Академический Документы

Профессиональный Документы

Культура Документы

Saic e 2002

Загружено:

jerinОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Saic e 2002

Загружено:

jerinАвторское право:

Доступные форматы

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.

00 31-Mar-15

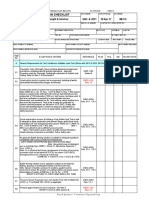

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Shell & Tube Heat

SAIC-E-2002 30-Apr-17 MECH-

Exchanger

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT

REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM RE-INSP

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No. DATE

A. Document Verification

Final Disposition Report was reviewed by the Contractor and Schedule

A1 submitted to Saudi Aramco within two weeks of acceptance of "Q",Att. III,

material or equipment. Para. 3.22

Final Disposition Report includes the following as a minimum:

a. Narrative details of Quality activities performed during

manufacturing and fabrication of the equipment or material.

b. Copies of SAUDI ARAMCO approved waivers to SAUDI

Schedule

ARAMCO’s requirements.

A2 "Q",Att. III,

c. All SA-175 CONTRACTOR witnessed inspections.

Para. 3.24

d. Copies of supplier quality records as specified in SA-175.

e. Copies of all NCR's with final dispositions and resolutions.

f. Outstanding punch list items from pre-shipment inspections.

g. Inspection/Shipping release.

All exchangers were designed in accordance with the rules of

the Boiler and Pressure Vessel Codes, ASME SEC VIII D1 or 32-SAMMS-

A3

ASME SEC VIII D2 (hereinafter referred to as the Codes), and 007,Para. 4.1

the requirements of 32-SAMMS-007.

Exchanger Manufacturer has submitted drawings, calculations, 32-SAMMS-

A4 data and furnished reports and records in accordance with 007,Para. 6.1.1

NMR SA-7922-1, Nonmaterial Requirements. and para. 6.3.

The quantities, sizes, ratings, (ASME pressure classes), 32-SAMMS-

A5 facings, elevations, and orientations of nozzles and manways 007,Para.

were specified on the data sheet. 7.7.10

The Exchanger Manufacturer submitted flow-induced vibration 32-SAMMS-

A6

analysis. 007,Para. 6.1.2

All materials for pressure and non-pressure components 32-SAMSS-

A7 conform with Data sheet (Form 2714-ENG) & are in accordance 007, Para.

with Attachment 1. 8.1.5

32-SAMSS-

Material test report is certified as per 175-323100.

A8 007, Para.

8.1.9

Materials specifications and tests procedures for base and

weldments materials for 1 Cr- ½ Mo, 1 ¼ Cr- ½ Mo, 2 ¼ Cr-1

32-SAMSS-

A9 Mo, 2 ¼ Cr-1 Mo- ¼ V, 3 Cr-1 Mo and 3 Cr-1 Mo- ¼ V were

007,Para. 8.1.7

submitted to Saudi Aramco Engineer for review and approval

prior to ordering the materials from the mill.

All materials, except carbon steels, are alloy verified by the 32-SAMSS-

A10 Exchanger Manufacturer in accordance with SAES-A-206. See 007,

Notes: Para. 8.1.12

Saudi Aramco: Company General Use

The Exchanger Manufacturer were prepare drawings, which

indicate the ultrasonic readings thickness of the exchanger

32-SAMMS-

shell, heads and nozzles. An adequate number of ultrasonic

A11 007,

thickness readings are taken to represent the actual thickness

Para. 6.1.4

of the components. such as vessel shell section, heads and

nozzles.

All approved data sheets, drawings and forms are typed and

32-SAMMS-

submitted to Engineering Drawings Services (EDSD)

A12 007,

EK&RD/Drawing Management Unit (DMU) for inclusion into

Materials Para. 6.1.5

Corporatefor exchangers

Drawings exposed to

Management SSC environments were in

System.

accordance with the following:

A) Forged flanges and forged fittings are restricted to: SA-

350 (Grade LF1 or Grade LF2) or SA-765 Grade II.

B)Studs are restricted to: SA-193 B7M or SA-320 32-SAMSS-007

A13

L7M. 8.1.20

C) Nuts are restricted to: SA-

194 Grade 2HM.

D) It shall

Impact test temperature for a component of a exchanger were

satisfy the requirements of ISO 15156 and NACE RP0472.

specified on the data sheet. Impact testing of materials and 32-SAMSS-007

A14

welding procedures are required when test temperature is lower 8.4.2 and 8.4.6

than -28°C.

