Академический Документы

Профессиональный Документы

Культура Документы

Halton Damper

Загружено:

marcel cocanИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Halton Damper

Загружено:

marcel cocanАвторское право:

Доступные форматы

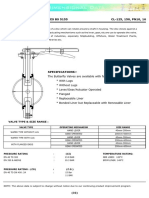

FDB2

A0(A60) Fire And Gas Damper

Halton FDB2 fire dampers are type-approved class • Blades contain silicone (effective up to 300 ºC)

A0(A60) fire and gas dampers for use in offshore, marine for low leakage in normal conditions and thermal

and navy ventilation systems. The FDB2 can be installed expansion graphite seals (effective from 150 ºC)

in rectangular or circular ducts. All fire dampers have a to increase tightness even up to 50% in a case of

fusible link and they prevent the spread of fire and gases fire. Tightness substantially better than NORSOK

within the ventilation ductwork. When the blades are in requirements. (tested size 1000x1000 mm, VTT test

the open position, the device does not cause significant report no. RTE4424/04)

pressure loss, noise or flow disturbance. Fire dampers • Nominal fuse release temperature 50 ºC, 74 ºC

are set from outside and can be installed in any position. or 100 ºC. Other temperatures available

An open-closed indicator is visible on the outside of the • Low weight due to patented double skin blade

damper. Fire dampers with non-standard dimensions structure

can be supplied on request. • Automatic electrical, pneumatic or spring operation

system available

• Type-approved by most recoganized classification • Maximum duct pressure for damper construction

societies, class A0 - A60 fire and gas damper when 5000 Pa and maximum air velocity 15 m/s. In case of

suitably insulated high duct pressure, contact Halton Marine for finding

• ATEX approved. Shock tested. the most suitable solution.

PART MATERIAL FINISHING NOTE

Frame Carbon steel Painted or galvanised -

Frame Stainless steel - -

Blades Steel Galvanized -

Blades Stainless steel - -

Maintenance-free bearings Stainless steel - Bronze bearings optional

Shafts Stainless steel - -

FDB2 - A0(A60) Fire And Gas Damper

3

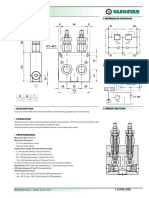

FDB2 DIMENSIONS AND MATERIAL THICKNESS Actuator effect in dimensions

FDB2 fire dampers meet international standards for

ACTUATOR DIMENSIONS

both rectangular (width B 100-1200 mm and height

R A

H 100-1600 mm, 1 mm division) and circular ducts Electrical GGA 326.1E 100 H<300 = 300

H>300 = H

(Ø100-1250 mm). Non-standard dimensions and flange

Pneumatic Linear actuator 170 H<500 = 500

drilling available on request. Standard flange width 27 PNL 245/300 N H>500 = H

mm. Flanges and drilling also available according to Pneumatic Pneumatic rotating 170 H<300 = 300

PNR actuator AT100 H>300 = H

ISO 15138 standards. Modular construction sizes up to Pneumatic Pneumatic rotating 190 H<350 = 350

2400x3200 mm are available. Standard frame material PNR actuator AT200 H>350 = H

Spring Spring 140 H

thickness 3 mm. Frame thickness 3-5 mm according to

The above table contains only some examples of actuators and their

SOLAS available on request.

effect on dimensions.

Frame thickness according to SOLAS

DIMENSIONS S L

If B or H > 100, but < 449 3 210

If B or H > 450, but < 649 4 212

If B or H > 650 5 215

GENERAL FDB2 DRAWING FDB2 CIRCULAR CONNECTIONS

2

10

ø1

n*150

S, ACCORDING TO SOLAS

ACTUATOR

150

H+58

H+4

ØD

A

150

n*150

MIN. 50

150 150

361, S=3

10

n*150 n*150

18 MIN. 50

B+4 365, S=4

10 10

370, S=5

30 R B+58

GENERAL FDB2 DRAWING, TOP FDB2 CIRCULAR, WITH CONNECTION FLANGES

240, BLADES IN OPEN POSITION

S, ACCORDING

TO SOLAS

S, ACCORDING TO SOLAS

215, S=5

212, S=4

210, S=3

160

ØD

367, S=3

373, S=4

380, S=5

FDB2 - A0(A60) Fire And Gas Damper

4

GENERAL FDB2 MODULE ASSEMBLY

V4M05Y2010/Halton Marine reserves the right to alter products without notice.

