Академический Документы

Профессиональный Документы

Культура Документы

Guo40 16no1 PDF

Загружено:

Adrian FerreyraОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Guo40 16no1 PDF

Загружено:

Adrian FerreyraАвторское право:

Доступные форматы

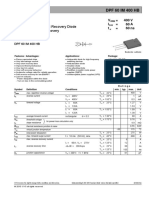

GUO40-16NO1

3~

Standard Rectifier Rectifier

VRRM = 1600 V

I DAV = 40 A

I FSM = 370 A

3~ Rectifier Bridge

Part number

GUO40-16NO1

Backside: isolated

+

D1 D3 D5

~

~

~

D2 D4 D6

Features / Advantages: Applications: Package: GUFP

● Low forward voltage drop ● Supplies for DC power equipment ● Isolation Voltage: 2500 V~

● Planar passivated chips ● Input rectifiers for PWM inverter ● Industry standard outline

● Easy to mount with one screw ● Battery DC power supplies ● RoHS compliant

● Space and weight savings ● Field supply for DC motors ● Epoxy meets UL 94V-0

● Soldering pins for PCB mounting

● Base plate: Plastic overmolded tab

● Reduced weight

Disclaimer Notice

Information furnished is believed to be accurate and reliable. However, users should independently

evaluate the suitability of and test each product selected for their own applications. Littelfuse products are not designed for,

and may not be used in, all applications. Read complete Disclaimer Notice at www.littelfuse.com/disclaimer-electronics.

IXYS reserves the right to change limits, conditions and dimensions. Data according to IEC 60747and per semiconductor unless otherwise specified 20191219d

© 2019 IXYS all rights reserved

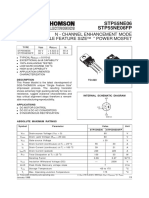

GUO40-16NO1

Rectifier Ratings

Symbol Definition Conditions min. typ. max. Unit

VRSM max. non-repetitive reverse blocking voltage TVJ = 25°C 1700 V

VRRM max. repetitive reverse blocking voltage TVJ = 25°C 1600 V

IR reverse current VR = 1600 V TVJ = 25°C 40 µA

VR = 1600 V TVJ = 150°C 1.5 mA

VF forward voltage drop IF = 10 A TVJ = 25°C 1.06 V

IF = 30 A 1.28 V

IF = 10 A TVJ = 150 °C 0.92 V

IF = 30 A 1.23 V

I DAV bridge output current TC = 90 °C T VJ = 175 °C 40 A

rectangular d=⅓

VF0 threshold voltage TVJ = 175 °C 0.74 V

for power loss calculation only

rF slope resistance 16.3 mΩ

R thJC thermal resistance junction to case 4.3 K/W

R thCH thermal resistance case to heatsink 0.5 K/W

Ptot total power dissipation TC = 25°C 35 W

I FSM max. forward surge current t = 10 ms; (50 Hz), sine TVJ = 45°C 370 A

t = 8,3 ms; (60 Hz), sine VR = 0 V 400 A

t = 10 ms; (50 Hz), sine TVJ = 150 °C 315 A

t = 8,3 ms; (60 Hz), sine VR = 0 V 340 A

I²t value for fusing t = 10 ms; (50 Hz), sine TVJ = 45°C 685 A²s

t = 8,3 ms; (60 Hz), sine VR = 0 V 665 A²s

t = 10 ms; (50 Hz), sine TVJ = 150 °C 495 A²s

t = 8,3 ms; (60 Hz), sine VR = 0 V 480 A²s

CJ junction capacitance VR = 400 V; f = 1 MHz TVJ = 25°C 10 pF

IXYS reserves the right to change limits, conditions and dimensions. Data according to IEC 60747and per semiconductor unless otherwise specified 20191219d

