Академический Документы

Профессиональный Документы

Культура Документы

Amarinth File

Загружено:

ratheeshОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Amarinth File

Загружено:

ratheeshАвторское право:

Доступные форматы

T Series – Petrochemical pumps (API 610 11th: 2010)

T Series – Vertical mounted tank top pumps

Documentation packs (ISO 5199 : 2002)

Documentation pack Inclusive documents Standard technical specification

Bronze pack Order acknowledgement (electronic)

Installation, Operating & Maintenance manual

Declaration of conformity

ATEX Declaration of conformity – only if contracted

Silver Pack Standard pump GA drawing

(Includes bronze pack) Hydrostatic test certificate

Pump HQ performance test certificate

Spare parts list – commissioning

Type 2.2 certificates (* pressure containing parts only) – only if contracted

Gold pack Quality plan

(Includes silver pack) Progress reports (monthly)

Spare parts list – operating

Customer specific pump GA drawing

Pump SA & parts list

Type 3.1 certificates (* pressure containing + process wetted parts only) – only if contracted

Pump HQ performance test curve

General Specification

Certification databook

Pump datasheet General description A range of vertical long shaft single stage centrifugal end suction sump pumps manufactured in a

Motor type test certificate variety of alloys. Designed to suit customer requirements with lengths available up to 6m sump depth

Motor GA drawing as standard, longer length available on request.

Motor datasheet Construction Heavy duty modular design maximising flexibility to suit customer’s application.

Motor Declaration of conformity Design methodology Advanced computer techniques including 3D modelling, FEA & CFD

Motor ATEX Declaration of conformity Design standards ISO 5199 : 2002

Documentation format Electronic CD – Adobe (.pdf), ms office (.xls .doc) ATEX EC-Directive 94/9/EC

Hard copy Design pressure rating 20 bar g at 20°C (pressure containing parts)

Operating temperature rating -40°C to 100°C (standard construction)

NDT

Design temperature 150°C

Pump test Test standard Acceptance criteria Standard

Performance envelope

Hydrostatic BSEN25199 / ISO 5199 BSEN25199 / ISO 5199 (1.5 x MAWP) Flowrate Up to 500m3/h

Head & flow (reduced length) BSEN25199 / ISO 5199 ISO 9906 Grade 2

Differential head Up to 225m

BSEN25199 / ISO 5199 ISO 9906 Grade 1

Speed Up to 3600 rpm

Mechanical run – 1 hour at rated duty Amarinth procedure Amarinth procedure

Configurations ANSI mount flange

Mechanical run – 4 hours at rated duty Amarinth procedure Amarinth procedure

Rectangular plate

NPSH – single point (close coupled) BSEN25199 / ISO 5199 ISO 9906 Grade 2

BSEN25199 / ISO 5199 ISO 9906 Grade 1 Frame sizes 040x025x145 to 200x150x410

NPSH – 4 points (close coupled) BSEN25199 / ISO 5199 ISO 9906 Grade 2 Design life 20 years (2 years uninterrupted operation)

BSEN25199 / ISO 5199 ISO 9906 Grade 1

Noise – single point at 1m BSEN12693:2000 Mutual Agreement Material Options

Vibration – single point BSEN25199 / ISO 5199 BSEN25199 / ISO 5199 Material Options Casing Impeller

NDE SS 316 / SS 316 ASTM A744 CF 8M ASTM A744 CF 8M

Cast Iron / Cast Iron BS EN 1561 Gr EN GJL 250 BS EN 1561 Gr EN GJL 250

Dyepenetrant of machined surfaces Pressure containing castings only

Cast Iron / SS 316 BS EN 1561 Gr EN GJL 250 ASTM A744 CF 8M

Dyepenetrant of cast surfaces Pressure containing castings only

Dyepenetrant of welds Delivery pipework SG Iron / SS 316 BS EN 1563 Gr EN GJS 400 18 LT ASTM A744 CF 8M

Positive Material Identification Excludes minor components (nuts & bolts etc) Carbon Steel / SS 316 ASTM A216 WCB ASTM A744 CF 8M

