Академический Документы

Профессиональный Документы

Культура Документы

Lindapter Hollo-Bolt Testing Results Summary

Загружено:

Rajed MaglinteОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Lindapter Hollo-Bolt Testing Results Summary

Загружено:

Rajed MaglinteАвторское право:

Доступные форматы

Summary of Lindapter Hollo-Bolt Testing

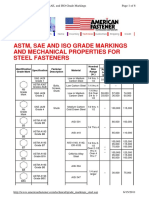

Bolt Dia. Tensile Tensile Shear Shear Critical Slip # Critical Slip # Clamping Force

SWL $ Ult Load !! SWL $ Ult Load !! SWL $ Ult Load !! Ult Load !!

M8

899.2 4496.00 1124.0 7358.03 103.41 449.62 1798.48

M10

1910.9 9554.50 2248.1 12841.15 195.58 899.24 2023.29

M12

2360.5 11802.50 3372.2 17872.39 269.77 1124.05 2248.1 (7598.58)*

M16

4945.8 24729.00 6744.3 33946.31 402.41 2787.64 6744.30

M20

8992.4 44962.00 8992.4 45636.43 476.60 3147.34 15466.93

Notes:

All loads are in pounds

Tensile Safe Working Loads shown in bold italics are those for the Hollo-Bolt itself

$ All Safe Working Loads (SWL) include a Factor of Safety of 5:1

* Figure in brackets refers to M12 5-Part Hollo-Bolt manufactured as a special for Sydney Olympic Stadium

All tests carried out by Lindapter International, British Steel (now Corus) Swinden Technology Centre, British Steel (now Corus

Tubes & Pipes, University of Sheffield, University of Nottingham, Universita di Trento and Sidercad S.p.a. during 1995, 1996 &

Note

Safe Working Loads for the Hollo-Bolt are dependent upon the yield strength of the structural tube particularly with some of

the lighter sections. Safe working loads shown above have been determined through testing in material with mininum yield str

of 40 KSI. Use of steel with lower yield strength will result in lower safe working loads. The highest tensile figure given for

each bolt size is the safe working load of the Hollo-Bolt itself. Any lower figures against a particular size show that the mode o

failure in that case is the structural tube, rather than the Hollo-Bolt.

Вам также может понравиться

- Angular Contact Bearing SwivelsДокумент1 страницаAngular Contact Bearing SwivelsmeromikhaОценок пока нет

- TCI-ANSI Composite InsulatorsДокумент18 страницTCI-ANSI Composite InsulatorsDaniel Tapia MarcosОценок пока нет

- Fender Accessories (Panels, Chains, Brackets) Catalogue en V1.3Документ10 страницFender Accessories (Panels, Chains, Brackets) Catalogue en V1.3loicdertyОценок пока нет

- Group 2 Tightening TorqueДокумент3 страницыGroup 2 Tightening TorqueSergey MovchanОценок пока нет

- Group 2 Tightening Torque: 1. Major ComponentsДокумент3 страницыGroup 2 Tightening Torque: 1. Major ComponentsSergey MovchanОценок пока нет

- Group 2 Tightening Torque: 1. Major ComponentsДокумент3 страницыGroup 2 Tightening Torque: 1. Major Componentslevinton jose tobias genesОценок пока нет

- GROUP 2 TIGHTENING TORQUE SPECSДокумент3 страницыGROUP 2 TIGHTENING TORQUE SPECSSergey MovchanОценок пока нет

- Unistrut UKДокумент108 страницUnistrut UKPaul SinclairОценок пока нет

- Macalloy Brochure Tension Structures December - 2017 - V1Документ16 страницMacalloy Brochure Tension Structures December - 2017 - V1Isabel Christina Gonzalez MoralesОценок пока нет

- Sling Saver ShackleДокумент1 страницаSling Saver ShackleFatihTufanОценок пока нет

- Assymetrical WedgeДокумент1 страницаAssymetrical WedgeNurettin IsikОценок пока нет