B+58 FDB2

B+56 FDL

FLAT BARS TO BE SEALED WITH PYROCRYL SEALANT

max. FDL 1300

Ø12.0 L DETAIL I

max. FDB2 1200

max. FDB2 1600

FLAT BAR CROSS STEEL 5*40

ACTUATOR

ACTUATOR

max. FDL 1200

FLAT BAR STEEL 5*40

2.0

I

H+58 FDB2

H+56 FDL

M10*20 8.8

ACTUATOR

ACTUATOR

10.0 FDB2

9.0 FDL S

9.0 FDL

10.0 FDB2

BOLTED FROM

BOTH SIDES

FDB2 PRODUCT OPTIONS OPERATION PRINCIPLE

Halton FDB2 is available with following actuators: In the event of a temperature rise in ductwork:

• FDB2-EL: Electrical spring return motor; standard • FDB2-EL: fusible link releases and cuts off operating

actuators being 24 V or 230 V or 120 V. The motor voltage to the spring return motor, allowing the

contains built-in open-closed limit switches. Separate spring to close the damper blades. The fire damper

junction box included in the EL-model. A wide range opens automatically when the fuse has been

of eex-proof actuators available, including a one changed and the operating voltage to the motor is

second closing time function as an option. re-established.

• FDB2-PNL: Pneumatic linear actuator, • FDB2-PNL, FDB2-PNR: fusible link releases and cuts

material AISI 316 off operating pressure to the spring return actuator,

• FDB2-PNR: Pneumatic rotating actuator allowing springs to close the damper blades. The

• FDB2-SP: Manual spring-actuated damper with fire damper opens automatically when the fuse

fusible link. has been changed and the pneumatic air supply is

DOT: manual override function available for PNL, PNR re-established.

and EL models. A wide range of accessories available. • FDB2-SP: fusible link releases allowing the spring to

close the damper blades. When the fuse has been

changed, the fire damper must be reset into open

position manually.

WEIGHTS OF STANDARD HALTON MARINE FDB2 DAMPERS (KG) without an actuator

H/Height B / Width (mm)

mm 100 200 300 400 500 600 700 800 900 1000 1100 1200 D2 ØD Weight

100 5 (5) 7 (7) 9 (9) 10 (10) 12 (13) 14 (15) 15 (22) 17 (25) 19 (27) 20 (30) 22 (32) 24 (35) mm kg

200 7 (7) 9 (9) 11 (11) 12 (12) 14 (16) 16 (18) 18 (26) 20 (28) 22 (31) 23 (34) 25 (36) 27 (39) 100 8 (8)

300 9 (9) 11 (11) 13 (13) 15 (15) 17 (19) 19 (21) 21 (30) 23 (32) 25 (35) 27 (38) 29 (41) 31 (43) 125 8 (8)

400 11 (11) 13 (13) 15 (15) 17 (17) 20 (22) 22 (24) 24 (33) 26 (36) 28 (39) 30 (42) 32 (45) 34 (48) 160 12 (12)

500 13 (16) 16 (19) 18 (22) 21 (25) 23 (27) 25 (30) 28 (38) 30 (41) 32 (44) 35 (47) 37 (50) 39 (54) 200 13 (13)

600 15 (18) 18 (21) 20 (24) 23 (27) 25 (30) 28 (33) 30 (41) 33 (45) 35 (48) 38 (51) 40 (55) 43 (58) 250 19 (19)

700 18 (25) 21 (28) 23 (32) 26 (35) 29 (39) 32 (42) 34 (46) 37 (50) 40 (53) 42 (57) 45 (60) 48 (64) 315 20 (20)

