Академический Документы

Профессиональный Документы

Культура Документы

Apcodur Ehb 500-Voc

Загружено:

Moin AltafИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Apcodur Ehb 500-Voc

Загружено:

Moin AltafАвторское право:

Доступные форматы

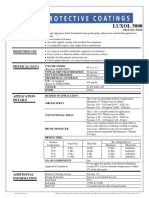

APCODUR EHB 500

High Build High Solid Epoxy

PRODUCT A high solids and high build epoxy coating designed to serve the requirements of on-shore, off-

shore installations.

DESCRIPTION • Excellent resistance to cathodic disbondment.

• Excellent Corrosion resistance.

• Excellent resistance against fresh and sea water.

• Excellent abrasion resistance.

• Good resistance against mild chemicals..

• Available in glass flake & non glass flake versions.

DESIGNED USE • Steel and concrete structures in splash / tidal zone and buried vessels or pipelines.

• As a single coat maintenance system.

• As a general coating for on-shore and off-shore installations.

• Can be used in conjunction with CP.

• Suitable for buried conditions like Im3 Environment as per ISO12944 Part 2

PHYSICAL DATA VOLUME SOLIDS

99 % + 1 %

(Based on ASTM D2697)

TYPICAL DRY FILM THICKNESS 500-700 microns

WET FILM THICKNESS 500-700 microns

THEORETICAL COVERAGE 2 m2/litre @ 500 microns DFT

VOC “As Supplied”

15 gms/ltr

(Based on ASTM D3960)

COLOUR Off-white

FINISH Low Sheen to glossy

APPLICATION METHOD OF APPLICATION :

DETAILS This is the recommended method of application:

Maximum 3% Thinner may be added.

AIRLESS SPRAY

Tip Size: 0.63 – 0.78 mm (0.025 - 0.031 in)

Pressure: 206 - 241 kg/cm2 (3000 – 3500 psi)

May be used for difficult shapes or touch-up.

BRUSH OR ROLLER However, additional coats may be required to achieve

the recommended film thickness.

DRYING TIME:

Surface Re coating Interval

Touch Dry Hard Dry Pot Life

Temperature Minimum Maximum

15°C 9 Hrs 18 Hrs 32 Hrs 21 Days 3 Hrs

25°C 6 Hrs 12 Hrs 20 Hrs 14 Days 2 Hrs

35°C 4 Hrs 8 Hrs 14 Hrs 7 Days 1 Hr

45°C 2 Hrs 6 Hrs 8 Hrs 5 Days 30 mins

NO. OF COMPONENTS Two

Mixing Ratio Base : Hardener by 2:1 by volume

Do not apply this product if the Relative Humidity

Application Conditions exceeds 85% or if the substrate temperature is within

3°C of the dew point

ADDITIONAL Thinner / Cleaning solvent Solvalux 7-45

INFORMATION Storage Instruction Store in a cool shaded dry area

Flash Point Mixed 24°C

Packaging 20 liters

March 2017 Version 1 Protective Coatings Sales & Service Dubai Tel 04- 3391000 Fax 04-3391322 Abu Dhabi Tel 02-6798202 Fax 02-6713774

Shelf Life 12 months from the date of manufacture.

APCODUR EHB 500

High Build High Solid Epoxy

SURFACE This product can be applied directly to blasted steel or over suitable primer (e.g. EPILUX 610/78

Primers).

PREPARATION • Remove all wax, oil and grease by solvent cleaning in accordance with the guidelines given by

SSPC-SPI.

• Where necessary remove weld spatter and round off all rough weld seams and sharp edges to a

smooth surface.

• Abrasive blast clean to a minimum standard of Sa 2½ Swedish Standard SIS 05 59 00 or ISO 8501-

1 : 1988.

• For direct application, the surface profile should be in between 50-75 micron.

• Any surface defects revealed by blast cleaning should be ground, filled or treated in a suitable

manner.

• After blasting, remove dust from the surface.

• The surface to be applied must be clean, dry and free from soluble salts. If required, fresh water

wash should follow to remove soluble salts.

CONCRETE

• Ensure the surface is sound. Remove laitance by through wire-brushing, acid etching or sweep

blasting. Blowholes and other defects should be filled with EPILUX 829.

