Академический Документы

Профессиональный Документы

Культура Документы

30,000ltrs Overhead Water Tank Support Tower and Foundation

Загружено:

ChuksbozmentОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

30,000ltrs Overhead Water Tank Support Tower and Foundation

Загружено:

ChuksbozmentАвторское право:

Доступные форматы

GEOSCIENCES CENTRE OF EXCELLENCE

Design of 30,000 Litres Overhead Water Tank Support Tower and

Foundation

September, 2018

Design of Overhead Water Tank Support Tower and Foundation

Job Title: DESIGN OF 30,000 LITRES OVERHEAD TANK SUPPORT TOWER AND FOUNDATION

STRUCTURAL DESIGN INFORMATION

INTENDED USE & BRIEF DESCRIPTION OF STRUCTURE

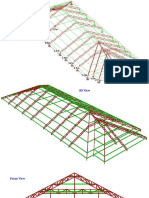

The proposed steel tower is to provide support for a 30,000 litres-capacity Braithwaite pressed steel tank at a height of 27.0m above ground level. The tank measures 3.66m square on plan and

is 2.44m deep i.e reference code 3*3*2.

The structural solution consists of a 4-legged lattice tower, 27m high, carrying a platform, which measures 5.46m square on plan. The platform is made of 254X146UB31 secondary girders

`POS 14’, placed at 1.22m intervals over 305x165UB40 Main girders `POS 13’ which are, in turn, supported by the tower legs made of 203x203UC23 at the corners of a square of side 3.66m

. Both the secondary and main girders are extended to carry the walkway and the handrails.

For stability the tower is braced horizontally at 3.0m intervals with 100EA8 `POS 02’. Cross bracing is made of 80EA8 `POS 03’, designed as ties. The Holding Down system consists of

350mmx350mmx20 base plates which are anchored to the concrete pedestals with M20 grade 8.8 bolts.

The Holding Down system consists of 350mmx350mmx20 base plates ,which are anchored to the foundation concrete with M20 grade 8.8 bolts. The foundation is made of 600mm thick

reinforced concrete raft slab. Further details of the design are given in the accompanying drawings.

GENERAL LOADING CONDITION

Dead and Imposed loading

Self weight of tank = 27.43kN (from catalogue).

Contents (Water) = 327.31kN

Open flooring system = 0.51kN/m² (35x5 steel grating)

Maintenance load=5.0kN/m²

Railing & Posts = 0.35kN/m

Wind loading

Basic wind speed, v=32m/s (3-sec gust speed)

DURABILITY & FIRE RESISTANCE

Fire resistance-: 1 hour for all elements

Minimum cover to all reinforcement - 50mm substructure

CODES OF PRACTICE & REFERENCES

EUROCODE 1: EN1991–1–1: 2002: Actions on Structures,

EUROCODE 2: EN1992–1 - 1–2004: Design of Conceret Structures,

EUROCODE 3: EN1993 - 1 - 1: 2005: Design of Steel Structures,

EUROCODE 3: EN1993 - 1 - 8: Design of Joints

ANSI/EIA/TIA-222-G-2003: Structural Standards for Steel Antenna Towers and Antenna Supporting Structures

MATERIALS & STRENGTHS

Normal Weight Concrete grade C25/30

Characteristic cube strength, fcu = 30N/mm²

Characteristic cylinder strength at 28 days, fck = 0.8 x characteristic cube strength = 25N/mm²

Reinforcement

High yield deformed bars type 2 to BS 4449

Characteristic strength, fyk = 410N/mm²

Structural Steel Grade S275 (43A)

Young’s Modulus, Es =210kN/mm²

Bolts

Mild steel bolts grade 8.8

Prepared by: Kelvin Nasamu, B.Eng

Design of Overhead Water Tank Support Tower and Foundation

Job No. Sheet No. Rev.

Calculation Sheet 01 OF 21

XXXXXXXX Member/Location

Job Title: Design of Overhead Water Tank Support Tower Drg Ref.

Made By KN Date:09/2018 Chd CE

REFERENCE CALCULATIONS OUTPUT

BASIC ASSESSMENT OF OVERHEAD WATER TANK

STRUCTURAL DESIGN INFORMATION

Tank Value Unit

Type: Pressed Steel Braithwaith

Reference Code: 332

Length of Tank, L: 3.66 m

Breadth of Tank, B: 3.66 m

Depth of Tank, D: 2.44 m

Volume of Tank: 32,731.00 Litres

Width of inspection corridor, b: 0.90 m

Spacing of Secondary girders, l: 1.22 m

Gravity Loads:

Maintenance Load on walkway, Wm : 5 kN/m²

Self Weight of Tank, Wt : 27.43 kN

Weight of Water in Tank, Ww : 327.31 kN

Open Flooring System, Wf : 0.51 kN/m²

Railings and Post, Wr : 0.35 kN/m

PLATFORM LOADING

INTERNAL TANK BEARER 'SG1'

From tank own weight, gk : =l*Wt/(L*B) = 2.50 kN/m

From water, qk : =l*Ww/(L*B) = 29.81 kN/m

Open flooring system, gk : =l*Wf = 0.62 kN/m

Maintenance load, qk : at Cantilever =l*Wm = 6.10 kN/m

Railings + Post, gk : =l*Wr = 0.43 kN

EXTERNAL TANK BEARER 'SG2'

From tank own weight: =0.5*l*Wt/(L*B)= 1.25 kN/m

Open flooring system @ span =0.5*b*Wf= 0.23 kN/m

gk= 1.48 kN/m

From water: =0.5*l*Ww/(L*B)= 14.90 kN/m

Maintenance Load @ span =0.5*b*Wm= 2.25 kN/m

qk= 17.15 kN/m

Open flooring system, gk: =0.5*(l+b)*Wf= 0.54 kN/m

Maintenance load, qk: at Cantilever =0.5*(l+b)*Wm= 5.30 kN/m

Railings + Post, gk: =0.5*(l+b)*Wr= 0.37 kN/m

PERIMETER BEAM 'SG3'

Open flooring system: =0.5*b*Wf= 0.23 kN/m

Railings + Post (UDL): =Wr= 0.35 kN/m

gk= 0.58 kN/m

Railings + Post (point load), gk: =0.5*b*Wr= 0.16 kN/m

Maintenance load, qk: =0.5*b*Wm= 2.25 kN/m

Design of Overhead Water Tank Support Tower and Foundation

Job No. Sheet No. Rev.

Calculation Sheet 02 OF 21

XXXXXXXX Member/Location

Job Title: Design of Overhead Water Tank Support Tower Drg Ref.

Made By KN Date:09/2018 Chd CE

REFERENCE CALCULATIONS OUTPUT

INTERNAL TANK BEARER 'SG1'

Factors of Safety: γG= 1.35 γ Q= 1.5

gk (kN/m)= 0.62 gk (kN/m)= 2.50 gk (kN/m)= 0.62

qk (kN/m)= 6.10 qk (kN/m)= 29.81 qk (kN/m)= 6.10

gk (kN)= 0.43 gk (kN)= 0.43

(mm) 900 3660 900

M (kNm) 4.60 4.60 76.00 4.60 4.60

V (kN) 9.70 88.00 88.00 9.70

Rp (kN) 6.10 6.10

Rv (kN) 60.10 60.10

EXTERNAL TANK BEARER 'SG2'

Factors of Safety: γG= 1.35 γ Q= 1.5

gk (kN/m)= 0.54 gk (kN/m)= 1.48 gk (kN/m)= 0.54

qk (kN/m)= 5.30 qk (kN/m)= 17.15 qk (kN/m)= 5.30

gk (kN)= 0.37 gk (kN)= 0.37

(mm) 900 3660 900

M (kNm) 4.00 4.00 42.50 4.00 4.00

V (kN) 8.30 50.70 50.70 8.30

Rp (kN) 4.00 4.00

Rv (kN) 36.20 36.20

PERIMETER BEAM 'SG3'

Factors of Safety: γG= 1.35 γ Q= 1.5

gk (kN/m)= 0.58

qk (kN/m)= 2.25

gk (kN)= 0.16 gk (kN)= 0.16

(mm) 900 3660 900

M (kNm) 1.90 1.90 5.10 1.90 1.90

V (kN) 4.00 7.60 7.60 4.00

Rp (kN) 1.80 1.80

Rv (kN) 6.10 6.10

TYPICAL TANK BEARER 'SG'

z I - section

Calculations in accordance with BS EN 1993-1-1:2005

BS EN 1993- All moments and loads are factored.

1-1:2005 Design Info:

y y h

Design bending moment about major axis Msd, = 76.00 kNm

Design shear force Vsd = 88.00 kN

tw

tf

z

b

Preliminary Sizing

Checking Moment

2

Table 3.1, Steel grade S275 fy = 275 N/mm

EN 1993-1- Assume t < 40mm Wpl,y reqd =

1:2005 3 3

Plastic Modulus, Wpl,y reqd = Msd/fy = 276.36 cm 276.36 cm

Checking Deflection w

Steel Assume simply supported, actual deflection,δ=(wL4/384EI)(5-24n2)

Designer's Limiting deflection,δlim=span/720 = L/720

Manual-6th

Ensuring deflection is within limit, Ireq=720wL4(5-24n2)/384EL N L N

Edition

(2003), pg where

1086 w=1.0gk+1.0qk = 32.31 kN/m

n=N/L

L= 3.66 m N= 0.90 m

2

n= 0.245901639 E= 2.10E+08 kN/m Ireq=

4 4

therefore; Ireq= 5.02E-05 m 5.02E-05 m

Try 254x146UB31kg/m

Steel Section Properties Mass per meter = 37 kg/m

Designer's 4

Width of flange, bf = 146.1 mm Second moment of area about yy-axis, Iyy = 4410 cm

Manual-6th Depth of section, h = 251.4 mm Radius of gyration about yy-axis, ryy = 10.5 cm

Edition

depth of web, hw = 219.0 mm Radius of gyration about zz-axis, rzz = 3.36 cm

(2003), pg 3

1168&1169 web thickness, tw = 6.0 mm Plastic modulus about the yy-axis, Wpl,y = 393 cm

3

Flange thickness, tf = 8.6 mm Elastic modulus about the yy-axis, Wel,y = 351 cm

Root radius, r = 7.6 mm Torsional Index, x = 29.6

2

Area of cross - section, A = 39.7 cm Buckling parameter, u = 0.879

Design of Overhead Water Tank Support Tower and Foundation

Job No. Sheet No. Rev.

