Академический Документы

Профессиональный Документы

Культура Документы

WPS Vessel

Загружено:

Naqqash Sajid0 оценок0% нашли этот документ полезным (0 голосов)

27 просмотров1 страницаАвторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

27 просмотров1 страницаWPS Vessel

Загружено:

Naqqash SajidАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

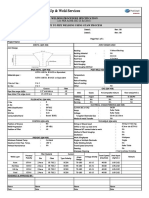

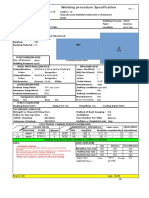

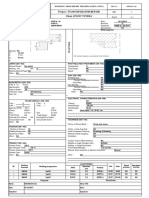

WENDT-WE-FOR-001, R0, Dated: 30/04/2019

WELDING AND NDT

QW-482 WELDING PROCEDURE SPECIFICATION (WPS)

(See QW-200.1,Section, IX, ASME Boiler and Pressure Vessel code )

PW.P.S. NO. : GS-001 Supporting PQR(s) To be Qualified POSTWELD HEAT TREATMENT (QW-407) ELECTRICAL CHARACTERISTICS (QW-409)

Revision No.: 0 Welding Process(es): GTAW + SMAW .1 Ø Type of PWHT: NONE .4 (a) Ø Current (AC or DC): SEE BELOW

Date: 30/04/2019 Type(s): MANUAL + MANUAL .2 (a) Temperature Range :(°C) NA .4 (b) Ø Polarity (EN or EP): SEE BELOW

Equipment Name: Applicable only for qulaification of PQR No 001 Joint Type: GROOVE/FILLET .2 (b) Time Range:(Minute) NA .8 (a) Ø Amperes (Range): SEE BELOW

JOINTS (QW-402) Method of PWHT: NA .8 (b) Ø Voltage (Range): SEE BELOW

.1 Ø Joint Design: Refer Typical Typical: .4 T Limits NONE .12 Ø Tungsten Type:* 2% Thoriated Size (mm): 2.4 mm OR EQUI

.5(a) + Backing: (Yes/No) No Rate Of Heating:(°C/hr) NA .1 > Heat Input : NA

.5(b) Backing Material (type): NA Thickness Rate Of Cooling:(°C/hr) NA .3 ± Pulsing Current : NA

.10 Ø Root Spacing 2~4 mm Others : NA Others : NA

.11 ± Retainers : NA GAS (QW-408)

Root face & Included Angle: 1-1.5 mm & 60° P1 G2 P1 G1 .2 (a) Ø Gas(es) .2(b) Ø Mixture & .2 © Ø % Composition .3 Ø Flow rate (LPM)

BASE METALS (QW-403) .2d ± Shielding Gas: ARGON SINGLE (NO CHANGE IN COMPOSITION) 5~15

MATERIAL - 1 MATERIAL - 2 .5 ± Backing Gas or Ø Backing Flow: NA NA NA

.11 Ø P.NO.: 1 P.NO.: 1 .1 ± Trailing Gas or Ø Comp: NA NA NA

.5 Ø Group No.: 2 Group No.: 1 .9 - Backing Gas or Ø Comp : NONE NONE NA

Specification/Grade: SA 516 Gr 70 Specification/Grade: SA 516 Gr 60 .10 Ø Shielding Trailing gas : NONE NONE NONE

.8 Thickness Range : (mm) TECHNIQUE (QW-410)

a) Base Metal Groove : 5-32 Fillet : NA Tubesheet: NA .1 Ø String/Weave Bead: STRING/WEAVE @ .3 Ø Gas Cup Size: (mm) 6.3 mm Dia or EQUI

b) Pipe Dia Range Groove : ALL Fillet : ALL Ligament: Width : NA .15 Ø Electrode Spacing : NA .11 Ø Closed to out Chamber : NONE

