control

network and its address can be set using the “NETWORK” button from the AUTOCHARGE™ setup screen.

The network setup screen is shown in Figure 6. The controller does not support dynamic address

assignment through DHCP. It must be configured for a static IP address that is compatible with the plant

control network.

AUTOCHARGE™ Operations & Maintenance Manual Page 15

Figure 6 Network setup screen

To enter an address, subnet mask, gateway and DNS, click on each number of the address field and

enter the appropriate values using the on-screen numeric keypad. When the address settings are

correct, click the “Update” button to apply the changes. Updating the network address takes several

seconds and will reset the controller. A message is displayed on the screen while the address is being

updated. After the update is complete, click “Close” to return to the AUTOCHARGE™ setup screen.

The internal IP address (Ethernet 1) is set to 192.168.96.55/255.255.255.0 and the panel PC

address is 192.168.96.2/255.255.255.0. If these addresses conflict with the plant network,

please contact PERI for assistance on modifying the internal addresses.

For more information on remote operation, see the Remote Operation section of this manual.

7.6 Local Automatic Operation

When the AUTOCHARGE™ is configured, local operation is possible by setting the feed rate and clicking

the “START” button. The feeder will discharge balls according to the desired feed rate and the number

of balls counted at each discharge. The delay between discharges is automatically adjusted based on

the weight per discharge and the desired feed rate. The delay time is displayed on the main screen (in

both local and remote modes), as well as the average weight per discharge, measured charge rate and

feeder status. The feed rate is only adjustable locally when LOCAL mode is selected. When in remote

mode, the feed rate is displayed but cannot be modified.

AUTOCHARGE™ Operations & Maintenance Manual Page 16

To stop the feeder in local mode, click the STOP button (STOP is only visible when the AUTOCHARGE™ is

running). To stop the feeder locally when it is being operated remotely, first click “LOCAL” then click

“STOP”.

7.7 Local Manual Operation

In local mode, the feeder can be operated manually by clicking the “MANUAL” button on the main

screen. If the feeder was running in automatic, it will be stopped for manual operation. The manual

operation screen is shown in Figure 7. There are four controls on the manual operation screen

described below.

Figure 7 Manual operation screen

Advance – causes the feeder to advance one half of one full discharge cycle, which is to extend and

retract the air cylinder once. Using the Advance button does not perform any weighing.

Extend – extends the air cylinder (feeder or discharge chute), no balls are weighed using this action.

Retract – retracts the air cylinder (feeder or discharge chute), no balls are weighed using this action.

The raw and filtered input signals from the load cells are displayed for testing/troubleshooting.

To exit manual operation, click either the REMOTE or AUTO button to return to automatic remote or

automatic local operation, respectively.

AUTOCHARGE™ Operations & Maintenance Manual Page 17

7.8 Feed Simulator

The AUTOCHARGE™ controller has a simple feed simulator used for testing of the controller and screens.

The simulator is accessed through the Setup page (described in section 7.4 Initial Configuration above).

Click the “Simulator” button to open the AUTOCHARGE™ Simulator screen shown in Figure 9. Click the

selector switch to start or stop the simulator.

When the AUTOCHARGE™ runs with the simulator, all actual inputs and outputs from the controller box

are disabled and replaced with simulated inputs and outputs.

Figure 8 AUTOCHARGE™ Feed Simulator

When “RUN SIMULATOR” is selected, the controller generates a random weight for the discharge chute

and actual outputs to the air cylinders are disabled.

When the selector switch is set to “RUN SIMULATOR” the AUTOCHARGE™ controller will not

actuate the feeder mechanism. When finished using the simulator, ensure the selector is

returned to “NORMAL OPERATION.”

If the controller is reset or powered off, the controller automatically returns to “NORMAL OPERATION.”

When the simulator is running a message is displayed in both local and remote modes indicating the

simulator is running and I/O is disabled as shown in Figure 7.

AUTOCHARGE™ Operations & Maintenance Manual Page 18

8.0 Remote Operation

This section contains information related to both the counter-based and weight based

AUTOCHARGE™ systems. Reading parameters for the wrong type of system may result in

undefined values. Writing version-specific parameters for the wrong type of system will be

ignored by the AUTOCHARGE™ controller.

8.1 Functional Description

Remote operation of the AUTOCHARGE™ is provided via the secondary Ethernet port on the controller

located inside the control box. By reading/writing values to controller memory addresses, a remote

system can start and stop the AUTOCHARGE™, set configuration parameters, and adjust the feed rate

set point. All individual channel counts plus overall counters are accessible over the remote connection.

The AUTOCHARGE™ controller simultaneously supports three separate communication protocols.

Obviously, there must be only one remote source writing values to the AUTOCHARGE™ controller. The

three protocols are EtherNet/IP, Modbus/TCP and IEEE 1394 memory mapped protocol.

