Академический Документы

Профессиональный Документы

Культура Документы

Lldpe Ga564189

Загружено:

xy2zjgОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Lldpe Ga564189

Загружено:

xy2zjgАвторское право:

Доступные форматы

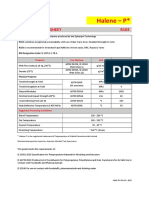

Technical Data Sheet

Petrothene GA564189

Linear Low Density Polyethylene

Product Description

Petrothene GA564189 exhibits good stiffness and low temperature toughness. Typical applications include trash

cans, industrial containers, housewares and toys.

Regulatory Status

For regulatory compliance information, see Petrothene GA564189 Product Stewardship Bulletin (PSB) and

Safety Data Sheet (SDS).

Status Commercial: Active

Availability North America

Application Housewares; Outdoor and Power Tools; Sports, Leisure & Toys; Trash Cans; Wire &

Cable

Market Compounding; Rigid Packaging; Wire & Cable

Processing Method Compounding; Injection Molding; Wire & Cable

Nominal English Nominal SI

Typical Properties Value Units Value Units Test Method

Physical

Melt Flow Rate, (190 °C/2.16 kg) 20 g/10 min 20 g/10 min ASTM D1238

Density, (23 °C) 0.924 g/cm³ 0.924 g/cm³ ASTM D1505

Spiral Flow 12.6 in 32.1 cm LYB Method

Mechanical

Flexural Modulus

(1% Secant) 63000 psi 440 MPa ASTM D790

(2% Secant) 55000 psi 380 MPa ASTM D790

Tensile Strength at Break, (23 °C) 1200 psi 8 MPa ASTM D638

Tensile Strength at Yield, (23 °C) 2100 psi 14 MPa ASTM D638

Tensile Elongation at Yield, (23 °C) 12 % 12 % ASTM D638

Hardness

Shore Hardness, (Shore D) 57 57 ASTM D2240

Thermal

Vicat Softening Temperature 196 °F 91 °C ASTM D1525

Low Temperature Brittleness, F೦ೡ <-105 °F <-76 °C ASTM D746

Deflection Temperature Under Load, (66 psi,

113 °F 45 °C ASTM D648

Unannealed)

Notes

Tensile properties were run with a crosshead speed of 20 inches/min or 500 mm/min.

Flexural Modulus properties were run with a crosshead speed of 0.5 inches/min or 12.5 mm/min.

LyondellBasell Petrothene GA564189

Technical Data Sheet Recipient Tracking #:

Date: 9/10/2017 Page 1 of 3 Request #: 969621

Spiral Flow measures the number of inches of flow produced when molten resin is injected into a long, spiral

channel (0.0625" insert), at a constant injection pressure of 1000 psi with a melt temperature of 440 °F.

Deflection Temperature Under Load and Low Temperature Brittleness data are for control and development

work and are not intended for use in design or predicting performance at elevated or sub-ambient temperatures.

These are typical property values not to be construed as specification limits.

Processing Techniques

Specific recommendations for resin type and processing conditions can only be made when the end use,

required properties and fabrication equipment are known.

Company Information

For further information regarding the LyondellBasell company, please visit http://www.lyb.com/.

© LyondellBasell Industries Holdings, B.V. 2017

Disclaimer

Before using a product sold by a company of the LyondellBasell family of companies, users should make their

own independent determination that the product is suitable for the intended use and can be used safely and

legally.

SELLER MAKES NO WARRANTY; EXPRESS OR IMPLIED (INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR ANY WARRANTY) OTHER THAN

AS SEPARATELY AGREED TO BY THE PARTIES IN A CONTRACT.

Users should review the applicable Safety Data Sheet before handling the product.

This product(s) may not be used in the manufacture of any of the following, without prior written approval by

Seller for each specific product and application:

(i) U.S. FDA Class I or II Medical Devices; Health Canada Class I, II or III Medical Devices; European Union

Class I or II Medical Devices;

(ii) film, overwrap and/or product packaging that is considered a part or component of one of the

aforementioned medical devices;

(iii) packaging in direct contact with a pharmaceutical active ingredient and/or dosage form that is intended for

inhalation, injection, intravenous, nasal, ophthalmic (eye), digestive, or topical (skin) administration;

(iv) tobacco related products and applications, electronic cigarettes and similar devices.

(v) safety components in automotive applications, for example: air bags, air bag unit housings and covers,

seat belt mechanisms, brake systems, pedals and pedal supports, steering systems.