Overlay thickness (Min): NA Tube thickness: NA .10 Ø Multiple/Single Electrode: SINGLE .9 Ø Multi/Single pass (per side): MULTI PASS

.9 t Pass<12.7 mm NONE .6 T Limits : NA .7 Ø Oscillation: NA .26 ± Peening: NA

FILLER METALS (QW-404) .5 Ø Initial or Interpass WIRE BRUSH OR GRIND/MACHINED ;SURFACE TO BE GROUND

ROOT PASS FILL UP PASS(es) COVERING PASS(es) Cleaning: OR POWER WIRE BRUSHED OR MACHINED

.4 Ø F.NO.: 6 6+4 4 .6 Ø Method of Back Gouging: BY GRINDING IF REQUIRED

.5 Ø A.NO.: 1 1+1 1 .25 Ø Manual or Automatic Manual

Spec No.(SFA): 5.18 5.18 + 5.1 5.1 .64 Ø Use of Thermal Process : NONE

.12 & .33 Ø AWS No.(Class): ER70S-2 ER70S-2 + E7018 E7018 Others : NA

.3 Ø Size of Filler Metal (mm): 2.4/2.5 2.4/2.5 + 3.2,4.0 4 Filler Metal Current Travel Energy or Maximum Minimum

Weld Volt

.23 Ø Filler Metal Product Form: SOLID (BARE) WIRE SOLID (BARE) WIRE + NA NA Process Dia. Type & Amp. Speed Power Heat Input Bead Length

Layer(s) Classification (Range)

.50 ± Flux : NA NA + NA NA (mm) Polarity (Range) (mm/min) (Range) (KJ/mm) (mm)

.14± Filler : WITH ADDITION ONLY WITH ADDITION ONLY + NA NA

Flux Trade Name: NA NA + NA NA AS REQ GTAW ER70S-2 2.4/2.5 DCEN 80-150 10-18 AS PER PQR NA NA NA

.22 ± Consumable Insert: NA NA + NA NA

.30 Ø Weld Metal Thk Range: GTAW UPTO 06 mm(MAX) SMAW UPTO 10 mm (MAX) REMAINING SMAW E7018 3.2 DCEP 100-140 22-28 AS PER PQR NA 1.5 150

Chemical Composition: NA REMAINING SMAW E7018 4.0 DCEP 150-180 22-28 AS PER PQR NA 1.5 180

Brand Name/ Batch No: GTAW WIRE OF APPROVED BRAND & E7018 OF APPROVED BRAND TO BE USED

Other : NA

POSITIONS (QW-405)

.1 + (a) Position(s) of Groove : ALL

.2 & .3 Ø Welding Progression : VERTICAL UPHILL

.1 + (b) Position(s) of Fillet : ALL

Other: NA

PREHEAT (QW-406)

Thickness Range (mm) ≤25 >25-38

.1 Preheat Temp (MIN)⁰ C : 25 100 *Tungsten electrode can be identified as : 1)EWTh-2 or WT 20(Red Colour)

.3 Interpass Temp (MAX)⁰ C: 275 275 NA : NOT APPLICABLE NONE : ESSENTIAL VARIABLE BUT NOT USED

Preheat Maintenance : NA Legend :

Method of measuring .1 & .3 Temperature indicating crayon / Laser gun + Addition > Increase/greater than ↑ Uphill ← Forehand ø Change

-Deletion < Decrease/less than ↓ Downhill → Backhand

PEPARED BY: WELDING ENGINEER REVIEWED BY: WELDING MANAGER APPROVED BY: CLIENT/CUSTOMER/TPI

ASME

DESIGNATOR

NAME: NAME: NAME:

REQ.

DATE: DATE: DATE:

NOT REQ.

