Академический Документы

Профессиональный Документы

Культура Документы

3322902WT I

Загружено:

SinaiDasОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

3322902WT I

Загружено:

SinaiDasАвторское право:

Доступные форматы

Weaving Technology: 1 Course Code: 3322902

GUJARAT TECHNOLOGICAL UNIVERSITY, AHMEDABAD, GUJARAT

COURSE CURRICULUM

Course Title: Weaving Technology:-1

Course Code: 3322902

Diploma Programmes in which this Semester in which offered

course is offered

Diploma in Textile Manufacturing Second Semester

Technology

1. RATIONALE

Weaving is one of the methods of fabric productions. The other methods are knitting,

lace making, felting, and braiding or plaiting. In weaving two distinct sets of yarns or

threads are interlaced at right angles in various patterns to form a fabric or cloth of

numerous designs. The longitudinal threads are called the warp and the lateral threads

are the weft or filling. There is continuous pressure on industries to reduce cost, use

automations, and increase quality with variety and designs as early as possible.

Therefore, as a textile technologist, the knowledge of weaving process, power looms,

and weaving preparatory processes and machines is very essential. In this course, the

students are exposed to knowledge of weaving process, power looms, its preparatory

processes and production calculations.

2. COMPETENCY

The course content should be taught and implemented with the aim to achieve different

types of skills so that students are able to acquire the following competency:

i. Weave the simple fabric with the help of power loom including yarn

preparation in winding and pirn winding, along with production

calculations.

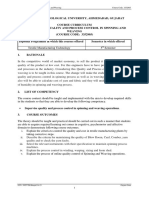

3. TEACHING AND EXAMINATION SCHEME

Teaching Scheme Total Credits Examination Scheme

(In Hours) (L+T+P) Total

Theory Marks Practical Marks

Marks

L T P C ESE PA ESE PA

200

3 0 4 7 70 30 40 60

Legends: L-Lecture; T – Tutorial/Teacher Guided Student Activity; P -Practical; C – Credit;; ESE -End

Semester Examination; PA - Progressive Assessment.

Note: It is the responsibility of the institute heads that marks for PA of theory & ESE and PA

of practical for each student are entered online into the GTU Portal at the end of each semester

within the dates specified by GTU.

GTU/NITTTR Bhopal/12-13 Gujarat State

Weaving Technology: 1 Course Code: 3322902

4. DETAILED COURSE CONTENTS

Unit Major Learning Outcomes Topics and Sub-topics

Unit – I 1a. Describe objectives of 1.1 Sequence of weaving preparatory process.

Yarn winding 1.2 Objects of winding.

preparation- 1b. Explain process for 1.3 Methods of package driving and yarn take

Winding winding. up.

1c. Explain winding machine 1.4 Methods of yarn traversing.

and automatic with 1.5 Type of wind.

mechanisms. 1.6 Yarn clearing device, Tensioning device ,

1d. Describe defects in Balloon breaker, Automatic thread stop

winding process. motion, Driving arrangement, Anti-

1e. Carryout production patterning device etc.

calculations in winding 1.7 Super Speed winding machine.

machines. 1.8 Automation in winding (Knotter, Types &

quality of knot, Splicing, Comparison of

knotting & splicing)

1.9 Defects of winding package

1.10 Requirement of package for shuttle less

weaving machine, knitting machine, Beam

& sectional warping and yarn dyeing

1.11 Production calculations

Unit– II 2a. Describe purpose of Pirn 2.1 Objects of Pirn winding

Pirn winding. 2.2 Advantage of rewound weft over direct weft

Winding 2b. Explain automatic Pirn 2.3 Automatic Pirn winding machine

winding machine along 2.4 Various adjustments on auto pirn winding

with adjustments. Machine.

2c. Describe faults & 2.5 Unifil loom winder in brief

remedies in pirn winding 2.6 Package fault in pirn winding

process. 2.7 Production calculations

2d.Carryout production

calculations.

Unit–III 3a. Explain mechanisms and 3.1 Passage of warp and cloth through a plain

Basics motions of a plain power power

of Weaving loom- basic cloth loom

making machine. 3.2 Primary motion of loom. ( Objects, Types)

3b. Describe cloth defects & 3.3 Shedding motion- Different shedding

remedies in a power mechanism, Types of shed, Negative tappet

loom, and their shedding motion with timing and settings,

remedies. Early and late shedding, Heald staggering,

3c. Carry out production Dwell period.

calculations for a power 3.4 Picking and checking motion -different

loom. types of picking, Over pick and Under

motion with timing and settings, Picking

accessories, Shuttle box.