PRODUCT USE • This product has to be applied over a dry surface

• Finish will be matt if cured underwater.

RESTRICTIONS • Consult Berger if product is to be applied in non-tropical climate.

• Pot life short, hence mix base and hardener only when ready to use.

• As common with all Epoxy products, this product also will tend to discolour and chalk on exposure

to direct sunlight.

• May also be applied between 350 and 500 microns DFT.

• Contact Berger Representative for suggesting suitable paint system

SAFETY • Avoid contact with the skin and eyes. Wear suitable protective clothing such as overalls, goggles, dust

masks and gloves. Use a barrier cream.

PRECAUTIONS • Ensure that there is adequate ventilation in the area where the product is being applied. Do not breathe

vapor or spray.

• This product is flammable. Keep away from sources of ignition. Do not smoke. Take precautionary

measures against static discharge. In case of fire – blanket flames with foam, carbon dioxide or dry

chemicals

• Refer to MSDS for further information.

FIRST AID • Eyes: In the event of accidental splashes, flush eyes with water immediately and obtain medical advice

• Skin: Wash skin thoroughly with soap and water or approved industrial cleaner.

• DO NOT USE solvent or thinners.

• Inhalation: Remove to fresh air, loosen collar and keep patient rested.

• Ingestion: In case of accidental ingestion, DO NOT INDUCE VOMITING.

Obtain immediate medical attention

The information provided on this data sheet is not intended to be complete and is provided as general advice only. It is the responsibility

DISCLAIMER of the user to ensure that the product is suitable for the purpose for which he wishes to use it. As we have no control over the treatment of

the product, the standard of surface preparation of the substrate, or other factors affecting the use of this product, we are not responsible

for its performance nor would we accept any liability whatsoever or howsoever arising from the use of this product unless specifically

agreed to in writing by us. The information contained in this data sheet may be modified by us from time to time, and without notice, in

the light of our experience and continuous product development.

March 2017 Version 1 Protective Coatings Sales & Service Dubai Tel 04- 3391000 Fax 04-3391322 Abu Dhabi Tel 02-6798202 Fax 02-6713774

Вам также может понравиться

- Steel Shield 1200Документ2 страницыSteel Shield 1200Moin AltafОценок пока нет

- Epilux 82: Product DescriptionДокумент2 страницыEpilux 82: Product DescriptionMoin AltafОценок пока нет

- Epilux 155Документ2 страницыEpilux 155Allana100% (1)

- Epilux 219: Product DescriptionДокумент2 страницыEpilux 219: Product DescriptionMoin AltafОценок пока нет

- Zincanode 620 Voc v1 Jan 2018Документ2 страницыZincanode 620 Voc v1 Jan 2018Moin AltafОценок пока нет

- Epimastic 7200: Product DescriptionДокумент2 страницыEpimastic 7200: Product DescriptionSu KaОценок пока нет

- Pds Epilux 218 VocДокумент2 страницыPds Epilux 218 VocmuthukumarОценок пока нет

- EPIMASTIC 5100-March 2019 Version 2Документ2 страницыEPIMASTIC 5100-March 2019 Version 2PraveenОценок пока нет

- Epilux 218: Product DescriptionДокумент2 страницыEpilux 218: Product DescriptionMoin AltafОценок пока нет

- Apcotherm Epn 200Документ2 страницыApcotherm Epn 200Moin AltafОценок пока нет

- Epilux 800Документ2 страницыEpilux 800anandОценок пока нет

- Epilux 58 M.I.O.: Product DescriptionДокумент2 страницыEpilux 58 M.I.O.: Product DescriptionMoin AltafОценок пока нет

- Pds Epilux 218 Hs VocДокумент2 страницыPds Epilux 218 Hs VocmuthukumarОценок пока нет

- Pds Zincanode 690 VocДокумент2 страницыPds Zincanode 690 VocmuthukumarОценок пока нет

- Pds Zincanode 620 VocДокумент2 страницыPds Zincanode 620 VocmuthukumarОценок пока нет

- Epimastic 7200 SRДокумент2 страницыEpimastic 7200 SRqc_531040655Оценок пока нет