© 2019 IXYS all rights reserved

GUO40-16NO1

Package GUFP Ratings

Symbol Definition Conditions min. typ. max. Unit

I RMS RMS current per terminal 70 A

TVJ virtual junction temperature -40 175 °C

T op operation temperature -40 150 °C

Tstg storage temperature -40 150 °C

Weight 8.5 g

MD mounting torque 0.8 1.2 Nm

FC mounting force with clip 20 120 N

d Spp/App terminal to terminal 6.7 5.4 mm

creepage distance on surface | striking distance through air

d Spb/Apb terminal to backside 10.0 8.0 mm

VISOL isolation voltage t = 1 second 2500 V

50/60 Hz, RMS; IISOL ≤ 1 mA

t = 1 minute 2100 V

RthJA thermal resistance junction to ambient 50 K/W

Ordering Ordering Number Marking on Product Delivery Mode Quantity Code No.

Standard GUO40-16NO1 GUO40-16NO1 Tube 14 514899

Similar Part Package Voltage class

DNA40U2200GU GUFP 2200

DMA40U1800GU GUFP 1800

GUO40-12NO1 GUFP 1200

GUO40-08NO1 GUFP 800

Equivalent Circuits for Simulation * on die level T VJ = 175°C

I V0 R0 Rectifier

V 0 max threshold voltage 0.74 V

R0 max slope resistance * 13.7 mΩ

IXYS reserves the right to change limits, conditions and dimensions. Data according to IEC 60747and per semiconductor unless otherwise specified 20191219d

© 2019 IXYS all rights reserved

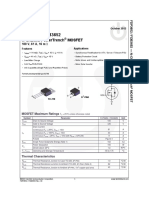

GUO40-16NO1

Outlines GUFP

Millimeter Inches

Dim.

min typ. max min typ. max

A 5.40 5.50 5.60 0.213 0.217 0.221

Z1 A2 3.90 4.00 4.10 0.154 0.158 0.162

O A2 A3 0.95 1.00 1.10 0.037 0.039 0.043

A4 0.95 1.00 1.05 0.037 0.039 0.041

A5 1.60 1.70 1.80 0.063 0.067 0.071

Q

Z2

ØP A6 1.25 1.30 1.35 0.049 0.051 0.053

b 0.95 1.00 1.05 0.037 0.039 0.041

D

S1 b2 1.95 2.00 2.05 0.077 0.079 0.081

+2 C 0.45 0.50 0.55 0.018 0.020 0.022

X2

+1 D 24.80 25.00 25.20 0.977 0.985 0.993

Y2

X1

_

R

~ ~ ~ + E 34.70 35.00 35.30 1.367 1.379 1.391

e BSC 7.50 BSC 0.296

L1

F 2.40 2.50 2.60 0.095 0.099 0.102

Y1

S2

5x b2 L 20.30 20.40 20.50 0.800 0.804 0.808

L

L1 3.70 3.75 3.80 0.146 0.148 0.150

5x b O 17.40 17.50 17.60 0.686 0.690 0.693

C ØP 4.10 4.20 4.30 0.162 0.165 0.169

Q 9.20 9.30 9.40 0.362 0.366 0.370

e A3 Ø 1.77 0.070

/2 R

4x e A4 s1 3.45 3.50 3.55 0.136 0.138 0.140

F s2 1.45 1.50 1.55 0.057 0.059 0.061

E A5 t1 0.95 1.00 1.05 0.037 0.039 0.041

t2 0.95 1.00 1.05 0.037 0.039 0.041

A6

x1 3.20 3.30 3.40 0.126 0.130 0.134

A x2 1.90 2.00 2.10 0.075 0.079 0.083

y1 1.60 1.65 1.70 0.063 0.065 0.067

y2 4.65 4.70 4.75 0.183 0.185 0.187

z1 2.80 2.90 3.00 0.110 0.114 0.118

+

D1 D3 D5

~

~

~

D2 D4 D6

IXYS reserves the right to change limits, conditions and dimensions. Data according to IEC 60747and per semiconductor unless otherwise specified 20191219d

© 2019 IXYS all rights reserved

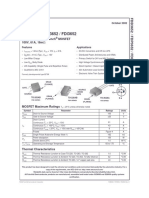

GUO40-16NO1

Rectifier

60 300 800

50 Hz

0.8 x V RRM VR = 0 V

600

40 250 TVJ = 45°C

IF IFSM

I 2t TVJ = 45°C

400

[A] [A] 2

[A s]