Special Testing for Steels under Scope of API RP 934-A are

below. A) Microstructure Testing

B) Hardness Testing 32-SAMSS-007

A15

C) Stress Rupture Test 8.5

D) Reheat Transverse Cracking Susceptibility

Qualification

A report for the cleaning, drying and lay-up if applicable prior to 32-SAMSS-007

A16

shipping is available. 10.3.9

Clad exchangers (partial or complete cladding) conformed to 32-SAMSS-

A18 32-SAMSS-031 in addition to the requirements of of 32- 007,

SAMSS-007. Para. 7.2

B Walkthrough of the equipment

Schedule "Q",

Received heat exchangers are free of physical damage on its

B1 Att. IV, Para.

mechanical components.

3.3

32-SAMMS-

Exchangers are verified to be dried and free of loose scales and

B2 007,

weld slags, dirt and debris.

Para. 11.1.2

Shipping protection was maintained as follows:

a) Flanged connections and all other machined surfaces are

protected /using of rust preventive compound such as Cortec

VpCI-369 or equivalent.

b) Flanges are fitted with a 3 mm thick steel or wood cover with

32-SAMMS-

neoprene gaskets and 4 bolts as a minimum with rust

007,

B3 protection. Flanges with permanent blind flanges shall be

Para. 11.12, 13

secured with the gaskets and bolting specified for service.

14 and 15

c) Threaded nozzle connections are protected with threaded

plugs and by the use of an appropriate lubricant with rust

preventive compound such as Cortec VpCI-369 or equivalent.

d) Tell-tale holes in repads are protected with wooden plugs or

packed with a rust preventative grease such as, Denso paste.

32-SAMMS-

Flange bolt holes shall straddle the normal horizontal and

B4 007,

vertical centerlines of the exchanger.

Para. 7.7.12.

Hardened washers are provided under nuts for all bolts having

API - 660, Para.

B5 diameters of 38mm (1 1/2 in) or larger. The washers are atleast

7.8.6.

6mm (1/4 in) thick.

Saudi Aramco: Company General Use

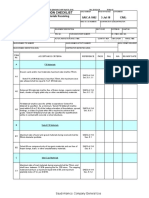

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Shell & Tube Heat

SAIC-E-2002 30-Apr-17 MECH-

Exchanger

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

All internal and external attachments, including clips, welded

32-SAMSS-

directly to pressure parts are attached by continuous welding

B6 007,

except for blank nuts used for external insulation where tack

Para. 7.21.6

welding is allowed.

Exchangers are provided with a grounding lug connection 32-SAMSS-

B7 welded to the fixed exchanger support in accordance with PIP 007,

VEFV1100. Para. 7.21.5

Single tube pass TEMA rear end floating head type exchangers 32-SAMSS-

B8 have a removable shell cover to provide easy access to the 007,

expansion joint in the tube side nozzle. Para. 7.23.1

Kettle type reboilers are provided with guide rails and a hold 32-SAMSS-

B9 down angle located above the floating end, in order to keep the 007,

bundle in place during shipment. Para. 7.23.3

32-SAMSS-

For tube bundles that can be rotated 180 degrees, additional

B10 007,

impingement plate, bundle runners etc. are provided

Para. 7.23.4

Exchangers with sea water on the tube side are fitted with

ferrules (tube end protectors) at the inlet end of tubes at each

tube pass. Commentary Note: 32-SAMSS-

B11 Saudi Aramco Standard Drawing AE-036250 gives ferrules 007,

details for 0.75 inch outside diameter tubes. For larger tube Para. 7.23.5

diameters, Exchanger Manufacturer shall propose ferrule

details for the consideration of the Saudi Aramco Engineer

32-SAMSS-

Nameplate is type 304 SS or Monel, 3 mm minimum thick and

B12 007,

welded to the mounting bracket according to PIP VEFV1100.

Para. 10.4.1

Mounting bracket is continuously seal welded & positioned such

32-SAMSS-

as not to allow for collection of moisture or rain. Mounting

B13 007,

bracket material shall conform to Attachment 1, Note 4 and

Para. 10.4.7

shall be the same ASME material as that it is attached to.

The nameplate and its mounting bracket are located such that 32-SAMSS-

B14 the nameplate was not covered by insulation and it is easily 007,

readable from grade or platform. Para. 10.4.5

32-SAMSS-

The brackets are extended from the outside of the exchanger to

B15 007,

clear insulation.

