Академический Документы

Профессиональный Документы

Культура Документы

A 176 - 99 (2009) PDF

Загружено:

أسامة وحيد الدين رمضانОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

A 176 - 99 (2009) PDF

Загружено:

أسامة وحيد الدين رمضانАвторское право:

Доступные форматы

Designation: A176 − 99 (Reapproved 2009)

Standard Specification for

Stainless and Heat-Resisting Chromium Steel Plate, Sheet,

and Strip1

This standard is issued under the fixed designation A176; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2.2 SAE Standard:3

1.1 This specification covers stainless and heat-resisting J1086 Practice for Unified Numbering for Metals and Alloys

chromium steel plate, sheet, and strip available in a wide (UNS)

variety of surface finishes. 3. Chemical Composition

1.2 The values stated in inch-pound units are to be regarded 3.1 The steel shall conform to the requirements as to

as the standard. chemical composition specified in Table 1, and shall conform

to applicable requirements specified in Specification A480/

NOTE 1—Grades that were previously covered in both Specifications

A176 and A240/A240M have been removed from this specification and A480M.

may now be supplied and purchased in compliance with Specification

A240/A240M. The chemical and mechanical property requirements of

4. Mechanical Properties

these grades were identical in Specifications A176 and A240/A240M at 4.1 The material shall conform to the mechanical properties

the time of removal from Specification A176. specified in Table 2.

2. Referenced Documents 5. General Requirements

2.1 ASTM Standards:2 5.1 The following requirements for orders for material

A240/A240M Specification for Chromium and Chromium- furnished under this specification shall conform to the appli-

Nickel Stainless Steel Plate, Sheet, and Strip for Pressure cable requirements of the current edition of Specification

Vessels and for General Applications A480/A480M.

A370 Test Methods and Definitions for Mechanical Testing 5.1.1 Definitions,

of Steel Products 5.1.2 General requirements for delivery,

A480/A480M Specification for General Requirements for 5.1.3 Ordering information,

Flat-Rolled Stainless and Heat-Resisting Steel Plate, 5.1.4 Process,

Sheet, and Strip 5.1.5 Special tests,

E527 Practice for Numbering Metals and Alloys in the 5.1.6 Heat treatment,

Unified Numbering System (UNS) 5.1.7 Dimensions and permissible variations,

5.1.8 Workmanship, finish, and appearance,

5.1.9 Number of tests/test methods,

5.1.10 Specimen preparation,

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, 5.1.11 Retreatment,

Stainless Steel and Related Alloysand is the direct responsibility of Subcommittee

A01.17 on Flat-Rolled and Wrought Stainless Steel. 5.1.12 Inspection,

Current edition approved May 1, 2009. Published May 2009. Originally 5.1.13 Rejection and rehearing,

approved in 1935. Last previous edition approved in 2004 as A176 – 99 (2004). 5.1.14 Material test report, and

DOI: 10.1520/A0176-99R09.

2

5.1.15 Certification.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright by ASTM Int'l (all rights reserved); 1

A176 − 99 (2009)

TABLE 1 Chemical RequirementsA

UNS Composition, %

Type

DesignationB Carbon Manganese Phosphorus Sulfur Silicon Chromium Nickel Nitrogen Other ElementsC

S40300 403 0.15 1.00 0.040 0.030 0.50 11.5–13.0 0.60 ... ...

S42000 420 0.15 min 1.00 0.040 0.030 1.00 12.0–14.0 0.75 ... Mo 0.50 max

S42200 422 0.20–0.25 0.50–1.00 0.025 0.025 0.50 11.0–12.5 0.50–1.00 ... Mo 0.90-1.25

V 0.20-0.30

W 0.90-1.25

S43100 431 0.20 1.00 0.040 0.030 1.00 15.0–17.0 1.25–2.50 ... ...

S44200 442 0.20 1.00 0.040 0.040 1.00 18.0–23.0 0.60 ... ...

S44600 446 0.20 1.50 0.040 0.030 1.00 23.0–27.0 0.75 0.25 ...

A

Maximum unless range or minimum is indicated.

B

New designation established in accordance with Practice E527 and SAE J1086.