20 200 TVJ = 150°C

TVJ = TVJ = 150°C 200

125°C

150°C TVJ = 25°C

0 150 0

0.4 0.8 1.2 1.6 10-3 10-2 10-1 100 1 10

VF [V] t [s] t [ms]

2

Fig. 1 Forward current vs. Fig. 2 Surge overload current Fig. 3 I t vs. time per diode

voltage drop per diode vs. time per diode

20 40

DC = RthJA:

1 0.6 KW DC =

0.5 0.8 KW 1

16

0.4 30 0.5

1 KW

0.33

0.17 2 KW 0.4

12 0.08 4 KW

IF(AV)M 0.33

Ptot

8 KW 0.17

20

[A] 0.08

[W] 8

10

4

0 0

0 4 8 12 16 0 25 50 75 100 125 150 175 0 25 50 75 100 125 150 175

IF(AV)M [A] TA [°C] TC [°C]

Fig. 4 Power dissipation vs. forward current Fig. 5 Max. forward current vs.

and ambient temperature per diode case temperature per diode

ZthJC 3 Constants for ZthJC calculation:

[K/W] i Rth (K/W) ti (s)

2

1 0.302 0.002

1 2 1.252 0.032

3 1.582 0.227

0

4 1.164 0.820

1 10 100 1000 10000

t [ms]

Fig. 6 Transient thermal impedance junction to case vs. time per diode

IXYS reserves the right to change limits, conditions and dimensions. Data according to IEC 60747and per semiconductor unless otherwise specified 20191219d

© 2019 IXYS all rights reserved

Вам также может понравиться

- Standard Rectifier ModuleДокумент5 страницStandard Rectifier ModuleAndri AwanОценок пока нет

- Dsi45 16arДокумент5 страницDsi45 16arMohammad Reza FaghihОценок пока нет

- Standard Rectifier ModuleДокумент5 страницStandard Rectifier ModulerafaelrgrОценок пока нет

- DPG60IM300PCДокумент5 страницDPG60IM300PCFay AgodoloОценок пока нет

- mcc200 14io1Документ6 страницmcc200 14io1marcinhokОценок пока нет

- Standard Rectifier: Phase LegДокумент6 страницStandard Rectifier: Phase Legdanilo pereiraОценок пока нет

- Hiperfred : High Performance Fast Recovery Diode Low Loss and Soft Recovery Single DiodeДокумент4 страницыHiperfred : High Performance Fast Recovery Diode Low Loss and Soft Recovery Single DiodeАндрей ПоляковОценок пока нет

- Vuo28 08no7Документ5 страницVuo28 08no7edy985Оценок пока нет

- Ixys dpg60c300hb Datasheets 9568Документ5 страницIxys dpg60c300hb Datasheets 9568matesimic50Оценок пока нет

- Single Diode Fast Recovery Epitaxial Diode: DSEI30-06AДокумент6 страницSingle Diode Fast Recovery Epitaxial Diode: DSEI30-06AErasmo Franco SОценок пока нет

- 1.5A Low Drop Fixed and Adjustable Positive Voltage RegulatorsДокумент18 страниц1.5A Low Drop Fixed and Adjustable Positive Voltage RegulatorsteknoalexОценок пока нет

- DSP25 12aДокумент5 страницDSP25 12aDaniel BarbuОценок пока нет

- Very Low Drop Voltage Regulator: DescriptionДокумент8 страницVery Low Drop Voltage Regulator: DescriptionJhonatan CervantesОценок пока нет

- Thyristor / Diode Module: Phase LegДокумент6 страницThyristor / Diode Module: Phase LegCJRCОценок пока нет

- CMA30E1600PNДокумент6 страницCMA30E1600PNMeriem daasОценок пока нет

- Standard Rectifier Module: Phase LegДокумент6 страницStandard Rectifier Module: Phase LegShwe Thin AungОценок пока нет