800 20 (27) 23 (31) 25 (35) 28 (38) 31 (42) 34 (46) 37 (50) 40 (53) 43 (57) 46 (61) 49 (64) 51 (68) 400 27 (27)

900 22 (31) 25 (35) 28 (39) 32 (42) 35 (46) 38 (50) 41 (54) 44 (58) 47 (62) 50 (66) 53 (70) 56 (74) 500 35 (43)

1000 24 (33) 27 (37) 31 (41) 34 (45) 37 (50) 40 (54) 44 (58) 47 (62) 50 (66) 53 (70) 57 (74) 60 (78) 630 46 (62)

1100 26 (36) 30 (41) 33 (45) 37 (49) 40 (54) 44 (58) 47 (62) 51 (67) 54 (71) 58 (75) 61 (79) 65 (84) 800 62 (89)

1200 28 (39) 32 (44) 36 (48) 39 (52) 43 (57) 46 (61) 50 (66) 54 (70) 57 (75) 61 (79) 65 (84) 68 (88) 1000 83 (118)

1300 31 (42) 35 (47) 38 (52) 42 (56) 46 (61) 50 (66) 54 (70) 58 (75) 62 (80) 65 (84) 69 (89) 73 (94) 1250 113 (162)

1400 32 (45) 37 (50) 41 (55) 45 (59) 49 (64) 53 (69) 57 (74) 61 (79) 65 (84) 69 (88) 73 (93) 77 (98)

(Frame thickness

1500 35 (48) 39 (53) 43 (58) 48 (63) 52 (68) 56 (73) 60 (78) 65 (83) 69 (89) 73 (94) 77 (99) 82(104)

according to SOLAS)

1600 36 (51) 41 (56) 45 (61) 50 (66) 54 (72) 59 (77) 63 (82) 67 (87) 72 (92) 76 (98) 81 (103) 85 (108)

Examples of actuator weights: FDB2-EL GGA 326.1E 2,3 kg, GNA 326.1E 1,3 kg, BF230 +3,2 kg, BLF230 +1,7 kg, ExMax /Redmax +3,5 kg, FDB2-PNL Roder +4 kg,

FDB2-PNR AT100 +2,1 kg, AT100 as AISI316 4,4 kg, AT200 +3,2kg, AT200 as AISI316 +6,2 kg, FDB2-SP +1 kg.

FDB2 - A0(A60) Fire And Gas Damper

5

FDB2-EL WIRING DIAGRAM FDB2-PNR/PNL PNEUMATIC DIAGRAM

CLOSED 21 13 21 13 OPEN

9

POWER DAMPER DAMPER 1. SPRING RETURN ACTUATOR 22 14 22 14

SUPPLY CLOSED OPEN 1

(-) (+) JUNCTION BOX 2. QUICK EXHAUST VALVE

PC IP66/67

3. SILENCER 12 3

13

4. FUSIBLE LINK VALVE 7

2

5. OPTION: SOLENOID VALVE

1 2 3 4 5 6 7 8 9 10 11 3 6

6. MALE CONNECTOR 8

THERMAL FUSE

SM-072-A0-2A (72°C) 7. DOUBLE NIPPLE 6

4

8. PLASTIC TUBE

3 6

9. OPTION: OPEN/CLOSED SWITCHES

8

10. OPTION: MANUAL VALVE 6 10

11. PRESSURE REGULATOR

3 6

FUSIBLE LINK

OPTION: 50/74/100°C 12. MALE ELBOW 8

6

13. SPEED CONTROLLER 5

S2

S3

S4

S5

S6

S1

24 VDC

2

1

230 VAC

M

BF24/BF120/BF230 MOTOR 6

BLF24/BLF230 MOTOR NOTICE! 3

8

3° 87° IP 54 ADDITIONAL SOLENOID VALVE 11

6

MAX 10 METER FROM FIRE

DAMPER

PNEU. INLET (5-10 6

BAR)