Para. 10.4.5

Exchangers with a component weighing up to and including 27

32-SAMSS-

kg (60 lb.) are provided with at least one lifting lug per

B16 007,

component. (Two lifting lugs shall be provided for heavier

Para. 7.11.5

weights).

The lifting device are a weld-on lug or ring provided with a hole

not less than 38mm (1 1/2 in) in diameter. Wherever possible,

API - 660, Para.

B17 the lug or ring are located at the top of component , above its

7.11.1.

centre of gravity; otherwise , two suitably lugs or ring are

provided.

32-SAMSS-

B18 Protective plugs are fully engaged. 007,

Para. 7.11.7

32-SAMSS-

Lugs on insulated exchangers are of sufficient standout to clear

B19 007,

insulation

Para. 7.11.6

The nameplate markings are stamped or engraved such that 32-SAMSS-

B20 the nameplate material is permanently deformed with the 007,

symbols. Para. 10.4.5

Saudi Aramco: Company General Use

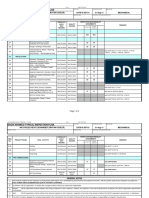

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Shell & Tube Heat

SAIC-E-2002 30-Apr-17 MECH-

Exchanger

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

The nameplate are marked with the information per the

requirements of ASME VIII, UG-116 as follows as a minimum:

a. ASME Code symbol (for vessels made outside of Saudi

Arabia)

b. Name of the Manufacturer preceeded by the words

“certified by”;

c. maximum allowable working pressure psi at design

ASME

temperature

B21 SECTION VIII,

d. minimum design metal temperature °F at max allowable

UG-116

working

pressure psi

e. Manufacturer’s serial number;

f. year built.

g. The type of construction used for the vessel indicated

directly

under the Code Symbol by applying the appropriate letter(s)

Removable pressure parts are permanently marked in a

manner to identify them with the vessel or chamber of which

they form a part. {Ref: ASME VIII, UG-117 (l).} NOTE: Mfg's

API - 660 para.

B22 Serial Number is used & this applies to shell flange, shell cover

10.4.3

flange, channel or bonnet flange, channel cover, stationary

tubesheet, floating tubesheet, floating head cover flange,

floating head backing device & test ring flange and gland.

Grounding lug material is austenetic stainless steel when

PIP VEFV1100

attached to carbon steel or low alloy steel parts. When attached

B23 number

to other materials, lug material shall be similar to the material to

VEFV1103

which attached.

C Supports

Type of support conformed with details specified in the data SAES-E-004,

C1

sheet. Para. 9.1

Where lugs are used as a support for vertical exchangers,

minimum number of four lugs are installed for exchangers SAES-E-004,

C2

above 24 inches in diameter. The locations and orientations of Para. 9.2

lugs shall be specified on the data sheet.

Horizontal exchangers are supported by at least two saddles.

(The exchanger are fixed at one saddle and free to move in the SAES-E-004,

C3

longitudinal direction, due to thermal and pressure differentials, Para. 9.3.1

at the other saddle).

Vertical exchangers, which are externally insulated, are 32-SAMSS-

C4 provided with insulation supports in accordance with SAES-N- 007,

001. Para. 7.21.7

Data sheet specifies location of saddles (fixed, sliding) &

SAES-E-004,

C5 dimension from exchanger centerline to underside of saddle

Para. 9.3.2

base plate.

D Coating of External Surface

Type Coating applied is suitable for the service condition of the SAES-E-004,

D1

of the equipment per SAES-H-001. Para. 11.2

The Approved Protective Coating Systems (APCS) are selected

from SAES-H-001101V and specified on the data sheet SAES-E-004,

D2

together with the applicable Class 09 specification for the Para. 11.3

surface preparation and painting systems.

The shell and external surfaces are protected by preparing the 32-SAMSS-

D3 surface and fully coating the external surfaces using the 007,

specified Saudi Aramco coating specification. Para. 11.1.19.2

Saudi Aramco: Company General Use

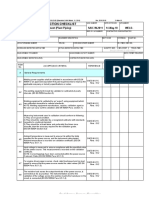

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Shell & Tube Heat

SAIC-E-2002 30-Apr-17 MECH-

Exchanger

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Tie-rods or tie-bars installed on shell expansion joints for

API 660 Para.