8.2 EtherNet/IP

To use the AUTOCHARGE™ with EtherNet/IP, two assemblies exist in the controller. The EtherNet/IP

compatible device must be configured to read/write values from these assemblies. In ControlLogix, the

AUTOCHARGE™ controller is configured as a “Generic EtherNet/IP” device. See the relevant Rockwell

Automation or other vendor documentation for exact configuration options.

The first assembly (100) consists of 80 DINT values in the order specified in the Integer Variables table

below. All locations support both read and write operations, however values written to read-only

variables will be ignored.

The second assembly (101) consists of 32 REAL values in the order specified in the Float Variables table

below. All locations support both read and write operations, however values written to read-only

variables will be ignored.

8.3 Modbus/TCP

The AUTOCHARGE™ controller supports Modbus/TCP acting as a Modbus slave device (i.e. it can be

read/written by a Modbus master, but cannot initiate Modbus communication itself). Since the

AUTOCHARGE™ controller has more accessible data than is possible in a single Modbus device, its

memory locations are divided into multiple Modbus units. The unit ID for AUTOCHARGE™ variables is

110. Each variable is accessed through a register address given in the Integer and Real Variable tables

below. If the Modbus master device uses register number rather than register address, it is necessary to

add 1 to the address value to determine the register number.

AUTOCHARGE™ Operations & Maintenance Manual Page 19

8.4 OptoMMP/IEEE 1934 Memory Mapped Protocol

The AUTOCHARGE™ controller supports the IEEE 1394 memory mapped protocol standard. The memory

mapped address is shown for each AUTOCHARGE™ variable in the tables below.

AUTOCHARGE™ Operations & Maintenance Manual Page 20

8.5 Variable Conventions

The variable definitions use the following conventions

VariableName (DataType, Access, Persistence) – Description.

Where DataType is one of the following

Int32 – 32-bit integer value. Either taken as an integer value or using individual bits to indicate a

particular state

Real – 4-byte floating point value

String*Len – a string with maximum Len characters

Int32*n – an array of 32-bit integer values

Access is given by RO for read-only or RW for read-write access.

Persistence is P for a persistent variable, that is the value will be maintained even if the controller is

powered off. T is for a transitory variable that does not maintain its value during controller

power-off

8.6 Variable Definitions

bInputError (Int32, RO, T) – each bit corresponds to a ball counter channel when set indicates the

number of flights of balls with zero counts through the channel has exceeded the limit set by

nChannelZeroCountThreshold.

bRemoteMode (Int32, RO, T) – flag controlling the remote/local mode of the AutoCharge controller.

Non-zero indicates remote operation (parameter values changed by remote DCS or other

network connection). When this value is zero, the controller will only accept parameters from

the local operator display. This value is only changeable from the operator display.

bState (Int32, RO, T) – each bit corresponds to one or more states set in the AutoCharge controller

Bit 0 – Configuration error (one or more parameters has not been set)

Bit 1 – Ball jam or bin empty indicator

Bits 2-31 – not defined/future use

fAvgWeightPerDischarge (Real, RO, T) – calculated average weight of balls charged per flight, in user-

defined units (see szUnits)

fBallWeight (Real, RW,P) – user-entered nominal ball weight, in user-defined units (see szUnits)

fDischargePerHour (Real, RO, T) – calculated feed rate, in user-defined units (see szUnits) per hour.

fDischargeTime (Real, RW, T) – the time (in seconds) required for the discharge chute to move to the

fully lowered position.

fFeedDelayCalc (Real, RO, T) – calculated delay between flights of balls in seconds.

AUTOCHARGE™ Operations & Maintenance Manual Page 21

fFeedRate (Real, RW ,P) – user-entered feed rate, in user-defined units (see szUnits) per hour.

fTimeDetect (Real, RW, P) – time allowed, in seconds, for detection of balls through the counter chutes

after a discharge.

fTimeDischarge (Real, RO, T) – calculated total time, in seconds, for a single discharge.

fTimeExtend (Real, RW, P) - user-entered time required to extend the air cylinder, in seconds.

fTimeRetract (Real, RW, P) – user-entered time required to retract the air cylinder, in seconds.

fWeight (Real, RO, T) – calculated weight in the current discharge of balls in user-entered units (see

szUnits)

fWeightFilter (Real, RO, T) – calculated weight value given to the current discharge used to determine

the average weight per discharge according to (fWeightFilter * fWeight) +

(fAvgWeightPerDischarge * (1-fWeightFilter)).

fScaleFactor (Real, RW, P) – user-entered weight conversion factor for load-cells. This factor should

convert 1 kg to 1 unit of the user-defined ball weight units.

fSettlingTime (Real, RW, P) – the delay time between feeder discharge into the discharge chute and

reading of the load cell inputs.

