Академический Документы

Профессиональный Документы

Культура Документы

CUP 04 BOIN USA 02 Web

Загружено:

Majid abdulОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CUP 04 BOIN USA 02 Web

Загружено:

Majid abdulАвторское право:

Доступные форматы

T E C H N I CA L

DATA S H E E T

Bottom Intake Submersible Pump

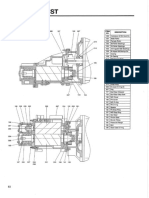

P U M P OVE RVI EW

ClydeUnion S&N Pumps bottom intake submersible pumps are

water and propylene-glycol filled pumps that feature a compact,

high-efficient, corrosion-resistant pump design that functions in low

water levels. The pump has the technical features of a submersible

pump with the benefits of a line shaft pump offering the offshore oil

and gas industry secure, reliable, and long-lasting seawater handling

capabilities.

FEATU R E S

The structure of the ClydeUnion S&N Pumps bottom intake pump

is equivalent to an inverted submersible motor pump. All pump

casing parts are zinc-free bronze with heavy-duty and high efficiency

nickel-aluminum bronze impellers as a standard. The single stage or

multi-stage pump incorporates double silicon-carbide mechanical

shaft sealing for environmental safety and tilting axial thrust bearings

and guarantees high thrust absorption. The stator shroud is zinc-free

bronze. The pump incorporates a (ZFB) suction port with an anti-

vortex plate that helps prevent pump cavitation. The submersible three

phase rewindable wet stator motor is wound with high-temperature

resistant PE2 wiring.

TYP I CAL APPLI CAT I O N S

• Emergency de-ballast systems

TYP I CAL PU M P CON S TR U CTI ON

Po w e r s u p p l y c a b l e

PART D E S CR I PTI O N DIN A ST M

D i s ch a r g e p i e c e

D i s ch a r g i n g p i e c e G CuSn10 Z FB B-427 C91600

N RV casing G CuSn10 Z FB B-427 C91600

Pump shaft sleeves/coupling 1.4401/1.4462 316 G R F316/ 318 LN

Upper bearing

Impeller Ni Alum Brz. NAB B148 C95500

N e ck r i n g s 1.4580 316 Ti

Pump shroud

Stage casings G CuSn10 ZFB B-427 C91600

Lower bearing

Wi n d i n g

Intake Screen/ Hardware 1.4571 316 Ti

Stator shroud

TYP I CAL M OTOR CON S TR U CTI ON Axial thrust bearing

Intermediate piece

PA RT D E S CR I PTI O N DIN A S TM M e ch a n i c a l s h a f t s e a l

Shaft

Upper bearing-spiral grooved Graphite Graphite

End guide casing

Impeller

M o t o r Wi n d i n g s , 2 0 ° C P E 2 + PA 40°C

Suction port

Motor stator housing 1.4571 3 1 6 Ti

Strainer

Motor end bell G CuSn10 Z FB B-427 C91600

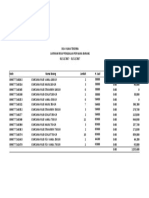

RAN G E COVE RAG E CH A R T

Flow (USgpm)

200 300 400 500 1,000 2,000 3,000 4,000 • 1.15 Motor service factor - 40°C (-40ºF) motor

windings

700

• No fluid flow required up to 40°C (104ºF ) for

200

cooling purposes

600

• Fully repairable pumps and motors - motor is

fluid filled and fully rewindable

500

K126P

Head (m)

400

Flow (ft)

KM150P

100 K146P

300

DCH980P

K127P D500P

200

100

0

100 1,000

Flow (m3/hr)

P: +1 (281) 445-2243 F: +1 (281) 445-4061 E: cu.sales@spx.com

For more information about our worldwide locations, approvals, certifications, and local representatives, please visit www.spx.com.

SPX Corporation reserves the right to incorporate our latest design and material changes without notice or obligation. Design features, materials of construction and dimensional data,

as described in this bulletin, are provided for your information only and should not be relied upon unless confirmed in writing.

