Академический Документы

Профессиональный Документы

Культура Документы

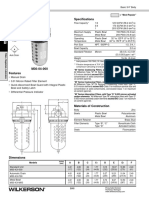

Filters FP

Загружено:

MAZENИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Filters FP

Загружено:

MAZENАвторское право:

Доступные форматы

COMPRESSED AIR FILTERS (UP TO 16 BAR)

The compressed air filters are used to treat compressed air and other gases by removing solid

particles and oil from them.

They are the necessary part of the compressed air preparation system, whose aim is to improve durability

and extend service life of the pneumatic and control elements and actuators. Depending on the filter

element used, with specific filtration accuracy, the required compressed air purity class suitable for

individual industrial applications is obtained.

FP series dust, oil and carbon filters

Pre-filter Initial filtration of solid particles

Q

Solid particles 3 µm

Compressed air quality (solid particles) ISO 8573.1 Class 3

Pressure drop in filter 0,01 bar

Fine filtration of solid particles

Fine filter

and water and oil mist

Solid particles < 1 µm

Residual oil content < 0,1 mg/m3

Compressed air quality (oil particles) ISO 8573.1 Class 2

P

Pressure drop in filter 0,05 bar

Very fine filtration of solid particles

Very fine filter

and water and oil mist

Solid particles 0,01 µm

Residual oil content < 0,01 mg/m3

Compressed air quality (oil particles) ISO 8573.1 Class 1

Pressure drop in filter 0,08 bar

S

Carbon filter (with activated carbon) Adsorption of oil vapour and odour

Residual oil content 0,003 mg/m3

Compressed air quality (oil particles) ISO 8573.1 Class 1

Pressure drop in filter

0,06 bar

(install always together with filter and S element)

C

FP series filter elements:

Q – pre-filter element P – fine filter element

S – very fine filter element C – carbon filter element

Differential pressure gauge Condensate drains

- indicator of the filter element

contamination (option)

mechanical condensate

drain – standard

equipment

float operated mechanical

condensate drain

electronic timer

controlled condensate

drainu

electronic no-loss drain

(condensate level sensor)

Max Dimensions

Flow* operating Weight

Type Connection pressure A B C D Cartridge

m3/h bar mm mm mm mm kg

FP 78 78 G 1/2 16 187 88 20 60 1,1 Q,P,S,C

FP 120 120 G 3/

4 16 257 88 20 80 1,2 Q,P,S,C

FP 335 335 G1 16 363 125 32 120 3,2 Q,P,S,C

FP 510 510 G 11/2 16 461 125 32 140 3,7 Q,P,S,C

FP 780 780 G 11/2 16 640 125 32 160 4,8 Q,P,S,C

FP 996 996 G2 16 684 163 43 520 8,8 Q,P,S,C

FP 1500 1500 G2 16 935 163 43 770 13,5 Q,P,S,C

FP 2400 2760 G3 16 1000 240 59 780 30,5 Q,P,S,C

*Nominal flow at: 1bar abs. and 200C at the compressor suction and compressed air pressure of 7 bar.

Correction factors for FP flow filters for operating conditions other than nominal

Compressed air pressure [bar]

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

0,38 0,52 0,63 0,75 0,88 1,00 1,13 1,26 1,38 1,52 1,65 1,76 1,87 2,00 2,14

Airpol Compressors Ltd.

ul. Nieszawska 15, 61-021 Poznań, Poland tel. +48 61 650 45 67, e-mail airpol@airpol.com.pl

www.airpol.com.pl

Вам также может понравиться

- Elgi EG 90 160kW 50Hz D I PDFДокумент8 страницElgi EG 90 160kW 50Hz D I PDFMAZENОценок пока нет

- Inspection Checklist For Installation of Earthing System123 PDFДокумент1 страницаInspection Checklist For Installation of Earthing System123 PDFKuljinder VirdiОценок пока нет

- Ideals Vs PsalmДокумент2 страницыIdeals Vs PsalmJesse Nicole Santos100% (1)

- Hatapla WinchДокумент32 страницыHatapla WinchRaffaele Piccirillo100% (1)

- Oil-X FabricatedДокумент4 страницыOil-X FabricatedMohsen ParpinchiОценок пока нет