MAX_CHANNEL (Int32, RW, P) – defines the maximum number of channels to scan, must be from 0 to 15

(the first channel is 0).

nChannelCountZeroThreshold (Int32, RW, P) – defines the maximum number of discharges with zero

counts through a chute before an error is indicated for a chute in bInputError.

nCountDelay (Int32, RW, P) – defines the time, in milliseconds, allowed between successive counts in

the same chute. This value provides some signal debounce for the limit switch return to center

position, typically between 5 and 20 ms.

nDischargeCount (Int32, RO, T) – number of balls counted in the current discharge.

nFeedStep (Int32, RO, T) – the current step of the discharge according to the following values

0 – Idle/Waiting for next discharge

1 – First extension of the air cylinder

2 – First retraction of the air cylinder

3 – Second extension of the air cylinder

4 – Second retraction of the air cylinder

5 – Detecting balls passing through the chutes

nManualCommand (Int32, RW, T) – when in manual mode, it will execute a command according to the

following values

1 – One complete discharge cycle

AUTOCHARGE™ Operations & Maintenance Manual Page 22

2 – Advance feeder one-half discharge (extend and retract the air cylinder)

3 – Extend the air cylinder

4 – Retract the air cylinder

nRunMode (Int32, RW, T) – determines the AutoCharge run mode according to the following values

0 – Stop, the AutoCharge will not actuate the air cylinder or count balls through the feeder

1 – Auto, the AutoCharge will automatically feed balls according the user-entered feed rate

2 – Manual, the AutoCharge will process manual commands (see nManaualCommand above)

nZeroDischargeCount (Int32, RO, T) – is the number of successive discharges where no balls have been

counted. When this value exceeds the limit set by nZeroDischargeCountThreshold, the

AutoCharge will indicate a ball jam or bin empty condition in bState.

nZeroDischargeCountThreshold (Int32, RW, P) – sets the limit for the number of successive discharges

with no balls counted before indicating a ball jam/bin empty condition.

szUnits (String*10, RW, P) – user-defined weight unit of measure for grinding balls (not currently

accessible remotely)

tbl_counts (Int32*16, RO, P) – counts in each channel since installation or table reset.

tbl_curcounts (Int32*16, RO, T) – counts for each channel in the current discharge

tbl_zero_counts (Int32*16, RO, T) – number of successive zero-ball discharges for each channel

