Академический Документы

Профессиональный Документы

Культура Документы

Proper Flange Bolting

Загружено:

Poppy Irawan0 оценок0% нашли этот документ полезным (0 голосов)

10 просмотров2 страницыАвторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

10 просмотров2 страницыProper Flange Bolting

Загружено:

Poppy IrawanАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

PROPER FLANGE BOLTING

Flanges Flange Installation Procedures

In theory, if it were possible to have two 1. Inspect the flanges. Check for tool marks,

perfectly mated flanges with total effective dents, scratches or corrosion. Look for

contact at all points, a gasket would not be pitting and any other defects which would

required to effect a seal. Obviously since make sealing impossible. Repairs must be

this is not possible, a gasket is required made before bolting.

and its function is to seal two imperfect 2. Inspect the gasket. Verify to be sure the

surfaces. gasket is of the proper material and style.

Look for defects or damage.

There are limits on the degree of flange

surface imperfections that can be sealed 3. Inspect and clean bolts, nuts and washers.

successfully with a gasket. Large nicks, Verify to be sure they are of the specified

dents and gouges must be avoided, since material.

a gasket cannot seal against them 4. Lubricate the bolt threads and the nut

properly. Also, a gasket cannot seal contact surfaces. This cannot be

improperly aligned flanges. overstressed. The use of an anti-seize

compound should be considered to facilitate

Another problem is waviness in the flanges subsequent disassembly. The better the

and warped or bowed flanges. This can lubricant, the more consistent the actual

be caused by heat during the achieved bolt stress at installation will be.

manufacturing or welding process, internal 5. Center the gasket on the flange. This is

stress and excessive bolt loads during extremely vital when raised faced flanges

installation. See figure 1. are used.

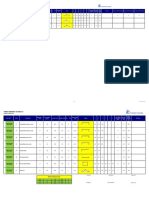

6. Tighten the bolts approximately 30% to the

To obtain a satisfactory seal, it is

final torque following the sequence shown in

necessary that basic procedures are

Figure 2 (shown on next page). If the

followed during installation. These

correct tightening sequence is not followed,

procedures are of fundamental importance

the flanges can be misaligned, making it

for a successful operation no matter what

impossible to have uniform seating of the

style of gasket or type of bolting materials

gasket. Numbering the bolts may be helpful

are used. While these flange installa-

in following the bolt sequence.

tion procedures may seem elementary,

they are extremely important and 7. Repeat step 6, elevating the torque to 50 to

should be carefully followed. 60 percent of the final torque.

8. Continue tightening in the recommended

sequence until the final torque value is

reached. Each bolt normally has to be

tightened more than once.

9. All gaskets relax after seating. Retightening

is recommended 24 hours after installation

to compensate for the relaxation. On high-

pressure or high-temperature applications, it

is recommended that the flanges be

retorqued to the required stress after 24

hours at operating pressure and

temperatures to compensate for any

A - Bowing of flange due to too high bolt load relaxation.

A DIVISION OF TRIPAC MARKETING, INC.

475 KLUG CIRCLE • CORONA, CA 92880-6406

(951) 280-4488 • FAX: (951) 272-4445

PROPER FLANGE BOLTING

Gaskets Bolting

Gaskets are used to create a static seal A bolt is a spring. It is an elastic member

between two flanges and to maintain that seal which has been stretched to develop a load

under operating conditions. Proper gasket by elongating its length. It must not be over-

selection is critical and must be considered elongated (over-strained), or the elastic limit

during the design and engineering process of of the steel will be exceeded. The bolt then

any system. deforms and with continued loading

(stressing) will quickly fail.

Once the type of material and style of gasket is

determined, proper installation is critical to To avoid such problems with bolt tightening,

achieve “seating” of the gasket. A seal is the use of a torque wrench is recommended.

effected by compressing the gasket material The designer of the flange system

and causing it to flow into the imperfections on normally specifies the torque required to

the flanges so that intimate contact is made achieve a proper seal.

preventing leaking of the joint. The most

common method of effecting a seal on a flange The inch-per-inch relationship demonstrates

joint is through compression force applied by that the longer the bolt, the more it must be

bolting. strained to yield a desired load; thus, the more

follow-up or comeback there will be in actual

inches. This is highly desirable, since most

Torque gasketing materials tend to remold, to relax, to

Torque is a twisting force. When applied to a take a permanent set. This is called the

bolt it is generally expressed in foot pounds. creep-relaxation phenomenon.