- Product CatalogueДокумент44 страницыProduct CatalogueTo Van TinhОценок пока нет

- 3-c Cu 5kv 115 Nlepr 133 Percent Aia PVC Mv-105.SpecДокумент2 страницы3-c Cu 5kv 115 Nlepr 133 Percent Aia PVC Mv-105.SpecRodrigo Chambilla VernazaОценок пока нет

- Ume 1312 Som Lab Ese QP - A2 Batch PDFДокумент19 страницUme 1312 Som Lab Ese QP - A2 Batch PDFDhanush NatesanОценок пока нет

- Fastenr GradesДокумент5 страницFastenr GradesVipul ShereОценок пока нет

- Crosby 198Документ1 страницаCrosby 198oscar_jfrОценок пока нет

- The Nelson System Catalouge Version 2 2017 Shear StudsДокумент8 страницThe Nelson System Catalouge Version 2 2017 Shear StudsMacОценок пока нет

- Rawl R Kex 400 SpecДокумент1 страницаRawl R Kex 400 Speccromwell2000Оценок пока нет

- 15XW 1c, 25kV, 260mil XLP (100%), WS, PVC6871 PDFДокумент2 страницы15XW 1c, 25kV, 260mil XLP (100%), WS, PVC6871 PDFLuis MartinezОценок пока нет

- BBBarBrochure - 2011 05 30 PDFДокумент7 страницBBBarBrochure - 2011 05 30 PDFKS LeeОценок пока нет

- Mac AlloyДокумент16 страницMac AlloyAnonymous u7YkrCwCОценок пока нет

- Z-Purlins Technical DocumentationДокумент11 страницZ-Purlins Technical Documentationardit bedhiaОценок пока нет

- ER Spring Collet Chuck System: Mounting Instructions For ER Collets DIN 6499-A and DIN 6499-BДокумент10 страницER Spring Collet Chuck System: Mounting Instructions For ER Collets DIN 6499-A and DIN 6499-BdavicocasteОценок пока нет

- According To International Standard IEC 60502 - 1: Single Core and Three Core Medium Voltage CablesДокумент10 страницAccording To International Standard IEC 60502 - 1: Single Core and Three Core Medium Voltage CablesRaj KiranОценок пока нет

- Nylon Lock Nuts MetricДокумент2 страницыNylon Lock Nuts MetricshivendrakumarОценок пока нет

- CAT Buckets Technical SpecificationsДокумент6 страницCAT Buckets Technical SpecificationsEhab Attia SelimОценок пока нет

- C Lift+Lash PointsДокумент10 страницC Lift+Lash PointssabanimОценок пока нет

- Mechanics of Materials: Relation between Torsion Moment, Torsion Angle and Shear ModulusДокумент9 страницMechanics of Materials: Relation between Torsion Moment, Torsion Angle and Shear ModulusMoiz AmirОценок пока нет

- Data Sheet Southwire 3c#500kcmilДокумент2 страницыData Sheet Southwire 3c#500kcmilNestor-leoОценок пока нет

- Iso 965 2 1998Документ8 страницIso 965 2 1998Gerald CelisОценок пока нет

- Soow H07RN-F Aj 24.02.2022Документ4 страницыSoow H07RN-F Aj 24.02.2022Tamara TrejosОценок пока нет

- Giddings & Lewis Zappendix AДокумент9 страницGiddings & Lewis Zappendix AAngel AdautaОценок пока нет

- Crosby Swivels: S-1 Jaw & HookДокумент1 страницаCrosby Swivels: S-1 Jaw & HookZeckОценок пока нет

- Unbrako Catalog FastenerДокумент26 страницUnbrako Catalog Fastenerdesign_rajeev100% (1)

- Type ST-C Cables: DescriptionДокумент51 страницаType ST-C Cables: DescriptiongilmarquijanoОценок пока нет