Calculation Sheet 03 OF 21

XXXXXXXX Member/Location

Job Title: Design of Overhead Water Tank Support Tower Drg Ref.

Made By KN Date:09/2018 Chd CE

REFERENCE CALCULATIONS OUTPUT

Classification of section

for flange

BS EN 1993- tf <40mm tf = 8.6 mm Class of section

1-1:2005, Steel grade S275 Compact section

2

Table 5.2 Design strength fy = 275 N/mm Slender section

(sheets 1 of Constant, ɛ =(235/fy)= 0.92

3 & 2 of 3) Compression flange, c/t = 0.5(b -t -2 7.26

f f w

Limiting c/tf = 10ɛ = 9.24 Compact section

for web Section is ok

c/tw = hw/tw = 36.50 Class 2

Limiting c/tw = 83ɛ 76.73 Compact section Section is at least compact

Shear Buckling Check

BS EN 1993- c/tw <72ɛ/Ƞ Ƞ= 1.2 (S275)

1-5:2006, cl. 72ɛ/Ƞ = 55.46

5.1(2) therefore, the check for shear buckling resistance of the web does not need to be verified. Section is ok

Restraint Assumption

Full lateral restraint.

Shear Capacity Check

BS EN 1993- Applied shear force, VEd = 88 kN

1-1:2005 Shear area, Av = A-2bftf+(tw+2r)tf > Ƞhwtw

cl. 6.2.6(2) 1639.4 > 1576.80

Partial factor for resistance of a section, γmo= 1.05 Shear Capacity

Therefore, shear capacity Vc,Rd= Vpl,Rd= =Av(fy/sqrt3)/(γmo*1000) 247.89 kN > VEd ok

BS EN 1993- Moment Resistance Check

1-1:2005 Moment Capacity with low shear value

Cl. 6.2.5 Shear force VEd = 88 kN < 0.5Vpl,Rd 123.95 kN low shear Moment Resistance

Cl. 6.2.8 Moment Resistance Mc,Rd = Mpl,Rd =Wpl*fy/(γmo*1000) 102.93 kNm > 76 kNm ok

Lateral Torsional Buckling Check

The beam is laterally restraint, hence lateral-torsional buckling check does not need to be verified.

Deflection Checks Under Serviceability Load

Span of beam for deflection, Ls 3660 mm

BS EN 1993- For a unit load i.e w= 1 kN/m

2

1-1:2005 Modulus of Elasticity, Es = 210 kN/mm

Steel 4 2

Deflection, d = wLs (5-24n )/384EI N L N

Designer's n=N/L

Manual-6th d= 0.179 mm

Edition Permanent action,wp = 1.0gk = 2.50 kN/m

(2003), pg

Deflection d1 = wpd = 0.447 mm

1086

Variable action,wv = 1.0qk = 29.81 kN/m

Structural Deflection d2 = wvd = 5.338 mm

Engineering Limiting defelction = L s /(2*350) 5.229 mm < 5.338 mm

Pocket dmax = d1 + d2 Defection requirement

Book; 5.785 mm is satisfied

Second Limiting deflection = Ls/(2*250) = 7.32 mm > 5.785 mm

Edition;

Design of Overhead Water Tank Support Tower and Foundation

Job No. Sheet No. Rev.

Calculation Sheet 04 OF 21

XXXXXXXX Member/Location

Job Title: Design of Overhead Water Tank Support Tower Drg Ref.

Made By KN Date:09/2018 Chd CE

REFERENCE CALCULATIONS OUTPUT

Web Crushing (bearing on the web) Check

Force applied through flange, Fsd = 97.7 kN

Stiff bearing length Ss = 2(tf + r) + t 38.40 mm

Design Stress in beam flange

2

σEd = MEd/Wel,y = 216.52 N/mm

Material partial factor of safety, γM1 1.05

Length over which the effect takes place

sy = 2n = 2tf(bf/tw)^0.5*(fyf/fyw)^0.5*(1-(σEd/fyf)^2)^0.5

2 2

fyf = 275 N/mm fyw = 275 N/mm (tf , tw<40mm)

sy = 52.32 mm

Crushing Resistance/load capacity of web Load bearing capacity

Ry,Rd = ((ss + sy)twfyw)/γM1 = 142.57 kN > Fsd 97.7 kN of web ok

BS EN 1993- Web Buckling Check

2 2

1-1:2005 Effective length of web, Beff = (h + ss )^0.5

Cl. 6.3.1.3 254.32 mm

Effective height of web for buckling, L =0.7d

=0.7hw

153.3 mm

Radius of gyration of web, iweb = tw/√12

1.73 mm

Effective Area Aeff = =twBeff

2

1525.89 mm

Non dimensional slenderness, λ = (Lcr/i)*(1/λ1)

λ1 = π√(E/fy)= 86.83

OR λ1 = 93.9ɛ

therefore,

λ= 1.02

Table 6.2 h/b = > 1.2

BS EN 1993- and for buckling about the z - z axis,

1-1:2005 use curve (b)

Table 6.1 Imperfection factor α = 0.34

2

ɸ = 0.5(1+α(λ-0.2) + λ )

= 1.16

Reduction factor χ = 1/(ɸ+sqrt(ɸ2-λ2) <= 1.00

Cl. = 0.58

6.3.1.1(3) Nb,Rd (Design buckling resistance of compression member)

EN 1993-1- = χAfy/γM1 Web buckling capacity

1:2005 = 233.70 kN > Fsd 97.7 kN ok

No load carrying stiffeners is required to prevent web buckling

SECTION SUMMARY

SECTION 254x146UB31kg/m

Design Shear Force 88.00 kN

Shear Capacity 247.89 kN

Design Moment 76.00 kNm

Moment Capacity 102.93 kNm

Applied Flange Force 97.70 kN

Local Web Capacity 142.57 kN

Web Buckling Capacity 233.70 kN

Section is Adequate

Design of Overhead Water Tank Support Tower and Foundation

Job No. Sheet No. Rev.

Calculation Sheet 05 OF 21

XXXXXXXX Member/Location

Job Title: Design of Overhead Water Tank Support Tower Drg Ref.

Made By KN Date:09/2018 Chd CE

REFERENCE CALCULATIONS OUTPUT

MAIN GIRDER 'MG'

LOADING

From internal tank bearer, gk 6.10 kN qk 60.10 kN

From external tank bearer, gk 4.00 kN qk 36.20 kN

From secondary beam, gk 1.80 kN qk 6.10 kN

Factors of Safety: γG= 1.35 γ Q= 1.5

1.80 4.00 6.10 6.10 4.00 1.80 gk (kN)

6.10 36.20 60.10 60.10 36.20 6.10 qk (kN)

900 1220 1220 1220 900 (mm)

10.42 10.42 109.61 10.42 10.42 M (kNm)

11.58 98.38 98.38 11.58 V (kN)

11.90 11.90 Rp (kN)

102.40 102.40 Rv (kN)

MAIN GIRDER 'MG' DESIGN

z I - section

Calculations in accordance with BS EN 1993-1-1:2005

BS EN 1993- All moments and loads are factored.

1-1:2005 Design Info:

y y h

Design bending moment about major axis Msd, = 109.61 kNm

Design shear force Vsd = 98.38 kN

tw

tf

z

b

Preliminary Sizing

Checking Moment

2

Table 3.1, Steel grade S275 fy = 275 N/mm

EN 1993-1- Assume t < 40mm Wpl,y reqd =

1:2005 3 3

Plastic Modulus, Wpl,y reqd = Msd/fy = 398.58 cm 398.58 cm

Alternatively,

Steel Checking Deflection

Designer's Since the maximum moment occur at the midspan, midpsan loads are critical for sizing;

3

Manual-6th δmax = 23PL /648EI P= 1.0 gk + 1.0qk L= 3.66 m

Edition Limiting deflection,δlim=span/720 = L/720 66.20 kN

(2003), pg To ensure deflection is within limits,I =then

720*(23PL2)/648E Ireq=

1083 4 4

I= 1.08E-04 m 1.08E-04 m

Try 305x165UB40kg/m

Steel Section Properties Mass per meter = 54 kg/m

Designer's 4

Width of flange, bf = 165.0 mm Second moment of area about yy-axis, Iyy = 8500 cm

Manual-6th Depth of section, h = 303.4 mm Radius of gyration about yy-axis, ryy = 12.9 cm

Edition

depth of web, hw = 265.2 mm Radius of gyration about zz-axis, rzz = 3.86 cm

(2003), pg 3

1168&1169 web thickness, t w = 6.0 mm Plastic modulus about the yy-axis, Wpl,y = 623 cm

3

Flange thickness, tf = 10.2 mm Elastic modulus about the yy-axis, Wel,y = 560 cm

4

Root radius, r = 8.9 mm Torsional constant, It = 14.7 cm

2

Area of cross - section, A = 51.3 cm Buckling parameter, u = 0.889

4 6

Second moment of area about zz-axis, I 764 cm Warping constant, Iw = 0.164 dm

Design of Overhead Water Tank Support Tower and Foundation

Job No. Sheet No. Rev.

Calculation Sheet 06 OF 21

XXXXXXXX Member/Location

Job Title: Design of Overhead Water Tank Support Tower Drg Ref.