- Filtro ISOДокумент13 страницFiltro ISORafael LimaОценок пока нет

- Evo Filters 174004403 - ENДокумент4 страницыEvo Filters 174004403 - ENandre_silva_camposОценок пока нет

- Hze1ghze2gen - En617 - hze2g15gABДокумент3 страницыHze1ghze2gen - En617 - hze2g15gABMohammad Adeel KhanОценок пока нет

- Product Information Sheet - OIL-X Compressed Air Filter Grades AO and AA - (English)Документ4 страницыProduct Information Sheet - OIL-X Compressed Air Filter Grades AO and AA - (English)ademgsОценок пока нет

- Gas AnalyserДокумент3 страницыGas AnalyserviahulОценок пока нет

- Spin OnДокумент2 страницыSpin OntarobaclashОценок пока нет

- Balston Coalescing Compressed Air and Gas FiltersДокумент75 страницBalston Coalescing Compressed Air and Gas FiltersPradeep KumawatОценок пока нет

- Filtro HydacДокумент2 страницыFiltro HydacWendel AndradeОценок пока нет

- Service Unit FRC-1/2-D-MAXI-A: Data SheetДокумент1 страницаService Unit FRC-1/2-D-MAXI-A: Data SheetWahyu ArdiansyahОценок пока нет

- Compressed Air FiltersДокумент3 страницыCompressed Air FilterskellyteamoОценок пока нет

- Bekomat 31U-32U-33U-33U COДокумент4 страницыBekomat 31U-32U-33U-33U CODipak SatavОценок пока нет

- Filtro RFM ON 185 V D 10 E 1.x (Hydac)Документ2 страницыFiltro RFM ON 185 V D 10 E 1.x (Hydac)OARIASCOОценок пока нет

- Compressed Air Filter & Separator: Italian TechnologyДокумент16 страницCompressed Air Filter & Separator: Italian TechnologyRUN GOОценок пока нет

- OIL XPlusHighPressureДокумент2 страницыOIL XPlusHighPressureSuprimentos IndaloОценок пока нет

- WWTP+sizing SampleДокумент1 страницаWWTP+sizing Sampleerlima pengasinanОценок пока нет

- FESTO FRC Filter/Regulator-Lubricatorsor LubricatorsДокумент17 страницFESTO FRC Filter/Regulator-Lubricatorsor LubricatorsNickОценок пока нет

- DM40 SGA BT Battery OperatedДокумент2 страницыDM40 SGA BT Battery OperatedZayОценок пока нет

- 78-00052 Profo Bekomat 1x 4p Int RZ DisplayДокумент4 страницы78-00052 Profo Bekomat 1x 4p Int RZ DisplayPragnesh PrajapatiОценок пока нет

- Purgeur UFM-D130Документ4 страницыPurgeur UFM-D130youcef alimОценок пока нет

- E7215 2 11 16 - WHC KatalogversionДокумент4 страницыE7215 2 11 16 - WHC KatalogversionQuy HoangОценок пока нет

- Series: Micro Mist SeparatorДокумент49 страницSeries: Micro Mist SeparatorRodrigoBurgosОценок пока нет

- Filter Regulator LFR-1/2-D-7-O-MIDI: Data SheetДокумент1 страницаFilter Regulator LFR-1/2-D-7-O-MIDI: Data SheetRichard Rodriguez GarciaОценок пока нет

- List of Tables: No No Table Name Practical No NoДокумент21 страницаList of Tables: No No Table Name Practical No NoHassan Iftekhar AhmedОценок пока нет

- E) DSF1000 AlДокумент5 страницE) DSF1000 AlAgeng A. PooОценок пока нет

- Kaesr Filter CompresorДокумент11 страницKaesr Filter CompresorAgus Waluyo100% (1)

- PIONEERAIR Air Compressor For Laser 2022Документ13 страницPIONEERAIR Air Compressor For Laser 2022Anto SiminОценок пока нет

- Intro PF en V4Документ6 страницIntro PF en V4plasticos_jfm6580Оценок пока нет

- Coalescing Filter M30: Specifi CationsДокумент2 страницыCoalescing Filter M30: Specifi CationsSeetharaman KSОценок пока нет

