Академический Документы

Профессиональный Документы

Культура Документы

WBPI Agosto Settembre 2015r

Загружено:

xavier6680 оценок0% нашли этот документ полезным (0 голосов)

21 просмотров3 страницыaug sep 2015 of wbpi

Оригинальное название

WBPI-Agosto-Settembre-2015r

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документaug sep 2015 of wbpi

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

21 просмотров3 страницыWBPI Agosto Settembre 2015r

Загружено:

xavier668aug sep 2015 of wbpi

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

e Focuson Italy

Onwards and upwards

lmal-Palwas the nextstop for our

Focuson ltalytrip,withthe company

havingjust celebratedits 45th

anniversary.StephenPowneyreporls

here's rarely a quiet moment at the

head offlce of Imal-Pal in Modena,

which is understandable for a

companywhich suppliessuch a vast range

of machineryand engdneerìng

for wood

L^^^l -^-^l -ì^-+^

!qùYu pdffEt pfdffLS.

The group, whÍch comprises Imal, Pal

and Globus, has now grown to over 350

employees, working at five facilities in Italy,

and has a sales turnover forecast for 2015 of

around €120m.

As well as being a busy Ligna year for

the group, 2015 has also marked lts 45th

anniversary, which provided an interesting

moment and perhaps an insight into the VRG (VietnamRubberGroup)Ouang-Tri,

ethos of the company. with a 150,0000m3/year

capacity.

Unbeknown to the company directors, This involved the supply of all machinery,

staff took it on themselves to design an incìuding a log yard from Globus, while Pal

adveft for daily newspaper Il Resto cJel supplied a rotary debarker, Dynascreen, Dry

Carlino to mark the 45th anniversary.

listing all the employees' names and

Cleaner for Chips (DCC), chip silos and f,bre

former.

.l*hil"

including a thank you to the company for

its commitment and dedication to building

up Imal-Pal into a highly-regarded business

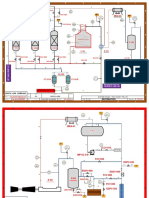

Imal supplied its continuous press, with

Dynasteam pre-heating, as well as a Hi-Jet

Blowline Resination System. laboratory

I

tt l,

across the world. equipment and automatic storage, while also

This unusual move delighted the owners co-ordinating the supply of Andritz reflning

and the adveft has been framed in the and Stelnemann sandrng machines.

boardroom. "We have big business in the pipeline, "

Loris Zanasi, group ceo, returned from said Mr Zanasi, confidently.

the Ligna show in Hannover in confldent This includes a palìet block plant

mood. currently being assembled in the workshops

(D

"Ligna was very successful and we got for a project in Poland.

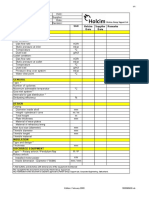

many contracts - about 10 deals in total, The company is also having some success The new PL100laboratorypress

rnrnrrh €Fm " ho cairì with wood pellet plant technology; it is

This rncludes particleboard and MDF currently in negotiations on a couple of

resination technology orders and several large projects in South East Asla and North

Dynasteam systems (fol dry steam pre- America regarding large capacity - 12

heating of the fibre mat before the press). tonnes per hour - peìlet presses.

Imal has now supplied about 70 Dynasteam "There is an increase in business ln

units in total. North America, it's a market which is

Imal says the Dynasteam technology is growing. In the past we sold a lot there,

designed to quicken curing l.imes, increase but of course sales had been down in North

productÌon capacity by between 15 to 30%, America for a number of years, " pointed out

reduce panel over-thickness, contribute to Mr Zanasi.

a better surface density and lower press

belt power absorption, alì without causing Ouality Control

any condensation which could discolour the "We have been very successful in online

board surface. quality control equipment," said the chief

"This year our budget is full and we have

a number of orders for 2076," said Mr Zanasi Imal staff took out this ad in an Italian

One of its recent projects was a fulì daily newspaper to celebrate the

turnkey MDF plant contract in Vietnam for company's 45th anniversary

44 WBPI I www.wbpionline.com ISSUE4 2015

a

executÍve."We sold a number of these at board density prof,le analysis, graphic Another type of quality control equipment