Radiography Shot plan – critical areas Carbon steel / 12% Cr SS ASTM A216 WCB ASTM A217 Gr CA 15

Hardness report NACE (certain materials only – please ask for details) Duplex SS / Duplex SS ASTM A890 Gr 1B CD 4MCuN ASTM A890 Gr 1B CD 4MCuN

Various motor tests Super Duplex SS / Super Duplex SS ASTM A890 Gr 6A (UNS J93380) ASTM A890 Gr 6A (UNS J93380)

Hastelloy B / Hastelloy B ASTM A494 Gr N 7M ASTM A494 Gr N 7M

Hastelloy C / Hastelloy C ASTM A494 Gr CW 12MW ASTM A494 Gr CW 12MW

Monel / Monel ASTM A494 Gr M35 1 ASTM A494 Gr M35 1

Titanium / Titanium ASTM B367 Gr C2 ASTM B367 Gr C2

*Pressure containing parts include; volute casing, casing adaptor & delivery pipework. Process wetted parts include additional shaft & impeller columns, impeller

Customer specified Other alloys available on request Other alloys available on request

hubcap & nut. A full range of testing and documentation can be tailored to suit your exact requirements. Amarinth reserves the right to alter any information within

this document without prior notification. © Copyright 2005-2017. Amarinth Limited. E&OE. including NACE compliant materials including NACE compliant materials

MP2510-360 REV E (Nov 17)

Bentwaters Parks, Rendlesham, Woodbridge, Suffolk, IP12 2TW. United Kingdom Bentwaters Parks, Rendlesham, Woodbridge, Suffolk, IP12 2TW. United Kingdom

tel: +44 (0)1394 462 120 fax: +44 (0)1394 462 130 email: enquiries@amarinth.com web: www.amarinth.com tel: +44 (0)1394 462 120 fax: +44 (0)1394 462 130 email: enquiries@amarinth.com web: www.amarinth.com

T Series – Petrochemical pumps (API 610 11th: 2010) Amarinth Limited

Features Technical notes Benefits Standard Features Technical notes Benefits Standard

Casing & delivery pipe Thrust bearing / motor pedestal

Construction One piece casting with integral suction Minimal leakage path, prolonged pump life Thrust bearing type Self contained bearing unit

cover and 3mm corrosion allowance Thrust bearing lubrication Grease

Fasteners High tensile matched to casing Matched to fluid

Design bearing life 25,000 hours (L10) @ standard duties

Customer specified

Running temperature Less than 40°C above ambient Long life, ATEX

Casing gasket Reinforced graphite Covers most fluids

Pedestal construction Fully welded fabrication Better alignment

Expanded PTFE Covers certain acid duties

Monitoring Vibration monitoring points Assist planned maintenance

Customer specified Matched to site standard

Wear ring Suction side Prolonged pump life Temperature sensor location points

Jacking screws Matched to casing Ease of maintenance Motor pedestal materials Carbon steel

Delivery pipe construction Schedule 40 seamless pipe with Strength & corrosion resistance Stainless steel 316L

butt welded joints Customer specified

Delivery pipe gasket(s) CSF Coupling & guard

Delivery flange standard ISO PN20 / ANSI 150 Matched to site standard Coupling style Non spacer type with metal membranes Cost benefit

ISO PN16 Spacer type with metal membranes Easy maintenance

Orifice plate Loose tang type Matched to customer requirement Customer specified Matched to site standard

Impeller

Construction Bored & keywayed Easy removal

Construction One piece casting Strength & integrity

Balancing Inherent by design Low vibration

Vanes Francis type – 4 / 5 off Low NPSHr & stable H/Q curve

Dynamic to ISO 1940 G 2.5 (hubs only) Prolonged pump life

Style Shrouded Optimum efficiency

Manufacturers John Crane

Semi open Handles solids content in fluid

Fixing Keyed with retention nut and lockwasher Ease of maintenance Customer specified Matched to site standard