8.7 AUTOCHARGE™ Integer Variables Memory Addresses

INTEGER VARIABLES

Scratch

Pad IEEE 1394 Modbus

Register

Index Address Unit ID Address Variable Access

0 F0D81000 110 2049 bRemoteMode RO

1 F0D81004 110 2051 bState RO

2 F0D81008 110 2053 bInputError RO

3 F0D8100C 110 2055 nFeedStep RO

4 F0D81010 110 2057 nDischargeCount RO

5 F0D81014 110 2059 nZeroDischargeCount RO

6 F0D81018 110 2061 Not Used

7 F0D8101C 110 2063 Not Used

8 F0D81020 110 2065 Not Used

9 F0D81024 110 2067 Not Used

10 F0D81028 110 2069 Not Used

11 F0D8102C 110 2071 Not Used

AUTOCHARGE™ Operations & Maintenance Manual Page 23

12 F0D81030 110 2073 Not Used

13 F0D81034 110 2075 Not Used

14 F0D81038 110 2077 Not Used

15 F0D8103C 110 2079 Not Used

16 F0D81040 110 2081 nRunMode RW

17 F0D81044 110 2083 nManualCommand RW

18 F0D81048 110 2085 nChannelCountZeroThreshold RW

19 F0D8104C 110 2087 nZeroDischargeCountThreshold RW

20 F0D81050 110 2089 MAX_CHANNEL RW

21 F0D81054 110 2091 nCountDelay RW

22 F0D81058 110 2093 Not Used

23 F0D8105C 110 2095 Not Used

24 F0D81060 110 2097 Not Used

25 F0D81064 110 2099 Not Used

26 F0D81068 110 2101 Not Used

27 F0D8106C 110 2103 Not Used

28 F0D81070 110 2105 Not Used

29 F0D81074 110 2107 Not Used

30 F0D81078 110 2109 Not Used

31 F0D8107C 110 2111 Not Used

32 F0D81080 110 2113 Total counts channel 0 RO

33 F0D81084 110 2115 Total counts channel 1 RO

34 F0D81088 110 2117 Total counts channel 2 RO

35 F0D8108C 110 2119 Total counts channel 3 RO

36 F0D81090 110 2121 Total counts channel 4 RO

37 F0D81094 110 2123 Total counts channel 5 RO

38 F0D81098 110 2125 Total counts channel 6 RO

39 F0D8109C 110 2127 Total counts channel 7 RO

40 F0D810A0 110 2129 Total counts channel 8 RO

41 F0D810A4 110 2131 Total counts channel 9 RO

42 F0D810A8 110 2133 Total counts channel 10 RO

43 F0D810AC 110 2135 Total counts channel 11 RO

44 F0D810B0 110 2137 Total counts channel 12 RO

45 F0D810B4 110 2139 Total counts channel 13 RO

46 F0D810B8 110 2141 Total counts channel 14 RO

47 F0D810BC 110 2143 Total counts channel 15 RO

48 F0D810C0 110 2145 Current counts channel 0 RO

49 F0D810C4 110 2147 Current counts channel 1 RO

50 F0D810C8 110 2149 Current counts channel 2 RO

51 F0D810CC 110 2151 Current counts channel 3 RO

52 F0D810D0 110 2153 Current counts channel 4 RO

AUTOCHARGE™ Operations & Maintenance Manual Page 24

53 F0D810D4 110 2155 Current counts channel 5 RO

54 F0D810D8 110 2157 Current counts channel 6 RO

55 F0D810DC 110 2159 Current counts channel 7 RO

56 F0D810E0 110 2161 Current counts channel 8 RO

57 F0D810E4 110 2163 Current counts channel 9 RO

58 F0D810E8 110 2165 Current counts channel 10 RO

59 F0D810EC 110 2167 Current counts channel 11 RO

60 F0D810F0 110 2169 Current counts channel 12 RO

61 F0D810F4 110 2171 Current counts channel 13 RO

62 F0D810F8 110 2173 Current counts channel 14 RO

63 F0D810FC 110 2175 Current counts channel 15 RO

64 F0D81100 110 2177 Zero counts channel 0 RO

65 F0D81104 110 2179 Zero counts channel 1 RO

66 F0D81108 110 2181 Zero counts channel 2 RO

67 F0D8110C 110 2183 Zero counts channel 3 RO

68 F0D81110 110 2185 Zero counts channel 4 RO

69 F0D81114 110 2187 Zero counts channel 5 RO

70 F0D81118 110 2189 Zero counts channel 6 RO

71 F0D8111C 110 2191 Zero counts channel 7 RO

72 F0D81120 110 2193 Zero counts channel 8 RO

73 F0D81124 110 2195 Zero counts channel 9 RO

74 F0D81128 110 2197 Zero counts channel 10 RO

75 F0D8112C 110 2199 Zero counts channel 11 RO

76 F0D81130 110 2201 Zero counts channel 12 RO

77 F0D81134 110 2203 Zero counts channel 13 RO

78 F0D81138 110 2205 Zero counts channel 14 RO

79 F0D8113C 110 2207 Zero counts channel 15 RO

AUTOCHARGE™ Operations & Maintenance Manual Page 25

8.8 AUTOCHARGE™ Real Variable Memory Addresses

REAL VARIABLES

Scratch

Pad IEEE 1394 Modbus

Register

Index Address Unit ID Address Variable Access

0 F0D82000 110 4097 fDischargePerHour RO

1 F0D82004 110 4099 fFeedDelayCalc RO

2 F0D82008 110 4101 fTimeDischarge RO

3 F0D8200C 110 4103 fWeight RO

4 F0D82010 110 4105 fWeightFilter RO

5 F0D82014 110 4107 fAvgWeightPerDischarge RO

6 F0D82018 110 4109 Not Used

7 F0D8201C 110 4111 Not Used

8 F0D82020 110 4113 Not Used

9 F0D82024 110 4115 Not Used

10 F0D82028 110 4117 Not Used

11 F0D8202C 110 4119 Not Used

12 F0D82030 110 4121 Not Used

13 F0D82034 110 4123 Not Used

14 F0D82038 110 4125 Not Used

15 F0D8203C 110 4127 Not Used

16 F0D82040 110 4129 fFeedRate RW

17 F0D82044 110 4131 fBallWeight RW

18 F0D82048 110 4133 fTimeDetect RW

19 F0D8204C 110 4135 fTimeExtend RW

20 F0D82050 110 4137 fTimeRetract RW

21 F0D82054 110 4139 fScaleFactor RW

22 F0D82058 110 4141 fDischargeTime RW

23 F0D8205C 110 4143 fSettlingTime RW

24 F0D82060 110 4145 Not Used

25 F0D82064 110 4147 Not Used

26 F0D82068 110 4149 Not Used

27 F0D8206C 110 4151 Not Used

28 F0D82070 110 4153 Not Used

29 F0D82074 110 4155 Not Used

30 F0D82078 110 4157 Not Used

31 F0D8207C 110 4159 Not Used

AUTOCHARGE™ Operations & Maintenance Manual Page 26

9.0 Version History

9.1 Version 3.0W

This document applies to version 3.0W of the AutoCharge PAC-based controller with feeder and weight-

based discharge chute. This version includes an embedded PC with touchscreen control mounted on the

AutoCharge controller enclosure. The AutoCharge star feeder empties balls into a discharge chute where

they are weighed from load cell inputs and then discharged onto the mill feed conveyor.

9.2 Version 3.0

Applies to version 3.0 of the AutoCharge PAC-based controller with limit switch counters. This version

includes an embedded PC with touchscreen control mounted on the AutoCharge controller enclosure.

Version 3.0 includes two AutoCharge models, the 301 and 301W. Model 301 uses limit-switches to

count individual balls charged to the mill through ball discharge chutes. Model 301W is the

weightometer-based unit that measures actual weight of balls charge through separate instrumented

discharge hopper (See Version 3.0W above).