D4 protection during shipping are painted in a contrasting color and

11.1.9

clearly tagged to specify their removal before commissioning.

E Insulation (if furnished by Vendor)

The extent and thickness of external insulation are specified on SAES-E-004,

E1

the data sheet in accordance with SAES-N-001. Para. 11.1

Insulation installed is acceptable using Inspection Checklist,

Schedule Q,

E2 SAIC-N-2010 (for cold insulation) or SAIC-N-2016 (for hot

Att III

insulation).

F Fireproofing

The extent of fireproofing required on exchanger supports are in

SAES-E-004,

F1 accordance with the requirements of SAES-B-006 and specified

Para. 12

on the data sheet.

G Refractory lining

The value of the design density of the refractory is in

SAES-E-004,

G1 accordance with SAES-N-100 and is specified on the data

Para. 7.10.4

sheet.

H Nozzles

Welds attaching nozzles and their reinforcement pads and other

32-SAMSS-

attachments to pressure components are not closer than 20 mm

H1 007,

from any pressure retaining welds. See also 32-SAMSS-007,

Para. 9.5.11

Para 10.2.1.4.

Threaded or socket-welded connections are prohibited in

hydrogen, lethal, wet sour and caustic services. However, for

other services, threaded or socket-welded connections with

6000-lb. rating SAES-E-004

H2

conforming to ASME B16.11 may be used for NPS 1½ and Para. 8.1.5

smaller

vents, drains and instrument connections.

Nozzles NPS 1½ and larger are flanged.

Flanged connections are one of the following types:

1) Forged steel long welding neck.

2) Forged steel welding neck flange with seamless pipe, or

rolled

plate (100% RT). Bores of nozzle flanges match nozzle neck

32-SAMSS-

bore.

H3 007,

3) Studded nozzles & proprietary designs (alternatives) meet

Para. 7.7.4

Code

and have the prior approval of the Saudi Aramco Engineer.

4) Lap-type joints with loose end flange can be used for utility

services with pressure up to 1.4 MPa (200 psi) and a

temperature of 120°C (250°F).

Slip-on type flange with seamless pipe nozzle necks or rolled

plate with 100% radiography is permissible for exchangers, in

only non-cyclic utility services with design temperature and 32-SAMSS-

H4 design pressure not exceeding 400°C (750°F) and 2.1 MPA 007,

(300 psi), respectively. Slip-on flange shall be welded on the Para. 7.7.5

front or face and at the back of the hub per ASME SEC VIII D1,

Figure UW-21, detail (1), (2) or (3).

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Shell & Tube Heat

SAIC-E-2002 30-Apr-17 MECH-

Exchanger

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Unless otherwise specified on the data sheet, the minimum

projections for nozzle necks, as measured from the outside

surface of the shell or head to the face of a flange, shall meet

the following requirements:

a) 6 inches for NPS 6 nozzles and smaller.

32-SAMSS-

b) 8 inches for NPS 8 nozzles and larger.

H5 007,

c) For insulated exchangers, projection shall be sufficient to

Para. 7.7.6

allow bolting of studs without interference with the insulation.

d) For exchangers drain connections and other

connections, where a process stream is likely to be stagnant,

the projection shall not exceed three times the connection

nominal diameter.

For exchangers drain connections and other connections, 32-SAMSS-

H5 where a process stream is likely to be stagnant, the projection 007,

shall not exceed three times the connection nominal diameter. Para. 7.7.6.d

Pressure ratings of flanges are in accordance with the

following:

1) Pressure ratings of flanges 24 inch NPS and smaller are in SAES-E-004

H6

accordance with ASME B16.5. Para. 8.2.3

2) Pressure ratings of flanges larger than 24 inch NPS are in

accordance with ASME B16.47, Series A.

Flange facings are raised face or ring-type joint per SAES-L-

109.

NOTE: Flat face flanges may be used in utility services. ASME

SAES-E-004

H7 pressure classes & facings shall be as specified on data sheet.

Para. 8.2.4

Equipment

specifies flange facings to be compatible with ASME B31.3

Code Piping - Identify associated piping specs

J Gaskets

The type of gasket is specified on the data sheet in accordance

with SAES-L-109. SAES-E-004,

J1

Note: All gaskets shall be in accordance with API STD 660 and Para, 8.4.1, 2

ASME B16.20.