Wear ring Suction side Prolonged pump life Standards ATEX

Axial adjustment Shaft lock nuts accessible above Optimised performance Guard Single piece wrap around in SS 304L Non sparking/ATEX compliant

mounting plate Support

plate

Hydraulic balancing Backvanes Low NPSHr Style ANSI 150 flange Sealed environment

Dynamic balancing Static Plate flange

ISO 1940 G 2.5 Rectangular plate Cost benefit

ISO 1940 G 6.3 Prolonged pump life Customer specified Matched to customer requirement

Columns & line bearings

Construction Blind flange with lifting points Rugged construction

Column construction Fully welded with flanged & spigoted joints Maximise strength & alignment

Plate with 4 lifting points

Column sizes 4”, 6”, 8” (dependant on pump size) Optimised drive shaft stability

Standards ANSI B16.5, ASME B16.47

Column materials Stainless steel 316L Suits most fluids

Earthing connections 2 off M10 tapped holes

Customer specified Material to match casing / fluid

Line bearing type Grooved bush Clog resistant Material Carbon steel Cost benefit

Line bearing materials Carbon / PTFE Suits most fluids Stainless steel 316 Resistance to low temperature

Customer specified Matched to site standard Customer specified

Line bearing lubrication Pumped fluid Simplified construction Driver

External flush Improved pump life when solids present Motor type Safe area, EExN, EExd, EExde, Exe, Matched to area requirements

Maximum distance between bearings As defined in API610 Minimised vibration Motor mounting Flanged for vertical mounting

Standards ISO frames Matched to site standard

Shaft

Shaft & shaft sealing

diameters 30mm, 40mm, 50mm NEMA frames

Shaft diameters 30mm, 40mm , 50mm

ATEX Hazardous area requirement

Line shaft coupling Screwed sleeve

Supply 380 – 440 / 3 / 50, 440 – 460 / 3 / 60 Matched to site standard

Screwed sleeve (with locking device)

Manufacturers ABB, ATB, Brook Hansen, Loher, Seimens, Matched to site standard

Hardened sleeve Longer life

TECO, WEG, Customer specified

Shaft materials Duplex stainless steel

Paint

Customer specified Material to match casing / fluid

Seal types Twin grease packed lip Cost benfit Industrial specification Air drying alkyd – Bgreen Black 233

Single cartridge (dry running) ATEX compliant Refinery specification 3 coat system (Min DFT 225µm) – off grey

Double cartridge Environmentally safer, ATEX Offshore specification 4 coat system (Min DFT 300µm) – off grey

Seal piping arrangements None Simplified construction Customer specification Matched to site standard

Plan 52, 53, 54 Match customers requirements Packing

Customer specified Road Palletised & cling wrap

Cartridge seal manufacturers AES, Burgmann, John Crane or Matched to site standard Seafreight Wooden box paper lined Long term storage

customer specified

Wooden box with vacuum sealed bag Moisture free

Airfreight Wooden box paper lined Long term storage

Wooden box with vacuum sealed bag Moisture free

Bentwaters Parks, Rendlesham, Woodbridge, Suffolk, IP12 2TW. United Kingdom

tel: +44 (0)1394 462 120 fax: +44 (0)1394 462 130 email: enquiries@amarinth.com web: www.amarinth.com

Вам также может понравиться

- Rashtriya Chemicals & Fertilizers Ltd.,ThalДокумент41 страницаRashtriya Chemicals & Fertilizers Ltd.,ThalratheeshОценок пока нет

- Pump Calculations EquationДокумент3 страницыPump Calculations EquationToan LeОценок пока нет

- Torque, Speed and PowerДокумент9 страницTorque, Speed and PowerratheeshОценок пока нет

- 4 Presentation Cooling TowerДокумент35 страниц4 Presentation Cooling TowerratheeshОценок пока нет

- King Salman International Complex For Maritime Industries and ServicesДокумент7 страницKing Salman International Complex For Maritime Industries and ServicesratheeshОценок пока нет

- Belt & Bucket Elevator: Installation, Maintenance & Spare Parts ManualДокумент13 страницBelt & Bucket Elevator: Installation, Maintenance & Spare Parts ManualratheeshОценок пока нет