FOR A PLASTIC TUBE

Ø6 MM

FDB2 - A0(A60) Fire And Gas Damper

6

Page 1 of 4

PRODUCT CODE

FD2/S-W-H-D

S = Type of duct connections

R Rectangular connections

C Circular connections

D Special circular connection

W = Width

S=R: 100,+1,..,1200

S=C and D>=100 and D<=1200: D

S=C and D=1250: 1200

S=D and D<=1200: D

S=D and D>1200: 1200

H = Height

S=R: 100,+1,..,1600

S=C and W<1250: W

S=C and W=1250: 1200

S=D and W<=1200: W

S=D and W>1200: 1200

D = Diameter of duct connection

S=C: 100, 125, 160, 200, 250, 315, 400, 500, 630, 710, 800, 1000, 1250

S=R:

S=D: 100,+1,..,1250

Specifics and accessories

GO = Gas tight (N/Y)

N No

Y Yes

FA = Fire approval

C1 American bureau of shipping (ABS)

C2 Marine equipment directive (MED)

C3 Lloyds register (LRS)

C4 Det Norske Veritas (DNV)

C5 Bureau Veritas (BV)

C6 Germanischer Lloyds (GL)

CT = Type of circular connection

D1 1 circular connection

D2 2 circular connections

SF = Flange option

NA No special frame construction

N0 NORSOK

F1 Counter flange on one side

F2 Counter flange on both sides

file://C:\Program Files\Haltonware\sys2\offline\Hit_product_data_sheet.html 3/22/2011

Page 2 of 4

N3 1 Norsok circular connection flange

N4 2 Norsok circular connection flanges

N5 H2 + 1 loose Norsok circular flange

N6 H2 + 2 loose Norsok circular flanges

N7 H1 + 1 loose Norsok circular flange

N8 H1 + 2 loose Norsok circular flanges

H1 1 circular connection flange

H2 2 circular connection flanges

H3 H2 + 1 loose circular flange

H4 H2 + 2 loose circular flanges

H5 H1 + 1 loose circular flange

H6 H1 + 2 loose circular flanges

MA = Material

CG Galvanized steel

SS Stainless steel, AISI 304

AS Stainless steel, AISI 316

LS Stainless steel, AISI 316L

FM = Frame material

CS Carbon steel

C3 Carbon steel 3 mm

C5 Carbon steel 5 mm

AS Stainless steel AISI 316

A3 Stainless steel AISI 316, 3 mm

A5 Stainless steel AISI 316, 5 mm

SS Stainless steel AISI 304

S3 Stainless steel AISI 304, 3 mm

S5 Stainless steel AISI 304, 5 mm

LS Stainless steel AISI 316L

L3 Stainless steel AISI 316L, 3mm

L5 Stainless steel AISI 316L, 5mm

FI = Finishing of frame

NA No finishing

PN Painted (Grey, RAL 7001)

HG Hot galvanized

BM = Bearing material

AS Stainless steel / AISI316

SS Stainless steel / AISI304

MS Brass

BR Bronze JN5

RE = Release type

P0 Pneumatic, Rotating AT100

P4 Pneumatic, Rotating ES40

P5 Pneumatic, Rotating ES65

P3 Pneumatic, Rotating AT100, AISI316

P1 Pneumatic, Linear RODER 245 N

P2 Pneumatic, Linear RODER 300 N

P6 Pneumatic, Linear RODER 245N,DOT

P7 Pneumatic, Linear RODER 300N,DOT

P8 Pneumatic, Rotating AT100, DOT

P9 Pneumatic, Rotating AT100, AISI316, DOT

I1 Electric InMax 15-SF

T3 Electric BF230-2-T-HL

file://C:\Program Files\Haltonware\sys2\offline\Hit_product_data_sheet.html 3/22/2011

Page 3 of 4

T1 Electric BF24-2-T-HL

E1 Electric BF24-2-HL

E3 Electric BF230-2-HL

E7 Electric BF120-HL

F1 Electric BF24-2-HL (EL-DOT)

F2 Electric BF230-2-HL (EL-DOT)

F3 Electric BF120-2-HL (EL-DOT)