Gaskets in hydrocarbon or steam service are double-jacketed

metal with a soft gasket filler, solid metal, serrated metal with a API - 660, Para.

J2

soft gasket-seal facing, corrugated metal with a soft gasket-seal 7.10.1.

facing or spiral wound.

Spiral wound gaskets are as follows:

1) For all services and design temperatures, spiral wound

gaskets

shall be specified with solid outer centering rings.

2) For design temps above 450°C, spiral wound gaskets shall

be specified with solid outer centering rings & inner confining SAES-E-004,

J3

rings. Para, 8.4.3

3) For exchangers in continuous vacuum service, irrespective of

design temperature or design pressure, spiral wound gaskets

shall

be specified with solid outer centering rings & inner confining

rings.

Gaskets for nozzle connections in utility services may be

specified as non-asbestos per ASME B16.21, & must be SAES-E-004,

J4

chemically resistant and mechanically suitable for the service Para. 8.4.5

conditions.

K Identification

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Shell & Tube Heat

SAIC-E-2002 30-Apr-17 MECH-

Exchanger

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

The item number, shipping mass and purchase order number API - 660, Para.

K1

are painted on the heat exchanger. 11.2.1

All boxes, crates or packages are identified with the purchaser's API - 660, Para.

K2

order number and the item number. 11.2.2

The words " DO NOT WELD" are stenciled ( atleast two places

API - 660, Para.

K1 180 degress apart) on the side of the equipment that has been

11.2.3

post- weld heat-treated.

REMARKS:

Notes: The use of C-½ Mo steels in hydrogen services is prohibited.

REFERENCE DOCUMENTS:

1. 32-SAMSS-007, Manufacture of Shell and Tube Heat Exchangers, 01 December 2013

2. SAES-H-001, Coating Materials & Application Requirements for Industrial Facilities, 10 April 2011

3. SAES-E-004, Design Criteria of Shell and Tube Heat Exchangers, 11 July 2012

4. SAES-H-101V, Approved Saudi Aramco Data Sheets - Paints and Coatings, 25 September 2012

5. Schedule Q, Contractor's Quality Requirements, Project Specific

6. API 660 Eight Edition August 2007, Shell-and-tube Heat Exchangers

ATTACHMENTS:

1. 32-SAMSS-007 Tables 1 & 2 (Exchanger Material & Impact Test Reqmts)

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: QC Record

T&I Witnessed Work Verified

Reviewed

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed QC Record

Work / Rework May Proceed T&I Witnessed Work Verified

Inspection Reviewed

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: QC Record

T&I Witnessed Work Verified

Name, Organization, Reviewed

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Shell & Tube Heat

SAIC-E-2002 30-Apr-17 MECH-

Exchanger

ATTACHMENT 1 - 32-SAMSS-007 Tables 1 & 2 (Exchanger Material & Impact Test Reqmts)

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Вам также может понравиться

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechДокумент2 страницыSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanОценок пока нет

- Saic M 1034Документ3 страницыSaic M 1034Hussain Nasser Al- NowiesserОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент19 страницSaudi Aramco Inspection ChecklistIrshad IqbalОценок пока нет

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldДокумент19 страницSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldIrshad IqbalОценок пока нет

- Saic D 2025Документ12 страницSaic D 2025Md ShariqueОценок пока нет

- Saudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechДокумент1 страницаSaudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechmominОценок пока нет

- Saudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 WeldДокумент1 страницаSaudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 Weldm4metzОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент2 страницыSaudi Aramco Inspection Checklistkarthi51289Оценок пока нет

- Installation of Main Steel Structure/ Platform & Steam SilencerДокумент4 страницыInstallation of Main Steel Structure/ Platform & Steam SilencerzhangОценок пока нет

- Saudi Aramco Test ReportДокумент8 страницSaudi Aramco Test ReportJagdishОценок пока нет

- Saic D 2024Документ9 страницSaic D 2024Md ShariqueОценок пока нет

- Saic LPT 2006Документ12 страницSaic LPT 2006jerinОценок пока нет

- Saudi Aramco Inspection Checklist: Review Procedure - Pressure Testing (All Applications) SAIC-A-2001 15-Nov-17 MechДокумент27 страницSaudi Aramco Inspection Checklist: Review Procedure - Pressure Testing (All Applications) SAIC-A-2001 15-Nov-17 MechNaushad AlamОценок пока нет

