Академический Документы

Профессиональный Документы

Культура Документы

Push Over Analysis PDF

Загружено:

SardimalAmirИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Push Over Analysis PDF

Загружено:

SardimalAmirАвторское право:

Доступные форматы

Gen Training Series Pushover Analysis as per EC8:2004

Pushover Analysis of steel structure

as per EC8:2004

DL SD NC

Program Version Gen 2015 (v 1.1)

Revision Date 5 Nov 2014

MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Overview Optimal Design Procedure

Pushover analysis is one of the performance-based design The pushover analysis procedure is as follows:

methods, recently attracting practicing structural engineers

engaged in the field of seismic design. The objective of a

performance-based design is achieved after the owner and the Modeling & Design

designer collectively select a target performance for the - Details of Building

structure in question. The engineer carries out the conventional - Perform analysis

design and subsequently performs a pushover (elasto-plastic) - Perform steel code checking

analysis to evaluate if the selected performance objective has

been met. Pushover Analysis

- Pushover Global Control

In midas Gen V741, pushover analysis as per EN1998:2004 - Pushover Load Cases

is newly added, and analysis performance and usability are - Define Hinge Properties

significantly improved. This tutorial explains the method and - Assign Hinge Properties

procedure for pushover analysis of 3-dimensional Steel - Perform Pushover Analysis

structures as per EN1998:2004. For this reason, the procedure - Pushover Curve

for modeling and analysis were not explained in detail. For the - Pushover Hinge Status Results

users who are not familiar with the basic functions for modeling - Safety Verification Table

and analysis, it is recommended to review “Application 1”

tutorial before following this tutorial.

2 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

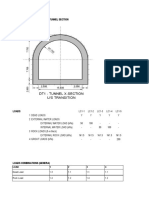

Details of the example structure

Section Name Section ID Section DB Section Size

C1 1 UNI HEA240

C2 2 UNI HEA300

G1 21 UNI HEA280

G2 22 UNI IPE240

Brace1 31 UNI HEA160

Brace2 32 UNI HEA120

Figure 1. Three-dimensional structural model

1 2 3

3,000

BR1

10,000

2,500 2,500 2,500 2,500

BR

G2

B

C2 C1 G2 C2

3,000

9,000

BR1

6,000

G1

G1

G1

3,000

BR2

G2 G2

A

BR C1 C2

C2

Figure 2. Structural plan Figure 3. Elevation

3 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Applied Design Code

•Eurocode3:2005

Materials

•Column: S235

•Beam: S235

•Brace: S235

Applied Loads

Gravity loads Unit Load Cases

•Dead load: 4.9kN/m2

•Live load : 2.5kN/m2

Load Name Details

Static Wind Loads

•Applied code: Eurocode1:2005 1 DL Dead Load

•Terrain Category : II

• Fundamental Basic Wind Velocity (Vb,o): 26m/s 2 LL Live Load

Wind Load

Static Seismic Loads Static 3 WX

(X-direction in the global coordinates)

•Applied code: Eurocode8:2004 Load

Cases Wind Load

•Ground Type: B 4 XY

(Y-direction in the global coordinates)

•Design Ground Acceleration: 0.08g Seismic Load

5 EX

•Behavior Factor (q): 1.5 (X-direction in the global coordinates)

•Lower Bound Factor (b): 0.2 Seismic Load

6 EY

•Importance Factor (I) : 1 (Y-direction in the global coordinates)

4 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Step 1. Open the model file and perform analysis

1. Open “Steel pushover analysis_start.mgb” Pushover analysis is carried out in the post-processing mode

2. Select Works tab in the Tree Menu. after completing elastic analysis.

3. Check the entered section data and boundary condition in

Properties and Boundaries.

4. In the tree menu, select Static Loads>Static Load Case 1

and then right click Floor Loads:3. 7

5. In the context Menu, select Display and then check the 2

applied loads.

6. By this way, check the applied seismic loads and wind

loads.

7. Click icon to perform analysis.

5 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Step 2: Check Steel Design Code

1. Design > Design > Steel Design > Design Code Design Code specified in the Steel Design Code dialog is

2. Specify the code as ‘Eurocode3:05’. applied to calculate the capacity of members in pushover

3. Check [OK] button.

analysis.

6 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Step 3: Steel Code Checking

Rotation capacity at the end of steel beams

or columns depends on the class of cross

1. Design > Design > Steel Design > Steel Code Check section. In order for the program to

automatically determine the class of cross

section for the pushover analysis, select

‘Auto’. For the automatic classification

Steel Code Checking should be performed

first.

7 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Step 4-1: Pushover Global Control

1. Pushover > Control > Global Control

2. Select DL in the combo box and click [Add] button.

In this step, we will define the initial load cases, which

3. Select LL in the combo box and enter the Scale Factor as 0.25.

4. Click [Add] button. will be applied prior to pushover analysis such as dead

5. Click [OK] button. load and live load.

2,3

2,4

8 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Step 4-2: Pushover Global Control

‘Reference Design code (Eurocode 8:2004)’ option is displayed when

the design code (in the main menu, Design > Design > RC Design or

Steel Design > Design code) is specified as Eurocode and Design code

in preferences (in the main menu, Tools > Setting > Preferences) is

specified as Eurocode.