- SCC Cat 597Документ6 страницSCC Cat 597Anonymous K3FaYFlОценок пока нет

- Pump SelectionДокумент112 страницPump SelectionSIVAPATHASEKARAN100% (6)

- Refer Design Change List For Raw Naptha Pump, 511-P-001 A/B Attached in This Transmittal For The Changes Made in This DatasheetДокумент5 страницRefer Design Change List For Raw Naptha Pump, 511-P-001 A/B Attached in This Transmittal For The Changes Made in This DatasheetratheeshОценок пока нет

- Sample - Belt Bucket Elevator DesignДокумент7 страницSample - Belt Bucket Elevator Designmfhasnain100% (1)

- Code 1 Pump GAD 511-P-001 Rev.4Документ1 страницаCode 1 Pump GAD 511-P-001 Rev.4ratheeshОценок пока нет

- Performance Curves For 511-PM-001 ABДокумент1 страницаPerformance Curves For 511-PM-001 ABratheeshОценок пока нет

- BCR Header Bcs Header: To Bearing Cooling Water Return HeaderДокумент1 страницаBCR Header Bcs Header: To Bearing Cooling Water Return HeaderratheeshОценок пока нет

- Affinity LawДокумент1 страницаAffinity LawratheeshОценок пока нет

- TechnocratesДокумент89 страницTechnocratesratheeshОценок пока нет

- TORAY Pressurized PVDF Hollow Fiber Membrane Module "TORAYFIL " Instruction Manual Model: "HFU Series"Документ34 страницыTORAY Pressurized PVDF Hollow Fiber Membrane Module "TORAYFIL " Instruction Manual Model: "HFU Series"ratheeshОценок пока нет

- Monroe, LA 71203-9573: RR 5, Box 357AДокумент2 страницыMonroe, LA 71203-9573: RR 5, Box 357AratheeshОценок пока нет

- Rolling Element Bearing BasicsДокумент3 страницыRolling Element Bearing BasicssubbusenthilОценок пока нет

- TractelДокумент71 страницаTractelratheeshОценок пока нет

- BearingsДокумент23 страницыBearingsratheeshОценок пока нет

- Bearing Failure ModesДокумент13 страницBearing Failure ModesmayureshrmahajanОценок пока нет

- Bearing Basics: SKF Reliability Maintenance Institute On-Line Work Execution CourseДокумент2 страницыBearing Basics: SKF Reliability Maintenance Institute On-Line Work Execution CourseratheeshОценок пока нет

- General Concepts of Mixing PDFДокумент9 страницGeneral Concepts of Mixing PDFratheeshОценок пока нет

- Selecting The Proper Conveyor Belt: Single Pulley DriveДокумент18 страницSelecting The Proper Conveyor Belt: Single Pulley Drivettr_1983Оценок пока нет

- J940305 PDFДокумент4 страницыJ940305 PDFratheeshОценок пока нет

- Conveyor BeltsДокумент10 страницConveyor BeltsMalvika KoushikОценок пока нет

- Self Priming Pumps IssuesДокумент5 страницSelf Priming Pumps IssuesratheeshОценок пока нет

- Self Priming Pumps IssuesДокумент5 страницSelf Priming Pumps IssuesratheeshОценок пока нет

- Fluids Lecture 15Документ6 страницFluids Lecture 15juanfepoОценок пока нет

- North Tank Farm and Loading Arms Facilities (Pkg.4) Contract No: 6600029560 Petrofac Job No: JI-2018Документ2 страницыNorth Tank Farm and Loading Arms Facilities (Pkg.4) Contract No: 6600029560 Petrofac Job No: JI-2018ratheeshОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Atulya Beharwal: Class - 7 AДокумент15 страницAtulya Beharwal: Class - 7 AAtul Beharwal100% (1)

- ANtenna PropagationДокумент63 страницыANtenna PropagationPrasanna PandeyОценок пока нет

- Explicit Dynamics Chapter 6 Explicit MeshingДокумент50 страницExplicit Dynamics Chapter 6 Explicit MeshingAnonymous 0tqzNTWyy100% (4)