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 MechДокумент4 страницыSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 Mechkarthi51289Оценок пока нет

- Saic M 1006Документ2 страницыSaic M 1006Hussain Nasser Al- NowiesserОценок пока нет

- Saic H 2082Документ8 страницSaic H 2082jerin100% (1)

- Saudi Aramco Inspection ChecklistДокумент6 страницSaudi Aramco Inspection Checklistkarthi51289Оценок пока нет

- SAES-M-009 PDF Download - Design Criteria For Blast Resistant Buildings - PDFYAR - Engineering Notes, Documents & LecturesДокумент7 страницSAES-M-009 PDF Download - Design Criteria For Blast Resistant Buildings - PDFYAR - Engineering Notes, Documents & LecturesZahidRafiqueОценок пока нет

- Saic W 2036Документ2 страницыSaic W 2036Neelam AhmadОценок пока нет

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 1-Nov-09 CivilДокумент2 страницыSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 1-Nov-09 CivilNaushad AlamОценок пока нет

- Saic B 1001Документ1 страницаSaic B 1001Hussain Nasser Al- NowiesserОценок пока нет

- Saudi Aramco Inspection Checklist: Duct System Handling, Storage and Preservation SAIC-K-4011 15-Dec-09 HvacДокумент1 страницаSaudi Aramco Inspection Checklist: Duct System Handling, Storage and Preservation SAIC-K-4011 15-Dec-09 HvacmohamadОценок пока нет

- Saic A 1002Документ2 страницыSaic A 1002karthi51289Оценок пока нет

- Saudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 WeldДокумент1 страницаSaudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 Weldkartik_harwani4387Оценок пока нет

- Saic W 2003Документ14 страницSaic W 2003Mohammed IlliasuddinОценок пока нет

- Saudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechДокумент3 страницыSaudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechmominОценок пока нет

- Saic B 1004Документ2 страницыSaic B 1004jerinОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент2 страницыSaudi Aramco Inspection Checklistkarthi51289Оценок пока нет

- Saudi Aramco Inspection Checklist: Pre Welding Inspection - Offshore Structures SAIC-W-1312 WeldДокумент1 страницаSaudi Aramco Inspection Checklist: Pre Welding Inspection - Offshore Structures SAIC-W-1312 Weldkartik_harwani4387Оценок пока нет

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechДокумент2 страницыSaudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechJagdishОценок пока нет

- Saic M 1053Документ1 страницаSaic M 1053Hussain Nasser Al- NowiesserОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент5 страницSaudi Aramco Inspection ChecklistAbdul HannanОценок пока нет

- Saudi Aramco Inspection Checklist: Concrete Sampling, Testing & Placement Inspection SAIC-Q-1060 15-Nov-17 MAH-SA-CДокумент3 страницыSaudi Aramco Inspection Checklist: Concrete Sampling, Testing & Placement Inspection SAIC-Q-1060 15-Nov-17 MAH-SA-CAbdul HannanОценок пока нет

- Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 WeldДокумент4 страницыSaudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 WeldMAZHARULОценок пока нет

- SAIC-W-2084 Buttering or Build-Up of JointsДокумент1 страницаSAIC-W-2084 Buttering or Build-Up of Jointskarioke mohaОценок пока нет

- Satip e 007 01Документ2 страницыSatip e 007 01Anonymous 4e7GNjzGWОценок пока нет

- Saudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 CivilДокумент2 страницыSaudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 Civilkarthi51289Оценок пока нет

- Saudi Aramco Inspection Checklist: SAIC-L-1003 29-Jun-17Документ1 страницаSaudi Aramco Inspection Checklist: SAIC-L-1003 29-Jun-17Zia ur RehmanОценок пока нет

- SAIC-L-2136 Rev 0Документ3 страницыSAIC-L-2136 Rev 0philipyapОценок пока нет

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 InstДокумент17 страницSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 Instkarthi51289Оценок пока нет

- Saic L 2004Документ18 страницSaic L 2004ejazОценок пока нет

- A A A A A A: Saudi Aramco Inspection ChecklistДокумент2 страницыA A A A A A: Saudi Aramco Inspection ChecklistAbdul HannanОценок пока нет

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureДокумент8 страницSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289Оценок пока нет

- Saic W 2011Документ3 страницыSaic W 2011munnaОценок пока нет

- Saudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechДокумент7 страницSaudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechmominОценок пока нет