3.5 Beating up motion - Beat up motion with

timing and settings, Different types of reed

and Heald shaft, Reed Count and Heald

count.

3.6 Secondary motion of loom with objects and

different type -Seven wheel take up,

Negative let off

3.7 Auxiliary motions -Objects and type of

warp protector motion, Working of

different Warp protector motion, Objects

and type of Weft stop motion, Working of

GTU/NITTTR Bhopal/12-13 Gujarat State

Weaving Technology: 1 Course Code: 3322902

Unit Major Learning Outcomes Topics and Sub-topics

Side weft fork stop motion, Temples, Brake

3.8 Cloth defects their causes and remedies.

3.9 Production calculations

5. SUGGESTED SPECIFICATION TABLE WITH HOURS & MARKS

(THEORY )

Distribution of Theory Marks

Unit Unit Title Teaching (Duration – 2.5 Hours)

No. Hours R U A Total

Level Level Level

I Yarn Preparations 12 4 8 6 18

-Winding

II Pirn Winding 06 2 4 2 08

III Basics of Weaving 24 8 24 12 44

Total 42 14 36 20 70

Legends: R = Remember; U = Understand; A = Apply and above levels (Bloom’s revised taxonomy)

Note: This specification table shall be treated as only general guideline for students and

teachers. The actual distribution of marks in the question paper may vary from above

table.

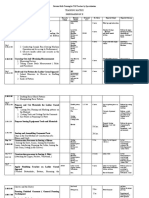

6. SUGGESTED LIST OF PRACTICAL/EXERCISES:

The practical/exercises should be properly designed and implemented with an attempt to

develop different types of skills that students are able to acquire above mentioned

competency

S. No. Unit No. Practical /Exercises No of hours

1 I Observe & study passage of warp through high 04

speed winding m/c

2 I Observe & study passage of warp through super 04

speed winding m/c

3 I Observe & study Mechanical and Electrical yarn 04

clearer & yarn tensioning device bunch length

4 II Set pirn diameter, taper & length of wind on pirm 04

winding m/c

5 II Study of passage of warp through l00m identify 04

the various parts

6 III Set over pick motion 06

7 III Set under Pick motion 06

8 III Set Negative tappet shedding motion 06

9 III Set Beating up motion 06

10 III Set Negative let off motion 04

11 III Set seven wheel take up motion 04

12 III Set side weft fork motion 04

Total 56

GTU/NITTTR Bhopal/12-13 Gujarat State

Weaving Technology: 1 Course Code: 3322902

7. SUGGESTED LIST OF PROPOSED STUDENT ACTIVITIES

Following is the list of proposed student activities like: course/topic based seminars,

internet based assignments, teacher guided self learning activities,

course/library/internet/lab based mini-projects---etc.

Collection of various Textile fabrics.

Visit to weaving preparatory unit, and preparing report with sketches.

Visit to weaving unit, and preparing report with sketches.

8. SUGGESTED LEARNING RESOURCES

A. List of Books

S.No. Title of Books Author Publication

1 Technology of Fabric R. Muthusamy & S. SSM Institute of Textile

Manufacture – I ( Yarn Kathirvelu Technology & Polytechnic

preparation & Shuttle College, Komarapalayam

weaving)

2 Principle of Weaving Marks & Robinson

3 Weaving machine, material & D.B. Ajgaonakar &

management Talukdar

B. List of Major Equipment/ Instrument

i. Textile Laboratory – One Winding machine, One Pirn winding machine & two

to three Plain power looms.

C. LIST OF SOFTWARE /LEARNING WEBSITES-

Searching engine could be used to locate textile related sites

i. http://www.textileassociationindia.org/

ii. http://www.nitma.org/

iii. http://www.sitra.org/

iv. www.itamma.org/

v. http://www.uttaindia.org/

vi. http://www.cottonjouney.com/Storyofcotton/page5.asp

vii. http://textiletechinfo.com/spinning/BLOWROOM.htm

viii. http://en.wikipedia.org/wiki/weaving

ix. http://textilelearner.blogspot.in

x. http://sazidrahman.blogspot.in/2009/02/lecture-notes-on-weaving-technology.html