C

The terms Columbium (Cb) and Niobium (Nb) both relate to the same element.

D

Carbon + nitrogen = 0.030 max.

TABLE 2 Mechanical Test Requirements

Tensile Strength, min Yield Strength, minA Elongation Hardness, maxB

UNS in 2 in. or Cold Bend,

Type

Designation 50 mm, degC

ksi MPa ksi MPa min, % Brinell Rockwell B

S40300 403 70 485 30 205 25.0D 217 96 180

S42000 420 100E 690 ... ... 15.0 217 96 ...

S42200 422 ... ... ... ... ... 248 24F not required

S43100 431 ... ... ... ... ... 285 29F not required

S44200 442 65 515 40 275 20.0 217 96 180

S44600 446 65 515 40 275 20.0 217 96 135

A

Yield strength shall be determined by the offset method at 0.2 % in accordance with Test Methods and Definitions A370. Unless otherwise specified (see 5.1.10), an

alternative method of determining yield strength may be based on a total extension under load of 0.5 %.

B

Either Brinell or Rockwell B hardness is permissible.

C

Bend test not required for steels thicker than 1 in. (25.4 mm) unless specified by the purchaser.

D

Material 0.050 in. (1.27 mm) and under in thickness shall have a minimum elongation of 20.0 %.

E

Maximum. Type 420 is usually used in the heat-treated condition (quenched and tempered to a specified range of hardness or tensile strength).

F

Rockwell C scale.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

Copyright by ASTM Int'l (all rights reserved); 2

Вам также может понравиться

- A 455 - A 455M - 12a PDFДокумент3 страницыA 455 - A 455M - 12a PDFأسامة وحيد الدين رمضانОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- A 247 - 17 PDFДокумент13 страницA 247 - 17 PDFأسامة وحيد الدين رمضانОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- A 254 - A 254M - 12 PDFДокумент4 страницыA 254 - A 254M - 12 PDFأسامة وحيد الدين رمضانОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A 249 - A 249M - 16a PDFДокумент10 страницA 249 - A 249M - 16a PDFأسامة وحيد الدين رمضانОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- A 240 - A 240M - 16a PDFДокумент14 страницA 240 - A 240M - 16a PDFأسامة وحيد الدين رمضانОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- A 232 - A 232M - 05 (2011) E1 PDFДокумент4 страницыA 232 - A 232M - 05 (2011) E1 PDFأسامة وحيد الدين رمضانОценок пока нет

- Astm A242-13 PDFДокумент3 страницыAstm A242-13 PDFsingaravelan narayanasamyОценок пока нет

- A 435 - A 435M - 90 (2012) PDFДокумент2 страницыA 435 - A 435M - 90 (2012) PDFأسامة وحيد الدين رمضانОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- A 234 - A 234M - 17 PDFДокумент9 страницA 234 - A 234M - 17 PDFأسامة وحيد الدين رمضانОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A 184 - A 184M - 06 (2011) PDFДокумент3 страницыA 184 - A 184M - 06 (2011) PDFأسامة وحيد الدين رمضانОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- A 109 - A 109M - 16 PDFДокумент9 страницA 109 - A 109M - 16 PDFأسامة وحيد الدين رمضانОценок пока нет

- A 203 - A 203M - 12 PDFДокумент3 страницыA 203 - A 203M - 12 PDFأسامة وحيد الدين رمضانОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A 182 - A 182M - 16a PDFДокумент15 страницA 182 - A 182M - 16a PDFأسامة وحيد الدين رمضانОценок пока нет

- Request Form For MELISA Metal Allergy Testing: Instructions For Sample Taking Referred byДокумент1 страницаRequest Form For MELISA Metal Allergy Testing: Instructions For Sample Taking Referred byMárk KöllnerОценок пока нет

- Specifying Harmonized Standard Grade Compositions For Wrought Carbon, Low-Alloy, and Alloy SteelsДокумент13 страницSpecifying Harmonized Standard Grade Compositions For Wrought Carbon, Low-Alloy, and Alloy Steelsalucard375100% (2)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Abrasive Wear Behavior of Austempered Ductile Iron With Niobium AdditionsДокумент8 страницAbrasive Wear Behavior of Austempered Ductile Iron With Niobium AdditionsEverton CostaОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Mil HDBK 270aДокумент97 страницMil HDBK 270aAnshuman RoyОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Tantalum Based Materials For Implants and Prostheses ApplicationsДокумент8 страницTantalum Based Materials For Implants and Prostheses Applicationsviktorija bezhovskaОценок пока нет