The product(s) may not be used in:

(i) U.S. FDA Class III Medical Devices; Health Canada Class IV Medical Devices; European Class III Medical

Devices;

(ii) applications involving permanent implantation into the body;

(iii) life-sustaining medical applications.

All references to U.S. FDA, Health Canada, and European Union regulations include another country’s

equivalent regulatory classification.

In addition to the above, LyondellBasell may further prohibit or restrict the use of its products in certain

applications. For further information, please contact a LyondellBasell representative.

LyondellBasell Petrothene GA564189

Technical Data Sheet Recipient Tracking #:

Date: 9/10/2017 Page 2 of 3 Request #: 969621

Trademarks

Adflex, Adstif, Adsyl, Akoafloor, Akoalit, Alastian, Alathon, Alkylate, Amazing Chemistry, Aquamarine,

Aquathene, Avant, Catalloy, Clyrell, CRP, Crystex, Dexflex, Duopac, Duoprime, Explore & Experiment, Filmex,

Flexathene, Fueling the power to win, Glacido, Hifax, Hiflex, Histif, Hostacom, Hostalen, Hyperzone, Ideal,

Indure, Integrate, Koattro, LIPP, Lucalen, Luflexen, Lupolen, Luposim, Lupostress, Lupotech, Metocene,

Microthene, Moplen, MPDIOL, Nerolex, Nexprene, Petrothene, Plexar, Polymeg, Pristene, Prodflex, Pro-fax,

Punctilious, Purell, Refax, SAA100, SAA101, Sequel, Softell, Spherilene, Spheripol, Spherizone, Starflex,

Stretchene, Superflex, TBAc , Tebol, T-Hydro, Toppyl, Trans4m, Tufflo, Ultrathene, Vacido and Valtec are

trademarks owned and/or used by the LyondellBasell family of companies.

Adsyl, Akoafloor, Akoalit, Alastian, Alathon, Aquamarine, Avant, CRP, Crystex, Dexflex, Duopac, Duoprime,

Explore & Experiment, Filmex, Flexathene, Hifax, Hostacom, Hostalen, Ideal, Integrate, Koattro, Lucalen,

Lupolen, Metocene, Microthene, Moplen, MPDIOL, Nexprene, Petrothene, Plexar, Polymeg, Pristene, Pro-fax,

Punctilious, Purell, Sequel, Softell, Spheripol, Spherizone, Starflex, Tebol, T-Hydro, Toppyl, Tufflo and

Ultrathene are registered in the U.S. Patent and Trademark Office.

LyondellBasell Petrothene GA564189

Technical Data Sheet Recipient Tracking #:

Date: 9/10/2017 Page 3 of 3 Request #: 969621

Вам также может понравиться

- Clariant Brochure Exolit Flame Retardants For Thermoplastics 201306 EN PDFДокумент24 страницыClariant Brochure Exolit Flame Retardants For Thermoplastics 201306 EN PDFxy2zjgОценок пока нет

- Strength of MaterialsДокумент66 страницStrength of MaterialsSaiKiran Reddy PonnapuReddy100% (3)

- Astm F606 PDFДокумент16 страницAstm F606 PDFEnrike GarciaОценок пока нет

- Mechanical Properties of Metals - Lecture 9, MetE 143Документ53 страницыMechanical Properties of Metals - Lecture 9, MetE 143陈小花Оценок пока нет

- PVC Design Guide ApprovedДокумент222 страницыPVC Design Guide Approvedgabox7Оценок пока нет

- CE 200L Report 3Документ13 страницCE 200L Report 3Hayden Chappelear-Robbins100% (1)

- ASTM D7205D7205M-06 (2016) A. Standard Test Method For Tensile Properties of Fiber Reinforced Polymer Matrix Composite BarsДокумент13 страницASTM D7205D7205M-06 (2016) A. Standard Test Method For Tensile Properties of Fiber Reinforced Polymer Matrix Composite BarsWentao Wang100% (1)

- Ashirvad Pipes Pvt. LTD., Bangalore: Test Report of CPVC Pipes As Per Is 15778Документ7 страницAshirvad Pipes Pvt. LTD., Bangalore: Test Report of CPVC Pipes As Per Is 15778mohd shiraz100% (1)

- Hdpe Alathon H5520 EquistarДокумент2 страницыHdpe Alathon H5520 EquistarEric Mahonri PereidaОценок пока нет

- Adflex: Technical Data SheetДокумент3 страницыAdflex: Technical Data Sheetnouman ashrafОценок пока нет