xi. http://www.elearning-textiles.co.uk/CatalogueofModules/

GTU/NITTTR Bhopal/12-13 Gujarat State

Weaving Technology: 1 Course Code: 3322902

9. COURSE CURRICULUM DEVELOPMENT COMMITTEE

Faculty Members from Polytechnics

Prof. V. N. Soni, HOD Textile Manufacturing , RCTI, Ahmedabad

Prof. R. T. Patel, Lecturer in Textile Manufacturing, RCTI, Ahmedabad

Prof (Ms.) S.S. Parmar, Lecturer in Textile Manufacturing, RCTI,

Ahmedabad

Prof S. M. Zala, Lecturer in Textile Manufacturing, Shri BPTI, Bhavanagar

Co-ordinator and Faculty Member from NITTTR Bhopal

Dr. C. K. Chugh, Professor and head Dept. of Electronic Media

Dr. S. K. Gupta, Professor and coordinator for state of Gujarat

GTU/NITTTR Bhopal/12-13 Gujarat State

Вам также может понравиться

- Texturising Processing of Microfilament On Texturising MachineДокумент5 страницTexturising Processing of Microfilament On Texturising MachineSher Hai HamОценок пока нет

- Gujarat Technological University, Ahmedabad, Gujarat Course Curriculum Course Title: CourseДокумент6 страницGujarat Technological University, Ahmedabad, Gujarat Course Curriculum Course Title: CourseSher Hai HamОценок пока нет

- 3352905Документ5 страниц3352905Sher Hai HamОценок пока нет

- Legends: L-Lecture T - Tutorial/Teacher Guided Student Activity P - Practical C - Credit ESE - EndДокумент6 страницLegends: L-Lecture T - Tutorial/Teacher Guided Student Activity P - Practical C - Credit ESE - EndSher Hai HamОценок пока нет

- 3352902Документ7 страниц3352902Sher Hai HamОценок пока нет

- Elements of Textile and Garment TechnologyДокумент7 страницElements of Textile and Garment Technologypavan panwalaОценок пока нет

- Shuttle - Less Loom Weaver - AirjetДокумент221 страницаShuttle - Less Loom Weaver - AirjetDeepanshu GuptaОценок пока нет

- MIDДокумент85 страницMIDMD. Sharifuzzaman JoyОценок пока нет

- Underground Mining of Coal Course Code: 3362203Документ6 страницUnderground Mining of Coal Course Code: 3362203Santosh KumarОценок пока нет

- Control Devices (CD) 3342001Документ7 страницControl Devices (CD) 3342001BHATT RONAK MT-04Оценок пока нет

- TCF GuideДокумент25 страницTCF GuideAlicia ForbesОценок пока нет

- Trainee Operator Progress ChartДокумент1 страницаTrainee Operator Progress Chartrajurana25Оценок пока нет

- The Rieter Manual of Spinning LL Textilestudycenter - Com LL v-3 (Spinning Preparation)Документ80 страницThe Rieter Manual of Spinning LL Textilestudycenter - Com LL v-3 (Spinning Preparation)Durjoy Roy100% (1)

- Diploma Programme in Which This Course Is Offered Semester in Which OfferedДокумент6 страницDiploma Programme in Which This Course Is Offered Semester in Which OfferedCatalinCatalinОценок пока нет

- PDFДокумент9 страницPDFVipul SolankiОценок пока нет

- The Rieter Manual of SpinningДокумент80 страницThe Rieter Manual of SpinningAline Freire100% (1)

- The Rieter Manual of SpinningДокумент80 страницThe Rieter Manual of SpinningHashinclude Iostream Int MainОценок пока нет

- Dressmaking TrainingДокумент3 страницыDressmaking TrainingLawson SohОценок пока нет

- The Rieter Manual of Spinning Vol. 4 1924-V3 83538 Original English 83538Документ80 страницThe Rieter Manual of Spinning Vol. 4 1924-V3 83538 Original English 83538Oscar Morales100% (3)

- WeavingДокумент15 страницWeavingsdeveloper100% (1)

- Textile Internship Guidelines (BFT-V) 20.01.2020 PDFДокумент9 страницTextile Internship Guidelines (BFT-V) 20.01.2020 PDFSejal Goyal100% (1)

- Fitter Lesson Plans 2Документ138 страницFitter Lesson Plans 2sureshsharmamkОценок пока нет

- SMO Training ManualДокумент11 страницSMO Training ManualSheena BansalОценок пока нет

- Lab Report: BGMEA University of Fashion and TechnologyДокумент5 страницLab Report: BGMEA University of Fashion and TechnologyRian HossainОценок пока нет

- The Rieter Manual of Spinning LL Textilestudycenter - Com LL v-5 (Rotor Spinning)Документ112 страницThe Rieter Manual of Spinning LL Textilestudycenter - Com LL v-5 (Rotor Spinning)Souro Banerjee50% (2)

- Federal TVET Institute Textile and Apparel Fashion Technology DivisionДокумент24 страницыFederal TVET Institute Textile and Apparel Fashion Technology DivisionGurumurthy BRОценок пока нет