- Above & Beyond: Compressed Air & Gas FiltrationДокумент4 страницыAbove & Beyond: Compressed Air & Gas FiltrationPaul GirkinОценок пока нет

- Compressed Air Treatment Diagram For Rotary Screw CompressorsДокумент3 страницыCompressed Air Treatment Diagram For Rotary Screw CompressorsВасилий ЗотовОценок пока нет

- Oil Mist Separator Sales LeafletДокумент2 страницыOil Mist Separator Sales LeafletAhmad SodikinОценок пока нет

- Hyperfilter Die-Cast Aluminium Compressed Air FiltersДокумент4 страницыHyperfilter Die-Cast Aluminium Compressed Air FiltersOcta DosОценок пока нет

- Compressed Air Purification ProductsДокумент28 страницCompressed Air Purification Productsherysyam1980Оценок пока нет

- Central Pollution Control Board: Cems - The Ultimate Tool For Emission RegulationДокумент46 страницCentral Pollution Control Board: Cems - The Ultimate Tool For Emission RegulationRaden MasОценок пока нет

- 42XQ EBrochure3Документ2 страницы42XQ EBrochure3Paul Flores RoblesОценок пока нет

- MBBR STP - WastreatДокумент2 страницыMBBR STP - WastreatA3S ENVIROОценок пока нет

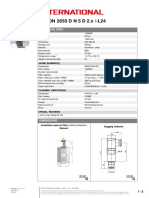

- NF ON 2650 D N 5 D 2.x /-L24: Technical DataДокумент2 страницыNF ON 2650 D N 5 D 2.x /-L24: Technical DataGabriela - Vendas Amazon TecnologiaОценок пока нет

- Pisgsfeoilxpxdcaoaa 02 enДокумент8 страницPisgsfeoilxpxdcaoaa 02 enJumaidi AbdyОценок пока нет

- XM Filter ElementДокумент2 страницыXM Filter ElementhafsakrknОценок пока нет

- OIL XPlus50SeriesДокумент2 страницыOIL XPlus50SeriesSuprimentos IndaloОценок пока нет

- Aximax 2HL 3698SF FanДокумент3 страницыAximax 2HL 3698SF FanDhanus KodiОценок пока нет

- Micro Mist Separator SpecsДокумент1 страницаMicro Mist Separator SpecsMarcelo NoirОценок пока нет

- Compressed Air Quality - RENNERДокумент16 страницCompressed Air Quality - RENNERAbrahamNdewingo100% (1)

- Nooro Iii Tower CSP Power Plant: Operation & Maintenance Manual of DC SystemДокумент30 страницNooro Iii Tower CSP Power Plant: Operation & Maintenance Manual of DC Systemscribd birdОценок пока нет

- Axeon 4Документ2 страницыAxeon 4JoannaОценок пока нет

- Filtri GP, HE, AC, DPДокумент4 страницыFiltri GP, HE, AC, DPjuris.ligerisОценок пока нет

- Air Filter 894509 - 03 - A - 02 - DA400Документ4 страницыAir Filter 894509 - 03 - A - 02 - DA400Anonymous qpdY3hXMEОценок пока нет

- Everpure EV932421.SpecSheetДокумент2 страницыEverpure EV932421.SpecSheetRafael RuedaОценок пока нет

- Walker Filtration Compressed Air Duplex Filter DatasheetДокумент2 страницыWalker Filtration Compressed Air Duplex Filter DatasheetAbderraouf KhenchoucheОценок пока нет

- Dust Collector KOMPACДокумент7 страницDust Collector KOMPACHùng ThanhОценок пока нет

- 2nd-Fahu-01 EuДокумент5 страниц2nd-Fahu-01 EuMohammad IsmailОценок пока нет

- En7936 4 09 17 - Ofu PDFДокумент4 страницыEn7936 4 09 17 - Ofu PDFJhonny Velasquez PerezОценок пока нет

- En7936 4 09 17 - Ofu PDFДокумент4 страницыEn7936 4 09 17 - Ofu PDFJhonny Velasquez PerezОценок пока нет

- En7936 4 09 17 - Ofu PDFДокумент4 страницыEn7936 4 09 17 - Ofu PDFJhonny Velasquez PerezОценок пока нет