- Epilux 8: Product DescriptionДокумент2 страницыEpilux 8: Product DescriptionMoin AltafОценок пока нет

- EPILUX 850 SF VOC Jan-2017Документ2 страницыEPILUX 850 SF VOC Jan-2017PraveenОценок пока нет

- Epilux 5: Product DescriptionДокумент2 страницыEpilux 5: Product DescriptionShyam ShrishОценок пока нет

- Luxathane 5160Документ2 страницыLuxathane 5160shameelОценок пока нет

- Epimastic 5200: Product DescriptionДокумент2 страницыEpimastic 5200: Product DescriptionsreeОценок пока нет

- Luxatherm 6200Документ2 страницыLuxatherm 6200PraveenОценок пока нет

- Pds Luxaprime 1000 VocДокумент2 страницыPds Luxaprime 1000 VocmuthukumarОценок пока нет

- Rapid Air Dry 10Документ2 страницыRapid Air Dry 10Moin AltafОценок пока нет

- Epimastic 4100Документ2 страницыEpimastic 4100Moin AltafОценок пока нет

- Pds Luxaprime 1400 VocДокумент2 страницыPds Luxaprime 1400 VocmuthukumarОценок пока нет

- Apcoline 4100Документ2 страницыApcoline 4100Moin AltafОценок пока нет

- Steelshield Ve: Product DescriptionДокумент2 страницыSteelshield Ve: Product DescriptionMoin AltafОценок пока нет

- Berger: Product SpecificationsДокумент2 страницыBerger: Product SpecificationsAabhas UpadhyayaОценок пока нет

- Luxathane 5160-Voc March 2021 V1Документ2 страницыLuxathane 5160-Voc March 2021 V1PraveenОценок пока нет

- Pds Luxol 5000 VocДокумент2 страницыPds Luxol 5000 VocmuthukumarОценок пока нет

- RobbiathaneДокумент2 страницыRobbiathaneAnson FranklinОценок пока нет

- Epilux 155Документ2 страницыEpilux 155Tejinder KumarОценок пока нет

- Zincanode 402: Two Pack Zinc Rich Epoxy PrimerДокумент2 страницыZincanode 402: Two Pack Zinc Rich Epoxy PrimerlivefreakОценок пока нет

- Pds Luxathane 5000 VocДокумент2 страницыPds Luxathane 5000 Vocmuthukumar100% (1)

- Epilux 58 - 9702Документ2 страницыEpilux 58 - 9702anandОценок пока нет

- g9) Berger Apcofine 905 - 8096Документ2 страницыg9) Berger Apcofine 905 - 8096Wasek SarkerОценок пока нет

- Steel Shield 1100Документ3 страницыSteel Shield 1100Moin AltafОценок пока нет

- Pds Luxol 1000 VocДокумент2 страницыPds Luxol 1000 VocmuthukumarОценок пока нет

- Microsoft Word - L3 - Epilux82Документ2 страницыMicrosoft Word - L3 - Epilux82vitharvanОценок пока нет

- Pds Luxaprime 1500 VocДокумент2 страницыPds Luxaprime 1500 VocmuthukumarОценок пока нет

- Revchem HRC 870Документ3 страницыRevchem HRC 870marciobispoalmeidaОценок пока нет

- pm002 4446Документ2 страницыpm002 4446Dhanush Kumar RamanОценок пока нет

- Paragloss v2Документ2 страницыParagloss v2Adam FauzanОценок пока нет

- Garlock GSK 3-86 Strainer Gasket 04.2017 en-NAДокумент2 страницыGarlock GSK 3-86 Strainer Gasket 04.2017 en-NAAbuhurairah MunshiОценок пока нет

- Sherwin Williams Macropoxy M262 PDS Promain 05 09 2022Документ2 страницыSherwin Williams Macropoxy M262 PDS Promain 05 09 2022paОценок пока нет

- Luxepoxy UHB: Ultra High Build EpoxyДокумент2 страницыLuxepoxy UHB: Ultra High Build EpoxylivefreakОценок пока нет