- Satip F 001 04Документ4 страницыSatip F 001 04Anonymous 4e7GNjzGWОценок пока нет

- Saic Q 1046Документ1 страницаSaic Q 1046Gian CarloОценок пока нет

- Saic Q 1045Документ2 страницыSaic Q 1045Gian Carlo0% (1)

- Schedule B - Attachment IVДокумент29 страницSchedule B - Attachment IVAbdul Ahad LoneОценок пока нет

- Saic M 2010Документ17 страницSaic M 2010jerinОценок пока нет

- Saic M 2004Документ6 страницSaic M 2004Hussain Nasser Al- NowiesserОценок пока нет

- Saic M 1004Документ2 страницыSaic M 1004Hussain Nasser Al- NowiesserОценок пока нет

- 175 091300Документ2 страницы175 091300Abu Anas M.SalaheldinОценок пока нет

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechДокумент1 страницаSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWОценок пока нет

- Saic-M-1012 Rev 7 (Final)Документ3 страницыSaic-M-1012 Rev 7 (Final)Satheesh Rama SamyОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент13 страницSaudi Aramco Inspection ChecklistjunaidОценок пока нет

- Satr-W-2010Документ1 страницаSatr-W-2010Joni Carino SuniОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент8 страницSaudi Aramco Inspection ChecklistsureshОценок пока нет

- Saic D 2022Документ7 страницSaic D 2022sureshОценок пока нет

- Saic e 2005Документ13 страницSaic e 2005jerinОценок пока нет

- Saic H 2060Документ11 страницSaic H 2060jerinОценок пока нет

- Saic J 6903Документ9 страницSaic J 6903jerinОценок пока нет

- Saic LPT 2006Документ12 страницSaic LPT 2006jerinОценок пока нет

- Saic G 2002Документ32 страницыSaic G 2002jerinОценок пока нет

- Saic G 2011Документ15 страницSaic G 2011jerinОценок пока нет

- Saic Gi 2102Документ3 страницыSaic Gi 2102jerin100% (3)

- Saic A 1017Документ1 страницаSaic A 1017jerinОценок пока нет

- Saic LPT 2004Документ13 страницSaic LPT 2004jerinОценок пока нет

- Saic LPT 2001Документ22 страницыSaic LPT 2001jerinОценок пока нет

- Saic e 2004Документ8 страницSaic e 2004jerinОценок пока нет

- Saic LPT 2003Документ11 страницSaic LPT 2003jerinОценок пока нет

- Saic e 2005Документ13 страницSaic e 2005jerinОценок пока нет

- Saic A 1017Документ1 страницаSaic A 1017jerinОценок пока нет

- Saic e 2001Документ7 страницSaic e 2001jerinОценок пока нет

- Saic B 1004Документ2 страницыSaic B 1004jerinОценок пока нет

- Saic e 2003Документ7 страницSaic e 2003jerinОценок пока нет

- Saic M 1002Документ4 страницыSaic M 1002jerinОценок пока нет

- Saic A 1017Документ1 страницаSaic A 1017jerinОценок пока нет

- Saic A 2013Документ6 страницSaic A 2013jerinОценок пока нет

- Saic M 1004Документ2 страницыSaic M 1004jerinОценок пока нет

- Saic B 1002Документ3 страницыSaic B 1002jerinОценок пока нет

- Saic F 2022Документ4 страницыSaic F 2022jerinОценок пока нет

- Saic A 1017Документ1 страницаSaic A 1017jerinОценок пока нет

- Saic F 2021Документ11 страницSaic F 2021jerinОценок пока нет

- Saic A 1017Документ1 страницаSaic A 1017jerinОценок пока нет

- Saic A 2004Документ4 страницыSaic A 2004jerinОценок пока нет

- Saic A 1016Документ2 страницыSaic A 1016jerinОценок пока нет

- Saic A 2011Документ8 страницSaic A 2011jerinОценок пока нет

- Saic N 2031Документ3 страницыSaic N 2031jerinОценок пока нет

- Stainless CatalogДокумент65 страницStainless CatalogArun GuptaОценок пока нет

- Centralized Air ConditioningДокумент9 страницCentralized Air ConditioningA 04 Ankit SharmaОценок пока нет