9.3 Version 2.0

Version 2.0 added a local touchscreen display from a dedicated G70 terminal, replacing the output

counter, indicator lamps and pushbuttons. Operation and configuration are performed locally on the

touchscreen.

9.4 Version 1.0

Version 1.0 is the first programmable automation controller (PAC) based AutoCharge unit. Previous

systems used programmable logic controllers (PLC) . Version 1.0 included only an output counter, panel

indicator lamps and push-button controls for start, stop and reset. Configuration was provided through

a Windows client software program.

AUTOCHARGE™ Operations & Maintenance Manual Page 27

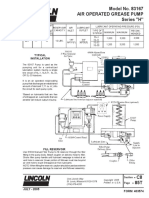

100BaseT Connection

to Plant Network

+V +V -V -V

MW

MEAN WELL DR-120-24 L N -V +V LED ADJ

230VAC

INPUT:

INPUT 100-120VAC 3.3A

100 – 240Vac

200-240VAC 2.0A

1.5A 50-60Hz

OUTPUT: 24VDC 5A

115VAC MW MODEL No:

MEAN WELL

DR-4505

UL

UL

N L

*24VDC power

supply must be

switched to match

incoming AC

voltage

+24V

GND

CAT5

LOAD CELL CONNECTION (USE 4-WIRE

CONNECTION FOR AUTOCHARGE, 24VDC

26

27

28

29

30

31

32

1

2

3

4

5

6

POWER NOT SHOWN ON DIAGRAM)

L1 L2 L3

+ - + -

PPC-L61T TOUCHSCREEN PANEL PC

G G

T1 T2 T3

AC MAIN SUPPLY

100-240VAC 50/60Hz

NEUT

LIVE

GND

AutoCharge Control Box

AutoCharge PAC-based Control Box with load cell input

and PPC-L61T

FSCM NO DWG NO REV

DAVID TAYLOR

AC-CBPAC-LC A

FEEDER CYLINDER DISCHARGE CHUTE CYLINDER 6/15/2012 SCALE 1:1 SHEET 1 OF 5

Вам также может понравиться

- F.C. Bond Bico Ball Mill Operating InstructionsДокумент25 страницF.C. Bond Bico Ball Mill Operating InstructionsNataniel LinaresОценок пока нет

- Tankcell® Flotation Machine: Bolt ConnectionsДокумент6 страницTankcell® Flotation Machine: Bolt ConnectionsJulver Goyzueta ArceОценок пока нет

- 1.2.1 PF Filter PlatesДокумент52 страницы1.2.1 PF Filter PlatesCristian Pulgar Fabres100% (1)

- Zinn Stein FlotationДокумент8 страницZinn Stein Flotationalexander beltranОценок пока нет

- Probebrochure Rev8Документ7 страницProbebrochure Rev8Matheus TorresОценок пока нет

- 15 - Load - Construction - Type - Resultado Cabeceras (Area 3000)Документ66 страниц15 - Load - Construction - Type - Resultado Cabeceras (Area 3000)Juan Jose San Martin AlfaroОценок пока нет

- Flow Sheet (Solis Egusquiza Ronald)Документ83 страницыFlow Sheet (Solis Egusquiza Ronald)Dan PerezОценок пока нет

- RANDOL AAC PumpcellДокумент9 страницRANDOL AAC PumpcelljadetorresОценок пока нет

- 1.3 Materiales de Caucho para PF Serie 60Документ33 страницы1.3 Materiales de Caucho para PF Serie 60ronald palomino100% (1)

- EMC 3273 E-Cat MechДокумент4 страницыEMC 3273 E-Cat Mechrichard gutierrezОценок пока нет

- CMP2015 - Assessing Vertimill Ultrafine Grinding PerformanceДокумент7 страницCMP2015 - Assessing Vertimill Ultrafine Grinding PerformancerodrigoОценок пока нет

- Curso F Prensa 1Документ52 страницыCurso F Prensa 1Rafael QuilicheОценок пока нет

- Outotec Oktop Agitator Unit UpgradeДокумент2 страницыOutotec Oktop Agitator Unit UpgradegicntОценок пока нет

- Vedanta Green Anode Plant Liquid Pitch Stirring ManualДокумент47 страницVedanta Green Anode Plant Liquid Pitch Stirring ManualSubhransu MohapatraОценок пока нет

- Strategies for Instrumentation and Control of ThickenersДокумент21 страницаStrategies for Instrumentation and Control of ThickenersPablo OjedaОценок пока нет

- Imhoflot pneumatic flotation technologyДокумент8 страницImhoflot pneumatic flotation technologyTandil Amira Matus HernándezОценок пока нет

- Flotation CellsДокумент6 страницFlotation CellsrgongoravОценок пока нет

- Filtro Marco y PlatosДокумент5 страницFiltro Marco y PlatosCesar LapaОценок пока нет

- Operating & Maintenance Manual Mini Pilot Plant System - Compact Lab ColumnДокумент41 страницаOperating & Maintenance Manual Mini Pilot Plant System - Compact Lab ColumnDiego Carhuaz VasquezОценок пока нет