CUP-04-BOIN-USA-02

COPYRIGHT © 2012 SPX Corporation

Вам также может понравиться

- Bomba Magnetica TE-7MD-SCДокумент2 страницыBomba Magnetica TE-7MD-SCBaruch Cervantes GonzalezОценок пока нет

- SpecДокумент2 страницыSpecdesmondОценок пока нет

- 1KZ-T EngineДокумент318 страниц1KZ-T EngineFerry Darmawan100% (1)

- OUTLINE DRAWING DRAWING 500kVA YNyn6Документ1 страницаOUTLINE DRAWING DRAWING 500kVA YNyn6SetiawanBudiОценок пока нет

- High-Performance External Gear Pump Azpb: FeaturesДокумент4 страницыHigh-Performance External Gear Pump Azpb: FeaturesMichail ArmitageОценок пока нет

- Service Instruction 1037KДокумент8 страницService Instruction 1037KLuis Amaya100% (1)

- Blackmer NP3 Parts ListДокумент2 страницыBlackmer NP3 Parts ListWilson wayerОценок пока нет

- Specification Sheet: MartensiticДокумент7 страницSpecification Sheet: MartensiticErick Renzo Hidalgo OrtegaОценок пока нет

- PG1 SeriesДокумент8 страницPG1 Seriesmkt mechoceanОценок пока нет

- Valve FittingsДокумент11 страницValve FittingsEduard Gonzalo Rojas CervantesОценок пока нет

- SI1037U Approved Pistons, Rings, and CylindersДокумент13 страницSI1037U Approved Pistons, Rings, and CylindersElmer VillegasОценок пока нет

- SI 1037T Approved Pistons Rings and CylindersДокумент13 страницSI 1037T Approved Pistons Rings and CylindersKamal Jit DhimanОценок пока нет

- StartingДокумент22 страницыStartingjasonphxОценок пока нет

- Production Test CouponДокумент4 страницыProduction Test CouponAbhijeet SahuОценок пока нет

- The Carbon Brush: ExchangeДокумент5 страницThe Carbon Brush: ExchangeJorge Morejon BuenoОценок пока нет

- Rodillos Ryobi ItekДокумент11 страницRodillos Ryobi Itekjuanluis201277Оценок пока нет

- Pontiac: Installation InstructionsДокумент3 страницыPontiac: Installation InstructionsGabe SilvaОценок пока нет

- SONNAX 45rfeДокумент2 страницыSONNAX 45rfefulltransmissionОценок пока нет

- Starting - Rav4 Sxa1Документ19 страницStarting - Rav4 Sxa1Christian Linares AbreuОценок пока нет

- Denison T6 Vane Pump PDFДокумент19 страницDenison T6 Vane Pump PDFZoran JankovОценок пока нет

- "L10" Drive End: Operation - Assembly Instructions and Parts List ForДокумент7 страниц"L10" Drive End: Operation - Assembly Instructions and Parts List ForACCA PumpsОценок пока нет

- Positive and Adjustable Choke CatalogueДокумент7 страницPositive and Adjustable Choke CatalogueAmer RehanОценок пока нет

- Halaman Dari MIO SOUL (14D)Документ16 страницHalaman Dari MIO SOUL (14D)HidayatОценок пока нет

- 2017 Concert Marching Parts CatalogДокумент32 страницы2017 Concert Marching Parts Cataloggabriel hongОценок пока нет

- MPP Side Channel Pump For Low NPSH Methanol Appl PDFДокумент3 страницыMPP Side Channel Pump For Low NPSH Methanol Appl PDFAnonymous ua66zYwrpОценок пока нет

- AERO 3in Diaphragm PumpДокумент2 страницыAERO 3in Diaphragm PumpjujuroyaleОценок пока нет

- Standard Actuator BrochureДокумент20 страницStandard Actuator BrochuretranquangtrungxdОценок пока нет