- En7936 4 09 17 - Ofu PDFДокумент4 страницыEn7936 4 09 17 - Ofu PDFJhonny Velasquez PerezОценок пока нет

- Medidor BiogasДокумент3 страницыMedidor BiogasMILITZA CAROLINA GALVEZ ZAVALETAОценок пока нет

- EFLOCHEM - Filter Pot MIDI - Data Sheet V1.1 08-2022Документ6 страницEFLOCHEM - Filter Pot MIDI - Data Sheet V1.1 08-2022j.iqubalОценок пока нет

- Dictionary of Textile Finishing: Deutsch/Englisch, English/GermanОт EverandDictionary of Textile Finishing: Deutsch/Englisch, English/GermanРейтинг: 1.5 из 5 звезд1.5/5 (3)

- 009 en Boge Sof Data 20210721 1Документ2 страницы009 en Boge Sof Data 20210721 1MAZENОценок пока нет

- Performance Data D75: D75 Technical Information Sheet 50 HZ, Fix Speed, Air Cooled, CE VersionДокумент1 страницаPerformance Data D75: D75 Technical Information Sheet 50 HZ, Fix Speed, Air Cooled, CE VersionMAZENОценок пока нет

- JL Components Blower LubricationДокумент4 страницыJL Components Blower LubricationMAZENОценок пока нет

- Elektronikon MKV PDFДокумент2 страницыElektronikon MKV PDFMAZENОценок пока нет

- Robuschi Data Sheet RoboxДокумент21 страницаRobuschi Data Sheet RoboxMAZENОценок пока нет

- 19 12 18 Tis D37H A UkДокумент1 страница19 12 18 Tis D37H A UkMAZENОценок пока нет

- 19 12 18 Tis D110HRS W UkДокумент1 страница19 12 18 Tis D110HRS W UkMAZENОценок пока нет

- V Series Boge FilterДокумент1 страницаV Series Boge FilterMAZENОценок пока нет

- Performance Data D110-10RS: Min. MaxДокумент1 страницаPerformance Data D110-10RS: Min. MaxMAZENОценок пока нет

- 19 12 18 Tis D50HRS A UkДокумент1 страница19 12 18 Tis D50HRS A UkMAZENОценок пока нет

- LMF-GP LX37-8 - 10 - 13Документ2 страницыLMF-GP LX37-8 - 10 - 13MAZENОценок пока нет

- Rotar Rotar Rotar Rotar Rotar Cube SD Cube SD Cube SD Cube SD Cube SDДокумент18 страницRotar Rotar Rotar Rotar Rotar Cube SD Cube SD Cube SD Cube SD Cube SDMAZENОценок пока нет

- 3 12 15 Tis L200RS A Ce 2015Документ1 страница3 12 15 Tis L200RS A Ce 2015MAZENОценок пока нет

- Robust and Powerful: Oil-Free Piston CompressorsДокумент8 страницRobust and Powerful: Oil-Free Piston CompressorsMAZENОценок пока нет

- Frecon HPRДокумент4 страницыFrecon HPRMAZENОценок пока нет

- R080Z - R180Z Watercooled, 50 HZ TIRZ80/11 SM 6.1 Technical Information Sheet 01/04Документ1 страницаR080Z - R180Z Watercooled, 50 HZ TIRZ80/11 SM 6.1 Technical Information Sheet 01/04MAZENОценок пока нет

- LMF-GP LX45-8 - 10 - 13Документ2 страницыLMF-GP LX45-8 - 10 - 13MAZENОценок пока нет

- LMF-GP LX18-8 - 10 - 13Документ2 страницыLMF-GP LX18-8 - 10 - 13MAZENОценок пока нет

- LMF-GP LX30-8 - 10 - 13Документ2 страницыLMF-GP LX30-8 - 10 - 13MAZENОценок пока нет

- LMF-GP LX15-8 - 10 - 13Документ2 страницыLMF-GP LX15-8 - 10 - 13MAZEN0% (1)

- LMF-GP LX11-8 - 10 - 13Документ2 страницыLMF-GP LX11-8 - 10 - 13MAZENОценок пока нет

- LMF-GP LX5-8 - 10 - 13Документ2 страницыLMF-GP LX5-8 - 10 - 13MAZENОценок пока нет