- Very Low Drop Voltage Regulator: DescriptionДокумент8 страницVery Low Drop Voltage Regulator: DescriptionJhonatan CervantesОценок пока нет

- Thyristor Module: 3 Rectifier Bridge, Half-Controlled (High-Side) + Free Wheeling DiodeДокумент5 страницThyristor Module: 3 Rectifier Bridge, Half-Controlled (High-Side) + Free Wheeling DiodeMohamed ReyadОценок пока нет

- Very Low Drop Voltage Regulator: DescriptionДокумент8 страницVery Low Drop Voltage Regulator: Descriptionjulio montenegroОценок пока нет

- Power Schottky Rectifier: With Common CathodeДокумент2 страницыPower Schottky Rectifier: With Common CathodeAhmed Sherif CupoОценок пока нет

- VNP20N07FI VNB20N07/VNV20N07: "Omnifet": Fully Autoprotected Power MosfetДокумент13 страницVNP20N07FI VNB20N07/VNV20N07: "Omnifet": Fully Autoprotected Power MosfetНаталія ЛіськевичОценок пока нет

- DHG20I1200HAasdasdfasdf PDFДокумент4 страницыDHG20I1200HAasdasdfasdf PDFSanthosh Kumar JОценок пока нет

- Dsei2x101 12aДокумент5 страницDsei2x101 12asongdashengОценок пока нет

- RR Series RelayДокумент4 страницыRR Series RelaypepitoОценок пока нет

- 30V Complementary MOSFET TitleДокумент9 страниц30V Complementary MOSFET TitleSebastian CorreaОценок пока нет

- dss20 0015bДокумент4 страницыdss20 0015bmihashОценок пока нет

- FDB13AN06A0Документ11 страницFDB13AN06A0kamil.smolinski.1980Оценок пока нет

- Power Supply Trainer Using Lm723 IcДокумент8 страницPower Supply Trainer Using Lm723 IcDinesh Kumar MehraОценок пока нет

- MCD95 16io1bДокумент6 страницMCD95 16io1bHungОценок пока нет

- Mur 1510Документ7 страницMur 1510Pablo AllosiaОценок пока нет

- STPS2045CTCFCGCFPCRДокумент8 страницSTPS2045CTCFCGCFPCROmaraye JoshuaОценок пока нет

- AN-1581 Application Note: High Speed Instrumentation Amplifier Using The Difference Amplifier and The JFET Input Op AmpДокумент4 страницыAN-1581 Application Note: High Speed Instrumentation Amplifier Using The Difference Amplifier and The JFET Input Op AmpAbolfazl Yousef ZamanianОценок пока нет

- Stp55ne06 PDFДокумент9 страницStp55ne06 PDFOmar CuevasОценок пока нет

- IR2112 high and low side driver data sheetДокумент18 страницIR2112 high and low side driver data sheetDimas BagusОценок пока нет

- VNB10N07/K10N07FM VNP10N07FI/VNV10N07: "Omnifet": Fully Autoprotected Power MosfetДокумент14 страницVNB10N07/K10N07FM VNP10N07FI/VNV10N07: "Omnifet": Fully Autoprotected Power MosfetEduardo MontoyaОценок пока нет

- Regulador 4949ed PDFДокумент11 страницRegulador 4949ed PDFluizОценок пока нет

- D D D D D D D D: DescriptionДокумент15 страницD D D D D D D D: Descriptionbernard smithОценок пока нет

- IRFB4610 IRFS4610 IRFSL4610: V 100V R Typ. 11m Max. 14m I 73AДокумент11 страницIRFB4610 IRFS4610 IRFSL4610: V 100V R Typ. 11m Max. 14m I 73ATomi OzzyОценок пока нет

- 7915Документ13 страниц7915ysfhkОценок пока нет

- Moeller on-OfF SwitchДокумент5 страницMoeller on-OfF SwitchR JОценок пока нет

- Op Amp StabilityДокумент32 страницыOp Amp Stabilityapdim79Оценок пока нет

- Fdp3652 / Fdb3652: N-Channel Powertrench MosfetДокумент14 страницFdp3652 / Fdb3652: N-Channel Powertrench Mosfethalil ibrahim soysalОценок пока нет