- "Type of Filter and Its Applications in Detail": G H Patel College of Engineering &technologyДокумент11 страниц"Type of Filter and Its Applications in Detail": G H Patel College of Engineering &technologyManav PatelОценок пока нет

- Wemco 11 BrochureДокумент8 страницWemco 11 Brochuresalvador_10Оценок пока нет

- Lamella Sedimentation EquipmentДокумент4 страницыLamella Sedimentation EquipmentTsakalakis G. KonstantinosОценок пока нет

- Curso F Prensa 2Документ55 страницCurso F Prensa 2Rafael QuilicheОценок пока нет

- Paper # 074 - SAG MILL OPERATIONS IN SOSSEGO MINE PDFДокумент9 страницPaper # 074 - SAG MILL OPERATIONS IN SOSSEGO MINE PDFcarloscjunoОценок пока нет

- Zambia DRC Training Plant SideДокумент67 страницZambia DRC Training Plant SideMetalurgista Sos100% (1)

- CIP CIL Interstage Screening SolutionsДокумент4 страницыCIP CIL Interstage Screening SolutionsevalenciaОценок пока нет

- Kemix Interstage Screen BrochureДокумент8 страницKemix Interstage Screen BrochureFernandim SoaresОценок пока нет

- Liner Assembly-Antamina Project: .63 Total Gap Typical 16 423.21 Available Length 10750Документ1 страницаLiner Assembly-Antamina Project: .63 Total Gap Typical 16 423.21 Available Length 10750jhonОценок пока нет

- Delkor EspesadorДокумент21 страницаDelkor Espesadorrichard gutierrezОценок пока нет

- Pebble Crusher Specific EnergyДокумент10 страницPebble Crusher Specific Energy12milehillОценок пока нет

- Planos SAG Shell PDFДокумент1 страницаPlanos SAG Shell PDFA̶l̶x̶a̶n̶d̶e̶r̶ PaniОценок пока нет

- Cabletorq Thickeners/Clarifiers: Gl&V/Dorr-Oliver100Ft - Dia.Type"S"CabletorqthickenerДокумент4 страницыCabletorq Thickeners/Clarifiers: Gl&V/Dorr-Oliver100Ft - Dia.Type"S"Cabletorqthickenerdgomez686Оценок пока нет

- Cono Sedimentador de LodosДокумент16 страницCono Sedimentador de LodosJaime Olazo MolloОценок пока нет

- Large Flotation Cells in Copper ProcessingДокумент8 страницLarge Flotation Cells in Copper Processinglouza8100% (1)

- Slon Magnetic Separators Applied in TheДокумент8 страницSlon Magnetic Separators Applied in TheMulti DELLОценок пока нет

- Y JEENДокумент1 страницаY JEENYousef AlipourОценок пока нет

- Kemix Interstage-Screen-Brochure 2018 Rev1Документ8 страницKemix Interstage-Screen-Brochure 2018 Rev1evalenciaОценок пока нет

- Selecting The Correct Concentrate Launder DesignДокумент2 страницыSelecting The Correct Concentrate Launder DesignMahlatse Mogashoa0% (1)

- Multotec Injection Moulded Screening Systems-Digital-4c504Документ6 страницMultotec Injection Moulded Screening Systems-Digital-4c504Nilton Inca TitoОценок пока нет

- White Paper On Conveyor Belt CapacityДокумент3 страницыWhite Paper On Conveyor Belt Capacityhimangshu mandal100% (1)

- Top SAG Mill ManufacturersДокумент2 страницыTop SAG Mill ManufacturersRodrigo GarcíaОценок пока нет

- Production of Nickel Concentrate From Ground Sulfide OreДокумент19 страницProduction of Nickel Concentrate From Ground Sulfide OreJadhira RamirezОценок пока нет

- Flowsheet Circuito ChipmoДокумент1 страницаFlowsheet Circuito ChipmoYusep Ronal Segura VillarrealОценок пока нет

- Mintek WAD Cynoprobe for Gold Plant Cyanide AnalysisДокумент8 страницMintek WAD Cynoprobe for Gold Plant Cyanide AnalysisMahlatse MogashoaОценок пока нет

- Celdas Wemco de 60 m3 - Planos IdДокумент17 страницCeldas Wemco de 60 m3 - Planos IdFrancisco Gil100% (1)

- Ws Tyler XL Class PartsДокумент6 страницWs Tyler XL Class Partsyolimar escorciaОценок пока нет

- Unidad Hidráulica PF1019Документ2 страницыUnidad Hidráulica PF1019Juan Carlos Lopez TorresОценок пока нет

- Liquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340Документ10 страницLiquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340pablodugalОценок пока нет

- 2 - 15B Ah-5vomДокумент1 страница2 - 15B Ah-5vomMamiherintsoa Issaia RanaivoarimananaОценок пока нет