- DSV SVДокумент1 страницаDSV SVPUNITHA KUMARОценок пока нет

- Liquid Ring Vacuum Pump: LPH 55312, LPH 55316, LPH 55320Документ12 страницLiquid Ring Vacuum Pump: LPH 55312, LPH 55316, LPH 55320Edu CordonОценок пока нет

- Lab-Java Programming Intro IДокумент83 страницыLab-Java Programming Intro IHeavenlyPlanetEarth80% (5)

- High Precision Ball Berings GMNДокумент72 страницыHigh Precision Ball Berings GMNSilvio Busdraghi AmorosoОценок пока нет

- Move Core Application: Fully Integrated 2D and 3D Model Building and AnalysisДокумент2 страницыMove Core Application: Fully Integrated 2D and 3D Model Building and AnalysisAlfredo Iguaran AmayaОценок пока нет

- TGE 5, TGE 5-Ex, TGM 5, TGM 5-Ex, TGU 5, TGU 5-Ex: Transmitter For Angular PositionДокумент10 страницTGE 5, TGE 5-Ex, TGM 5, TGM 5-Ex, TGU 5, TGU 5-Ex: Transmitter For Angular Positionvinodk335Оценок пока нет

- Delphi Heavy Duty Emissions Brochure 2011 2012Документ100 страницDelphi Heavy Duty Emissions Brochure 2011 2012Younwoo NamОценок пока нет

- ML10 OwnersManualДокумент16 страницML10 OwnersManualSalvador OlivasОценок пока нет

- J Fluids Engineering 2009 Vol 131 N4Документ120 страницJ Fluids Engineering 2009 Vol 131 N4Нильва АлександрОценок пока нет

- Chapter 3 Waveform Coding Techniques PDFДокумент33 страницыChapter 3 Waveform Coding Techniques PDFEunielyn SecretoОценок пока нет

- Structural Welding Inspection: 2019 CBC: DSA Forms DSA PublicationsДокумент3 страницыStructural Welding Inspection: 2019 CBC: DSA Forms DSA PublicationsfracevОценок пока нет

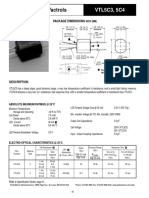

- Low Cost Axial Vactrols: VTL5C3, 5C4Документ2 страницыLow Cost Axial Vactrols: VTL5C3, 5C4sillyОценок пока нет

- OGC-FIC-004-I-Cable Insulation Resistance-Field Installation ChecklistДокумент2 страницыOGC-FIC-004-I-Cable Insulation Resistance-Field Installation ChecklistTaylorОценок пока нет

- ADPДокумент165 страницADPmohhizbarОценок пока нет

- Quake Cheat CodesДокумент21 страницаQuake Cheat CodeshugtheslugОценок пока нет

- RT-161 A1 PDFДокумент8 страницRT-161 A1 PDFRaul Diaz100% (1)

- Patriot MissileДокумент19 страницPatriot MissileBogdan Claudiu HututuiОценок пока нет

- EAC PowerPoint Template 2019Документ5 страницEAC PowerPoint Template 2019LeeОценок пока нет

- Research Report (JAHANGIR'S TOMB)Документ24 страницыResearch Report (JAHANGIR'S TOMB)ahmerОценок пока нет

- 015-Method Statement For Painting Works (Building) PDFДокумент21 страница015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- Durability of Clay BricksДокумент18 страницDurability of Clay BricksEmmanuel okelloОценок пока нет

- AC 43.13-1B Section 5 Penetrant InspectionДокумент8 страницAC 43.13-1B Section 5 Penetrant Inspection320338100% (1)

- M795 Spare PartsДокумент139 страницM795 Spare Partsวิรัตน์ อัครอภิโภคีОценок пока нет

- Non Vital BleachingДокумент19 страницNon Vital BleachingPriyabrat Pattanaik100% (1)

- ASAP MethodologyДокумент14 страницASAP MethodologyTiffany HughesОценок пока нет

- Aluminum Design Manual 2015Документ505 страницAluminum Design Manual 2015Charlie Henke100% (2)

- Bridge Inspection ManualДокумент539 страницBridge Inspection ManualماقوريОценок пока нет