Вам также может понравиться

- WPS, PQR & WPQ - Duplex 2205Документ20 страницWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- WPS PQR ProcedureДокумент31 страницаWPS PQR Proceduresudeesh kumarОценок пока нет

- WPS For A333 AДокумент1 страницаWPS For A333 ARamzi BEN AHMED100% (1)

- WPSДокумент6 страницWPSYASH BARDHAN SinghОценок пока нет

- Piping WPS SMAWДокумент2 страницыPiping WPS SMAWJk KarthikОценок пока нет

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- WPS 7018+70S2Документ8 страницWPS 7018+70S2rajuОценок пока нет

- Wps For Steel RodsДокумент5 страницWps For Steel RodsHamid MansouriОценок пока нет

- WPS GTAW Stainless SteelДокумент7 страницWPS GTAW Stainless SteelVarun MalhotraОценок пока нет

- Revised PWPS 001Документ2 страницыRevised PWPS 001stdshopОценок пока нет

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeДокумент6 страницWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberОценок пока нет

- WPS For Carbon Steel THK 7.11 GTAWДокумент1 страницаWPS For Carbon Steel THK 7.11 GTAWAli Moosavi100% (1)

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Документ2 страницыWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusОценок пока нет

- WPS CuNiДокумент1 страницаWPS CuNiDieter Huaman ToscanoОценок пока нет

- Wps - Asme Ix - Gtaw - Plat SteДокумент6 страницWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraОценок пока нет

- WpsДокумент2 страницыWpssamer8saifОценок пока нет

- HHHHHHHHJJJJJJ: O O O OДокумент1 страницаHHHHHHHHJJJJJJ: O O O OAli MoosaviОценок пока нет

- Condenser DesignДокумент1 страницаCondenser DesignNaqqash SajidОценок пока нет

- WPS PQR Procedure PDFДокумент31 страницаWPS PQR Procedure PDFsudeesh kumarОценок пока нет

- For Fillet Weld Joint Project:Production ManifoldДокумент1 страницаFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- According To ASME IX: Welding Procedure Specification (W.P.S)Документ4 страницыAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehОценок пока нет

- HVAC Duct & Fittings Area Calculation Formulas ??Документ12 страницHVAC Duct & Fittings Area Calculation Formulas ??Naqqash Sajid100% (2)

- Wps - Asme Ix - Gtaw - Plat SteДокумент6 страницWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraОценок пока нет

- Welding Procedure Specification "WPS": O O O OДокумент1 страницаWelding Procedure Specification "WPS": O O O OAli MoosaviОценок пока нет

- Welding Procedure SpecificationДокумент4 страницыWelding Procedure SpecificationBhargav BbvsОценок пока нет

- O O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Документ1 страницаO O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Ali MoosaviОценок пока нет

- GS 001 Link 1 PDFДокумент1 страницаGS 001 Link 1 PDFhichemokokОценок пока нет

- GTAWДокумент1 страницаGTAWabdulОценок пока нет

- Welding & NDTДокумент1 страницаWelding & NDTVijaya BaraniОценок пока нет

- S 001 Link 2Документ1 страницаS 001 Link 2wael badawiОценок пока нет

- Welding Procedure Specification: (As Per Asme Sec Ix)Документ1 страницаWelding Procedure Specification: (As Per Asme Sec Ix)Himanshu SinghОценок пока нет

- PWPS CS To SS446-3Документ5 страницPWPS CS To SS446-3BIIS QAQC Babu SivaОценок пока нет

- Mathew Associates Hook Up & Weld Services: Welding Procedure SpecificationДокумент1 страницаMathew Associates Hook Up & Weld Services: Welding Procedure SpecificationHimanshu SinghОценок пока нет

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewДокумент4 страницы(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaОценок пока нет

- (P1) NSC-1020-TR-0102-1.1-WPS-06Документ6 страниц(P1) NSC-1020-TR-0102-1.1-WPS-06BIIS QAQC Babu SivaОценок пока нет

- Wps For Carbon Steel THK 7.11 GtawДокумент1 страницаWps For Carbon Steel THK 7.11 GtawAli MoosaviОценок пока нет