- 13 18 517-443-A Middle Pulp Lifter Chrome Moly St. 2435: Item Qty. P.D.B. Description Material Ref. WT (KG)Документ1 страница13 18 517-443-A Middle Pulp Lifter Chrome Moly St. 2435: Item Qty. P.D.B. Description Material Ref. WT (KG)jhonОценок пока нет

- Siemens manuals for San Cristobal substation project C-479Документ18 страницSiemens manuals for San Cristobal substation project C-479Allen Marcelo Ballesteros LópezОценок пока нет

- 015-80T3-FW8 - Rev 1Документ1 страница015-80T3-FW8 - Rev 1José Luis TolaОценок пока нет

- AFG Alpine Fluidised Bed Opposed Jet Mills (En)Документ10 страницAFG Alpine Fluidised Bed Opposed Jet Mills (En)alevandrorОценок пока нет

- Deep Cone Paste ThicknerДокумент38 страницDeep Cone Paste ThicknerzementheadОценок пока нет

- Maelgwyn Imhoflot (Chile)Документ0 страницMaelgwyn Imhoflot (Chile)crazymax90Оценок пока нет

- 5-12 HSVS Mod-B 416+ 062212Документ73 страницы5-12 HSVS Mod-B 416+ 062212Alan MaidaОценок пока нет

- Service Manual: Separation Unit 840Документ158 страницService Manual: Separation Unit 840Jeros Garcia100% (4)

- 3054 Engine Valve Lash - InspectAdjustДокумент5 страниц3054 Engine Valve Lash - InspectAdjusthenry lavieraОценок пока нет

- Pilot Pressure To The Main Control Valve - CheckДокумент8 страницPilot Pressure To The Main Control Valve - CheckMiguel Angel Moreno100% (8)

- Actuator - 655R IOMДокумент14 страницActuator - 655R IOMvkeie0206Оценок пока нет

- 04-41-92-1 MuДокумент43 страницы04-41-92-1 Muerik masongОценок пока нет

- I 410 MBS Multi Belt Scale WebДокумент2 страницыI 410 MBS Multi Belt Scale Weberik masongОценок пока нет

- Siemens LW39-16B Cam Switch technical specsДокумент17 страницSiemens LW39-16B Cam Switch technical specsfahad pirzadaОценок пока нет

- 34-27-13 AutoBall Charger 301W Operations MaintenanceДокумент28 страниц34-27-13 AutoBall Charger 301W Operations Maintenanceerik masongОценок пока нет

- Model No. 83167 Air Operated Grease Pump Series "H": Typical InstallationДокумент4 страницыModel No. 83167 Air Operated Grease Pump Series "H": Typical Installationerik masongОценок пока нет

- Revision History: Instrument Data SheetsДокумент25 страницRevision History: Instrument Data Sheetserik masongОценок пока нет

- Instrument Data Sheets: Revision HistoryДокумент9 страницInstrument Data Sheets: Revision Historyerik masongОценок пока нет

- Product Code Revision: Outokumpu Mintec OyДокумент23 страницыProduct Code Revision: Outokumpu Mintec Oyerik masongОценок пока нет

- GFA-226B VersaMax SEДокумент2 страницыGFA-226B VersaMax SEerik masongОценок пока нет

- Oi-Or-Con-Ipc 002 F002 Ramsey Beltscale Calibration Report PDFДокумент1 страницаOi-Or-Con-Ipc 002 F002 Ramsey Beltscale Calibration Report PDFerik masongОценок пока нет

- Lay Out Piping of Air Cannon BlasterДокумент3 страницыLay Out Piping of Air Cannon Blastererik masongОценок пока нет

- Technical DataДокумент246 страницTechnical DataABDUL GHAFOORОценок пока нет

- Simatic12 Hmi kp400 ComfortДокумент250 страницSimatic12 Hmi kp400 Comforterik masongОценок пока нет

- 809.201669.050-00 (Operating and Control Philosophy) PDFДокумент23 страницы809.201669.050-00 (Operating and Control Philosophy) PDFerik masongОценок пока нет

- AM3 Code DocumentationДокумент2 страницыAM3 Code Documentationerik masong100% (1)

- D - BERNARD FILEDocumentBROCHUREYASKAWAYaskawa mp2200 Cpu02Документ22 страницыD - BERNARD FILEDocumentBROCHUREYASKAWAYaskawa mp2200 Cpu02erik masongОценок пока нет

- 3BHS112321 - Zab - E51 - F - Acs1000ad Appl SW Amc Table PDFДокумент390 страниц3BHS112321 - Zab - E51 - F - Acs1000ad Appl SW Amc Table PDFerik masongОценок пока нет

- ACS800 Maintenance Schedule 4FPS10000223379 Rev MДокумент2 страницыACS800 Maintenance Schedule 4FPS10000223379 Rev MGomez MancoОценок пока нет

- Bermamn574 Users Manual PDFДокумент32 страницыBermamn574 Users Manual PDFerik masongОценок пока нет

- When Raptor HMI FailsДокумент1 страницаWhen Raptor HMI Failserik masongОценок пока нет