- Auto-Strong-3law Check PDFДокумент36 страницAuto-Strong-3law Check PDFsmith johnОценок пока нет

- Cutting G Off of Turboc Charger (Temp Porary) : Ro Tor Locking Proce EdureДокумент6 страницCutting G Off of Turboc Charger (Temp Porary) : Ro Tor Locking Proce EdurepcatruongОценок пока нет

- T20000 Series: - DATEДокумент41 страницаT20000 Series: - DATESaraiva EquipamentosОценок пока нет

- 3412 BlockДокумент3 страницы3412 BlockYeison NavasОценок пока нет

- "L4" Drive End: Operation - Assembly Instructions and Parts List ForДокумент6 страниц"L4" Drive End: Operation - Assembly Instructions and Parts List ForDavid Torres SibajaОценок пока нет

- ASTUTE 2315-E Column SS-V1Документ4 страницыASTUTE 2315-E Column SS-V1phoenix_lwpОценок пока нет

- Es1003 Lathe Drawtube SpecificationsДокумент7 страницEs1003 Lathe Drawtube SpecificationsEMS Metalworking MachineryОценок пока нет

- 033 PDFДокумент1 страница033 PDFjugaad bazi rahul kumarОценок пока нет

- Pumps Spec Series2400 8 09Документ8 страницPumps Spec Series2400 8 09Hamatouty TottiОценок пока нет

- T6CC/T6DC/T6EC/T6ED Series: Parker Denison T6 Double Hydraulic Vane PumpДокумент56 страницT6CC/T6DC/T6EC/T6ED Series: Parker Denison T6 Double Hydraulic Vane Pumpbadawai sallamОценок пока нет

- Cam Clutch BR-HT Tltr2Документ8 страницCam Clutch BR-HT Tltr2dillipsh123Оценок пока нет

- TYPE 1604/2609/3609: First Edition API 682 Type C Sealol Metal Bellows SealsДокумент6 страницTYPE 1604/2609/3609: First Edition API 682 Type C Sealol Metal Bellows SealsKapa KamalakarОценок пока нет

- Toyota 5FG33 45 5FD33 45 5FGE35 5FDE35 Forklift Service Repair Manual PDF - p048Документ1 страницаToyota 5FG33 45 5FD33 45 5FGE35 5FDE35 Forklift Service Repair Manual PDF - p048sơn forkliftОценок пока нет

- Fileupload 1381941464Документ5 страницFileupload 1381941464Cim HanoiОценок пока нет

- Class 150 Bronze Globe Valves: Union Bonnet - Integral Seat - Renewable Seat DiscДокумент1 страницаClass 150 Bronze Globe Valves: Union Bonnet - Integral Seat - Renewable Seat DiscSujitH Sekar GnanasekaranОценок пока нет

- Ductile Iron Fully-Lugged PN16: Features & BenefitsДокумент1 страницаDuctile Iron Fully-Lugged PN16: Features & BenefitsRonaldОценок пока нет

- 170J CompressorsДокумент9 страниц170J Compressors潘学淼Оценок пока нет

- Estremità Uscita Output Configurations Enden Der AusgangswellenДокумент16 страницEstremità Uscita Output Configurations Enden Der AusgangswellenAnıl YavuzОценок пока нет

- "L3" Drive End: Operation - Assembly Instructions and Parts List ForДокумент7 страниц"L3" Drive End: Operation - Assembly Instructions and Parts List ForACCA PumpsОценок пока нет

- Intake Kyn Toyota 1zrДокумент2 страницыIntake Kyn Toyota 1zrALiito KОценок пока нет

- Brochure Carnival 22Документ2 страницыBrochure Carnival 22Alfandani AkbarОценок пока нет

- Manual Valves Datasheet. Rev 1Документ7 страницManual Valves Datasheet. Rev 1eke23Оценок пока нет

- (Example: CSP02-C) : Thread WДокумент2 страницы(Example: CSP02-C) : Thread WLeonardo AlexОценок пока нет