- WPS No. ST-CS-02-2Документ1 страницаWPS No. ST-CS-02-2Hussein JassimОценок пока нет

- WPS For SSДокумент1 страницаWPS For SSdeepakОценок пока нет

- Ce0034-Wps PQR02 E7.62 P01 01 PDFДокумент1 страницаCe0034-Wps PQR02 E7.62 P01 01 PDFKhaled BouhlelОценок пока нет

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04Документ9 страниц(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04BIIS QAQC Babu SivaОценок пока нет

- 347 310 WPSДокумент2 страницы347 310 WPSBIIS QAQC Babu SivaОценок пока нет

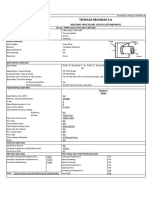

- Tecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)Документ2 страницыTecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)BIIS QAQC Babu SivaОценок пока нет

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Документ2 страницыWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- Welding Procedure Specification: PQR 2" Dia-5.54mm THKДокумент2 страницыWelding Procedure Specification: PQR 2" Dia-5.54mm THKNil BorichaОценок пока нет

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Документ3 страницыNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalОценок пока нет

- WPS Proposed CS (2''pwht-01e)Документ2 страницыWPS Proposed CS (2''pwht-01e)Rajeev KumarОценок пока нет

- Tecnicas Reunidas S.A: Welding Procedure Specification (WPS)Документ2 страницыTecnicas Reunidas S.A: Welding Procedure Specification (WPS)BIIS QAQC Babu SivaОценок пока нет

- Welding Procedure Specification (WPS) : Code: Asme-IxДокумент2 страницыWelding Procedure Specification (WPS) : Code: Asme-IxAnonymous 4WzixLwupОценок пока нет

- WPS-035 - (Pno.15e To Pno.7) - 2Документ2 страницыWPS-035 - (Pno.15e To Pno.7) - 2Allahyar YekkalamОценок пока нет

- Aic Asf PQR 133Документ3 страницыAic Asf PQR 133AHMED MEDANYОценок пока нет

- Data SHEET SEPARADOR 3Документ1 страницаData SHEET SEPARADOR 3Diego RuanoОценок пока нет

- Pwps-Gtaw FcawДокумент2 страницыPwps-Gtaw FcawAhmed ElsharkawОценок пока нет

- Astm 537 CL.1 WPSДокумент2 страницыAstm 537 CL.1 WPSaudiihussain67% (3)

- Welding Procedure Specification: JOINT (QW-402)Документ10 страницWelding Procedure Specification: JOINT (QW-402)Lipika GayenОценок пока нет

- WPS 84281 R06Документ1 страницаWPS 84281 R06Ritesh kumarОценок пока нет

- GM TCL 1 2F - WebExampleДокумент1 страницаGM TCL 1 2F - WebExamplesuronocaturatmojoОценок пока нет

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Документ2 страницыWelding Procedure Specification (WPS) : (Asme Sec. Ix)Emmanuel Loayza100% (1)

- WPS 10Документ2 страницыWPS 10Arab WeldersОценок пока нет

- Project: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Документ1 страницаProject: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Anonymous 7aUHXY1vWbОценок пока нет

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Документ3 страницыNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalОценок пока нет

- Preliminary - Welding Procedure Specification (WPS)Документ1 страницаPreliminary - Welding Procedure Specification (WPS)Rudi DaОценок пока нет

- Election Results Circular NOV 07, 2023Документ4 страницыElection Results Circular NOV 07, 2023Naqqash SajidОценок пока нет

- Pacheco Home Residence Drawings-EssentialsДокумент4 страницыPacheco Home Residence Drawings-EssentialsNaqqash SajidОценок пока нет

- Slant Fin Engineering DataДокумент2 страницыSlant Fin Engineering DataNaqqash SajidОценок пока нет