- VND7N04/VND7N04-1 VNP7N04FI/K7N04FM: "Omnifet": Fully Autoprotected Power MosfetДокумент14 страницVND7N04/VND7N04-1 VNP7N04FI/K7N04FM: "Omnifet": Fully Autoprotected Power MosfetGiovani PardinhoОценок пока нет

- Manual Tecnico Tiristor MCC56-12io1BДокумент6 страницManual Tecnico Tiristor MCC56-12io1BElmer Huayra HuanhuayoОценок пока нет

- Irf3207 MOSFETДокумент12 страницIrf3207 MOSFETKennedy IruОценок пока нет

- Multifunction Very Low Drop Voltage Regulator: DescriptionДокумент10 страницMultifunction Very Low Drop Voltage Regulator: DescriptionErasmo FrancoОценок пока нет

- HDLX Dimmer Transistor - IXDN 55N120D1Документ5 страницHDLX Dimmer Transistor - IXDN 55N120D1SuperhypoОценок пока нет

- FDP3652Документ11 страницFDP3652Dávid KisОценок пока нет

- Fdb20an06a0 1305401Документ14 страницFdb20an06a0 1305401Moi CanoОценок пока нет

- Cla 50 e 1200 HBДокумент5 страницCla 50 e 1200 HBmourad SysОценок пока нет

- STPR1020CB/CG/CT/CF/CFP/CR: Ultra-Fast Recovery Rectifier DiodesДокумент10 страницSTPR1020CB/CG/CT/CF/CFP/CR: Ultra-Fast Recovery Rectifier DiodesPeterAspegrenОценок пока нет

- IR2110/IR2113: High and Low Side DriverДокумент16 страницIR2110/IR2113: High and Low Side DriverĦøÐâОценок пока нет

- Unisonic Technologies Co., LTD: Multiple Rs-232 Drivers and ReceiversДокумент10 страницUnisonic Technologies Co., LTD: Multiple Rs-232 Drivers and ReceiversRamon Alexander PradaОценок пока нет

- High voltage Schottky rectifier guideДокумент7 страницHigh voltage Schottky rectifier guideVicente MiróОценок пока нет

- Infineon IR2110 DataSheet v01 00 enДокумент17 страницInfineon IR2110 DataSheet v01 00 enSergio BarbozaОценок пока нет

- 7912CT EtcДокумент13 страниц7912CT EtcCuong TranОценок пока нет

- MC3303/MC3403: Quad Operational AmplifierДокумент10 страницMC3303/MC3403: Quad Operational AmplifierVictor HemzОценок пока нет

- Fdp050an06a0 241446Документ14 страницFdp050an06a0 241446ElvisОценок пока нет

- 4n60 MosfetДокумент4 страницы4n60 MosfetRicardoОценок пока нет

- BT Rre RRBДокумент514 страницBT Rre RRBmordidomi88% (24)

- Jungheinrich EZS 330 - 350 - XL Operating Instructions Manual PDFДокумент85 страницJungheinrich EZS 330 - 350 - XL Operating Instructions Manual PDFAdrian FerreyraОценок пока нет

- Jungheinrich DFG - TFG 660-690 Service Manual PDFДокумент221 страницаJungheinrich DFG - TFG 660-690 Service Manual PDFAdrian Ferreyra100% (2)

- PreviewДокумент1 968 страницPreviewAdrian FerreyraОценок пока нет

- PowerpaK SEM & MicropaK - MДокумент60 страницPowerpaK SEM & MicropaK - MAdrian FerreyraОценок пока нет

- Jungheinrich DFG - TFG 660-690 Service Manual PDFДокумент221 страницаJungheinrich DFG - TFG 660-690 Service Manual PDFAdrian Ferreyra100% (2)

- BT RRДокумент456 страницBT RRslawny7794% (17)