- Octagonal PoleДокумент2 страницыOctagonal PoleARUN RAWATОценок пока нет

- "L8" Drive End: Operation - Assembly Instructions and Parts List ForДокумент7 страниц"L8" Drive End: Operation - Assembly Instructions and Parts List ForACCA PumpsОценок пока нет

- Data Motor Induksi Kerja PraktekДокумент13 страницData Motor Induksi Kerja PraktekChandro MarcelinusОценок пока нет

- R55-9 1Документ57 страницR55-9 1hungОценок пока нет

- Heidelberg FlyerДокумент11 страницHeidelberg Flyerdamar saktiОценок пока нет

- Drawing Auto Cleaner Caster WheelДокумент3 страницыDrawing Auto Cleaner Caster Wheelera chaolongОценок пока нет

- Parts List: Compressor Air EndДокумент14 страницParts List: Compressor Air EndQuy HoangОценок пока нет

- Peristaltic Pump Head Peristaltischer Pumpenaufsatz Cabeza de Bomba Peristáltica Tête de Pompe Péristaltique Testa Di Pompa PeristalticaДокумент7 страницPeristaltic Pump Head Peristaltischer Pumpenaufsatz Cabeza de Bomba Peristáltica Tête de Pompe Péristaltique Testa Di Pompa Peristalticadiegopal007Оценок пока нет

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Turbine Main Engines: The Commonwealth and International Library: Marine Engineering DivisionОт EverandTurbine Main Engines: The Commonwealth and International Library: Marine Engineering DivisionРейтинг: 5 из 5 звезд5/5 (4)

- CVRetno KartikaningrumДокумент13 страницCVRetno KartikaningrumMajid abdulОценок пока нет

- INVERTER OFF GRID SOLAR INVERTER (INPOWERS) HS SeriesДокумент1 страницаINVERTER OFF GRID SOLAR INVERTER (INPOWERS) HS SeriesMajid abdulОценок пока нет

- Led Area Light (Rekalux) (It-Series) Led Philips Chip PDFДокумент9 страницLed Area Light (Rekalux) (It-Series) Led Philips Chip PDFMajid abdulОценок пока нет

- Conext XW Datasheet ENGДокумент2 страницыConext XW Datasheet ENGAdhi Ne CutcakrowoОценок пока нет

- INVERTER OFF GRID SOLAR INVERTER (INPOWERS) MS Series BARUДокумент2 страницыINVERTER OFF GRID SOLAR INVERTER (INPOWERS) MS Series BARUMajid abdulОценок пока нет

- SP 9510Документ6 страницSP 9510Majid abdulОценок пока нет

- Grundfos - SP 160 7Документ11 страницGrundfos - SP 160 7Majid abdulОценок пока нет

- Progres DedДокумент14 страницProgres DedMajid abdulОценок пока нет

- INVERTER OFF GRID SOLAR INVERTER (INPOWERS) 1800 MPK-SeriesДокумент1 страницаINVERTER OFF GRID SOLAR INVERTER (INPOWERS) 1800 MPK-SeriesMajid abdulОценок пока нет

- Lampiran Dokumentasi Paket 19 Pedestrian JL - Indrapura: Kondisi EksistingДокумент3 страницыLampiran Dokumentasi Paket 19 Pedestrian JL - Indrapura: Kondisi EksistingMajid abdulОценок пока нет

- TokekДокумент1 страницаTokekMajid abdulОценок пока нет

- Heatexchanger 141216095212 ConversionДокумент23 страницыHeatexchanger 141216095212 Conversionraj2417705Оценок пока нет

- Butt VlaveДокумент6 страницButt VlaveChoon Wei WongОценок пока нет

- Ficha Tecnica Viking PDFДокумент11 страницFicha Tecnica Viking PDFRichie ChicolОценок пока нет