- Technical Data SheetДокумент2 страницыTechnical Data SheetIVANCHUОценок пока нет

- Hifax: Technical Data SheetДокумент3 страницыHifax: Technical Data SheetaLe08ajОценок пока нет

- Technical Data SheetДокумент2 страницыTechnical Data SheetIVANCHUОценок пока нет

- Technical Data SheetДокумент3 страницыTechnical Data SheetAdrián SánchezОценок пока нет

- Pro-Fax 7523: Pro-Fax 7523 Impact Polypropylene Copolymer Is Available in Pellet Form. This Resin Is TypicallyДокумент2 страницыPro-Fax 7523: Pro-Fax 7523 Impact Polypropylene Copolymer Is Available in Pellet Form. This Resin Is Typicallyalejandro hurtadoОценок пока нет

- Technical Data Sheet - Original Hoop MaterialДокумент2 страницыTechnical Data Sheet - Original Hoop MaterialMichelle Kozmik JirakОценок пока нет

- High Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Документ2 страницыHigh Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Phung LucОценок пока нет

- LD-PE LyondellBasell Purell 2410TДокумент3 страницыLD-PE LyondellBasell Purell 2410TNeagu MariusОценок пока нет

- Technical Data SheetДокумент2 страницыTechnical Data SheetEduardo MazariegosОценок пока нет

- Lupolen: Technical Data SheetДокумент3 страницыLupolen: Technical Data SheetJaime222Оценок пока нет

- Neogard 70690 Ficha TecnicaДокумент2 страницыNeogard 70690 Ficha TecnicaMaria Del Carmen Vidal SanchezОценок пока нет

- Material DataДокумент3 страницыMaterial DataR.Ranjan PradhanОценок пока нет

- Hifax: TYC 258X S92908Документ3 страницыHifax: TYC 258X S92908Alexander HermannОценок пока нет

- Lyondell Basell Moplen EP300RДокумент3 страницыLyondell Basell Moplen EP300RHung TranОценок пока нет

- C C14 LD2420F PlusДокумент3 страницыC C14 LD2420F PlusJaime222Оценок пока нет

- Technical Data SheetДокумент3 страницыTechnical Data SheetEmanuel TescheОценок пока нет

- Petrothene: Technical Data SheetДокумент3 страницыPetrothene: Technical Data SheetEli DelgadoОценок пока нет

- Alathon®: ApplicationsДокумент2 страницыAlathon®: ApplicationsCarlos Revilla FloresОценок пока нет

- 852XДокумент4 страницы852XAlp PalaОценок пока нет

- Lyondell Basell Moplen EP548PДокумент4 страницыLyondell Basell Moplen EP548PIndrajit SahaОценок пока нет

- Moplen: Technical Data SheetДокумент2 страницыMoplen: Technical Data SheetLaxman AhirОценок пока нет

- Alathon: Technical Data SheetДокумент3 страницыAlathon: Technical Data SheetJaime222Оценок пока нет

- AkzoNobel - QN102QF - Interpon ACE 2000Документ3 страницыAkzoNobel - QN102QF - Interpon ACE 2000Eslam FaroukОценок пока нет

- Dow Kt10000ueДокумент2 страницыDow Kt10000ueChu ChuОценок пока нет

- NA9800000Документ2 страницыNA9800000Noe floresОценок пока нет

- PEADM5372Документ2 страницыPEADM5372nicolas yoris marcoglieseОценок пока нет

- Durastar DS1910HFДокумент2 страницыDurastar DS1910HFEvelyn SigoliОценок пока нет

- 4011 TDДокумент2 страницы4011 TDFernando HalaburaОценок пока нет

- CirRenew C14 LD2420DДокумент3 страницыCirRenew C14 LD2420DJaime222Оценок пока нет

- Technical Data Sheet - Profile ExtrusionДокумент1 страницаTechnical Data Sheet - Profile ExtrusionEsteban Ibarra RuizОценок пока нет

- Ra R120MKДокумент1 страницаRa R120MKyansyafОценок пока нет

- LLGA1810Документ2 страницыLLGA1810KAKI BELANGОценок пока нет

- Microthene: Technical Data SheetДокумент2 страницыMicrothene: Technical Data SheetJaime222Оценок пока нет

- Dow KT 10000 UeДокумент2 страницыDow KT 10000 UeLuca GuadagnoОценок пока нет

- Datasheet Moplen EP340K 3288 - 1531149020Документ4 страницыDatasheet Moplen EP340K 3288 - 1531149020afidyusufОценок пока нет