- Fabric Manufacturing - I Unit 1Документ28 страницFabric Manufacturing - I Unit 1nikitaОценок пока нет

- Machine Knitting OperatorДокумент50 страницMachine Knitting OperatorDyah FanniОценок пока нет

- Gujarat Technological University Textile Technology (29) : Yarn Manufacturing-I B.E. Semester IiiДокумент3 страницыGujarat Technological University Textile Technology (29) : Yarn Manufacturing-I B.E. Semester IiiKagi mecОценок пока нет

- 2-Design and Drafting-20at42pДокумент8 страниц2-Design and Drafting-20at42pMD HUZAIFA HANDURОценок пока нет

- Production Technology (CD)Документ7 страницProduction Technology (CD)ParasОценок пока нет

- Robotics & Autotronics Course Code: 3361108Документ8 страницRobotics & Autotronics Course Code: 3361108venkatesh naniОценок пока нет

- The Rieter Manual of Spinning Vol. 1-Pages 40 PDFДокумент80 страницThe Rieter Manual of Spinning Vol. 1-Pages 40 PDFAbdul RafayОценок пока нет

- Yarn Manufacturing Process CardingДокумент119 страницYarn Manufacturing Process CardingAshutosh MishraОценок пока нет

- 4th Semester: Ptx4I102 Yarn Manufacture - IiДокумент2 страницы4th Semester: Ptx4I102 Yarn Manufacture - Iilalit kashyapОценок пока нет

- M.SC Fashion DesigningДокумент27 страницM.SC Fashion DesigningAIM INSTITUTEОценок пока нет

- 7 Rice Harvesting and Threshing Machinery and Equipment 1Документ12 страниц7 Rice Harvesting and Threshing Machinery and Equipment 1Kelly EstilongОценок пока нет

- IV B.E. (Textile Technology)Документ6 страницIV B.E. (Textile Technology)9y9aОценок пока нет

- Afmm WorkbookДокумент56 страницAfmm WorkbookDuaa Shahid100% (1)

- Automation in SewingДокумент11 страницAutomation in SewingShelly Khanna BudhirajaОценок пока нет

- Efficiency Losses Calculation and Identify Causes of Losses of Circular Knitting Machine During Knit Fabric ProductionДокумент5 страницEfficiency Losses Calculation and Identify Causes of Losses of Circular Knitting Machine During Knit Fabric ProductionabcindОценок пока нет

- The Rieter Manual of Spinning Vol. 1 1921-V3 en Original 68489Документ80 страницThe Rieter Manual of Spinning Vol. 1 1921-V3 en Original 68489singhgirendra20001523Оценок пока нет

- FF III SyllabusДокумент3 страницыFF III SyllabusBinal TivarОценок пока нет

- Department of Textile Technology Second Year: Proposed Scheme ForДокумент13 страницDepartment of Textile Technology Second Year: Proposed Scheme For007_tajasОценок пока нет

- Cotton Ginning Plant Operator PDFДокумент18 страницCotton Ginning Plant Operator PDFgizex2013Оценок пока нет

- TX450 Spinning Calculation: Schedule Website Instructor ContactДокумент3 страницыTX450 Spinning Calculation: Schedule Website Instructor Contactsandeep225Оценок пока нет

- Main ContentsДокумент16 страницMain ContentsPricopОценок пока нет

- MO Syllabus PDFДокумент7 страницMO Syllabus PDFBHAVINОценок пока нет

- Course Title: Cut & Sew Knitwear: Lecture PlanДокумент1 страницаCourse Title: Cut & Sew Knitwear: Lecture PlanRiponPrasadОценок пока нет

- BTech Textile Tech Syllabus PDFДокумент48 страницBTech Textile Tech Syllabus PDFDurjoy RoyОценок пока нет

- Fdocuments - in - Analysis of Rejected Ring Cops in Autoconer Winding MachineДокумент49 страницFdocuments - in - Analysis of Rejected Ring Cops in Autoconer Winding MachineAbel TayeОценок пока нет

- 116102005Документ4 страницы116102005mohan smrОценок пока нет

- Effect of Machine Parameters On Knit FabДокумент5 страницEffect of Machine Parameters On Knit FablfomlfomОценок пока нет

- Object-Oriented Magnetic Resonance: Classes and Objects, Calculations and ComputationsОт EverandObject-Oriented Magnetic Resonance: Classes and Objects, Calculations and ComputationsРейтинг: 3 из 5 звезд3/5 (1)

- WDM Technologies: Passive Optical ComponentsОт EverandWDM Technologies: Passive Optical ComponentsAchyut K. DuttaОценок пока нет