The formula for torque is T = R x S where:

The more follow-up of spring provided by the

R = radius or length of lever

bolt, the better the retention of stress on the

S = pounds pull on scale

gasket to maintain a leakproof joint. In the

same respect, a smaller diameter bolt must be

Properly fastened studs and bolts achieve

strained more to develop the same load. With

their holding power from the tension (or

the smaller diameter bolt, there is a serious

torque) that is derived from the mating of the

danger that it may be over-strained and

external and internal threads subject to the

stressed beyond the elastic limit, and finally

elastic limit of the material.

broken. The smaller bolt, within its elastic

What torque to apply is a generally limit, could give the same additional follow-up

asked question, but the answer as the larger diameter bolt of greater

Figure 2 length.

depends on the variables of

material, threads, and lubrication, if

any. As previously stated the Bolting Patterns

designer of the flange system

normally specifies the required Regardless of the number of bolts,

torque. this circular bolt pattern with

modification, will provide the correct

tightening sequence.

Circular Multi-Bolt

Installation Pattern

A DIVISION OF TRIPAC MARKETING, INC.

475 KLUG CIRCLE • CORONA, CA 92880-6406

(951) 280-4488 • FAX: (951) 272-4445

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Case Study of Optimal Byproduct Gas Distribution in Integrated Steel Mill Using Multi-Period Optimization - PaperДокумент6 страницCase Study of Optimal Byproduct Gas Distribution in Integrated Steel Mill Using Multi-Period Optimization - PaperPoppy IrawanОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Xlpe Insulated Power Cables PDFДокумент47 страницXlpe Insulated Power Cables PDFsouheil boussaidОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Sizing of Cable Tray Rev. D PDFДокумент13 страницSizing of Cable Tray Rev. D PDFAlvin SmithОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Anshan Iron & Steel Group Corporation, China, Construction and Operation Experience of 300 MW Blast Furnace Gas Firing Combined Cycle Power PlantДокумент6 страницAnshan Iron & Steel Group Corporation, China, Construction and Operation Experience of 300 MW Blast Furnace Gas Firing Combined Cycle Power PlantBanggas Hanistia PahleviОценок пока нет

- MetasolДокумент100 страницMetasolThuy ThanhОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Magneetschakelaars Technisch Manual 20180530161556Документ276 страницMagneetschakelaars Technisch Manual 20180530161556DomingoОценок пока нет

- EOCR Analogue en 2011Документ28 страницEOCR Analogue en 2011Poppy IrawanОценок пока нет

- ABB Control Product: Why Should AF Contactor ???Документ10 страницABB Control Product: Why Should AF Contactor ???Poppy IrawanОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Pany ProfileДокумент13 страницPany ProfilePoppy IrawanОценок пока нет

- Abb Ac Motor ConfДокумент20 страницAbb Ac Motor ConfAudi eko susatyoОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Catalogo Contactor Ingles 2001Документ81 страницаCatalogo Contactor Ingles 2001raulflores1959Оценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Softstarter From ABB: Controlling The ElementДокумент41 страницаSoftstarter From ABB: Controlling The ElementPoppy IrawanОценок пока нет

- Company Profile PT Gema IndustrialДокумент19 страницCompany Profile PT Gema IndustrialPoppy IrawanОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Yew Ut32a Ut35a ManualДокумент340 страницYew Ut32a Ut35a ManualvjОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Xlpe Insulated Power Cables PDFДокумент47 страницXlpe Insulated Power Cables PDFsouheil boussaidОценок пока нет

- Dryer KyungwonДокумент16 страницDryer KyungwonPoppy IrawanОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Tutorial 2 Thermo PDFДокумент3 страницыTutorial 2 Thermo PDFFattihiEkhmalОценок пока нет

- 16 ConstructionДокумент28 страниц16 Constructionalcibiades romeroОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Project: 1x950 TDS/Day Soda Recovery Boiler Customer: ITC LTD., - PSPD Enmas Engenius Projects LimitedДокумент2 страницыProject: 1x950 TDS/Day Soda Recovery Boiler Customer: ITC LTD., - PSPD Enmas Engenius Projects LimitedV U P RaoОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Technicalpresentation Mineraladmixtures 180611161645Документ20 страницTechnicalpresentation Mineraladmixtures 180611161645Shubham ParmarОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- ASME General 100 QuestionsДокумент54 страницыASME General 100 Questionsatulpatil99100% (2)