- Luxepoxy T: Tintable Two Pack Epoxy FinishДокумент2 страницыLuxepoxy T: Tintable Two Pack Epoxy FinishlivefreakОценок пока нет

- b3) Zincanode685 4586Документ2 страницыb3) Zincanode685 4586Syed FaridОценок пока нет

- Durebild HSE: High Build Two Pack Epoxy CoatingДокумент3 страницыDurebild HSE: High Build Two Pack Epoxy CoatinglivefreakОценок пока нет

- 323+ Data SheetДокумент5 страниц323+ Data SheetSergioОценок пока нет

- TDS - Supra Epoxy HB Mio CoatingДокумент2 страницыTDS - Supra Epoxy HB Mio CoatingSachin SinghalОценок пока нет

- 19.abcolux18hs Content 237Документ3 страницы19.abcolux18hs Content 237MbimbikОценок пока нет

- KANSAI PAINT Paralux - 15HBДокумент2 страницыKANSAI PAINT Paralux - 15HBYogalingam ArumugamОценок пока нет

- Berger: Product SpecificationsДокумент2 страницыBerger: Product SpecificationsAabhas UpadhyayaОценок пока нет

- Epilux 78Документ2 страницыEpilux 78MuthuKumar100% (1)

- Berger: Product SpecificationsДокумент2 страницыBerger: Product SpecificationsAabhas UpadhyayaОценок пока нет

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965От EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Оценок пока нет

- DEP-31403039 - Spec - 2017-02 - A01 - Internal FBE Coating For Water Injection LinesДокумент30 страницDEP-31403039 - Spec - 2017-02 - A01 - Internal FBE Coating For Water Injection LinesMoin AltafОценок пока нет

- Rapid Air Dry 10Документ2 страницыRapid Air Dry 10Moin AltafОценок пока нет

- 2023-RegisterBook Version 202212Документ95 страниц2023-RegisterBook Version 202212Moin AltafОценок пока нет

- Epilux 8: Product DescriptionДокумент2 страницыEpilux 8: Product DescriptionMoin AltafОценок пока нет

- HilonDeco Cryl 9200-MCДокумент2 страницыHilonDeco Cryl 9200-MCMoin AltafОценок пока нет

- Epilux 218: Product DescriptionДокумент2 страницыEpilux 218: Product DescriptionMoin AltafОценок пока нет

- Apcoline 4100Документ2 страницыApcoline 4100Moin AltafОценок пока нет

- PDS-Supreme Eggshell - Silk Version 1Документ2 страницыPDS-Supreme Eggshell - Silk Version 1Moin AltafОценок пока нет

- Apcotherm Epn 200Документ2 страницыApcotherm Epn 200Moin AltafОценок пока нет

- Epilux 58 M.I.O.: Product DescriptionДокумент2 страницыEpilux 58 M.I.O.: Product DescriptionMoin AltafОценок пока нет

- Steel Shield 1100Документ3 страницыSteel Shield 1100Moin AltafОценок пока нет

- Epimastic 4100Документ2 страницыEpimastic 4100Moin AltafОценок пока нет

- Steelshield Ve: Product DescriptionДокумент2 страницыSteelshield Ve: Product DescriptionMoin AltafОценок пока нет

- Can A SUNNI Man Marry A SHIA GirlДокумент2 страницыCan A SUNNI Man Marry A SHIA GirlMoin AltafОценок пока нет

- Mechanical ConcreteДокумент5 страницMechanical ConcreteAnonymous xEI5OJw7YОценок пока нет

- HVAC Questions and AnswersДокумент3 страницыHVAC Questions and AnswersAli ShamakhОценок пока нет

- Is.3987.2006 SorbitolДокумент14 страницIs.3987.2006 SorbitolHafizur RahmanОценок пока нет

- Zones of ScrewДокумент111 страницZones of Screwzubi0585100% (2)

- 3 E Recycled Glass As A Partial Replacement For Fine Aggregate in Self Compacting ConcreteДокумент7 страниц3 E Recycled Glass As A Partial Replacement For Fine Aggregate in Self Compacting Concretemaverick ownadorОценок пока нет

- Precision Grouting of TurbomachineryДокумент21 страницаPrecision Grouting of TurbomachineryRicardo Barros100% (1)