Ligna." illustration of the density profi]e, 2-D and shown at Ligna was the Full Blister

This includesthe OnlÍneDensityProfile 3-D visualÍsation, quick comparison of test Classifler(FBC)100.The FBC100has been

Meter, CDP700,which uses x-ray technoiogy results with other laboratory equipment and designedto detect unglued,delaminated,

installedbeneaththe line. The unit has been ease of maintenance without rnterruotino blown or low densÌty areas,bubbles,cracks

designedto perform the on-theline density production. and other flaws inside any type of board

profile analysison wood basedpanels Imal also says production may be (particleboard,MDF or OSB). Imal saÍd

while the productionprocessis in progress. changed without the need to change any that, unlike earlier systems (which had a

The system exploits the theory adopted in of the machine parameters and automatic limited number of measuring channels and

X-ray operatedsystemsto conducta non- calibration- Reducing start-up times and as a result were only able to guarantee

destructÍvetest on the board produced. optimisation of material used are other a maximumboard coverageof 30%),this

Its quoted beneflts include accurate stated beneflts. systemis able to detect defectsacrossthe

Resination the Imal way

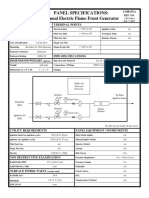

The HPRS(High PressureResinationSystem)

is a 36-monthproject, co-fundedby the

LIFE+ programme,whÍch is an instrument

supp-ofting environmentalprotection.

A consortium of four partners,

coordinatedby Imal, has designed a new

resin distribution system for application in

the production of engineeredwood panels.

This system,the HPRSsystem,has been

set up and tested on an existing panel

production line at the Xilopan facility in

Cigogrnoia(PV),Italy.

Resin consumptionhas undergone

close examinationover the last few years,

mainly due to cost and to the fact that resin

contains formaldehyde,a toxic substance.

Hencethe need has arisen in the production The innovative technologryapplied in the A Hi-Jet resination system installed in an

of wood based panels (MDF,particleboard HPRS,where pressurescan exceed100bar, MDF line

and OSB)to cut production costs and, at the employs a unique and revolutionary variable

sametime, to move towards environmental aperture nozzlero achieve optimal resin

sustainability. distribution while maintaining the same,or

Taking, by way of example,an MDF even better, board properties and qualÍty. It

plant with a daiiy productÍon of 1000m3of can also reduce resin additÍon and energ"y

board and an annual resin consumptionof requirementsby over20%.

32,000tonnes (equivalentin Europe to an The resin is distdbuted through these

averagecost of approximately 11-12million nozzlesat a constant pressure and with the

euro),reducing resin consumptionby B% right'drop' size, despite variations in flow

means saving €1,000,000/year, in addition rate or changesin production thickness,to

to a consequentdrop in the amount of achieve a perfect nebulisation.

formaldehydepresent in the board - and Another advantageof the HPRSsystem,

releasedinto the environment as a VOC says Imal, especiallyfor MDF plants, is that

(Volatile Organic Compound). the steam is not mixed with the resin but is Imal sold several resination systems at this

The drawbacks of the various atomisation injected into the blowline.through separate year's Ligna. This one is for particleboard

technologiesavailabletoday, where nozzles- suitably mounted wÍth respect to

compressedafuor steam is used to impel the resin nozzles- in a small. controlled.

the resin and increasethe surfaceover quantity.

which the resin comesinto contact with the This a-llowsthe fibre/steam flow to travel

fibre include the high temperature,which insÍde the piping to the dryer at a suitable

impacts on resin properties, poor control speed- and rapÍdly enough to facilitate the

management,and the fact that they cannot blending of the resin with the fibre.

be employedon particleboard or OSBlines To date,78 HPRSsystemshave been

becauseof the rise in molsture content. installed worldwide, approximately40

In the case of MDF production, of which are installed on MDF lines and

additional steam injected at the blowline the others on particleboardand OSB

can affect reflner performance,leading to lines, achíeving significant results in both

higher energy costs due to greater steam economicterms and environmentalimnact.