- Astm A351-A351mДокумент7 страницAstm A351-A351mJose Gregorio RodriguezОценок пока нет

- Zirconium and Zirconium Alloy Sheet, Strip, and Plate For Nuclear ApplicationДокумент6 страницZirconium and Zirconium Alloy Sheet, Strip, and Plate For Nuclear ApplicationSrinivasan KrishnamoorthyОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Nickel Alloy Forgings: Standard Specification ForДокумент11 страницNickel Alloy Forgings: Standard Specification ForClaudio Di GioseffoОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- The Periodic TableДокумент4 страницыThe Periodic TableAnonymous yZtBqIK100% (1)

- Material Safety Data SheetДокумент15 страницMaterial Safety Data SheetzuudeeОценок пока нет

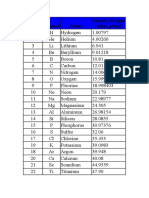

- Atomic Number Symbol Name Atomic Weight (Amu, G/mol)Документ5 страницAtomic Number Symbol Name Atomic Weight (Amu, G/mol)Strata GamingОценок пока нет

- Complete CatalogДокумент64 страницыComplete Catalogmohamed AdelОценок пока нет

- ME-ICP41 Trace Level Methods Using Conventional ICP-AES AnalysisДокумент3 страницыME-ICP41 Trace Level Methods Using Conventional ICP-AES AnalysishОценок пока нет

- ASTM Specs FittingsДокумент10 страницASTM Specs FittingskhaireddinОценок пока нет

- B54 1120 Raw MaterialДокумент13 страницB54 1120 Raw Materialcover077Оценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy With Improved Formability, and Ultra-High StrengthДокумент9 страницSteel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy With Improved Formability, and Ultra-High StrengthlinamariamonroyginetОценок пока нет

- Hot-Rolled Structural Steel, High-Strength Low-Alloy Plate With Improved FormabilityДокумент2 страницыHot-Rolled Structural Steel, High-Strength Low-Alloy Plate With Improved FormabilityketemaОценок пока нет

- Water-Soluble Niobium Peroxo Complexes As Precursors For The Preparation of Nb-Based Oxide CatalystДокумент9 страницWater-Soluble Niobium Peroxo Complexes As Precursors For The Preparation of Nb-Based Oxide CatalystAkina CareyОценок пока нет

- Common Ions and Their ChargesДокумент2 страницыCommon Ions and Their ChargesDip MajumderОценок пока нет

- B 863 PDFДокумент5 страницB 863 PDFGrato Jr SingcoОценок пока нет

- Materials For Reformer Furnace Tubes History of EvolutionДокумент7 страницMaterials For Reformer Furnace Tubes History of EvolutionAPI100% (1)

- Nilai Spesifik Gravity (Berat Jenis)Документ7 страницNilai Spesifik Gravity (Berat Jenis)ArfahHamzahОценок пока нет

- Advanced Materials and StructuresДокумент244 страницыAdvanced Materials and StructuresCarlos LlanoОценок пока нет

- Astm A216-A216m-04Документ4 страницыAstm A216-A216m-04NadhiraОценок пока нет

- 1278 - Filler Rods For Gas WeldingДокумент20 страниц1278 - Filler Rods For Gas WeldingKaushik SenguptaОценок пока нет

- Sir2010 5070 GДокумент234 страницыSir2010 5070 GDerlis CalderonОценок пока нет

- Astm b408Документ5 страницAstm b408wilian_coelho3309Оценок пока нет

- Braze Material Guide 082013Документ16 страницBraze Material Guide 082013G VОценок пока нет

- Astm A182Документ6 страницAstm A182Rayan AlfredОценок пока нет

- Tantalum and Niobium HC StarckДокумент12 страницTantalum and Niobium HC StarckYoami PerdomoОценок пока нет