Made By KN Date:09/2018 Chd CE

REFERENCE CALCULATIONS OUTPUT

Classification of section

for flange

BS EN 1993- tf <40mm tf = 10.2 mm Class of section

1-1:2005, Steel grade S275 Compact section

Table 5.2 Design strength fy = 275 N/mm

2

Slender section

(sheets 1 of

Constant, ɛ =(235/fy)= 0.92

3 & 2 of 3)

Compression flange, c/tf = 0.5(bf-tw-2 6.92

Limiting c/tf = 10ɛ = 9.24 Compact section

for web Section is ok

c/tw = hw/tw = 44.20 Class 2

Limiting c/tw = 83ɛ 76.73 Compact section Section is at least compact

Shear Buckling Check

BS EN 1993- c/tw <72ɛ/Ƞ Ƞ= 1.2 (S275)

1-5:2006, cl. 72ɛ/Ƞ = 55.46

5.1(2) therefore, the check for shear buckling resistance of the web does not need to be verified. Section is ok

Shear Capacity Check

BS EN 1993- Applied shear force, VEd = 98.38 kN

1-1:2005 Shear area, Av = A-2bftf+(tw+2r)tf > Ƞhwtw

cl. 6.2.6(2) 2006.76 > 1909.44

Partial factor for resistance of a section, γmo= 1.05 Shear Capacity

Therefore, Plastic shear resistance VVpl,Rd= =Av(fy/sqrt3)/(γmo*1000) 303.44 kN > 98.38 kN (VEd) ok

BS EN 1993- Moment Resistance Check

1-1:2005 Moment Capacity with low shear value

Cl. 6.2.5 Shear force VEd = 98.38 < 0.5Vpl,Rd =151.72 kN low shear Moment Resistance

Cl. 6.2.8 Moment Resistance Mc,Rd = Mpl,Rd =Wpl*fy/(γmo*1000) 163.17 kNm > 109.61 kNm ok

Lateral - Torsional Buckling Check

Since the beam is subject to possible lateral - torsional buckling, the buckling resistance moment is considered.

BS EN 1993- Length between adjacent restraint, L 3600 mm

2 2

1-1:2005 χLT = 1/(ɸLT + sqrt(ɸLT - βλLT ))

2 2 2

Cl. 6.3.2.3 ɸLT = 0.5(1 + αLT(λLT - λLT,O) + βλLT π EIz/Lcr = 1222137.34

λLT = sqrt(Wpl,yfy)/Mcr Iw/Iz= 21465.96859

Mcr = (π2EIz/Lcr2)*((Iw/Iz) + (Lcr2GIt/π2EIz))^0.5 Lcr2GIt/π2EIz= 9715.010366

G=E/2(1+v) v= 0.3

2

Therefore; G = 80769.23 N/mm

Mcr = 215.81 kNm

λLT = 0.8910

λLT,O = 0.2

β= 0.75

Cl. 6.3.2.2(4) λLT > λLT,O lateral torsional buckling cannot be ignored. curve c curve b

Table 6.5 h/b > 2 1.84 > 2 curve b

Table 6.3 αLT = 0.34

ɸLT = 0.915

χLT = 0.68 <= 1

2 ok

<= 1/λLT = 1.26

Cl. 6.3.2.1(3) Design buckling resistance moment χMLTWyfy/γM1=

110.20 kNm > MEd ok Section is adequate.

Design of Overhead Water Tank Support Tower and Foundation

Job No. Sheet No. Rev.

Calculation Sheet 07 OF 21

XXXXXXXX Member/Location

Job Title: Design of Overhead Water Tank Support Tower Drg Ref.

Made By KN Date:09/2018 Chd CE

REFERENCE CALCULATIONS OUTPUT

Deflection Checks Under Serviceability Load

Span of beam for deflection, Ls 3660.00 mm

BS EN 1993- For a unit load i.e P= 1 kN/m

2

1-1:2005 Modulus of Elasticity, Es = 210 kN/mm

Steel 3

Deflection d = 23PL /648EI

Designer's = 9.74895E-05 m

Manual-6th = 0.0975 mm

Edition

(2003), pg Permanent action,w = 1.0g = 6.10 kN

p k

1083

Deflection d1 = wpd = 0.595 mm

Variable action,wv = 1.0qk = 60.10 kN

Structural

Engineering Deflection d2 = wvd = 5.859 mm

Pocket Limiting defelction = Ls/(2*360) 5.08 mm > 5.859

Book; dmax = d1 + d2

Second 6.454 mm Deflection requirement is

Edition; Limiting deflection = Ls/(2*250) = 7.32 mm > 6.454 mm ok

2009 (pg 72)

Web Crushing Check

BS EN 1993- FRd = fywLefftw/γM1

1-5:2006 leff = χf ly

Cl. 6.2 ly = le + tf sqrt((m1/2)+(le/tf)^2 +m2

Cl. 6.5(3) or ly = le + tf sqrt(m1+m2) whichever is smaller

2

Cl. 6.5(1) m1 = fyf bf/fywtw fyf=fyw= 275 N/mm

m1 = 27.50 (tf & tw < 40mm)

Assume λf > 0.5

m2 = 0.02(hw/tf)^2

= 13.52

2

le = kfEtw /(2fywhw)

Cl. 6.1; fig. 6.1 kf = 2 + 6((ss+c)/hw) ss = 2(T+r)+tw = 44.2 mm

= 3.00 c= 0

le = 155.49 mm

ly = 319.85 mm

or ly = 220.82 mm ly = 220.82 mm

Cl. 6.4(1) Reduction Factor χf

χf = 0.5/λf λf = sqrt(lytwfyw/Fcr)

Fcr = 0.9kfEtw3/hw 461809.95 N

λf = 0.888 > 0.5 ok

χf = 0.563 < 1.0

leff = 124.30 mm

FRd = 195.33 kN > 109.96 kN ok

Design of Overhead Water Tank Support Tower and Foundation

Job No. Sheet No. Rev.

Calculation Sheet 08 OF 21

XXXXXXXX Member/Location

Job Title: Design of Overhead Water Tank Support Tower Drg Ref.

Made By KN Date:09/2018 Chd CE

REFERENCE CALCULATIONS OUTPUT

Web buckling check

BS EN 1993- Buckling resistance of web, Nb,Rd = χAfy/γM1

1-1:2005 A = twBeff

2 2

Cl. 6.3.1.1(3) Beff = (h + ss )^0.5 306.60 mm

2

A= 1839.62 mm

2 2

Cl. 6.3.1.2 χ = 1/(ɸ + sqrt(ɸ -λ )

ɸ= 0.5(1 + α(λ - 0.2) + λ2

λ= (Lcr/i)*(1/λ1) Lcr = 0.7d 185.64 mm

iweb = tw/sqrt12 1.73 mm

λ1 = 93.9ɛ 86.80

λ= 1.23

BS EN 1993- α (imperfection factor):

1-1:2005, h/b>1.2 1.84 > 1.2

Table 6.1 & Use buckling curve b (buckling about z - z axis)

6.2 therefore α = 0.34

ɸ= 1.44

χ= 0.46 < 1.0 ok Nb,Rd

Nb,Rd = 221.45 kN 221.45 kN

Nb,Rd > NEd Web buckling capacity

SECTION SUMMARY ok

SECTION 305x165UB40kg/m

Design Shear Force 98.38 kN

Shear Capacity 303.44 kN

Design Moment 109.61 kNm

Moment Capacity 163.17 kNm

Applied Flange Force 109.96 kN

Local Web Capacity 195.33 kN

Web Buckling Capacity 221.45 kN

Section is Adequate

Design of Overhead Water Tank Support Tower and Foundation

Job No. Sheet No. Rev.

Calculation Sheet 09 OF 21

XXXXXXXX Member/Location

Job Title: Design of Overhead Water Tank Support Tower Drg Ref.

Made By KN Date:09/2018 Chd CE

REFERENCE CALCULATIONS OUTPUT

Clause 4.4.2 Preliminary Sizing of Tower Members (Refer to Drawing No. 2018-194, sht 05 of 08)

of Stanchions (Legs)

ANSI/TIA/E Unbraced length, lo = 3000 mm ≈ 3m

IA-222-G: Effective length factor, k = 1.00 (Clause 4.5, TIA 222-G)

Structural Limiting slenderness ratio = klo/rzz = 150

Standards therefore, rzz(req) = klo/150 = 20 mm Try

for Antenna = 2.00 cm 203x203UC46kg/m

Supporting

Length of member = 27.00 m Width of section = 0.2036 m Nos = 2 rzz = 5.13cm

Structures

Horizontal Bracing

and

Unbraced length, lo = 3660 mm

Antennas.

Effective length factor, k = 1.00

Limiting slenderness ratio = klo/rvv = 200

therefore, rvv(req) klo/200 = 18.3 mm Try 100EA8

= 1.83 cm rvv 1.96cm

Length of member = 3.66 m Width of section = 0.10 m Nos = 9

Diagonal (cross) Bracing

Unbraced length, lo = 3514.10 mm

Effective length factor, k = 1.00

Limiting slenderness ratio = klo/rvv = 300

therefore, rvv(req) klo/300 = 11.71 mm Try 80EA8

= 1.17 cm rvv 1.56cm

Length of member = 3.51 m Width of section = 0.08 m Nos = 18

Calculation of effective areas for wind loading

2

Legs: 203x203UC46 10.9944 m

2

Horizontal Bracing: 100EA8 3.294 m

2

Diagonal (cross) Bracing: 80EA8 5.06 m

2

Total Effective Areas for Wind on Tower = 19.35 m

Tower

Height of Tower, HT: 27.00 m

Height to Top of Tower: 29.99 m

Width at Top: 3.66 m

Width at Bottom: 3.66 m

Classification of Structure

Structure is class II (table 2.1; ANSI/EIA/TIA 222-G)

Wind Direction Probability factor, k 0.85 (Table 2.2)

Importance Factor, I = 1.00 (Table 2.3)

Cl 2.6.6.2 & Topographic Factor, kzt = 1.00

2.6.6.4 (category 1)

Cl 2.6.5.1 Exposure Category C

Cl 2.6.5.2 Exposure Category Coefficients (Table 2.4):

zg = 274 m

α= 9.5

kzmin = 0.85

ke = 1.00

Height above ground level, z: 29.99 m

Wind Speed, V: 32 m/s

Cl 2.6.7.1 Gust Response Factor, Gh: 0.85

Projected Area of Structural Components, Af :

2

For tank 13.40 m

2

For tower 19.35 m

Gross Area, Ag:

2

For tank 13.40 m

2

For tower 104.32 m

Cl 2.6.9.1.1 Solidity Ratio, ξ = Af/Ag

For tank 1.00

For tower 0.19

Table 2.6 Directional Factors, Df :

ANSI/EIA/T Normal to Face= 1.00

For Tank o

IA 222-G 45 to Face= 1.20 max

Normal to Face= 1.00

for Tower o

45 to Face= 1.1325

Design of Overhead Water Tank Support Tower and Foundation

Job No. Sheet No. Rev.