requirements. says Ima.l. Another Hi-Jet blowline for MDF

T- *"t I www.wbpionline.com ISSUE4 2015

WEMHÓNER

l!-t

I

e Imal

Hi-Jet resination system for MDF in situ in a production line

whole board. It is possible to grade the includesa formaldehydetester,Optical

quality of the production in progress and to Lab Fibre Screen- Fibercam100- which is

adjust the product parameters in order to designed to give an accurate measurement

avoid rejects. The FBC measuring sensors of f,bre dimensions,even in caseswhere

are mounted on the top and bottom beams fibres are laid over eachother.

on the board outfeed side. Since the sensors There is alsothe flrm's Glue Mix Gel

do not come into direct contact with the Time Control- 'Gel Timer' - designedto

board, typical problems related to matedal measurethe gel time of the resin delivered

wear are eliminated. by the supplier and the gel time of the glue

mix applied in the blender and the blowline

Laboratory equipment MeanwhÍle,Imal has so far sold about

Imal is known for its extensiverange of 270 BoardPropertyTesterand Density

laboratoryequipmentand this year it has ProflleAnalysers- IBX700- designed

been presenting,for the first time, its PL100 to test the quality and mechanical

laboratory press, featurÍng full electronic characteristicsof wood based panels

controlof the press cycle and temperature. (particleboard,MDF,OSB)in compliance

This addition effectlvelycompletesthe with today's standards(European,North

full range of laboratory equipment available American,and othersupon request)and to

from the company,sardMr Zanasi. then processthe results obtained.

The PL100is able to produceraw Standardstested to inciude dimensions

or laminatedsampleboardsfor testing (EN 325),density (EN 323),tensile strength

purposes,with adjustablespecif,cpressure (EN319),surfacesoundness(8N311),screw

and adjustable temperature for binder holding (8N320),bending strength and

curing. The laboratorypressis complete modulusof elasticity(EN310).

with its own electronic and software control, Furthermore, the company is also telling

with thicknessand pressuretransducers. customersthey can outsourcetheir full

The data regardlng the cycle required is Iaboratory equipment requirements to Imal,

stored in its pre-programmedmemory. which can provide a fuil tuìnkey laboratory,

The system controls the various phases with all necessaryequipment and even the

of the cycle, following a logic sequence,and Iayout to fit their factory plans.

switches over from one phase to the next as "Basedon our experience,it is better

soon as a specificcondition is fulf,lled. to build a lab as a one-stopshop,rather

The parametersavaila-bleto the operator than taking a piecemeal-approach," said Mr

are thickness,time and pressure.The Zanasi.

memory is able to store a large number of This year's Ligna was the frrst time Imal

cycles,in addition to storing the parameters had promotedthis concept.

relating to each cycle.The system directly "We are a relativelysmall companyin

controls the hydraulic valves to obtain the this industry but no-onein the world has

desiredcycle. such a wide ranqe of products," concluded

Other laboratory equipment available Mr Zanasi, proudly. I

ISSUE4 2015

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Its Time To Change Your Password InfographicДокумент1 страницаIts Time To Change Your Password Infographicxavier668Оценок пока нет

- Locked Print-1Документ1 страницаLocked Print-1xavier668Оценок пока нет

- Do You Broadcast Sensitive InformationДокумент1 страницаDo You Broadcast Sensitive Informationxavier668Оценок пока нет

- Cable Lock Your LaptopДокумент1 страницаCable Lock Your Laptopxavier668Оценок пока нет

- 08 Press Release 18aДокумент1 страница08 Press Release 18axavier668Оценок пока нет

- ps2 04Документ49 страницps2 04xavier668Оценок пока нет

- Siempelkamp ContiRoll Forming and Press Lines-EngДокумент16 страницSiempelkamp ContiRoll Forming and Press Lines-Engxavier668Оценок пока нет

- TM420Документ34 страницыTM420igor6995100% (1)

- MTC Wood Guidebook PDFДокумент60 страницMTC Wood Guidebook PDFxavier668Оценок пока нет

- EN717-1 Chember MethodДокумент34 страницыEN717-1 Chember MethodheobukonОценок пока нет