- Forged Eye Bolts, Metric, Shoulder Pattern, Plain: Page 1 of 2 REV-01 Date: August 9, 2012 M.Feb - SH.PДокумент2 страницыForged Eye Bolts, Metric, Shoulder Pattern, Plain: Page 1 of 2 REV-01 Date: August 9, 2012 M.Feb - SH.Pdonnyars1979Оценок пока нет

- ISO 10243.die SpringsДокумент12 страницISO 10243.die SpringsКонстантин Косарев100% (1)

- 2.4 KV GENERAL CABLE PDFДокумент2 страницы2.4 KV GENERAL CABLE PDFjhernandezelОценок пока нет

- Nyyhy PDFДокумент2 страницыNyyhy PDFsri haryadiОценок пока нет

- Is StandardДокумент10 страницIs Standardsarkararup100% (1)

- All-Purpose Chain & Fittings Guarante Ed To Make The Right ConnectionДокумент8 страницAll-Purpose Chain & Fittings Guarante Ed To Make The Right ConnectionHong Chee FongОценок пока нет

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionДокумент2 страницыFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionAngga SenjayaОценок пока нет

- IPNДокумент1 страницаIPNarianto32Оценок пока нет

- TL Series Low Clearance / Direct Fit Hydraulic Wrench: Wwwbolttechmanningscom WwwbolttechmanningscomДокумент2 страницыTL Series Low Clearance / Direct Fit Hydraulic Wrench: Wwwbolttechmanningscom WwwbolttechmanningscomAlexsandro CordeiroОценок пока нет

- Complete Fastener Solutions Hexagon BoltsДокумент2 страницыComplete Fastener Solutions Hexagon Boltscoolkaisy100% (2)

- DB Cylinder216Документ4 страницыDB Cylinder216Bryan CárcamoОценок пока нет

- Woo Chang Coupling - 112438 - Paqndr oYtYHS8Документ14 страницWoo Chang Coupling - 112438 - Paqndr oYtYHS8Eng-anwer kadhimОценок пока нет

- ConduitsДокумент10 страницConduitsSiddiqui Abdul KhaliqОценок пока нет

- Group 2 Tightening Torque: Major Components 1Документ3 страницыGroup 2 Tightening Torque: Major Components 1АлексейОценок пока нет

- Low Voltage Cable - 1101230820Документ102 страницыLow Voltage Cable - 1101230820Mouath AlraoushОценок пока нет

- E-Catalogue of IKING GROUP Shear Stud and ARC WelderДокумент4 страницыE-Catalogue of IKING GROUP Shear Stud and ARC WelderJohnОценок пока нет

- SprinklerBrochures Schedule10 40Документ4 страницыSprinklerBrochures Schedule10 40Keshia Murillo PinnockОценок пока нет

- GTOI Non-Capacitive Type Bushings, 12 - 36kV: Your Independent Bushing and Busbar SupplierДокумент4 страницыGTOI Non-Capacitive Type Bushings, 12 - 36kV: Your Independent Bushing and Busbar SupplierKhalid AzmyОценок пока нет

- Closed Swage Sockets National Swage ButtonsДокумент1 страницаClosed Swage Sockets National Swage ButtonshoiОценок пока нет

- Blow Off Calculation Rev.1Документ4 страницыBlow Off Calculation Rev.1Ankit AgarwalОценок пока нет

- Amp Utp Cat6 CableДокумент2 страницыAmp Utp Cat6 CablePrakash RoutОценок пока нет

- Z PurlinsДокумент27 страницZ Purlinsmassive85Оценок пока нет

- Ae Adhesive HiДокумент68 страницAe Adhesive HiRajed MaglinteОценок пока нет

- Toggle Bolt: Installation ProceduresДокумент2 страницыToggle Bolt: Installation ProceduresRajed MaglinteОценок пока нет

- Infos 5 Powers Design Manual Part 1Документ33 страницыInfos 5 Powers Design Manual Part 1Abdul basith RajviОценок пока нет