Calculation Sheet 10 OF 21

XXXXXXXX Member/Location

Job Title: Design of Overhead Water Tank Support Tower Drg Ref.

Made By KN Date:09/2018 Chd CE

REFERENCE CALCULATIONS OUTPUT

Loading

Tank Loads:

Height to top of tank, z = 29.99 m

2/α

Cl 2.6.5.2 Velocity Pressure Coefficient, kz = 2.01(z/zg)

= 1.26 kz = 1.26

kzmin <= kz ok

kz <= 2.01 ok

2

Cl 2.6.9.6 Velocity Pressure, qz = 0.613kzkztkdV I

2

= 0.673 kN/m

Reynolds Force coefficients for Tank, Cf :

examples of h/b = 8.20

design of RC b/d = 1.00

buildings to Cf = 1.1

BS 8110 (pg

238)

Cl 2.6.9.1.1 Effective Projected Area, EPA = DfCfAf

Normal to face = 14.735 m2

@ 45o to face = 17.682 m2

Cl 2.6.9.1 Wind Load on Tank, FST1 = qzGh(EPA)s

Normal to face = 8.43 kN

@ 45o to face = 10.12 kN

Tower Loads

Mid -height from ground, z = 9.00 m

2/α

Cl 2.6.5.2 Velocity Pressure Coefficient, kz = 2.01(z/zg)

= 0.979

kzmin <= kz ok

kz <= 2.01 ok

2

Cl 2.6.9.6 Velocity Pressure, qz = 0.613kzkztkdV I

2

= 0.522 kN/m

2

Cl 2.6.9.1.1 Force coefficient for Tower, Cf = 4.0ξ - 5.9ξ + 4

= 3.04

Cl 2.6.9.1.1 Effective Projected Area, EPA = DfCfAf

2

Normal to face = 58.88 m

2

@ 45o to face = 66.69 m

Cl 2.6.9.1 Wind Load on Tower, FST2 = qzGh(EPA)s

Normal to face = 26.15 kN

@ 45o to face = 29.61 kN

Overturning Moments at Tower Base

Wind normal to face (CASE 1)

From Tank = FST1*(z - 0.5D) 242.61 kNm

From Tower = FST1*0.5HT 353.02 kNm

Total, SF (kN) = 34.58 595.63 kNm

o

Wind @ 45 to face (CASE 2)

From Tank = FST2*(z - 0.5D) 291.13 kNm

From Tower = FST2*0.5HT 399.80 kNm

Total, SF (kN) = 39.73 690.93 kNm

NOTE: Vertical bracing will be design to suit CASE 1 loading and the towe legsand its holding system will be design to suit CASE 2 loading.

Load Cases and Combinations

Two wind directions have been considered for the tower - tank assembly ( i.e normal to face and diagonal to face). Wind normal or perpendicular to tower

face will produce maximum stress in the bracing, while wind @ 45o to the face will result in maximum stress in the legs. For each wind direction, three load

combinations (dead, imposed, wind) are considered at the SLS and ULS.

Additional load schedule (from selfweight of designed members)

Member Self weight (kN/m) Length (m) Nos. Total (kN)

254x146UB31kg/m 0.311 5.46 4 6.792

305x165UB40kg/m 0.403 5.46 2 4.401

203x203UC46kg/m 0.460 27.00 4 49.68

100EA8 0.122 3.66 36 16.075

80EA8 0.0963 3.51 72 24.365

254x89 0.417 5.46 2 4.554

Total = 105.867

Design of Overhead Water Tank Support Tower and Foundation

Job No. Sheet No. Rev.

Calculation Sheet 11 OF 21

XXXXXXXX Member/Location

Job Title: Design of Overhead Water Tank Support Tower Drg Ref.

Made By KN Date:09/2018 Chd CE

REFERENCE CALCULATIONS OUTPUT

Axial load on diagonal column, Wk +/-

= 690.93/sqrt(2x3.66^2) +/- 133.49 kN

Permanent load per column, Gk = 11.90+(105.867/4) = 38.37 kN

Variable load per column, Qk = 102.40 kN

How to Load Combination 1: Permanent + Variable loads (STR)

design to Ultimate : 1.35Gk + 1.5Qk= 205.40 kN

Eurocode 2; Service : 1.0Gk+1.0Qk = 140.77 kN

Load Combination 2: Permanent + Variable + leading Variable i.e wind (STR)

EN1990 Variable load (accompanying) = γQ1Ψ1Qki Ψ1 = 0.9

:2002 1.35Gk + 1.35Qk + 1.5Wk = 390.27 kN Max Compression

Ultimate :

Tables A1.1, 1.35Gk + 1.35Qk - 1.5Wk = -10.20 kN Tension

A1.2, A1.4 1.0Gk + 1.0Qk + 1.0Wk = 274.25 kN

Service : All Compression

1.0Gk + 1.0Qk - 1.0Wk = 7.28 kN

EN Load Combination 3: Permanent + Variable (wind) loads (EQU)

1990:2002, 1.0Gk+1.5Wk = 238.60 kN Compression

Ultimate :

Table 0.9Gk-1.5Wk = -165.70 kN Tension, to be held

A1.2(A) down

Tower Member Forces

Maximum load, N = 390.27 kN Compression

Coulmns: Minimum load, T = -165.70 kN Tension

Associated shear force per leg = 14.90 kN

From wind load = 1.5*(SF/2) = 25.94 kN

Horizontal Bracing:

2.5% of force in restrained member = 9.76 kN

Total = 35.69 kN

2 2

Diagonal Bracing: Ft = (√(6 +3.66 )/3.66)*Horizontal Force = 68.54 kN

Design of Overhead Water Tank Support Tower and Foundation

Job No. Sheet No. Rev.

Calculation Sheet 12 OF 21

XXXXXXXX Member/Location

Job Title: Design of Overhead Water Tank Support Tower Drg Ref.

Made By KN Date:09/2018 Chd CE

REFERENCE CALCULATIONS OUTPUT

Typical Sanchion Design

BS EN 1993- NEd Axially loaded Column

1-1:2005 Calculations in accordance with BS EN 1993-1-1:2005

Compressive load is factoredmand length between restraint is the same for both axes.

Design Axial Compressive Load, NEd = 390.27 kN

h

Length between restraints, L = 3000 mm

≈ 3m

Section Properties: From Steel Detailers & Steel Designers Manuals

203x203UC46 kg/m Mass per meter = 46.1 kg/m

4

Section Properties Iyy = 4570 cm

Second moment of area = 4

Width of flange, bf = 203.2 mm Izz = 1550 cm

Depth of section, h = 203.2 mm Radius of gyration about yy-axis, ryy = 8.82 cm

depth of web, d = 160.8 mm Radius of gyration about zz-axis, rzz = 5.13 cm

3

web thickness, tw = 7.3 mm Wpl,y = 497 cm

Plastic modulus: 3

Flange thickness, tf = 11 mm Wpl,z = 231 cm

3

Root radius, r = 10.2 mm Wel,y = 450 cm

2 Elastic modulus: 3

Area of cross - section, A = 58.7 cm Wel,z = 152 cm

2 4

Modulus, E = 210 kN/mm Torsional Constant, It = 22.2 cm

6

Warping Constant, Iw = 0.143 dm

BS EN 1993- tf <40mm tf = 11 mm Class of section

1-1:2005, Steel grade S275 Compact section

Table 5.2 Design strength fy = 275 N/mm

2

Slender section

(sheets 1 of

Constant, ɛ =(235/fy)= 0.92

3 & 2 of 3)

Compression flange, c/tf = 0.5(bf-tw-2r)/t 7.98

Limiting c/tf = 14ɛ = 12.94 Cl 5.5.2(10) Compact section

for web Section is ok

c/tw = d/tw = 22.03 Class 2

Limiting c/tw = 124ɛ 114.63 Cl 5.5.2(10) Compact section Section is at least compact

For Buckling about z-z axis

Compressive Strength:

Applied Compressive Force, NEd = 390.27 kN

Effective length of Column, Lcr = LE = 3000 mm

Radius of Gyration, rzz = 51.30 mm

2

Effective Area, Aeff = 5870 mm

93.9ɛ

Slenderness Parameter, λ1 = 86.80

Cl 6.3.1.2 Non-dimensional Slenderness, λ

(Lcr/i)*(1/λ1) 0.67

BS EN 1993- α (imperfection factor):

1-1:2005, h/b<1.2 1.00 < 1.2

Table 6.1 & Use buckling curve c (buckling about z - z axis)

6.2 therefore α = 0.49

2

Cl.6.3.1.2 ɸ = 0.5(1+α(λ-0.2)+λ = 0.84

2 2

χ(Reduction factor) = 1/(ɸ + sqrt(ɸ -λ ) 0.74

Material Partial factor of safety γM1 1.05

Cl 6.3.1.1(3) Nb,Rd = χAfy/γM1 1139.04 kN

Cl 6.3.1.1(1) Since Nb,Rd > NEd Use 203x203UC46kg/m

3

Section is ok Wpl,z = 231 cm

Design of Overhead Water Tank Support Tower and Foundation

Job No. Sheet No. Rev.

Calculation Sheet 13 OF 21

XXXXXXXX Member/Location

Job Title: Design of Overhead Water Tank Support Tower Drg Ref.

Made By KN Date:09/2018 Chd CE

REFERENCE CALCULATIONS OUTPUT

Typical Horizontal Bracing Design

z

Axially Loaded

v u

Calculations in accordance with BS EN 1993-1-1:2005.