- Astm d6007-2Документ9 страницAstm d6007-2xavier668Оценок пока нет

- Wood ProductДокумент24 страницыWood Productxavier668Оценок пока нет

- Ecor WoodДокумент27 страницEcor Woodxavier668Оценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- CW1 Energy Audit SahmahДокумент21 страницаCW1 Energy Audit SahmahMohamed Al IsmailiОценок пока нет

- OVENTROPДокумент4 страницыOVENTROPbayunsОценок пока нет

- 2-A-GNLW363CD Standard Decanter CentrifugeДокумент6 страниц2-A-GNLW363CD Standard Decanter CentrifugeGeorgeОценок пока нет

- Electrical VivaДокумент5 страницElectrical VivaHari KrishnanОценок пока нет

- Belt DriveДокумент12 страницBelt DrivePrabir Kumar PatiОценок пока нет

- Ventilation of Transformer RoomДокумент4 страницыVentilation of Transformer Roomsauro100% (1)

- Fta and Eta: Faculty of Chemical Engineering Universiti Teknologi MARAДокумент22 страницыFta and Eta: Faculty of Chemical Engineering Universiti Teknologi MARACaratsSVTОценок пока нет

- Cyclone SeparatorДокумент1 страницаCyclone SeparatordadОценок пока нет

- Previews - ASHRAE 100Документ18 страницPreviews - ASHRAE 100souhaОценок пока нет

- A Canon CommunicationsДокумент55 страницA Canon Communicationsghazanfar100% (1)

- Raychem Heat Shrink Terminations HVTДокумент18 страницRaychem Heat Shrink Terminations HVTgerardoОценок пока нет

- Chapter No.5 Reactor DesignДокумент8 страницChapter No.5 Reactor DesignmichsantosОценок пока нет

- Valvepedia JuneДокумент14 страницValvepedia Juneali100% (1)

- Reformed Gas Waste Heat Boilers X 0Документ1 страницаReformed Gas Waste Heat Boilers X 0David PierreОценок пока нет

- B, 40,41, Case 2 Goodyear, Jea, Osumc and MonsantoДокумент10 страницB, 40,41, Case 2 Goodyear, Jea, Osumc and MonsantoSuhel PathanОценок пока нет

- FDP Business PDFДокумент31 страницаFDP Business PDFRANJINI02VОценок пока нет

- Panel Specifications: Manual Electric Flame Front Generator: CoronaДокумент1 страницаPanel Specifications: Manual Electric Flame Front Generator: CoronaOscarОценок пока нет

- Mini Refinery Feasibility OverviewДокумент9 страницMini Refinery Feasibility OverviewPouria SabbaghОценок пока нет

- Annual Report 2011Документ86 страницAnnual Report 2011hortalemosОценок пока нет

- The ABCs of Geothermal SystemsДокумент3 страницыThe ABCs of Geothermal SystemsRon MacKinnonОценок пока нет

- Foreign Material Exclusion PDFДокумент22 страницыForeign Material Exclusion PDFsdiamanОценок пока нет

- Press Kit Gestamp Renewables - EnglishДокумент8 страницPress Kit Gestamp Renewables - EnglishACEK RenewablesОценок пока нет

- Economic Analysis of LNG Distribution For Power PLДокумент9 страницEconomic Analysis of LNG Distribution For Power PLFachrurraziОценок пока нет

- Building Rules 2017Документ313 страницBuilding Rules 2017Raghu Ram86% (21)

- Broadcrown PresentationДокумент27 страницBroadcrown PresentationVicki AvolaОценок пока нет

- CCI Daily (Jul 7, 2021)Документ7 страницCCI Daily (Jul 7, 2021)Otgonchimeg BatjargalОценок пока нет

- Flow Diagrams PDFДокумент8 страницFlow Diagrams PDFbeshoy naseefОценок пока нет

- Dhl-Global Forwarding: Consolidation PROGRAM - Case StudyДокумент6 страницDhl-Global Forwarding: Consolidation PROGRAM - Case StudyDhananjay DasОценок пока нет

- Assam PVSyst ReportДокумент3 страницыAssam PVSyst ReportKristen ChangОценок пока нет

- Invitation Letter Petrolida 2021Документ91 страницаInvitation Letter Petrolida 2021Stephen ZhengОценок пока нет