Scale Factor for Ultimate Rotation

1) Wall: In calculating the total chord rotation capacity at ultimate , θu, for wall , the value is divided

by 1.6 as per EN1998-3:2004 A.3.1.1.

2) Cold-worked brittle steel: If cold-worked brittle steel is used the total chord rotation capacity is

divided by 1.6 as per EN1998-3:2004 A.3.1.1.

3) Without Detailing for earthquake resistance: In members without detailing for earthquake

resistance the total chord rotation capacity is multiplied by 0.85 as per EN1998-3:2004 .

4) Smooth longitudinal bars: in members with smooth (plain) longitudinal bars without lapping in

the vicinity of the end region where yielding is expected, the total chord rotation capacity may be

multiplied by 0.575 as per EN1998-3:2004.

9 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Step 4-3: Pushover Global Control

Secondary Seismic Elements

In order to calculate the total chord rotation capacity at ultimate, θu, the factor ‘γel’ is used. Since γel is differently applied for primary and

secondary seismic elements (γel = 1.5 for primary seismic elements, γel = 1.0 for secondary seismic elements as per EN1998-3:2004

A.3.1.1), the user can define Secondary Seismic Elements group. If Secondary Seismic Elements are not defined, all the elements are

considered as Primary Seismic Elements.

In this tutorial, Secondary Seismic Elements are not defined since pushover hinge properties are assigned to primary elements only.

10 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Step 5-1: Pushover Load Case

2

1. Pushover > Load Case > Pushover Load Cases

2. Click [Add] button.

3. Enter the pushover load case name as ‘Accel_X’.

4. Enter the Increment Steps as ‘30’.

5. Check on ‘Consider P-Delta Effect’ option.

6. Check on ‘Use Initial Load’ option.

7. Select ‘Displacement Control’ in the Increment Method.

8. Select ‘Mater Node’ option. 3

9. Click the entry field and click the node no. 20 with the

4

mouse in the model view. 5

10. Enter the Max. Displacement as 0.12m.

6

11. Check off ‘Limit inter-Story Deformation Angle’ option.

12. Specify the Load Pattern as ‘Uniform Acceleration’.

13. Specify the Direction as ‘DX’ in the combo box and click 7

[Add] button.

14. Click [OK] button.

8

10

11

9

12

13

13

14

11 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Step 5-2: Pushover Load Case

2

1. Pushover > Load Case > Pushover Load Cases

2. Click [Add] button.

3. Enter the pushover load case name as ‘EY_Y’.

4. Enter the Increment Steps as ‘30’.

5. Check on ‘Use Initial Load’ option.

6. Check on ‘Consider P-Delta Effect’ option.

7. Select ‘Displacement Control’ in the Increment Method.

8. Select ‘Mater Node’ option. 3

9. Click the entry field and click the node no. 20 with the

mouse in the model view. 4

5

10. Enter the Max. Displacement as 0.3m.

11. Check off ‘Limit inter-Story Deformation Angle’ option. 6

12. Specify the Load Pattern as ‘Static Load Cases’.

13. Specify the Load Case as ‘EY’ in the combo box and

7

click [Add] button.

14. Click [OK] button.

8

10

11

9

12

13

13

14

12 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Step 6-1: Define Pushover Hinge Properties for beams 2

1. Pushover > Assign > Assign Hinge Properties > Define Pushover

Hinge Properties

2. Click [Add] button.

3. Enter the pushover hinge properties name as ‘Beam’.

4. Select the Material Type as ‘Steel / SRC(Filled)’

5. Check on ‘Fz’ & ‘Mz’ components.

6. Click [Properties…] button for My component.

7. Select the Class of cross section as ‘Auto’.

8. Click [Apply] button.

3

In order to check or modify the hinge properties, click [Properties…]

button of the desired component.

4

9

13 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Step 6-2: Define Pushover Hinge Properties for Columns

1. Enter the pushover hinge properties name as ‘Column’.

2. Select the Material Type as ‘Steel / SRC(Filled)’

3. Select ‘P-M-M in Status Determination’ option for Interaction Type.

4. Check on ‘Fy’, ‘Fz’ & ‘My’ components. Coupled axial force-biaxial moment behavior is reflected by

5. Click [Yield Surface Properties…] button.

calculating the flexural yield strength of a hinge considering the

6. Click [Y-Axis…] button for My component.

7. Select the Class of cross section as ‘Auto’. effect of axial force.

8. Click [OK] button.

9. Click [z-Axis…] button for My component.

10. Select the Class of cross section as ‘Auto’.

11. Click [OK] button.

1

12. Click [OK] button. 7,10

13. Click [Apply] button.

6,9

8,11 3

13

12

14 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Step 6-3: Define Pushover Hinge Properties for braces