Compressive load is factored and length between restraints is the same for both axes.

h

y y

v

u z

b Design axial compressive load, NEd = 35.69 kN

Length between restraints, L = 3660 mm

Section Properties : From Steel Designers Manual (6th Edition)

100EA8 Mass per meter = 12.2 kg/m

4

depth of web, h = 100 mm Second moment of area, Iuu = 230 cm

4

width of section, b = 100 mm Ivv = 59.9 cm

flange thickness, t = 8 mm Radius of gyration, iyy,izz = 3.06 cm

root radius: r1 = 12 mm iuu = 3.85 cm

r2 = 6 mm ivv = 1.96 cm

2 3

Area of section, A = 15.5 cm Elastic modulus, Wel.y,Wel,z = 19.9 cm

2

Distance of centre of gravity, c = 2.74 cm Youngs modulus, E = 210 kN/mm

4

Second moment of area: Iyy, Izz = 145 cm

Classification of Section

2

Table 3.1 tf<40mm fy = 275 N/mm

Constant, ɛ =(235/fy)= 0.92

Table 5.2; h/t < 15ɛ 12.5 < 13.87 Compact section

Sht 3 of 3 h+b/(2t) < 11.5ɛ 12.5 < 10.63 Slender section

Section is slender. Therefore strength reduction or equivalent section should be carried out for the RSA

therefore, heff = beff = 11.5ɛt = 85.05 mm

2

Effective area, Aeff = A-2t(h-heff) = 1310.74 mm

BS 5950-1: Slenderness

2000; Cl Effective lengths:

4.7.3 Effective lengths between restraints, lo = 3660 mm

about v - v axis, lvv = 0.85lo = 3111 mm

about axis parallel to connected leg, lyy = 0.85lo = 3111 mm

about axis peerpendicular to connected leg, lzz = 1.0lo = 3660 mm

Since end connection is made by bolts or equivalent weld,

BS EN 1993- Effective Slenderness: is greater of;

1-1:2005 & (a) lvv/93.9ɛivv and 0.35+0.7λv = 0.35+(0.7lvv/93.9Unsymmetrical bending

BB1.2 1.83 1.63

(Appendix) (b) lyy/93.9ɛiyy and 0.5+0.7λy = 0.5+(0.7lyy/93.9ɛIn-plane bending

1.17 1.32

(c) lzz/93.9ɛizz and 0.5+0.7λz = 0.5+(0.7lzz/93.9ɛOut-of-plane bending

1.38 1.46

Therefore, Effective slenderness ratio λeff = λmax = 1.83

Table 6.2 For L - sections, use buckling curve (b)

Table 6.1 Imperfection factor, α = 0.34

2

Cl 6.3.1.2 ɸ = 0.5(1+α(λ-0.2)+λ = 2.45

2 2

χ(Reduction factor) = 1/(ɸ + sqrt(ɸ -λ ) 0.25

Material Partial factor of safety γM1 1.05

Design buckling resistance of web Nb,Rd = χAfy/γM1

Cl 6.3.1.1(3) 84.20 kN Compressive capacity is

Nb,Rd > NEd Section is ok adequate

BS EN 1993- Tensile Resistance

1-8:2005; Cl say; Applied tensile force, NEd = 35.69 kN

3.10.3 Hole diameter, do = bolt diameter + 2mm (assume ø20mm bolt)

do = 20+2 22 mm

Table 3.3 Minimum end (e1) and edge (e2) distances

1.2do == 26.4 mm

Maximum end (e1) and edge (e2) distances = 8t or 125mm (whichever is greater)

Thickness of section = 8 mm

BS EN 1993- With one bolt,

1-8:2005; Cl Nu,Rd = 2.0(e2-0.5do)tfu/γM2

3.10.3(2) fu = fub (ultimate tensile strength for bolt) = 800 N/mm2 (Bolt class 8.8) Design axial tensile load

Cl 3.1.1; γM2 = 1.25 (Cl 2.2, Table 2.1) does not exceed tensile

Table 3.1 Nu,Rd = 157.70 kN resistance of section.

Nu,Rd > NEd Section is ok section is adequate.

Use one bolt at each end

Design of Overhead Water Tank Support Tower and Foundation

Job No. Sheet No. Rev.

Calculation Sheet 14 OF 21

XXXXXXXX Member/Location

Job Title: Design of Overhead Water Tank Support Tower Drg Ref.

Made By KN Date:09/2018 Chd CE

REFERENCE CALCULATIONS OUTPUT

Typical Horizontal Bracing Design

z

Axially Loaded

v u

Calculations in accordance with BS EN 1993-1-1:2005.

Compressive load is factored and length between restraints is the same for both axes.

h

y y

v

u z

b Design axial compressive load, NEd = 68.54 kN

Length between restraints, L = 3514.10 mm

Section Properties : From Steel Designers Manual (6th Edition)

80EA8 Mass per meter = 9.63 kg/m

4

depth of web, h = 80 mm Second moment of area, Iuu = 115 cm

4

width of section, b = 80 mm Ivv = 29.9 cm

flange thickness, t = 8 mm Radius of gyration, iyy,izz = 2.43 cm

root radius: r1 = 10 mm iuu = 3.06 cm

r2 = 5 mm ivv = 1.56 cm

2 3

Area of section, A = 12.3 cm Elastic modulus, Wel.y,Wel,z = 12.6 cm

2

Distance of centre of gravity, c = 2.26 cm Youngs modulus, E = 210 kN/mm

4

Second moment of area: Iyy, Izz = 72.2 cm

Classification of Section

2

Table 3.1 tf<40mm fy = 275 N/mm

Constant, ɛ =(235/fy)= 0.92

Table 5.2; h/t < 15ɛ 10 < 13.87 Compact section Section is Class 3

Sht 3 of 3 h+b/(2t) < 11.5ɛ 10 < 10.63 Compact section compact

TIA 222-G Checking Limiting Slenderness

4.4.2 & 4.5 Since horizontal bracing is continuous through the cross-over point,

Effective length factor, k = 1

Effective length, LE = 3514.10 mm

Slendernes, λ = LE/ivv = 225

Limiting slenderness, λlim = 300

λ <= λlim ok

BS EN 1993- Tensile Resistance

1-8:2005; Cl say; Applied tensile force, NEd = 68.54 kN

3.10.3 Hole diameter, do = bolt diameter + 2mm (assume ø20mm bolt)

do = 20+2 22 mm

Table 3.3 Minimum end (e1) and edge (e2) distances

1.2do == 26.4 mm

Maximum end (e1) and edge (e2) distances = 8t or 125mm (whichever is greater)

Thickness of section = 8 mm

2

Net cross - sectional area of connected leg, a1 = (h-(t/2)-do)t = 432 mm

2

Net cross - sectional area of unconnected leg, a2 = (b-(t/2))t = 608 mm2

Effective area, Anet = a1+a2(3a1/(3a1+a2)) = 845.85 mm

BS EN 1993- With one bolt,

1-8:2005; Cl Nu,Rd = 2.0(e2-0.5do)tfu/γM2

3.10.3(2) fu = fub (ultimate tensile strength for bolt) = 800 N/mm2 (Bolt class 8.8) Design axial tensile load

Cl 3.1.1; γM2 = 1.25 (Cl 2.2, Table 2.1) does not exceed tensile

Table 3.1 Nu,Rd = 157.70 kN resistance of section.

Nu,Rd > NEd Section is ok section is adequate.

Use one bolt at each end

Design of Overhead Water Tank Support Tower and Foundation

Job No. Sheet No. Rev.

Calculation Sheet 15 OF 21

XXXXXXXX Member/Location

Job Title: Design of Overhead Water Tank Support Tower Drg Ref.

Made By KN Date:09/2018 Chd CE

REFERENCE CALCULATIONS OUTPUT

Column Base Plate y

hc

z z

Bp

tp

Dp Dp

Slab base y

Axial compressive load, NEd = 390.27 kN

Shear on base in z-z direction, Vsd 14.90 kN

Cl 4.13.2.1 Using the Effective area method,

dc

BS 5950

2

Effective Area, A = 4c +(2hc+4bc-2tw)c+hwtw+2bctf-2tftw c

Given that;

hc = 203.2 mm

bc

bc = 203.2 mm

tf = 11 mm

c

tw = 7.3 mm

2 2c+tw

Thus, effective loaded area, A = 4c +1206.4c+5783.84 (1) 2c+tf

2

Table 3.1 Assume t > 40mm; fy 255 N/mm hc

2

BS EN 1993- Assume grade of concrete, fcu = 30 N/mm

2

1-1:2005

BS EN 1992- Concrete characteristics cylinder strength, fck = 25 N/mm

1; Cl Concrete compressive strength, fcd =αccfck/γc γc = 1.5 (Cl 2.4.2.4; EN 1992-1) αcc = 0.85

2

3.1.6(1) fcd = 14.17 N/mm

2

BS EN 1993- Design bearing strength, fjd = 0.67fcd 9.49 N/mm

2

1-1:2005 But area of base plate required, Ap' =NEd/fjd = 41116.65 mm (2)

Cl 6.2.5(7) Equating (1) and (2),

2

4c +1206.4c+5783.84 = 41116.65 (3)

Solving the above quadratic equation i.e. eqn (3), we have

c= 26.89 mm or -328.49 mm

therefore use c = 26.89 mm

Thickness of base plate required;

Cl 6.2.5(4) tp = c/(fy/(3fjdγmo))^0.5 = γmo = 1 (Table 2.1 EN 1993-1-8) tp(req) = 8.99mm

tp = 8.99 mm tp(prov) = 20mm

2

provide tp = 20 mm fyp = 275 N/mm

Base plate thickness > column flange thickness ok

therefore, Minimum length of plate, Dp(min) = 2c+hc = 256.98 mm

Minimum width of plate, Bp(min) = 2c+bc = 256.98 mm

Use 350x350x20mm thick plate.

Design of Overhead Water Tank Support Tower and Foundation

Job No. Sheet No. Rev.

Calculation Sheet 16 OF 21

XXXXXXXX Member/Location

Job Title: Design of Overhead Water Tank Support Tower Drg Ref.

Made By KN Date:09/2018 Chd CE

REFERENCE CALCULATIONS OUTPUT

BS EN 1993- Holding Down Bolts

1-8:2005 Axial uplift force, Ft,Ed = -165.70 kN

Accompanying shear force on base, Fv,Ed = 14.90 kN

Table 3.4 Bolts in Tension

Applied force on bolt, Ft,Ed = 165.70 kN

Number of bolts to be used, n = 4

Bolt diameter, bd = 20 mm

2

Tensile stress area, As = 245 mm (From Table 4.22, Design of

structural elements by Chanakya Arya)

2

Table 3.1 Ultimate tensile strength, fub = 800 N/mm (Bolt class 8.8)

Tension force per bolt, Ft,Ed,1 = Ft,Ed/n = 41.43 kN

Tension resistance per bolt, Ft,Rd = k2fubAs/γM2 =

Cl 2.2, Table γM2 = 1.25

2.1 k2 = 0.9

therefore, Ft,Rd = 141.12 kN Tension capacity of bolt

Ft,Rd > Ft,Ed,1 ok is adequate.