- Regrinder PLCДокумент32 страницыRegrinder PLCerik masongОценок пока нет

- En Acs550 01 Um H A4-1Документ326 страницEn Acs550 01 Um H A4-1Thanh HaiОценок пока нет

- 1im05p03d21-11en 030Документ8 страниц1im05p03d21-11en 030erik masong100% (1)

- 61f PDFДокумент31 страница61f PDFAri SutejoОценок пока нет

- Master Table of Contents Hose PDFДокумент20 страницMaster Table of Contents Hose PDFerik masongОценок пока нет

- SpecsДокумент1 страницаSpecserik masongОценок пока нет

- Electrical Power Systems Wadhwa 6Документ1 страницаElectrical Power Systems Wadhwa 6teceeeОценок пока нет

- CompactRIO CRIO-FRC 8 SlotДокумент25 страницCompactRIO CRIO-FRC 8 SlotHieu LEОценок пока нет

- Chenbro: ES340 Chassis User ManualДокумент21 страницаChenbro: ES340 Chassis User ManualEric NgОценок пока нет

- AUGUST2007 REB500 LДокумент112 страницAUGUST2007 REB500 LRK KОценок пока нет

- 110Документ16 страниц110A FirdausОценок пока нет

- CBSE Class 12th Physics Sample EbookДокумент16 страницCBSE Class 12th Physics Sample EbookmisostudyОценок пока нет

- Ata21 A320Документ41 страницаAta21 A320David Morales100% (1)

- GSB 18 Ve 2 Li Professional Manual 135080 PDFДокумент162 страницыGSB 18 Ve 2 Li Professional Manual 135080 PDFElmer TimanaОценок пока нет

- Dha Suffa University: Course Enrollment FormДокумент1 страницаDha Suffa University: Course Enrollment Formkiranliaquat60Оценок пока нет

- Operational Amplifiers Questions and AnswersДокумент4 страницыOperational Amplifiers Questions and AnswersSuresh L100% (1)

- The Geological Interpretation of Well Logs Malcolm Rider PDFДокумент5 страницThe Geological Interpretation of Well Logs Malcolm Rider PDFgazi0% (1)

- ADB Financed Electric Vehicle Design in The PhilippinesДокумент9 страницADB Financed Electric Vehicle Design in The PhilippinesJerry EsquivelОценок пока нет

- Install GuideДокумент36 страницInstall GuideTonyОценок пока нет

- Electrical Power Up: If External Power Is NeededДокумент22 страницыElectrical Power Up: If External Power Is NeededjohnfcОценок пока нет

- MRA 4 Incoming and Outgoing Feeder ProtectionДокумент2 страницыMRA 4 Incoming and Outgoing Feeder ProtectionFlo MircaОценок пока нет

- AM Signal Bandwidth and Modulation IndexДокумент15 страницAM Signal Bandwidth and Modulation IndexMANDEEP REDDYОценок пока нет

- Report Lab 1Документ15 страницReport Lab 1Mohd Syamsul Ramli100% (1)

- Belcher Road South, Largo, FL 33773 - USA - Tel +1 (727) 447-6140 - Fax +1 (727) 442-5699Документ4 страницыBelcher Road South, Largo, FL 33773 - USA - Tel +1 (727) 447-6140 - Fax +1 (727) 442-5699Usman AzeemОценок пока нет

- Install Stand-Alone PV SystemДокумент37 страницInstall Stand-Alone PV SystemMahad omariОценок пока нет

- Testing Data Radio Modem With Serial Port Tool V1.13: 1. Usb Board DefinitionsДокумент13 страницTesting Data Radio Modem With Serial Port Tool V1.13: 1. Usb Board DefinitionsHimanshu VermaОценок пока нет

- Advanced Power Electronics and Drives LabДокумент8 страницAdvanced Power Electronics and Drives LabAkash MathurОценок пока нет

- 198 Form pg5Документ3 страницы198 Form pg5iosefatu63Оценок пока нет

- Magnetism - Science Year 8Документ15 страницMagnetism - Science Year 8b_syiera100% (7)

- Simatic HmiДокумент324 страницыSimatic HmiAyman ElotaifyОценок пока нет

- Electric Circuits Lab ManualДокумент34 страницыElectric Circuits Lab ManualMohamad FariezОценок пока нет

- (y5ii Cun-u29) Hướng Dẫn Cập Nhật Phiên Bản Android 5Документ4 страницы(y5ii Cun-u29) Hướng Dẫn Cập Nhật Phiên Bản Android 5Sarra ChoucheneОценок пока нет

- Protection I Notes UpdatedДокумент46 страницProtection I Notes UpdatednitalizОценок пока нет

- MS150A Feedback AC Modular Servo SystemДокумент12 страницMS150A Feedback AC Modular Servo SystemWaleed MuradОценок пока нет

- Inst PrabhaДокумент29 страницInst Prabharaj guptaОценок пока нет

- GME Land Communication CatalogueДокумент16 страницGME Land Communication CatalogueRadio PartsОценок пока нет