- WDM Technologies: Optical NetworksОт EverandWDM Technologies: Optical NetworksAchyut K. DuttaОценок пока нет

- Cbe - Schools List - 2021 January 28THДокумент4 страницыCbe - Schools List - 2021 January 28THsubragmОценок пока нет

- Elements of Writing StyleДокумент12 страницElements of Writing StyleMuhammad SaadОценок пока нет

- Bluebook Abbreviations of Law Reviews & Legal Periodicals Indexed in CILPДокумент20 страницBluebook Abbreviations of Law Reviews & Legal Periodicals Indexed in CILPRicharnellia-RichieRichBattiest-CollinsОценок пока нет

- Lebanon Research PaperДокумент12 страницLebanon Research Paperapi-251985800Оценок пока нет

- How To Manage A ClassroomДокумент34 страницыHow To Manage A ClassroomolgaОценок пока нет

- Mathematical ModelingДокумент3 страницыMathematical ModelingJunyipp ChaiОценок пока нет

- LESSON PLAN by Jorge Lorenzo VenezuelaДокумент2 страницыLESSON PLAN by Jorge Lorenzo VenezuelaJorge LorenzoОценок пока нет

- Social LearninigДокумент13 страницSocial Learninigapi-287008406Оценок пока нет

- Everett Rogers Diffusion of Innovations Theory PDFДокумент4 страницыEverett Rogers Diffusion of Innovations Theory PDFa lОценок пока нет

- H1B Visa Interview QuestionsДокумент2 страницыH1B Visa Interview QuestionsRicky RicsОценок пока нет

- Human Resources Manager Job ResponsibilitiesДокумент7 страницHuman Resources Manager Job ResponsibilitiesYaseen SaleemОценок пока нет

- RI/CSSI 2018-19: at Lions' Blind Girl'S School VadodaraДокумент26 страницRI/CSSI 2018-19: at Lions' Blind Girl'S School VadodaraDDeevv SShhaahhОценок пока нет

- Use of Sim (Strategic Intervention Material) As Strategy and The Academic Achievement of Grade 7 Students On Selected Topic in Earth ScienceДокумент11 страницUse of Sim (Strategic Intervention Material) As Strategy and The Academic Achievement of Grade 7 Students On Selected Topic in Earth ScienceGlobal Research and Development ServicesОценок пока нет

- Colonialism Middle East PDFДокумент2 страницыColonialism Middle East PDFJasonОценок пока нет

- Aspiritech Annual Report 2012Документ12 страницAspiritech Annual Report 2012Katie LevinОценок пока нет

- Engineering Economy 6th753-781Документ29 страницEngineering Economy 6th753-781Son PhamngocОценок пока нет

- Unit 5 CMDA RulesДокумент14 страницUnit 5 CMDA RulesHarini JayasankarОценок пока нет

- Classroom Observation QuestionsДокумент2 страницыClassroom Observation Questionsapi-488049837Оценок пока нет

- Bo de IELTS Listening Predicted CUON 2Документ501 страницаBo de IELTS Listening Predicted CUON 2Trọng LêОценок пока нет

- Inferential Reading: Use This Strategy: Targeted Reading SkillsДокумент4 страницыInferential Reading: Use This Strategy: Targeted Reading SkillsPuteri Angreni QistinaОценок пока нет

- Form SSA-3441-BKДокумент10 страницForm SSA-3441-BKMathis & MathisОценок пока нет

- Comparison of Fidic Conditions of Contract PDFДокумент212 страницComparison of Fidic Conditions of Contract PDFdarulrajОценок пока нет

- Student Miss Behaviour ReportДокумент7 страницStudent Miss Behaviour Reportapi-379659393Оценок пока нет

- RC Tycoon Lesson PlanДокумент5 страницRC Tycoon Lesson Planapi-248223707Оценок пока нет

- Midterm ReflectionДокумент4 страницыMidterm Reflectionapi-280866228Оценок пока нет

- REsume For Teacher JobДокумент4 страницыREsume For Teacher JobBavisetti Venkat100% (2)

- Gradation As On 01 03 2022 06374aee34897b3 97522778Документ3 339 страницGradation As On 01 03 2022 06374aee34897b3 97522778Naina GuptaОценок пока нет

- Student Answer Sheet For The Multiple-Choice SectionДокумент5 страницStudent Answer Sheet For The Multiple-Choice SectionVictoria LiОценок пока нет

- Be 23-24 ProposalДокумент3 страницыBe 23-24 ProposalJaine LuzОценок пока нет

- RPHДокумент6 страницRPHNonoy NolandaОценок пока нет