Table 3.4 Bolt in Shear

Applied shear force on bolt, Fv,Ed = 14.90 kN

Shear per bolt, Fv,Ed,1 = 3.72 kN

Shear resistance per shear plane, Fv,RdαvfubA/γM2 =

αv = 0.6

γM2 = 1.25

Fv,Rd = 94.08 kN

Fv,Rd > Ft,Ed,1 ok

Table 3.4 Combined Shear and Tension

Unity Check

(Fv,Ed/Fv,Rd)+(Ft,Ed/1.4Ft,Rd) ≤ 1.0 Bolt size and numbers are

0.25 ≤ 1.0 adequate

EN 1993-1- Column to baseplate welds

8: 2005; Cl Assumed leg length of weld, s = 6 mm

Throat thickness, a = 0.7s = 4.2 mm (EN 1993-1-8:2005; 4.5.2 & BS 5950-1-2000; 6.8.7.1)

Cl 4.5.1 Length of weld carrying axial load, l4h+2d-2a 1126 mm

Cl 4.5.3.3(1) Stress on weld due to compression, fNEd/l1 = 346.59 N/mm

stress on weld due to uplift, ft = Ft,Ed/l1 = 147.16 N/mm

length resisting shear force, lw = l1 = 1126 mm

Stress on weld due to shear, fw = vsd/lw = 13.23 N/mm

2 2

Resultant force, Fr = √(fc + fw ) = 346.85 N/mm

Shear stress accompanying uplift, fwuvsd/lw = 13.23 N/mm

2 2

Resultant force, Fru = √(ft + fwu ) = 147.75 N/mm

Critical resultant force, Fcrit = max(Fr,Fru) = 346.85 N/mm

therefore, design weld force per unit weld Fw,Ed = Fcrit = 346.85 N/mm

Cl 1993-1-1 Design shear strength of weld, Fvw,d (fu/√3)/(βwγm2)

EN4.5.3.3(3)

2

:2005, table fu = 430 N/mm ( t of weaker part < 40mm, S275)

3.1 βw = 0.85 (EN 1993-1-8:2005; table 4.1)

γm2 = 1.25 (Cl 2.2, table 2.1)

2

Fvw,d = 233.66 N/mm

Cl 4.5.3.3(2) Design resistance per unit length, Fw,Rd

Fvw,da 981.36 N/mm Weld capacity ok

Fw,Ed < Fw,Rd weld chosen is suitable 6mm fillet weld all round.

Design of Overhead Water Tank Support Tower and Foundation

Job No. Sheet No. Rev.

Calculation Sheet 17 OF 21

XXXXXXXX Member/Location

Job Title: Design of Overhead Water Tank Support Tower Drg Ref.

Made By KN Date:09/2018 Chd CE

REFERENCE CALCULATIONS OUTPUT

Gk= 38.37 Gk= 38.37

Qk= 102.40 Qk= 102.40

Wk = 0 Wk = 133.49

Gk, Qk, Wk in kN

3600

Gk= 38.37 Gk= 38.37

Qk= 102.40 Qk= 102.40

Wk = -133.49 Wk= 0

3600

0

Wind Direction Wind at 45

Gk= 38.37 Gk= 38.37

Qk= 102.40 Qk= 102.40

Wk = -81.37 Wk = 81.37

Wind Direction Gk, Qk, Wk in kN

3600

Gk= 38.37 Gk= 38.37

Qk= 102.40 Qk= 102.40

Wk= -81.37 Wk= 81.37

3600

Wind normal to face

Bending moment normal to face = 595.63 kNm

Force = M/D (Moment = Force(F)xDistance(D))

= 162.74 kN

wind load per leg (Wk) = 81.37 kN

Design of Overhead Water Tank Support Tower and Foundation

Job No. Sheet No. Rev.

Calculation Sheet 18 OF 21

XXXXXXXX Member/Location

Job Title: Design of Overhead Water Tank Support Tower Drg Ref.

Made By KN Date:09/2018 Chd CE

REFERENCE CALCULATIONS OUTPUT

Wind Loading

Wind normal to tower (wind direction D1)

Force on staging (tower) = 26.15 kN

Force on platform + tank = 8.43 kN

Wind at 450 to tower (wind direction D2)

Force on staging (tower) = 29.61 kN

Force on platform + tank = 10.12 kN

Overturning moment at tower base (at service)

Mo = 690.93 kNm

Reinforced

Soil stress in base τ = P± M

concrete

A Z

design by

Mosley and For a square footing (base), Z = I = BD3 x 2 = BD2

Bungey; 6th y 12 D 6

2

edition also, B = D = L; A = BD = L

therefore,τ = P ± 6M

2 3 (1)

L L

Total axial load (at service) - TANK FULL (condition 1)

Note: (203x203UC46kg/m) 49.68 kN

permanent load per column = 38.37 kN

therefore, P = 563.07 kN

eqn (1) becomes, τ = 563.07 ± 4145.59

2 3

L L

3

τL = 563.07L ± 4145.59

Assume a base slab thickness h = 450 mm

2

weight of base slab = 11.25 kN/m

2

Allowable soil bearing capacity = 140 kN/m

2

Net soil bearing capacity, τ = τnet = 128.75 kN/m

eqn (1) further becomes 128.75L3 = 563.07L ± 4145.59

3

= 128.75L - 563.07L - 4145.59 = 0

Lreq = 3.64 m

Total axial load (at service) - TANK EMPTY (condition 2)

2

P =4(38.37+102.40-81.83) + 11.25L

2

= 235.76 + 11.25L

τ = P _ 6M

L2 L3

2

= 235.76 + 11.25L _ 6(690.93)

2

L L3

3 3

τL = 235.76L + 11.25L - 4145.59

2

To ensure that the base remains in contact with the soil, τ = 0 kN/m

3

0 = 235.76L + 11.25L - 4145.59

Lreq = 6.2 m

2

Base area required Areq = 38.44 m

Provide 6.75 x 6.75 x 0.45m base.

Length of base L = 6.75 m Base Area

2

Width of base W = 6.75 m Prov. Aprov. 45.56 m

1575

6750

3660

1575

1575 3660 1575

6750

4.06

239.37

Wind direction 1 (wind normal to tower)

At ultimate,

N= 821.58 kN

Design of Overhead Water Tank Support Tower and Foundation

Job No. Sheet No. Rev.

Calculation Sheet 19 OF 21

XXXXXXXX Member/Location

Job Title: Design of Overhead Water Tank Support Tower Drg Ref.

Made By KN Date:09/2018 Chd CE

REFERENCE CALCULATIONS OUTPUT

Moment Mo = 893.45 kNm

Ultimate stresses for square base for wind normal to face

Fnet = P ± 6M

2 3

L L At ultimate,

= 821.58 ± 5360.70 N = 821.58 kN

6.75^2 6.75^3 Mo = 893.45kN

= 18.03 ± 17.43 Ultimate stresses

Fmax = (18.03 + 17.43)x6.75 239.37 kN/m Fmax = 239.37kN/m

Fmin = (18.03 - 17.43)x6.75 4.06 kN/m Fmin = 4.06kN/m

Ultimate loads:

(1) 1.35Gk + 1.35Qk + 1.5Wk 624.18 kN

(2) 1.35Gk + 1.35Qk - 1.5Wk 135.96 kN

135.96 624.18

1575 3600 1575

4.06

239.37

297.5

118.8

30.72

30.72

17.16

Shear Force Diagram (kN)

326.68

114.84

21.18

Bending Moment Diagram (kNm)

216.804

Shear

RCD by 2 2

Mosley and fck = 25 N/mm fyk = 410 N/mm

Bungey; 6th Maximum applied force, NEd = 624.18 kN

edition (pg At column face,

289) Depth of slab, h = 450 mm

Cover to reinforcement, c 50 mm

Assume bar size, ø = 12 mm

Mean effective depth, d = h - c - ø 388 mm

Column perimeter, u = 1400 mm

Max shear resistance, VRd,max = 0.5v1fcdud = 0.5v1(fck/1.5)ud0.5((0.6(1-f

= ck/250)(fck/1.5))ud

2444.40 kN

NEd < VRd,max ok Shear resistance ok

Punching Shear

@ 2d from column face

Critical perimeter = column perimeter + 4πd = 6276.38 mm

2 2 2

Area within perimeter ap= (350 + 4d) - (4 - π)2d = 3359270.50 mm

Table 8.2 & Assuming punching occurs at the bases of the four columns simultaneously, then

2

Table 8.3 Punching shear force VEd = =48.41(6.75 - 4ap) 1555.19 kN

2

Punching shear stress vEd = 0.16 N/mm

2 2

= 0.15 N/mm (fck = 25N/mm )

From table 8.2, ultimate shear stress is not excessive, therefore h = 450mm appears to be adequate.

Eqn. 4.7, 4.8 Bending Reinforcement

& 4.9; pgs M= 216.80 kNm

d= 388 mm

k= M = 0.058

bd2fck

Design of Overhead Water Tank Support Tower and Foundation

Job No. Sheet No. Rev.

Calculation Sheet 20 OF 21

XXXXXXXX Member/Location

Job Title: Design of Overhead Water Tank Support Tower Drg Ref.

Made By KN Date:09/2018 Chd CE

REFERENCE CALCULATIONS OUTPUT

k < 0.168 No compression reinf. Reqd.

la = 0.5 + √(0.25 - (k/1.134)) = 0.95

2

As(req) = M = 1655.37 mm

0.87fykz

2

Provide 44H12@150c/c Both ways, B & T As(prov) = 4972 mm

Minimum reinforcement = 100As/bd 0.19 > 0.13 ( Table 6.8 )

Table 2.1 & Minimum steel area required is satisfied.

eqn. 6.1; pgs Maximum bar size and bar spacing

24&130 fs = fyk x Gk + 0.8Qk x 1 Qk = leading variable action

resp. 1.15 (1.35Gk + 1.5Qk) δ δ = 1.0 (no redistribution)

2

fs = 212.18 N/mm

Table 6.7 & Bar size and spacing are satisfied to control cracking

6.9 Final check for punching shear

ρ = As/bd = 0.19% < 2%

2

Table 8.2 vRd,c = 0.43 N/mm

Shear resistance of concrete, VRd,c =vRd,cud 4188.61 kN

VRd,c > VEd ok

6.75m x 6.75m x 0.45m thick

TYPICAL STUB DESIGN

RCD by Preliminary Sizing

Mosley and Nud = 0.567fckAc + 0.87Asfyk (i)

Bungey; 6th Assuming minimum area of stee;

edition (pg As ≥ 0.002Ac

258) Nud = 0.567fckAc + 0.87(0.002Ac)fyk

Ac = Nud

0.567fck + 0.87(0.002)fyk

Nud = NEd = 390.27 kN

2

Ac = 26212.72 mm

assuming a square cross sectional stub,

stub plan dimension = 161.90 mm

161.90 mm

Column base plate dimension is critical for sizing; therefore,

Provide 600 mm square

900 mm long stub.