- LMF-GP LX7-8 - 10 - 13Документ2 страницыLMF-GP LX7-8 - 10 - 13MAZENОценок пока нет

- Manual Phe THTДокумент48 страницManual Phe THTWahyu Alghifari PuspitoОценок пока нет

- Anon 30-40TPD Rice Mill Details With CIF Douala, Cameroon-2Документ10 страницAnon 30-40TPD Rice Mill Details With CIF Douala, Cameroon-2ousmaneОценок пока нет

- Sil Verification Report Alkylation - RДокумент253 страницыSil Verification Report Alkylation - RxentrerОценок пока нет

- 6088B - WCFXДокумент40 страниц6088B - WCFXwoowkОценок пока нет

- Tesla Motors Shelby LeeДокумент13 страницTesla Motors Shelby Leeflh21gmail100% (1)

- AC10P Catalog 5.41Документ16 страницAC10P Catalog 5.41cocacolapepsiОценок пока нет

- XFEM Analysis of A Plate With An Edge Crack PDFДокумент14 страницXFEM Analysis of A Plate With An Edge Crack PDFNagaraj RamachandrappaОценок пока нет

- Guia de Componentes MotoresДокумент8 страницGuia de Componentes MotoresjantonioaragonsОценок пока нет

- S/N Item Description Qty Box No. 1Документ9 страницS/N Item Description Qty Box No. 1Nguyễn Kim HùngОценок пока нет

- Making Mars The New EarthДокумент4 страницыMaking Mars The New EarthPavel50% (2)

- Asme PTC ListДокумент2 страницыAsme PTC ListDeepikaОценок пока нет

- Concept of Spray Drying TechniqueДокумент7 страницConcept of Spray Drying TechniqueMaria Fernanda Bermudez ValeroОценок пока нет

- Metering Pumps Components Metering Systems ProMinent Product Catalogue 2016 Volume 1Документ198 страницMetering Pumps Components Metering Systems ProMinent Product Catalogue 2016 Volume 1kambiadoОценок пока нет

- Quotation Sunrise MachineryДокумент12 страницQuotation Sunrise MachinerySeby DeacОценок пока нет

- Science Learners Book Answers Stage 9Документ35 страницScience Learners Book Answers Stage 9Samanvitha Raavi100% (8)

- GasLit 2010Документ276 страницGasLit 2010thawminОценок пока нет

- Air Vent Heads DNV 2003 PDFДокумент7 страницAir Vent Heads DNV 2003 PDFBhargav PatelОценок пока нет

- Adex TXR Test GuideДокумент25 страницAdex TXR Test Guidetxr qcОценок пока нет

- Thermodynamics MRCP 2017Документ47 страницThermodynamics MRCP 2017Calvin LabialОценок пока нет

- 02 - Fundamentals of IPEДокумент25 страниц02 - Fundamentals of IPEJohn Lexmar LeynesОценок пока нет

- Basic Fire Awarness Traing - New Element 1 - Ammended Nov 2019.Ppt-2Документ67 страницBasic Fire Awarness Traing - New Element 1 - Ammended Nov 2019.Ppt-2L MОценок пока нет

- Pressure Relief Valve: For Unvented (Pressurised) Water HeatersДокумент4 страницыPressure Relief Valve: For Unvented (Pressurised) Water HeatersMax.infoОценок пока нет

- Experiment No. 6 7 8 Water TurbinesДокумент69 страницExperiment No. 6 7 8 Water TurbinesMilon MirdhaОценок пока нет

- Impact of Industrialization On Region and Community WelfareДокумент7 страницImpact of Industrialization On Region and Community WelfareTejaswini RastogiОценок пока нет

- Operating Instructions Micropilot NMR81: Tank GaugingДокумент260 страницOperating Instructions Micropilot NMR81: Tank GaugingJoshua OkekporoОценок пока нет

- Panasonic Hoszivattyu Es Klima Arlista 2014.09.15.Документ8 страницPanasonic Hoszivattyu Es Klima Arlista 2014.09.15.klaraОценок пока нет

- Metal FoamsДокумент135 страницMetal FoamsShahzaib B. AbbasiОценок пока нет