X1 EX-proof BEX24,IP66,T6,d

X2 EX-proof BEX230,IP66,T6,d

X3 EX-proof Schicheck24,IP66,T6,d

X4 EX-proof Schicheck230,IP66,T6d

L1 Electric BLF24-HL

L3 Electric BLF24-T-HL

L5 Electric BLF230-HL

L7 Electric BLF230-T-HL

R0 EX-proof, RedMax 15-F, zone 2, 24-230 VAC/DC

R1 EX-proof, RedMax 5.10-F, Zone 2, 24-230 VAC/DC

R2 EX-proof,RedMax 15-SF, Zone 2, 24-230 VAC/D, 2x switch

R3 EX-proof, RedMax 5.10-SF, zone2, 24-230 VAC/DC, 2x switch

R6 EX-proof, RedMax 5.10-YF, zone2, 24-230VAC/DC,mod./spring

R7 EX-proof, RedMax 15-YF, zone2, 24-230VAC/DC, mod./spring

R8 EX-proof,RedMax 15-SF DOT, zone2, 24-230VAC/DC, 2x switch

R9 EX-proof, RedMax 5.10-SF DOT,zone2, 24-230VAC/DC,2xSwitch

S1 Spring release

Z0 EX-proof, ExMax 15-F, zone1, 24-230 VAC/DC

Z1 EX-proof, ExMax 5.10-F, zone 1, 24-230 VAC/DC

Z2 EX-proof, ExMax 15-SF, zone 1, 24-230 VAC/DC, 2x Switch

Z3 EX-proof,ExMax 5.10-SF, zone 1, 24-230 VAC/DC, 2xSwitch

Z6 EX-proof, ExMax 5.10-YF, zone1, 24-230 VAC/DC,mod./spring

Z7 EX_proof, ExMax 15-YF, zone1, 24-230VAC/DC, mod./spring

Z8 EX_proof,ExMax 15-SF DOT, zone1, 24-230VAC/DC, 2x Switch

Z9 EX-proof,ExMax 5.10-SF DOT,zone1, 24-230 VAC/DC, 2xSwitch

MA Manual

FU = Fuse release temperature[OC]

50 50 °C

65 65 °C

70 70 °C

72 72 °C

74 74 °C

95 95 °C

100 100 °C

144 144 °C

NA No fuse

AC = Accessories

E2 EX-proof junction box, plastic, IP66,T5,m

E1 Junction box, plastic, IP65

L1 Limit switch, 1 pc, Bernstein

L2 Limit switches, 2 pcs, Bernstein

L3 EX-proof limit switch, 1 pc, IP66

L4 EX-proof limit switches, 2 pcs, IP66

M1 Solenoid valve 24 DC

M2 Solenoid valve 230 VAC

M8 Solenoid valve 120VAC

M3 EX-proof solenoid valve 24,T5,m

M4 EX-proof solenoid valve 230,T5,m

file://C:\Program Files\Haltonware\sys2\offline\Hit_product_data_sheet.html 3/22/2011

Page 4 of 4

P1 Pneumatic valve, manual

S1 Auxiliary switch SN1

S3 Auxiliary switch SN2

BC Belimo casing

F1 FD-CON-2 24 V main

F3 FD-CON-2 230 V main

F4 FD-CON-2 230 V main & slave

F5 FD-CON-2 120 V main

F6 FD-CON-2 120 V main & slave

F7 FD-CON-2 24V main & slave

Code example

FD2/R-100-100, GO=Y,FA=C1,SF=NA,MA=CS,FM=CS, FI=PN,BM=AS, RE=P0,FU=50

}

file://C:\Program Files\Haltonware\sys2\offline\Hit_product_data_sheet.html 3/22/2011

Вам также может понравиться

- Coring & Coring Analysis 2Документ21 страницаCoring & Coring Analysis 2Reband Azad100% (1)

- Pocket Guide to Flanges, Fittings, and Piping DataОт EverandPocket Guide to Flanges, Fittings, and Piping DataРейтинг: 3.5 из 5 звезд3.5/5 (22)

- The Human Genome ProjectДокумент19 страницThe Human Genome ProjectSuraj Bhattarai100% (3)