- Astm Carbon Steel Pipe and Flange Specifications PDFДокумент2 страницыAstm Carbon Steel Pipe and Flange Specifications PDFarunОценок пока нет

- Manual Calefa 1 PlantaДокумент29 страницManual Calefa 1 PlantanegrorocksОценок пока нет

- Ultratech Cement: Particulars Test Results Requirements ofДокумент1 страницаUltratech Cement: Particulars Test Results Requirements ofjitendraОценок пока нет

- Alloy Steels - Engineering Materials & Metallurgy Questions and Answers - SanfoundryДокумент6 страницAlloy Steels - Engineering Materials & Metallurgy Questions and Answers - SanfoundrySample UseОценок пока нет

- Moldex Realty, Inc. (Linda Agustin) 2.0 (With Sound)Документ111 страницMoldex Realty, Inc. (Linda Agustin) 2.0 (With Sound)Arwin AgustinОценок пока нет

- 2017 Fdot July Ebook PDFДокумент1 226 страниц2017 Fdot July Ebook PDFDamen JohnsonОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- PRIMOTECH - Solar Water HeaterДокумент14 страницPRIMOTECH - Solar Water HeaterPrimotech EnergyОценок пока нет

- En14511 4 2004Документ14 страницEn14511 4 2004pavlosmicОценок пока нет

- Bar Bending Batching PlantДокумент3 страницыBar Bending Batching PlantAnonymous 5OUozYОценок пока нет

- Home Construction Cost Calculator - UltratechДокумент7 страницHome Construction Cost Calculator - UltratechAkshayОценок пока нет

- Arkifloor AWДокумент2 страницыArkifloor AWChristinaОценок пока нет

- ACS Heat - Loss - Calculator Dryer 3050D X 21000L Thermal Analysis ReportДокумент7 страницACS Heat - Loss - Calculator Dryer 3050D X 21000L Thermal Analysis Reportdwi sutiknoОценок пока нет

- Marco Island Executive Airport Terminal Construction Change of Order #5 - 2021Документ5 страницMarco Island Executive Airport Terminal Construction Change of Order #5 - 2021Omar Rodriguez OrtizОценок пока нет

- Wa0082 PDFДокумент34 страницыWa0082 PDFmiteshОценок пока нет

- 4-1 Low Cycle Fatigue - High Cycle Fatigue - BДокумент9 страниц4-1 Low Cycle Fatigue - High Cycle Fatigue - BkandeabigaelОценок пока нет

- B353 OL3 026-1 - Pres - RevD-02 - Ba - UpdateДокумент49 страницB353 OL3 026-1 - Pres - RevD-02 - Ba - UpdateVraja DasiОценок пока нет

- 2017 LATBSDC CRITERIA - Final - 06 08 17 PDFДокумент72 страницы2017 LATBSDC CRITERIA - Final - 06 08 17 PDFRannie IsonОценок пока нет

- SUP032BR: Esp. E74104 Rev.01Документ5 страницSUP032BR: Esp. E74104 Rev.01kimanski01Оценок пока нет

- JL-89-January-February Lateral Stability of Long Prestressed Concrete Beams-Part 1Документ20 страницJL-89-January-February Lateral Stability of Long Prestressed Concrete Beams-Part 1Dong-Yong KimОценок пока нет

- Weld-Crete® Concrete Bonding AgentДокумент3 страницыWeld-Crete® Concrete Bonding AgentMario LanzaОценок пока нет

- Cyprus National Annex en 1993-1-1Документ11 страницCyprus National Annex en 1993-1-1Atalay YordamОценок пока нет

- 2 1-Thermodynamics PDFДокумент34 страницы2 1-Thermodynamics PDFBrielle 'Оценок пока нет

- 1D and 2D PlasticityДокумент24 страницы1D and 2D PlasticityChandra ClarkОценок пока нет

- Kodak Carousel Service ManualДокумент51 страницаKodak Carousel Service ManualRobert B. Whitaker100% (1)

- Company: 4 Seasons Climate ComfortДокумент39 страницCompany: 4 Seasons Climate ComforttvassilopoulosОценок пока нет

- Waste: One Woman’s Fight Against America’s Dirty SecretОт EverandWaste: One Woman’s Fight Against America’s Dirty SecretРейтинг: 5 из 5 звезд5/5 (1)