- Commodity ClassificationsДокумент24 страницыCommodity ClassificationsNaqqash SajidОценок пока нет

- Project SummaryДокумент10 страницProject SummaryNaqqash SajidОценок пока нет

- Energy Audit ReportДокумент22 страницыEnergy Audit ReportNaqqash SajidОценок пока нет

- ,,,,,,,,,,,,, Heat Transfer Coefficient Input ParametersДокумент2 страницы,,,,,,,,,,,,, Heat Transfer Coefficient Input ParametersNaqqash SajidОценок пока нет

- Huayi Compressor CMLT90LD N R404A 115 60Документ2 страницыHuayi Compressor CMLT90LD N R404A 115 60Naqqash SajidОценок пока нет

- International Journal of Heat and Mass Transfer: B.K. Hardik, P.K. Baburajan, S.V. PrabhuДокумент17 страницInternational Journal of Heat and Mass Transfer: B.K. Hardik, P.K. Baburajan, S.V. PrabhuNaqqash SajidОценок пока нет

- Eco-Smart HEPA ERV: Best Indoor Air For YouДокумент1 страницаEco-Smart HEPA ERV: Best Indoor Air For YouNaqqash SajidОценок пока нет

- Enhancement of Heat Transfer Coefficient Through Helical CoilДокумент5 страницEnhancement of Heat Transfer Coefficient Through Helical CoilNaqqash SajidОценок пока нет

- AD10B AD10B: E4 Intake at West Areaway E4 Intake at West AreawayДокумент24 страницыAD10B AD10B: E4 Intake at West Areaway E4 Intake at West AreawayNaqqash SajidОценок пока нет

- Helical Coil Length - UpdДокумент2 страницыHelical Coil Length - UpdNaqqash SajidОценок пока нет

- Ground Floor: N E W S Zone 3 4.1x54.7 Internal Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Zone 6 Zone 7 Zone 8Документ1 страницаGround Floor: N E W S Zone 3 4.1x54.7 Internal Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Zone 6 Zone 7 Zone 8Naqqash SajidОценок пока нет

- Design DataДокумент283 страницыDesign DataNaqqash SajidОценок пока нет

- General Demolition Notes: Mercy Hall RenovationДокумент17 страницGeneral Demolition Notes: Mercy Hall RenovationNaqqash SajidОценок пока нет

- Project 2: The Capital Asset Pricing Model and Portfolio TheoryДокумент11 страницProject 2: The Capital Asset Pricing Model and Portfolio TheoryNaqqash SajidОценок пока нет

- Comparsion of Existing System and New SystemДокумент4 страницыComparsion of Existing System and New SystemNaqqash SajidОценок пока нет

- Evaporator DesignДокумент1 страницаEvaporator DesignNaqqash SajidОценок пока нет

- Report FinalДокумент99 страницReport FinalNaqqash SajidОценок пока нет

- Tank 4 Ice Filling New DesignДокумент14 страницTank 4 Ice Filling New DesignNaqqash SajidОценок пока нет

- Load CalculationДокумент13 страницLoad CalculationNaqqash SajidОценок пока нет

- Load Calculation NewДокумент13 страницLoad Calculation NewNaqqash SajidОценок пока нет

- Fire Fighting LayoutДокумент1 страницаFire Fighting LayoutNaqqash SajidОценок пока нет

- E Rich Burn Control System: With Stablesense™ TechnologyДокумент4 страницыE Rich Burn Control System: With Stablesense™ TechnologyYasir JamilОценок пока нет

- Chapter 8Документ7 страницChapter 8Maiane JunqueiraОценок пока нет

- Crane Wheels-General InformationДокумент3 страницыCrane Wheels-General InformationArvind VaishОценок пока нет