- Simson Strong Tie Anchor Selection GuideДокумент1 страницаSimson Strong Tie Anchor Selection GuideRajed MaglinteОценок пока нет

- A325 and Class 8.8 PDFДокумент3 страницыA325 and Class 8.8 PDFRajed MaglinteОценок пока нет

- Blue-Tip Screw BoltДокумент16 страницBlue-Tip Screw BoltRajed MaglinteОценок пока нет

- Dacromet A490Документ2 страницыDacromet A490linceokОценок пока нет

- Buyersguide LoДокумент72 страницыBuyersguide LoRajed MaglinteОценок пока нет

- Ae Mech Hi PDFДокумент209 страницAe Mech Hi PDFRajed MaglinteОценок пока нет

- HowthetcboltworksДокумент1 страницаHowthetcboltworksRajed MaglinteОценок пока нет

- Ref 1 - Technical - Grade - Markings - SteelДокумент2 страницыRef 1 - Technical - Grade - Markings - SteelRajed MaglinteОценок пока нет

- Askew Head BoltsДокумент1 страницаAskew Head BoltsRajed MaglinteОценок пока нет

- Lag ScrewsДокумент2 страницыLag ScrewsRajed MaglinteОценок пока нет

- Groove WeldsДокумент8 страницGroove WeldsNaveen KumarОценок пока нет

- Monthly Steel Quiz Tests Your KnowledgeДокумент2 страницыMonthly Steel Quiz Tests Your KnowledgeRajed MaglinteОценок пока нет

- Hollo BoltДокумент3 страницыHollo BoltrajedmaglinteОценок пока нет

- Crack Injection GuideДокумент5 страницCrack Injection GuideRajed MaglinteОценок пока нет

- Forged Steel Clevis: Caution: Never Exceed The Working Load LimitДокумент1 страницаForged Steel Clevis: Caution: Never Exceed The Working Load LimitrajedmaglinteОценок пока нет

- Lightweight powerful electric shear wrench for 5/8-7/8Документ3 страницыLightweight powerful electric shear wrench for 5/8-7/8Rajed MaglinteОценок пока нет

- DLSHSI ASCPEO Template INSTRUCTIONAL DESIGN FOR CONTINUING DEVELOPMENT PROGRAM ACTIVITYДокумент2 страницыDLSHSI ASCPEO Template INSTRUCTIONAL DESIGN FOR CONTINUING DEVELOPMENT PROGRAM ACTIVITYDustin GrimaresОценок пока нет

- CPDD PTR 02 Instructional Design - 0Документ1 страницаCPDD PTR 02 Instructional Design - 0Shuwb Ne PheshОценок пока нет

- CPDD-RES-03 Rev 00 Instructional Design TemplateДокумент2 страницыCPDD-RES-03 Rev 00 Instructional Design TemplateJho NaОценок пока нет

- CSF10 Member Check ParametersДокумент1 страницаCSF10 Member Check ParametersRajed MaglinteОценок пока нет

- 2b - Cufsm Tutorial 2Документ17 страниц2b - Cufsm Tutorial 2Rajed MaglinteОценок пока нет

- Purlin DesignДокумент9 страницPurlin DesignMungkorn SattОценок пока нет

- PURLINS DESIGN OPTIMIZEDДокумент42 страницыPURLINS DESIGN OPTIMIZEDLaw MolinaОценок пока нет

- Statics Sap2000 Ex Prbset7 Chpt4 66Документ18 страницStatics Sap2000 Ex Prbset7 Chpt4 66moises_quiroz_3Оценок пока нет

- Integrated Finite Elements Analysis and Design of StructuresДокумент50 страницIntegrated Finite Elements Analysis and Design of Structuresaeiou321Оценок пока нет

- Purlins, Rails & Eaves Beams: Design GuideДокумент44 страницыPurlins, Rails & Eaves Beams: Design GuideMinhphuc DaoОценок пока нет