- Valves Pipe Fittings DimensionsДокумент37 страницValves Pipe Fittings DimensionstsoheilОценок пока нет

- Screw Compressor ASY (R-134) Series PDFДокумент52 страницыScrew Compressor ASY (R-134) Series PDFNajam2450% (2)

- Ksb-Omega-Pump Sarcina Pe Flanse PDFДокумент56 страницKsb-Omega-Pump Sarcina Pe Flanse PDFRusu DimaОценок пока нет

- Casting DefectsДокумент24 страницыCasting DefectsMohamedSabryОценок пока нет

- Solubility CurveДокумент2 страницыSolubility CurveDanni SulaimanОценок пока нет

- Brazing PrinciplesДокумент118 страницBrazing PrinciplesKingsman 86100% (1)

- OrificeMaster Single Chamber Orifice FittingДокумент8 страницOrificeMaster Single Chamber Orifice FittingPaul Wowor100% (1)

- Axial Fan 7028 PDFДокумент9 страницAxial Fan 7028 PDFHuyОценок пока нет

- FDL 2015Документ6 страницFDL 2015Antonio MartinОценок пока нет

- FDB2 - A0 (A60) Fire and Gas DamperДокумент4 страницыFDB2 - A0 (A60) Fire and Gas DamperphlxuОценок пока нет

- Valvula Crosby Series 800 PDFДокумент196 страницValvula Crosby Series 800 PDFYuri PalomarОценок пока нет

- Krausz Spesifications Hymax-Flensemuffe enДокумент4 страницыKrausz Spesifications Hymax-Flensemuffe enibrahimОценок пока нет

- Recool Static Flyer ENДокумент4 страницыRecool Static Flyer ENMichał BorodziukОценок пока нет

- Multileaf Data VCDДокумент4 страницыMultileaf Data VCDalexa_liviaОценок пока нет

- Datasheet Hydraulic Radiator AOCHMДокумент5 страницDatasheet Hydraulic Radiator AOCHMLauraОценок пока нет

- MODULAIR NEUJKF Fevi ENДокумент4 страницыMODULAIR NEUJKF Fevi ENEco TechОценок пока нет

- Shin Nan Catalogue PDFДокумент38 страницShin Nan Catalogue PDFElan ChezhiyanОценок пока нет

- Products: Ventilation Air Conditioning Refrigeration HeatingДокумент16 страницProducts: Ventilation Air Conditioning Refrigeration HeatingzainulmarengОценок пока нет

- Katalog Acn Acg Acp AjДокумент32 страницыKatalog Acn Acg Acp AjBudy GedhaBlackОценок пока нет

- Series 2400 Fiberglass Pipe and Fittings: Using Key-Lock Mechanical Joint or Taper/ Taper Adhesive JointДокумент7 страницSeries 2400 Fiberglass Pipe and Fittings: Using Key-Lock Mechanical Joint or Taper/ Taper Adhesive JointChristian UhreОценок пока нет

- Applications: H D P TДокумент2 страницыApplications: H D P TEnrique MurgiaОценок пока нет

- 26 2000 Pressure Reducing RegulatorДокумент4 страницы26 2000 Pressure Reducing RegulatorMFERRОценок пока нет

- PlasmaДокумент37 страницPlasmaJuniorОценок пока нет

- STP CatalogueДокумент37 страницSTP CataloguemmkattaОценок пока нет

- fdb2 - Fire and Damper PDFДокумент4 страницыfdb2 - Fire and Damper PDFcandratrikusumaОценок пока нет

- Force Ksb-Omega-Pump Sarcina Pe Flanse PDFДокумент19 страницForce Ksb-Omega-Pump Sarcina Pe Flanse PDFRusu DimaОценок пока нет

- EXACTFILL Housing For Tubular Filters ENДокумент3 страницыEXACTFILL Housing For Tubular Filters ENLuís CamposОценок пока нет

- 77e5-B005 (Hydraulic Cylinder)Документ4 страницы77e5-B005 (Hydraulic Cylinder)Sandeep JoshiОценок пока нет