- Sevcon PowerpaK (SEM & MicropaK) Manual - With Calibrator SectionДокумент60 страницSevcon PowerpaK (SEM & MicropaK) Manual - With Calibrator SectionKrishna KhandigeОценок пока нет

- Owner'S Manual: Industrial Battery ChargerДокумент24 страницыOwner'S Manual: Industrial Battery ChargerLuis F OrtegaОценок пока нет

- Forklift Owner's ManualДокумент101 страницаForklift Owner's ManualΓιώργος Πλέσσας71% (21)

- Gen4 Product Manual V3 4 PDFДокумент115 страницGen4 Product Manual V3 4 PDFRuben DuranОценок пока нет

- 51151902Документ243 страницы51151902Mohammed Al-hewaimel100% (2)

- Jungheinrich EFG-Vac 22-30 - 25L - S - SL Service ManualДокумент81 страницаJungheinrich EFG-Vac 22-30 - 25L - S - SL Service Manualeduardo chavez0% (1)

- Ev100zx TechДокумент83 страницыEv100zx TechJohn Jairo OsornosoОценок пока нет

- Ept20 20wa Parts ManualДокумент88 страницEpt20 20wa Parts ManualAdrian FerreyraОценок пока нет

- Gek 28897B PDFДокумент19 страницGek 28897B PDFAdrian FerreyraОценок пока нет

- 038-1029EPL PartsList BGS25 IndustrialTruckДокумент60 страниц038-1029EPL PartsList BGS25 IndustrialTruckAdrian FerreyraОценок пока нет

- Owner'S Manual: Operation Maintenance Parts ListДокумент124 страницыOwner'S Manual: Operation Maintenance Parts ListDmitryОценок пока нет

- C10513050 PDFДокумент108 страницC10513050 PDFtruckman1000Оценок пока нет

- SKS20i Original ManualДокумент58 страницSKS20i Original ManualAdrian FerreyraОценок пока нет

- Cat DP40 55N Diesel Forklift BrochureДокумент12 страницCat DP40 55N Diesel Forklift BrochureAdrian FerreyraОценок пока нет

- User Manual: Electronic - Oleodynamic - Industrial Equipments ConstructionДокумент31 страницаUser Manual: Electronic - Oleodynamic - Industrial Equipments ConstructionДима СелютинОценок пока нет

- Ace3 Inverter: User ManualДокумент139 страницAce3 Inverter: User ManualАндрей9Оценок пока нет

- DIODE BOARD DIAGNOSTICSДокумент14 страницDIODE BOARD DIAGNOSTICSJose MelgarОценок пока нет

- 1313combined Manual enДокумент114 страниц1313combined Manual enAdrian FerreyraОценок пока нет

- Ametek Manual 049 Power Pro 100Документ39 страницAmetek Manual 049 Power Pro 100Adrian FerreyraОценок пока нет

- 1212 12PДокумент56 страниц1212 12PMohammed Al-hewaimelОценок пока нет

- 1209B (11e) PDFДокумент56 страниц1209B (11e) PDFmohammedОценок пока нет

- 1204m1205m NДокумент40 страниц1204m1205m Ninderhearth13Оценок пока нет

- Manual de Partes y Operación de Trituradora Vsi Canica Modelo 65Документ105 страницManual de Partes y Operación de Trituradora Vsi Canica Modelo 65Jose AlfaroОценок пока нет

- Computer Aided Design Course Code: 3341904Документ7 страницComputer Aided Design Course Code: 3341904Dhaval UpadhyayОценок пока нет

- Beam and Slab DesignДокумент41 страницаBeam and Slab DesignSridhara MunimakulaОценок пока нет

- Asphalt Institute PresentationДокумент43 страницыAsphalt Institute PresentationMax Cedeño De LeónОценок пока нет

- Multisite ErpДокумент5 страницMultisite ErparavindhsekarОценок пока нет

- Engineering Data Sheet: 49187073 E 1145842 1 of 1 October 21, 2016 60HzДокумент1 страницаEngineering Data Sheet: 49187073 E 1145842 1 of 1 October 21, 2016 60HzGustavo VillarrealОценок пока нет