- Technical Data SheetДокумент2 страницыTechnical Data SheetLeductoan LeОценок пока нет

- POLYMER C150Y - Jan15 - New - Rev1Документ2 страницыPOLYMER C150Y - Jan15 - New - Rev1W I Prayogo100% (1)

- Moplen: Technical Data SheetДокумент3 страницыMoplen: Technical Data SheetMonica BoccaОценок пока нет

- Technical Data Sheet - ASTM PDFДокумент2 страницыTechnical Data Sheet - ASTM PDFnielОценок пока нет

- TDS - Marlex® K306 PolyethyleneДокумент1 страницаTDS - Marlex® K306 PolyethyleneMauricio Alejandro Castillo SorianoОценок пока нет

- Technical Data Sheet ADFLEX F 500Документ2 страницыTechnical Data Sheet ADFLEX F 500leftpowtaОценок пока нет

- K-Resin Styrene-Butadiene Copolymers (SBC) : Customer Benefits Typical ApplicationsДокумент1 страницаK-Resin Styrene-Butadiene Copolymers (SBC) : Customer Benefits Typical ApplicationsPatricio Bravo CastilloОценок пока нет

- Purell ACP 6031 D Technical Data SheetДокумент3 страницыPurell ACP 6031 D Technical Data SheetPiyush A JoshiОценок пока нет

- CR C14 LD2420KДокумент3 страницыCR C14 LD2420KJaime222Оценок пока нет

- ELITE 5401G: Blown Film ResinДокумент2 страницыELITE 5401G: Blown Film ResinEndayenew MollaОценок пока нет

- 105 Ta D411-350Документ3 страницы105 Ta D411-350isaacalvareztejanoОценок пока нет

- Topilene R200P PDFДокумент2 страницыTopilene R200P PDFAli MОценок пока нет

- R200P Data SheetДокумент2 страницыR200P Data SheetPRIME STEEL RE-ROLLING MILLSОценок пока нет

- Topilene R200P PDFДокумент2 страницыTopilene R200P PDFEmmylouCasanovaОценок пока нет

- Topilene R200PДокумент2 страницыTopilene R200PNguyễn Hồng NamОценок пока нет

- Re H200MKДокумент1 страницаRe H200MKnisargpatel766Оценок пока нет

- Polypropylene Random Copolymer: Technical Data SheetДокумент2 страницыPolypropylene Random Copolymer: Technical Data SheetEmmylouCasanovaОценок пока нет

- Haldia PP Raffia - R103 DatasheetДокумент2 страницыHaldia PP Raffia - R103 DatasheetNarender RawatОценок пока нет

- TDS HP740T DaelimДокумент1 страницаTDS HP740T Daelimbrandon abella gutierrezОценок пока нет

- Rhodia - Tds - Technylstar S 218 v30 Black 31 N - enДокумент5 страницRhodia - Tds - Technylstar S 218 v30 Black 31 N - ennimonhОценок пока нет

- Ficha Tecnica Polipropileno Moplen Ep300l (J440)Документ1 страницаFicha Tecnica Polipropileno Moplen Ep300l (J440)Carlos SiuОценок пока нет

- Upp Tds Ep548s EnglishДокумент1 страницаUpp Tds Ep548s EnglishRula SiuОценок пока нет

- Exolit-FR-Clariant 2014Документ6 страницExolit-FR-Clariant 2014xy2zjgОценок пока нет

- Iriotec - 8850 - EMD - TDS (For US and Canada) PDFДокумент2 страницыIriotec - 8850 - EMD - TDS (For US and Canada) PDFxy2zjgОценок пока нет

- EXOLIT OP 1400 (LP) - SDS (Self-ignition-340C; Particle size-14 μm (Median value) )Документ11 страницEXOLIT OP 1400 (LP) - SDS (Self-ignition-340C; Particle size-14 μm (Median value) )xy2zjgОценок пока нет

- Fusabond® E226Документ2 страницыFusabond® E226xy2zjgОценок пока нет

- Clariant - Exolit Overview 2016Документ12 страницClariant - Exolit Overview 2016xy2zjgОценок пока нет

- Dismantling Service: Your Screw Elements Professionally Handled by Means of Our Dismantling ServiceДокумент2 страницыDismantling Service: Your Screw Elements Professionally Handled by Means of Our Dismantling Servicexy2zjgОценок пока нет