- Weicco - Flexible Connector PDFДокумент2 страницыWeicco - Flexible Connector PDFmsmrizhwanОценок пока нет

- Minor Losses in Bends Lab ReportДокумент8 страницMinor Losses in Bends Lab Reportalex starrett0% (1)

- Transvazare EngДокумент3 страницыTransvazare EngGeorge PopescuОценок пока нет

- Bender Tube Pipe Benders RDB SeriesДокумент8 страницBender Tube Pipe Benders RDB SeriesEdSoloОценок пока нет

- Tuboquip ComparaisonДокумент8 страницTuboquip Comparaisongrincheu70Оценок пока нет

- 2 Vertical Pumps: 2.1 Types and NomenclatureДокумент4 страницы2 Vertical Pumps: 2.1 Types and NomenclatureAde ImanudinОценок пока нет

- Concrete Construction Article PDF - How A Concrete Pump WorksДокумент2 страницыConcrete Construction Article PDF - How A Concrete Pump WorksSiva Subramani100% (2)

- Brosur Singer PFCДокумент3 страницыBrosur Singer PFCPutu Agus SantosaОценок пока нет

- Sewage Forcemain DesignДокумент9 страницSewage Forcemain DesignMarlon A. MendozaОценок пока нет

- Drag CoefficientsДокумент103 страницыDrag CoefficientsFilip StojkovskiОценок пока нет

- Pipes. Flow Rate and Pressure Loss EquationsДокумент62 страницыPipes. Flow Rate and Pressure Loss EquationsFrancisco AlvarezОценок пока нет

- Satip F 001 04Документ4 страницыSatip F 001 04Anonymous 4e7GNjzGWОценок пока нет

- PSV Sizing (Steam)Документ2 страницыPSV Sizing (Steam)Saeid Rahimi Mofrad100% (1)

- Spare Parts Catalogue: Purifier Unit 100 Separation SystemДокумент66 страницSpare Parts Catalogue: Purifier Unit 100 Separation SystemCosmin NichiforОценок пока нет

- Friction and Singular Pressure DropДокумент24 страницыFriction and Singular Pressure DropSherif Abdel Hamid FakhryОценок пока нет

- C110-M433.01 - Rev. G - Chilled Water Piping Schematic DiagramДокумент7 страницC110-M433.01 - Rev. G - Chilled Water Piping Schematic DiagramZwe1991Оценок пока нет

- Pump 150918161223 Lva1 App6891 PDFДокумент325 страницPump 150918161223 Lva1 App6891 PDFJohn RajОценок пока нет

- Cri Pumps PricelistДокумент10 страницCri Pumps PricelistMunish Vashistha100% (1)

- Marine ValvesДокумент6 страницMarine ValvesENG PTBBSОценок пока нет

- Previews HI 9 6 1 2012 PreДокумент12 страницPreviews HI 9 6 1 2012 Prearundhamodharan4294Оценок пока нет

- Valve Remote Control System With Hydraulic Control Actuator 03. SH076 Final Drawing PDFДокумент386 страницValve Remote Control System With Hydraulic Control Actuator 03. SH076 Final Drawing PDFAshitosh100% (2)

- 2010 Product Guide and Price List Americas: Effective April 1, 2010Документ496 страниц2010 Product Guide and Price List Americas: Effective April 1, 2010_srobert_Оценок пока нет

- Pumping Stations Design Lecture 4Документ46 страницPumping Stations Design Lecture 4p_ignatius100% (1)

- 5 - A9a SpecificationДокумент4 страницы5 - A9a SpecificationPrasanta Kumar BeheraОценок пока нет

- Flow and Pressure Drop in Valves and FittingsДокумент5 страницFlow and Pressure Drop in Valves and FittingsĐoàn TrangОценок пока нет

- Pump SizingДокумент31 страницаPump SizingTuấn VũОценок пока нет

- Opti Flow Gas Lift Catalog PDFДокумент20 страницOpti Flow Gas Lift Catalog PDFsatyendraОценок пока нет