- Pfaff 360 Sewing Machine Instruction ManualДокумент55 страницPfaff 360 Sewing Machine Instruction ManualiliiexpugnansОценок пока нет

- Specification Substation AutomationДокумент258 страницSpecification Substation Automationmspd2003100% (1)

- Fitter ToolsДокумент7 страницFitter ToolsSainadhReddy100% (1)

- 864 Wiring Schematic: S/N 518913001-14999 S/N 516812001-14999 S/N 517512001-14999 (Printed March 2001) V-0072Документ6 страниц864 Wiring Schematic: S/N 518913001-14999 S/N 516812001-14999 S/N 517512001-14999 (Printed March 2001) V-0072Ataa AssaadОценок пока нет

- MSOFTX3000 BICC Data Configuration 20090227 B 1 0Документ52 страницыMSOFTX3000 BICC Data Configuration 20090227 B 1 0Amjad VtОценок пока нет

- PuleyДокумент9 страницPuleynicolasОценок пока нет

- History of JS: From Netscape to Modern WebДокумент2 страницыHistory of JS: From Netscape to Modern WebJerraldОценок пока нет

- Physics (Jee Advanced)Документ8 страницPhysics (Jee Advanced)PranavMachingal100% (1)

- SAE StandardДокумент28 страницSAE Standardwei foo83% (6)

- Manual WkhtmltopdfДокумент5 страницManual WkhtmltopdfGeorge DiazОценок пока нет

- Tds G. Beslux Tribopaste L-2-3 S (26.03.09)Документ1 страницаTds G. Beslux Tribopaste L-2-3 S (26.03.09)Iulian BarbuОценок пока нет

- NOx Control of Kiln and Preheater Complete AnalysisДокумент129 страницNOx Control of Kiln and Preheater Complete AnalysisAnonymous sfY8T3q0100% (2)

- BYG Опросный лист на режущую кромкуДокумент51 страницаBYG Опросный лист на режущую кромкуMMM-MMMОценок пока нет

- Well Control - Fundamental - W2 - Well Control PrincipleДокумент17 страницWell Control - Fundamental - W2 - Well Control PrincipleGilbert SunaryoОценок пока нет

- Genetic AlgorithmДокумент46 страницGenetic AlgorithmJerryОценок пока нет

- Plasmon CD-R ReviewДокумент11 страницPlasmon CD-R Reviewgrudva2Оценок пока нет

- DDNS Management System User's Manual V1.0 - 20120301Документ7 страницDDNS Management System User's Manual V1.0 - 20120301judapiesОценок пока нет

- Quality Management Project On Quality Tools of "Ford Motors"Документ6 страницQuality Management Project On Quality Tools of "Ford Motors"Anuj SharmaОценок пока нет

- PM IS - 12818 June2021Документ10 страницPM IS - 12818 June2021Mahendra AhirwarОценок пока нет

- Introduction To CAL ProgrammingДокумент198 страницIntroduction To CAL ProgrammingSalam Mohamed RiyadОценок пока нет

- EE105 - Fall 2015 Microelectronic Devices and Circuits: Prof. Ming C. Wu Wu@eecs - Berkeley.edu 511 Sutardja Dai Hall (SDH)Документ5 страницEE105 - Fall 2015 Microelectronic Devices and Circuits: Prof. Ming C. Wu Wu@eecs - Berkeley.edu 511 Sutardja Dai Hall (SDH)Kulanthaivelu RamaswamyОценок пока нет

- MS Electrical Cable InstallationДокумент11 страницMS Electrical Cable InstallationAhmed Rashed AОценок пока нет

- Active Front EndДокумент5 страницActive Front EndDaleel LillaОценок пока нет

- Queen Sala Celinda Del Rosario LECCION2 Actividad de Produccion 2.4Документ4 страницыQueen Sala Celinda Del Rosario LECCION2 Actividad de Produccion 2.4Salustino AbreuОценок пока нет