- Datasheet Strenx 100 XFДокумент2 страницыDatasheet Strenx 100 XFLuis Alberto BelmonteОценок пока нет

- Ratnamani - Manufacturing RangeДокумент2 страницыRatnamani - Manufacturing RangeRenny DevassyОценок пока нет

- VAV DamperДокумент7 страницVAV DamperAdades Safede EfdОценок пока нет

- Vail /va 34: Pressure Relief ValvesДокумент2 страницыVail /va 34: Pressure Relief ValvesSachin RamadasanОценок пока нет

- Omega/Omega V: Axially Split Volute Casing PumpsДокумент56 страницOmega/Omega V: Axially Split Volute Casing Pumpsmohammad ziad khatibОценок пока нет

- Kovaz S.r.o.: Guiding Tape (Piston/rod)Документ2 страницыKovaz S.r.o.: Guiding Tape (Piston/rod)Omkar TerkhedkarОценок пока нет

- B B B B B B: Multi-Leaf DampersДокумент52 страницыB B B B B B: Multi-Leaf DampersSérgio AmorimОценок пока нет

- Bol SeriesДокумент6 страницBol SeriesAlexisAlejandroSandovalFloresОценок пока нет

- Aluminium Alloy - Commercial Alloy - 6063 - T6 ExtrusionsДокумент4 страницыAluminium Alloy - Commercial Alloy - 6063 - T6 ExtrusionsOgulcan CafОценок пока нет

- Data Sheet SS316L Seamless Tube Fluidline CustomerДокумент2 страницыData Sheet SS316L Seamless Tube Fluidline Customerinstrument.engineer.123Оценок пока нет

- 1H050100 PDFДокумент2 страницы1H050100 PDFSachin RamadasanОценок пока нет

- 1H050100 PDFДокумент2 страницы1H050100 PDFSachin RamadasanОценок пока нет

- 1H050100 PDFДокумент2 страницы1H050100 PDFSachin RamadasanОценок пока нет

- Astm A105 A105nДокумент1 страницаAstm A105 A105nestimationОценок пока нет

- HD 242 Flexible HoseДокумент4 страницыHD 242 Flexible HoseSelvakumar EkambaramОценок пока нет

- Jetcontrol 600-S UK 17072014Документ4 страницыJetcontrol 600-S UK 17072014Zeko AmeenОценок пока нет

- 26 289a2267-100Документ8 страниц26 289a2267-100Arun BabuОценок пока нет

- RS-RQ: Ø 32 ÷ 100 MM - STRONG Compact CylindersДокумент22 страницыRS-RQ: Ø 32 ÷ 100 MM - STRONG Compact CylindersMohammad Adeel KhanОценок пока нет

- Reguladore SENSUS para Gas CombustibleДокумент20 страницReguladore SENSUS para Gas CombustibleJorge BaronОценок пока нет

- Atos CHДокумент4 страницыAtos CHStéphane ArnaudОценок пока нет

- HALTON-airflow Dampers ENДокумент44 страницыHALTON-airflow Dampers ENMariusMОценок пока нет

- TFP725 08 2016Документ8 страницTFP725 08 2016Jun AntonioОценок пока нет

- 32 Koenig 2013Документ1 страница32 Koenig 2013shashibagewadiОценок пока нет

- Aperval101 Brochure ENGДокумент8 страницAperval101 Brochure ENGMoon ServiceОценок пока нет

- Boehler Metal Cored WiresДокумент1 страницаBoehler Metal Cored Wiresrusf123Оценок пока нет

- Butterfly ValveДокумент4 страницыButterfly ValveghjtyuОценок пока нет

- Non Returns Dampers Single PageДокумент12 страницNon Returns Dampers Single PageALIОценок пока нет

- Ahu Fan-Ada PDFДокумент47 страницAhu Fan-Ada PDFappuОценок пока нет

- SFДокумент15 страницSFHai PhanОценок пока нет

- M33F ISO Full Bore Ball Valve API 6D Firesafe API 607 2" To 8" ASME 150 and 300Документ4 страницыM33F ISO Full Bore Ball Valve API 6D Firesafe API 607 2" To 8" ASME 150 and 300HARSHAОценок пока нет