- NDT VTL-3-3Документ2 страницыNDT VTL-3-3Priyesh MauryaОценок пока нет

- Astm A106-2002Документ13 страницAstm A106-2002henryОценок пока нет

- Falcon 4 CLHS Cameras: True High-Performance: High-Speed Global Shutter CMOS CamerasДокумент4 страницыFalcon 4 CLHS Cameras: True High-Performance: High-Speed Global Shutter CMOS CamerasEkpetorson ChinweikeОценок пока нет

- LTTS Corporate BrochureДокумент20 страницLTTS Corporate BrochureshountyОценок пока нет

- R172 NTG4.5 EngineeringMenuДокумент5 страницR172 NTG4.5 EngineeringMenualeksandar_tudzarovОценок пока нет

- Pre-Assessment Form Problem Solving Techniques (2 Day Course)Документ1 страницаPre-Assessment Form Problem Solving Techniques (2 Day Course)sumit1975Оценок пока нет

- Section 3 Quiz, Database Design ORACLEДокумент8 страницSection 3 Quiz, Database Design ORACLEMostragОценок пока нет

- How Microprocessors Work PDFДокумент2 страницыHow Microprocessors Work PDFdanielconstantin4Оценок пока нет

- Electric Power Applications, Engine & Generator SizingДокумент120 страницElectric Power Applications, Engine & Generator SizingDIPPOSОценок пока нет

- Studi Dampak Lalu Lintas Pembangunan Gudang Dan Kantor Pt. Wismilak Group Di Jalan Raya Solo SragenДокумент8 страницStudi Dampak Lalu Lintas Pembangunan Gudang Dan Kantor Pt. Wismilak Group Di Jalan Raya Solo SragenIlung MarpaungОценок пока нет

- CAT Álogo de Peças de Reposi ÇÃO: Trator 5403Документ364 страницыCAT Álogo de Peças de Reposi ÇÃO: Trator 5403MARCOS DIONIS ALVES LIMAОценок пока нет

- Lec.5 (Prameters of OHTL Pt.2)Документ10 страницLec.5 (Prameters of OHTL Pt.2)AbdullahОценок пока нет

- Sheet Pile Analysis Sheet v1.07-18.1Документ2 страницыSheet Pile Analysis Sheet v1.07-18.1SES DESIGN100% (1)

- JAVA NotesДокумент12 страницJAVA NotesVarun BawaОценок пока нет

- Determinants of Income InequalityДокумент30 страницDeterminants of Income InequalityKorawit Booranakit100% (1)

- Simulation Tool ComparisonДокумент8 страницSimulation Tool ComparisonsmautifОценок пока нет

- SQL1Документ13 страницSQL1Devalla Bhaskar GaneshОценок пока нет

- Overview of Missile Flight Control Systems: Paul B. JacksonДокумент16 страницOverview of Missile Flight Control Systems: Paul B. JacksonrobjohniiiОценок пока нет

- Assignment 176020307045 PDFДокумент82 страницыAssignment 176020307045 PDFnikita gohelОценок пока нет

- Periodic Table of ElementsДокумент60 страницPeriodic Table of ElementsruchitlpatelОценок пока нет

- Chapter 1 - Steam GenerationДокумент23 страницыChapter 1 - Steam GenerationAzhan FikriОценок пока нет

- Tutorial - How To Use The Poser Format ExporterДокумент7 страницTutorial - How To Use The Poser Format ExporterMimhypopbummilha SwuОценок пока нет

- Nylon Bag BisДокумент13 страницNylon Bag Bisbsnl.corp.pbОценок пока нет

- Oral Histology & Embryology-FikreДокумент240 страницOral Histology & Embryology-FikreHeran A AlhadiОценок пока нет

- 7 - Introduction To Intelligent ControlДокумент21 страница7 - Introduction To Intelligent ControlIsmael Espinoza100% (1)

- Ece R13Документ36 страницEce R13DilipReddiarОценок пока нет

- Theories and Methods of Two Way Slab Design-5-8-2017Документ3 страницыTheories and Methods of Two Way Slab Design-5-8-2017amerta 4320Оценок пока нет