LOADINGS:

3

Unit weight of concrete 25 kN/m

S/wt of stub = 8.10 kN

wgt of baseplate (350x350x20) 0.19 kN

Say: Imposed loads

Wgt of 1 leg of tower 390.27 kN

Design load = 596.59 kN

Design of stub

N= 596.59 kN

from (i)

590.78x10^3 = 0.567(25)(600x600) + 0.87(As)(410)

2

As = -6390mm

therefore, provide nominal reinforcement

2

As = 0.2%bh 720 mm

2

Provide 12H12 ( 1356mm )

links = 1/4ø12 3 mm

spacing = 20ø12 240 mm

Provide H10 @ 200 c/c

Design of Overhead Water Tank Support Tower and Foundation

Job No. Sheet No. Rev.

Calculation Sheet 21 OF 21

XXXXXXXX Member/Location

Job Title: Design of Overhead Water Tank Support Tower Drg Ref.

Made By KN Date:09/2018 Chd CE

REFERENCE CALCULATIONS OUTPUT

y

L 1

DEFLECTION CHECK FOR TOWER 2 203x203UC46

3

h= 203.2 mm

A B b= 203.2 mm

T= 11 mm

t= 7.3 mm

d= 181.2 mm

z z

3600

D C

M M

3660

L

y

Area, a (mm2)

3

Shape Part 'y' (L-L) mm 'z' (M-M) mm ay (mm ) az (mm3)

1 2235.20 5.50 3761.60 12293.60 8407928.32

A 2 1322.76 101.60 3761.60 134392.42 4975694.02

3 2235.20 197.70 3761.60 441899.04 8407928.32

1 2235.20 3665.50 3761.60 8193125.60 8407928.32

B 2 1322.76 3761.60 3761.60 4975694.02 4975694.02

3 2235.20 3857.70 3761.60 8622731.04 8407928.32

1 2235.20 3665.50 101.60 8193125.60 227096.32

C 2 1322.76 3761.60 101.60 4975694.02 134392.416

3 2235.20 3857.70 101.60 8622731.04 227096.32

1 2235.20 5.50 101.60 12293.60 227096.32

D 2 1322.76 101.60 101.60 134392.42 134392.416

3 2235.20 197.70 101.60 441899.04 227096.32

Σ 23172.64 44760271.42 44760271.42

therefore, y' = 1931.6 mm

z' = 1931.6 mm

Iyy = Iyyi + A(z - z')

4

= 7.26E+10 mm

Izz = Izzi + A(y- y')

= 7.78E+10 mm4

3

Actual deflection of tower = PL /3EI

= 1.27E-02 m

Structural = 12.74 mm

Engineers Limiting deflection = L/180

pocket book, = 150 mm ok

2nd ed.,

2009, pg 72

Design of Overhead Water Tank Support Tower and Foundation

Вам также может понравиться

- Water Tank DesignДокумент82 страницыWater Tank DesignNikhil kumarОценок пока нет

- Water Tank Design Is 3370Документ103 страницыWater Tank Design Is 3370Intezaar100% (1)

- Footing Design According To BS8110 CodeДокумент4 страницыFooting Design According To BS8110 CodePre SheetОценок пока нет

- StaircaseДокумент1 страницаStaircaseIsaac Mureithi MainaОценок пока нет

- 350kl Overhead Water Intze Tank DesignДокумент30 страниц350kl Overhead Water Intze Tank DesignHarish Kumar Mahavar60% (5)

- Water Tank Load CalculationДокумент2 страницыWater Tank Load CalculationPre Sheet100% (2)

- Design of Overhead Water Tank 29Документ28 страницDesign of Overhead Water Tank 29rashmi bhailaОценок пока нет

- Water Tank DesignДокумент28 страницWater Tank DesignDurval Párraga100% (3)

- Overhead Water Tank - Structural Analysis ReportДокумент28 страницOverhead Water Tank - Structural Analysis Reportcollins unanka100% (3)

- Calculation of Loads For Column and Foundation DesignДокумент2 страницыCalculation of Loads For Column and Foundation DesignMandar Nadgaundi100% (1)

- Water Tank DesignДокумент37 страницWater Tank DesignWrishad Zia95% (98)

- Design of Column FootingДокумент14 страницDesign of Column Footingdash1991Оценок пока нет

- Water Tank DesignДокумент1 страницаWater Tank DesignAboalmaali100% (2)

- Design of Raft Foundation of Water TankДокумент1 страницаDesign of Raft Foundation of Water TankNIHARIKA KARETHAОценок пока нет

- Hip Roof Staad.Документ6 страницHip Roof Staad.WinОценок пока нет

- Design of Stair Case With Central Stringer BeamДокумент59 страницDesign of Stair Case With Central Stringer BeamGayathri Manjunath ShepurОценок пока нет

- Design of Rectangular Water Tanks Resting On Ground.Документ5 страницDesign of Rectangular Water Tanks Resting On Ground.ganesh.pg. GaniОценок пока нет

- Helical Stair - CalculationДокумент5 страницHelical Stair - CalculationLalima Chatterjee67% (6)

- Beam Design by SP 16Документ1 страницаBeam Design by SP 16Arnab Deb67% (3)

- Design Report of Intz Type Water Tank-Bia-01.07.2015 PDFДокумент56 страницDesign Report of Intz Type Water Tank-Bia-01.07.2015 PDFGR Kanna100% (1)

- Grade Slab DesignДокумент6 страницGrade Slab DesignMALAY MRIDHAОценок пока нет

- Dome Design in ExcelДокумент2 страницыDome Design in Excelجميل عبد الله الحماطي100% (2)

- Water Tank Design (Aci 318-05)Документ8 страницWater Tank Design (Aci 318-05)arnoldОценок пока нет

- Design of Overhead Circular Water TankДокумент30 страницDesign of Overhead Circular Water Tankvishnumani3011100% (1)

- Design Calculation For RC Ring BeamДокумент19 страницDesign Calculation For RC Ring Beamjologscresencia100% (2)

- Tank Analysis and Design by STAAD PROДокумент3 страницыTank Analysis and Design by STAAD PROnour100% (4)

- Design Water TankДокумент20 страницDesign Water Tankaselabambarandage95% (20)

- Hollow Pot Design WorksheetДокумент7 страницHollow Pot Design Worksheetpatrick chegeОценок пока нет

- Underground Water Tank DesignДокумент23 страницыUnderground Water Tank Designfawad_jawaid570072% (36)

- Design of Concrete Ring Beam For Storage TankДокумент6 страницDesign of Concrete Ring Beam For Storage TankMonty MathewsОценок пока нет

- Design of Rectangular Water TankДокумент24 страницыDesign of Rectangular Water TankPiyush12febОценок пока нет

- Culvert Design (1-Barrel 1x1.5m)Документ7 страницCulvert Design (1-Barrel 1x1.5m)Waqas AnjumОценок пока нет

- Design Forces For Shaft Supports of Elevated Water TanksДокумент10 страницDesign Forces For Shaft Supports of Elevated Water TanksIrfan MughalОценок пока нет

- Ractangular Ground Water TankДокумент24 страницыRactangular Ground Water Tanksurendra_panga100% (2)

- Plinth BeamDesignДокумент1 страницаPlinth BeamDesignsabahpm0% (1)

- Le160978 C WW SW DC 3220Документ31 страницаLe160978 C WW SW DC 3220PK RELHANОценок пока нет

- Bijnor 75KL, 12M Typical-1Документ34 страницыBijnor 75KL, 12M Typical-1RITIK YADAVОценок пока нет

- Gate Design PDFДокумент12 страницGate Design PDFJohn Emmanuel Nicole S. PalomaresОценок пока нет

- VWK Rmu RPT 0003 B GenДокумент42 страницыVWK Rmu RPT 0003 B Genniranjan paudelОценок пока нет

- Slab-Top Moment Support at Column FaceДокумент19 страницSlab-Top Moment Support at Column FaceRohit PhadatareОценок пока нет

- Hydrodynamic SBRДокумент17 страницHydrodynamic SBReco protectionОценок пока нет

- Intze Tank-175kL Design 18M STAGING BASI BLOCK - SMTДокумент55 страницIntze Tank-175kL Design 18M STAGING BASI BLOCK - SMTRajendra MittalОценок пока нет

- Box Culvert - 2x2-4.0m CushionДокумент69 страницBox Culvert - 2x2-4.0m CushionsmitaОценок пока нет

- Ug Sump Foundation Design Calculations For Capacity 15Klx2 Development of 50 MW Solar PV ProjectДокумент35 страницUg Sump Foundation Design Calculations For Capacity 15Klx2 Development of 50 MW Solar PV ProjectPriyanka GuleriaОценок пока нет

- Design of Well Foundation PresentationДокумент25 страницDesign of Well Foundation PresentationvijayОценок пока нет

- EA - Analysis of Water TankДокумент9 страницEA - Analysis of Water TankworldcentreОценок пока нет

- Pumping Station Design CalculationДокумент67 страницPumping Station Design CalculationAmit PatelОценок пока нет

- 1.load CalculationДокумент4 страницы1.load CalculationmahalakshmiОценок пока нет

- Chapter 2 Box Culvert Structure Analysis CPL 1.1 Ka 2.1. Box Culvert Structure AnalysisДокумент43 страницыChapter 2 Box Culvert Structure Analysis CPL 1.1 Ka 2.1. Box Culvert Structure AnalysisHilmy anugrah indra karya pola teknikОценок пока нет