- 1H050200 PDFДокумент2 страницы1H050200 PDFSachin RamadasanОценок пока нет

- Dowtherm sr-1Документ16 страницDowtherm sr-1Rafael LealОценок пока нет

- Mucosal Drug Delivery SystemДокумент34 страницыMucosal Drug Delivery SystemDebjani Baidya100% (1)

- Thermo-Kinetic and Diffusion Studies of Glycerol Dehydration ToДокумент11 страницThermo-Kinetic and Diffusion Studies of Glycerol Dehydration ToDaniel MorenoОценок пока нет

- Technical Data Sheet R32 ENGLISHДокумент6 страницTechnical Data Sheet R32 ENGLISHreddy PrasadОценок пока нет

- Inert Corrosion-Free Structural Repair and Protection SystemДокумент16 страницInert Corrosion-Free Structural Repair and Protection SystemLempira TorresОценок пока нет

- Kandhal Lecture 3 On Aggregate For Bituminous Road Construction - Handouts OnlyДокумент8 страницKandhal Lecture 3 On Aggregate For Bituminous Road Construction - Handouts OnlyProf. Prithvi Singh KandhalОценок пока нет

- Destilasi Binner & Multi KomponenДокумент8 страницDestilasi Binner & Multi KomponenApril Rianto BaktiarОценок пока нет

- D2361-Standard Test Method For Chlorine in CoalДокумент4 страницыD2361-Standard Test Method For Chlorine in CoalPradjnaParamitaMicheleОценок пока нет

- Kestopour PL 15Документ1 страницаKestopour PL 15Mantas ButrimaviciusОценок пока нет

- ASTUDYONAMYLASEREVIEWДокумент9 страницASTUDYONAMYLASEREVIEWzaharo putriОценок пока нет

- Energy Conservation in Pumping SystemДокумент33 страницыEnergy Conservation in Pumping SystemFahad KhanОценок пока нет

- Material Price ListДокумент43 страницыMaterial Price ListSathish RagavanОценок пока нет

- Drytec Aluminium Range Fine FiltersДокумент4 страницыDrytec Aluminium Range Fine FiltersDragoslav DzolicОценок пока нет

- Persediaan 2017, 2018Документ1 061 страницаPersediaan 2017, 2018Selly RianiОценок пока нет

- YL9100plus HPLC Total Brochure ENG Original Plus Ver 2.2 SДокумент16 страницYL9100plus HPLC Total Brochure ENG Original Plus Ver 2.2 SAmica LeeОценок пока нет

- Pourbaix DiagramДокумент5 страницPourbaix DiagramChayon MondalОценок пока нет

- Pore and Diffusion ModelДокумент19 страницPore and Diffusion ModelShumi NaharОценок пока нет

- XPS (X Ray Photoemission Spectroscopy) /ESCA (Electron Spectroscopy For Chemical Analysis)Документ46 страницXPS (X Ray Photoemission Spectroscopy) /ESCA (Electron Spectroscopy For Chemical Analysis)Serdar ArıcanОценок пока нет

- 0620 s15 QP 13Документ16 страниц0620 s15 QP 13karan79Оценок пока нет

- PPG2066-306A - Varnish Epoxi Amina GoldДокумент14 страницPPG2066-306A - Varnish Epoxi Amina GoldAlex SabinoОценок пока нет

- Bs 16105Документ14 страницBs 16105Mohammad MiyanОценок пока нет

- Foundation Chemistry 2811 June 2007Документ12 страницFoundation Chemistry 2811 June 2007M S RahmanОценок пока нет

- Api 510 PTR 7Документ3 страницыApi 510 PTR 7HemaОценок пока нет

- Gangadharan Nair Pulingat 2014 5Документ53 страницыGangadharan Nair Pulingat 2014 5Kedar A. MalusareОценок пока нет

- Heating Catalogue 2019Документ44 страницыHeating Catalogue 2019Zoran SimanicОценок пока нет