- Ethylene TankДокумент4 страницыEthylene TankatulОценок пока нет

- General Properties Rheological Properties: PVC Paste Resin (Homopolymer)Документ2 страницыGeneral Properties Rheological Properties: PVC Paste Resin (Homopolymer)AminulIslamОценок пока нет

- Errata No. 1 For Vol. 2 of SEAOC Seismic Design Manual (1997 UBC Version) PDFДокумент12 страницErrata No. 1 For Vol. 2 of SEAOC Seismic Design Manual (1997 UBC Version) PDFThomas John Doblas AgrabioОценок пока нет

- Gaulhofer Range of Products Novelties For 2011 Windows Doors Sun ProtectionДокумент32 страницыGaulhofer Range of Products Novelties For 2011 Windows Doors Sun Protectionthomas_sulzerОценок пока нет

- Golden Sand-2Документ73 страницыGolden Sand-2SahilОценок пока нет

- The Iron Carbon Phase DiagramДокумент2 страницыThe Iron Carbon Phase Diagramsinha.subhasis1417Оценок пока нет

- 2" Flowgrid 250 Regulator & Shutoff Valve Assembly: Parts ListДокумент1 страница2" Flowgrid 250 Regulator & Shutoff Valve Assembly: Parts ListJbr IrvingОценок пока нет

- Spec Water Storage TanksДокумент5 страницSpec Water Storage TanksparthivОценок пока нет

- Puta in AyurvedaДокумент34 страницыPuta in AyurvedaDrVikas96% (24)

- Stabilization of Desert RoadДокумент10 страницStabilization of Desert RoadPallavi PankajakshiОценок пока нет

- Catalogo SchulzДокумент61 страницаCatalogo SchulzIsabel PulidoОценок пока нет

- Monte - Kenrich Titanate Coupling AgentДокумент135 страницMonte - Kenrich Titanate Coupling AgentHIMANSHUU AROURAОценок пока нет

- Basic Welding ProgrammeДокумент104 страницыBasic Welding ProgrammeAmit SharmaОценок пока нет

- Form Inspection For Rebar Pilecap and ColumnДокумент4 страницыForm Inspection For Rebar Pilecap and ColumnHary Anugrah100% (1)

- Analysis of Singly Reinforced Concrete Beam PDFДокумент3 страницыAnalysis of Singly Reinforced Concrete Beam PDFAnton_Young_1962Оценок пока нет

- Penanganan KorosiДокумент28 страницPenanganan KorosiAulia InayatiОценок пока нет

- Company Profile Lemindo Group Tugas Manj. InternasionalДокумент14 страницCompany Profile Lemindo Group Tugas Manj. InternasionalTony UdinusОценок пока нет

- Goa As Per G+4Документ53 страницыGoa As Per G+4sameershedgeОценок пока нет

- Plaster Profiles and Other Accessories - ENДокумент9 страницPlaster Profiles and Other Accessories - ENaayasirОценок пока нет

- DO - 013 - S2013 Generic Specs For SmaДокумент7 страницDO - 013 - S2013 Generic Specs For SmaAndrei AlidoОценок пока нет

- Design and Construction Guide: Hi-Vi Vibratory Feeder TraysДокумент8 страницDesign and Construction Guide: Hi-Vi Vibratory Feeder TraysBryan ScofieldОценок пока нет

- Behaviour of Reinforced Concrete Beams With Coconut Shell As Coarse AggregatesДокумент7 страницBehaviour of Reinforced Concrete Beams With Coconut Shell As Coarse AggregatesKrishnan ChockalingamОценок пока нет

- Design Guide: Sheet Metal FabricationДокумент12 страницDesign Guide: Sheet Metal FabricationSanatan ChoudhuryОценок пока нет

- MS-01-181 Stainless Steel Seamless Tubing - Fractional, Metric and ImperialДокумент4 страницыMS-01-181 Stainless Steel Seamless Tubing - Fractional, Metric and ImperialJacques StrappeОценок пока нет

- Air-Cooled Chillers Maintenance & Inspection ChecklistДокумент3 страницыAir-Cooled Chillers Maintenance & Inspection ChecklistdjukalОценок пока нет

- 577 Rigid CouplingДокумент4 страницы577 Rigid CouplingwiswanathenОценок пока нет

- Laboratory No. 11 Laboratory Concrete Mix ProportioningДокумент7 страницLaboratory No. 11 Laboratory Concrete Mix ProportioningPhoebe Imee ThomasОценок пока нет