- Slab-Bottom Moment SpanДокумент13 страницSlab-Bottom Moment SpanRohit PhadatareОценок пока нет

- Box Culvert 1mДокумент69 страницBox Culvert 1mV P GUPTAОценок пока нет

- EA - Analysis of Water TankДокумент9 страницEA - Analysis of Water TankHanibal TesfamichaelОценок пока нет

- 4230 127 PVC U 009 02 00Документ33 страницы4230 127 PVC U 009 02 00raghav abudhabiОценок пока нет

- FOOTING DESIGN - MergedДокумент73 страницыFOOTING DESIGN - Mergedrahul choudharyОценок пока нет

- Zn-Al Tank-175kL Design 12M STAGING - SMTДокумент63 страницыZn-Al Tank-175kL Design 12M STAGING - SMTRajendra MittalОценок пока нет

- Load CalulationДокумент17 страницLoad Calulationjayant prustyОценок пока нет

- Slab-Top Moment SpanДокумент14 страницSlab-Top Moment SpanRohit PhadatareОценок пока нет

- Analysis and Design of A Heavy Cargo Berthing Structure: February 2018Документ9 страницAnalysis and Design of A Heavy Cargo Berthing Structure: February 2018Karim OuОценок пока нет

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresОт EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresРейтинг: 4 из 5 звезд4/5 (1)

- Soil Properties (Lpile & Com624p)Документ2 страницыSoil Properties (Lpile & Com624p)waleed4631100% (1)

- Complete RCC Design Very ImportantДокумент41 страницаComplete RCC Design Very ImportantAmal PremachandranОценок пока нет

- GEOTECH Soil ReportДокумент15 страницGEOTECH Soil ReportChuksbozmentОценок пока нет

- Erosion Control ChecklistДокумент2 страницыErosion Control ChecklistChuksbozmentОценок пока нет

- Calculation of Deflections Due To Shrinkage & CreepsДокумент2 страницыCalculation of Deflections Due To Shrinkage & CreepsChuksbozmentОценок пока нет

- Sika Concrete Repair & Protection To en 1504 Brochure NZ 0614Документ56 страницSika Concrete Repair & Protection To en 1504 Brochure NZ 0614Gandhi HammoudОценок пока нет

- Precast Roof Slab PDFДокумент3 страницыPrecast Roof Slab PDFChuksbozmentОценок пока нет

- 30,000ltrs Overhead Water Tank Support Tower and FoundationДокумент23 страницы30,000ltrs Overhead Water Tank Support Tower and FoundationChuksbozment67% (3)

- Precast Roof Slab PDFДокумент3 страницыPrecast Roof Slab PDFChuksbozmentОценок пока нет

- Precast Roof SlabДокумент4 страницыPrecast Roof SlabChuksbozmentОценок пока нет

- FOURFLOORS BeamDesДокумент31 страницаFOURFLOORS BeamDesChuksbozmentОценок пока нет

- 30,000ltrs Overhead Water Tank Support Tower and FoundationДокумент23 страницы30,000ltrs Overhead Water Tank Support Tower and FoundationChuksbozment67% (3)

- FOURFLOORS BeamDesДокумент31 страницаFOURFLOORS BeamDesChuksbozmentОценок пока нет

- Recruitment Resume Template For Unity RefineryДокумент6 страницRecruitment Resume Template For Unity RefineryChuksbozmentОценок пока нет

- Recruitment Resume Template For Unity RefineryДокумент6 страницRecruitment Resume Template For Unity RefineryChuksbozmentОценок пока нет

- MSC Dissertation GuideДокумент28 страницMSC Dissertation GuideChuksbozmentОценок пока нет

- Pull Out Resistance of Roof FastenersДокумент41 страницаPull Out Resistance of Roof FastenersChuksbozment100% (1)

- Tower Design CodesДокумент10 страницTower Design CodesMaribel Isaura Cunurana YapuchuraОценок пока нет

- MSC Dissertation GuideДокумент28 страницMSC Dissertation GuideChuksbozmentОценок пока нет

- Foundation AnalysisДокумент7 страницFoundation AnalysisChuksbozmentОценок пока нет

- Structural Analysis and Design of 132KV Power TransmissionДокумент30 страницStructural Analysis and Design of 132KV Power TransmissionChuksbozmentОценок пока нет

- Member StrengtheningДокумент2 страницыMember StrengtheningNitin ParulОценок пока нет

- Concrete Sheet Piling Design (EN1997)Документ11 страницConcrete Sheet Piling Design (EN1997)ChuksbozmentОценок пока нет

- UFGSДокумент27 страницUFGSChuksbozmentОценок пока нет

- Marine FendersДокумент17 страницMarine FendersVictor Manuel Bazaes Athens100% (1)

- 12 Cantilever StairsДокумент15 страниц12 Cantilever StairsGayathri Manjunath ShepurОценок пока нет

- Condition 1: Maximum Axial (Compression) Capacity: InputДокумент7 страницCondition 1: Maximum Axial (Compression) Capacity: InputChuksbozmentОценок пока нет

- Sheet Piling Analysis & Design in Accordance With BS EN1997-1:2004 - Code of Practice For Geotechnical Design and The UK National AnnexДокумент7 страницSheet Piling Analysis & Design in Accordance With BS EN1997-1:2004 - Code of Practice For Geotechnical Design and The UK National AnnexChuksbozmentОценок пока нет

- Eurocode 1 ComparisonДокумент10 страницEurocode 1 ComparisontbaysakОценок пока нет

- Compression Members: Young's Modulus BucklingДокумент8 страницCompression Members: Young's Modulus BucklingMyo AungОценок пока нет

- Tinh P DeltaДокумент15 страницTinh P DeltaLongChauОценок пока нет

- Kisssoft Tut 014 E Compression SpringsДокумент9 страницKisssoft Tut 014 E Compression SpringsJorge Ronald Cabrera ÑaupaОценок пока нет

- QB All Module MomДокумент11 страницQB All Module MomRakshith GowdaОценок пока нет

- Built-Up Compression MembersДокумент7 страницBuilt-Up Compression MembersDaniela DelgadoОценок пока нет

- Structure by Engr. Enghoy With AnswersДокумент15 страницStructure by Engr. Enghoy With AnswersRuby MagsinoОценок пока нет

- Columns and PipesДокумент15 страницColumns and Pipessotiris100% (2)

- Ansys Tutorial For Assignment 2Документ16 страницAnsys Tutorial For Assignment 2suhas_snaОценок пока нет

- Composites MaterialsДокумент21 страницаComposites MaterialsMayra AmandaОценок пока нет

- Design Limitations of Deployable Wings For Small Low Altitude UavsДокумент23 страницыDesign Limitations of Deployable Wings For Small Low Altitude UavsHuy VTXОценок пока нет

- Garg, Aamod. 'Gantry Girders in India'Документ5 страницGarg, Aamod. 'Gantry Girders in India'Aamod GargОценок пока нет

- Lecture Notes in Cve163 Design of Steel and Timber StructuresДокумент71 страницаLecture Notes in Cve163 Design of Steel and Timber StructuresMerwin Andrew UyОценок пока нет

- Buckling Lengths of Irregular Frame ColumnsДокумент9 страницBuckling Lengths of Irregular Frame ColumnsYi ZhuangОценок пока нет

- (Eng) Topic Training - Buckling Lengths For Steel 18.0Документ44 страницы(Eng) Topic Training - Buckling Lengths For Steel 18.0engkjОценок пока нет

- Civil 5 & 6 Semester Syllabus of B.tech Programs From The Session 2020-21Документ991 страницаCivil 5 & 6 Semester Syllabus of B.tech Programs From The Session 2020-21Moin Khan BisruОценок пока нет

- Berger Lahr - Linear Tables PDFДокумент16 страницBerger Lahr - Linear Tables PDFofanОценок пока нет

- The Flow Chart Below Can Be Used As A Guide To Design A Steel Beam MemberДокумент27 страницThe Flow Chart Below Can Be Used As A Guide To Design A Steel Beam MembernasyahrahОценок пока нет

- Tutorial 5 - Flexural Members - Lateral Torsional BucklingДокумент32 страницыTutorial 5 - Flexural Members - Lateral Torsional BucklingChan Keng ChunОценок пока нет

- Modelling Steel and Composite StructuresДокумент8 страницModelling Steel and Composite StructuresChan Pisith de PhalОценок пока нет

- Debre Markos UniversitДокумент26 страницDebre Markos Universitkidanemariam teseraОценок пока нет

- Cold Formed Steel Members and SheetingДокумент14 страницCold Formed Steel Members and SheetingMihai MariusОценок пока нет

- Petronas Technical Standards: Onshore Steel StructuresДокумент19 страницPetronas Technical Standards: Onshore Steel StructuresvinothОценок пока нет

- ECCS Examples To Eurocode 3Документ124 страницыECCS Examples To Eurocode 3toliveira80100% (6)

- Research Article Bayesian Regularization Backpropagation Neural Network For Glass Beams in Lateral - Torsional BucklingДокумент11 страницResearch Article Bayesian Regularization Backpropagation Neural Network For Glass Beams in Lateral - Torsional BucklingsaddamОценок пока нет

- 6-Msc.1-Circ.1343 - Guidelines For The Information To Be Included in A Ship Construction FileДокумент9 страниц6-Msc.1-Circ.1343 - Guidelines For The Information To Be Included in A Ship Construction FileLinglong XiongОценок пока нет

- BenchmarkmanualДокумент337 страницBenchmarkmanualapi-184316840Оценок пока нет

- Design of Steel Free StackДокумент37 страницDesign of Steel Free StackSantiago PEОценок пока нет

- Structural Calculation Frameless JulietДокумент12 страницStructural Calculation Frameless JulietSiYing LaiОценок пока нет

- Structural Behaviour of Composite Members With Recycled Aggregate Concrete - An OverviewДокумент21 страницаStructural Behaviour of Composite Members With Recycled Aggregate Concrete - An OverviewMoisés Ocampo FernándezОценок пока нет

- Example - Design of A Cold-Formed Steel Lipped Channel Wall Stud in Compression and BendingДокумент10 страницExample - Design of A Cold-Formed Steel Lipped Channel Wall Stud in Compression and BendingChristian ChetcutiОценок пока нет