- Sterivalve ENДокумент2 страницыSterivalve ENxy2zjgОценок пока нет

- Fusabond® E226 - SDSДокумент10 страницFusabond® E226 - SDSxy2zjgОценок пока нет

- Stellite 12Документ2 страницыStellite 12xy2zjgОценок пока нет

- Steer Best-Practises Effect-Pigments Master 19.04Документ7 страницSteer Best-Practises Effect-Pigments Master 19.04xy2zjgОценок пока нет

- Msds MX NylonДокумент6 страницMsds MX Nylonxy2zjgОценок пока нет

- PolyamidesДокумент1 страницаPolyamidesxy2zjgОценок пока нет

- Iriotec Box LeporelloДокумент2 страницыIriotec Box Leporelloxy2zjgОценок пока нет

- Radipol A45 TDSДокумент1 страницаRadipol A45 TDSxy2zjgОценок пока нет

- GA564189 - LyondellBasellДокумент2 страницыGA564189 - LyondellBasellxy2zjgОценок пока нет

- Radipol A SDSДокумент4 страницыRadipol A SDSxy2zjgОценок пока нет

- FLAMEGARD Line PDFДокумент16 страницFLAMEGARD Line PDFxy2zjgОценок пока нет

- ASTM A517 Grade B: General Product DescriptionДокумент2 страницыASTM A517 Grade B: General Product DescriptionBruno SantosОценок пока нет

- Activity6 2c More Engineering ProblemsДокумент7 страницActivity6 2c More Engineering ProblemsChristianОценок пока нет

- ASTM A514 Grade S: General Product DescriptionДокумент2 страницыASTM A514 Grade S: General Product DescriptionAGUSTINОценок пока нет

- A786a786m PDFДокумент11 страницA786a786m PDFleroy2007Оценок пока нет

- Reinforcing SteelДокумент39 страницReinforcing SteelGage Floyd Bitayo100% (1)

- Unit 6-Metals & Non-MetalsДокумент8 страницUnit 6-Metals & Non-MetalsRahul KumarОценок пока нет

- Aluminium - Copper AlloysДокумент3 страницыAluminium - Copper AlloysRex RusselОценок пока нет

- Production of Bioplastic From Cassava Peel With Different Concentrations of Glycerol and Caco As FillerДокумент9 страницProduction of Bioplastic From Cassava Peel With Different Concentrations of Glycerol and Caco As Fillerqueen ann toledoОценок пока нет

- An Atmospheric Ice Empirical Failure CriterionДокумент6 страницAn Atmospheric Ice Empirical Failure CriterionHicham FaridОценок пока нет

- Tensile Test of T-Joint WeldДокумент11 страницTensile Test of T-Joint WeldMohammad ziyaОценок пока нет

- Tensile Properties of Plastics by Use of Microtensile SpecimensДокумент5 страницTensile Properties of Plastics by Use of Microtensile SpecimensSrikanth Srikanti100% (1)

- Is1079 2017Документ10 страницIs1079 2017qualityОценок пока нет

- Astm B62Документ6 страницAstm B62Chaerul AnwarОценок пока нет

- G. Krauss and D.K. Matlock Colorado School of Mines: C. v. White Kettering UniversityДокумент7 страницG. Krauss and D.K. Matlock Colorado School of Mines: C. v. White Kettering UniversityMadhusudhan ModemОценок пока нет

- SK Ghosh Anchor Webinar HandoutДокумент37 страницSK Ghosh Anchor Webinar HandoutMikeОценок пока нет

- Expt 03 - Strain Aging Characteristics of SteelДокумент4 страницыExpt 03 - Strain Aging Characteristics of SteelDharmendra KumarОценок пока нет

- E Cospace: AE Aterial SpecificationДокумент5 страницE Cospace: AE Aterial SpecificationAsraff Abdul RahmanОценок пока нет

- FRP SlabДокумент8 страницFRP SlabKheanglouОценок пока нет

- Astm B 233Документ4 страницыAstm B 233Ryan LasacaОценок пока нет

- Industrial Plastics Theory and Applications 6Th Edition Lokensgard Test Bank Full Chapter PDFДокумент27 страницIndustrial Plastics Theory and Applications 6Th Edition Lokensgard Test Bank Full Chapter PDFnhatmaiqfanmk100% (9)

- Extended Abstract - David Simavorian (66007)Документ17 страницExtended Abstract - David Simavorian (66007)Relu MititeluОценок пока нет

- ENGN.2060 Assignment 06 SolutionДокумент3 страницыENGN.2060 Assignment 06 SolutionSandeep PetwalОценок пока нет