- Astm C1446Документ4 страницыAstm C1446deivisbtsОценок пока нет

- Experimental and Numerical Analysis For Determining The Mass Flow Rate of Two Phase Fluid Using Laminar Flow Rectangular ChannelДокумент11 страницExperimental and Numerical Analysis For Determining The Mass Flow Rate of Two Phase Fluid Using Laminar Flow Rectangular Channelsaju_s_rajОценок пока нет

- Example 11 - Cast-In-Place Concrete Cantilever Retaining WallДокумент15 страницExample 11 - Cast-In-Place Concrete Cantilever Retaining WallKawan EngОценок пока нет

- Canal Lining & Canal Regulation: 19 May, 2020 AP. Dr. MazharДокумент40 страницCanal Lining & Canal Regulation: 19 May, 2020 AP. Dr. MazharMuh UmaОценок пока нет

- Advances in FerroelectricsДокумент542 страницыAdvances in FerroelectricsPhelippe Mendonça de PaivaОценок пока нет

- Z99 SDS EVBCHMP5000 2012 09 Safety DatasheetДокумент7 страницZ99 SDS EVBCHMP5000 2012 09 Safety DatasheetJorge MonteiroОценок пока нет

- Characterization of Acetone-Solution Casting Film of PMMAДокумент3 страницыCharacterization of Acetone-Solution Casting Film of PMMASyiera MujibОценок пока нет

- Design of Friction Slab On Cut Rock Wall - Rs 39A: Width of Foundation Width of Toe 0.00 MДокумент7 страницDesign of Friction Slab On Cut Rock Wall - Rs 39A: Width of Foundation Width of Toe 0.00 MSravanthi MeharОценок пока нет

- Energy Elastic Strain EnergyДокумент14 страницEnergy Elastic Strain EnergyamirwmОценок пока нет

- Soda Snake Fireworks Lesson PlanДокумент4 страницыSoda Snake Fireworks Lesson PlanmMadMadamMimmОценок пока нет

- LASER DC 5030 Classic, 5040, 5060, 10.06, en MetricДокумент139 страницLASER DC 5030 Classic, 5040, 5060, 10.06, en MetricjcpirОценок пока нет

- Class 11 Chemistry Annual Paper Agra Region 2023-204Документ10 страницClass 11 Chemistry Annual Paper Agra Region 2023-204adarsh96785Оценок пока нет

- Industrial ProductДокумент10 страницIndustrial ProductFaisalKharisОценок пока нет

- Chapter3 AnswersДокумент3 страницыChapter3 AnswersKrishaad ManirajahОценок пока нет

- Colored Urban Furniture IterchimicaДокумент11 страницColored Urban Furniture IterchimicaTarta Ciprian RaresОценок пока нет

- Journal Group #4Документ13 страницJournal Group #4Vincent A. Sunggayan-NiezОценок пока нет

- Topic 3-Particulate PollutantsДокумент72 страницыTopic 3-Particulate PollutantsalyaОценок пока нет

- Mechanical Properties of NiTi and CuNiTi Shape-Memory Wires Used in Orthodontic Treatment. Part 1: Stress-Strain TestsДокумент9 страницMechanical Properties of NiTi and CuNiTi Shape-Memory Wires Used in Orthodontic Treatment. Part 1: Stress-Strain TestsClaudiaОценок пока нет

- Proses FerrovanadiumДокумент5 страницProses FerrovanadiumMuhammad Rizki Ash-ShidiqОценок пока нет

- Api 653Документ1 страницаApi 653BashMohandesssОценок пока нет

- An Overview of Hemp Fibre PDFДокумент4 страницыAn Overview of Hemp Fibre PDFscribbddОценок пока нет

- Manipis 2024 Agriculturalwastemgt Project ProfileДокумент8 страницManipis 2024 Agriculturalwastemgt Project ProfileDebah Diaz Baclayon WaycoОценок пока нет

- Certifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itДокумент2 страницыCertifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itMohamed Raafat100% (1)

- Silicone Compatibility TestДокумент2 страницыSilicone Compatibility TestDyeing DyeingОценок пока нет