1. Enter the pushover hinge properties name as ‘Brace’.

2. Select the Element Type as ‘Truss’.

3. Select the Material Type as ‘Steel / SRC(Filled)’

4. Check on ‘Fx’ component.

5. Click [Properties…] button for Fx component.

6. Select the Class of cross section as ‘Auto’. 9

7. Click [OK] button.

8. Click [OK] button.

9. Click [Close] button. 1

5

4

8

7

15 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Pushover Hinge Properties

Yield strength of Steel structures

Shear

Eurocode3:2005, equation (6.18)

Hinge

Yield rotation of Steel structures

Class Class 1 Class 2

DL 1.0θy 0.25 θy

Flexural

Hinge

SD 6.0 θy 2.0 θy

NC 8.0 θy 3.0 θy

*θy= MyL/6EI

Where, My: Yield moment, L: Length of a member, E: Elasticity of Modulus, I: moment of inertia

16 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Step 7-1: Assign Pushover Hinge Properties for columns

1. Select column members (Material ID 1:Column) from the Tree Menu.

2. Pushover > Assign > Assign Hinge Properties > Assign Pushover Hinge Properties

3. Select Hinge Properties Type as ‘Column’ in the combo box.

4. Click [Apply] button.

5. Click [Close] button.

Right-click

1

4 5

17 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Step 7-2: Assign Pushover Hinge Properties for Beams

1. Select beam members (Material ID 2:Girder) from the Tree Menu.

Pushover hinge properties can be simply assigned to the

2. Drag and drop the ‘Beam’ hinge property from the Tree Menu to the

Model Window . selected elements by Drag & Drop.

1

Right-click

18 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Step 7-3: Assign Pushover Hinge Properties for braces

1. Select brace members from the Tree Menu.

Pushover hinge properties can be simply assigned to the

2. Drag and drop the ‘Brace’ hinge property from the Tree Menu to the

Model Window . selected elements by Drag & Drop.

Right-click

1

19 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Step 8: Check assigned hinge properties

Before assigning hinge properties (while defining hinge

1. Right-click ‘B1_Column’ from the Tree Menu. properties), Yield Strength and Yield Strain are displayed

2. Select ‘Properties’ from the context menu. as ‘1’. After assigning hinge properties, calculated values

3. Check the calculated yield strength and yield strain.

for each element are displayed.

4. Click [Detail] button to check the calculated values in detail.

By clicking [Detail] button, the user can check the

detailed equation and values.

Right-click

1

Before assigning hinge properties

20 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Step 9: Perform pushover analysis

1. Click ‘Task Pane’.

2. Click ‘▼’ icon and select ‘Analysis’. Task Pane displays work procedure for

3. Click ‘Perform Pushover Analysis’. advanced analysis functions and

description on input items so as to enable

the user to work more easily.

2

midas program provides 4 types of

advanced analysis features - Pushover

3 Analysis, Nonlinear Time History

Analysis, Time History Analysis and

Material Nonlinear Analysis.

In addition, Task Pane data can be

saved in the html format in the User

Folder, so that the user can directly write

or add the required input items for

analysis.

21 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

2

Step 10-1: Pushover Curve

1. Click ‘Pushover Curve’ in the Task Pane.

2. Select the Pushover Load Case as ‘Accel_X’.

3. Select ‘For Target Displacement (EC8/OPCM)’.

4. Select the Spectrum Type as ‘Horizontal Design 3

Spectrum’.

5. Enter the Design Ground Acc.(Ag) as ‘0.5’.

6. Enter the Behavior Factor (b) as ‘1.5’. 4

7. Click [Draw] button.

For the detailed formula of the Target Displacement, refer to ‘ANNEX B DETERMINATION OF THE

TARGET DISPLACEMENT FOR NONLINEAR STATIC (PUSHOVER) ANALYSIS, EN 1998-1:2004’. The

target displacement, which is obtained from the above, corresponds to the seismic demand of the Limit State of

Significant Damage (SD). Target displacement of the Limit State of Near Collapse (NC) is taken equal to that

of SD multiplied by 1.5. Target displacement of the Limit State of Damage Limitation (DL) is taken equal to

that of SD divided by 2.5.

22 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

1

Step 10-2: Pushover Curve

1. Select the Pushover Load Case as ‘EY_Y’.

2. Select ‘For Target Displacement (EC8/OPCM)’.

3. Select the Spectrum Type as ‘Horizontal Design

Spectrum’.

2

4. Enter the Design Ground Acc.(Ag) as ‘0.5’.

5. Enter the Behavior Factor (b) as ‘1.5’.

6. Click [Draw] button.

7. Click [Close] button.

3

6 7

For the detailed formula of the Target Displacement, refer to ‘ANNEX B DETERMINATION OF THE

TARGET DISPLACEMENT FOR NONLINEAR STATIC (PUSHOVER) ANALYSIS, EN 1998-1:2004’. The

target displacement, which is obtained from the above, corresponds to the seismic demand of the Limit State of

Significant Damage (SD). Target displacement of the Limit State of Near Collapse (NC) is taken equal to that

of SD multiplied by 1.5. Target displacement of the Limit State of Damage Limitation (DL) is taken equal to

that of SD divided by 2.5.

23 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Step 11-1: Hinge Status Results

1. Click ‘Hinge Status Results’ in the Task Pane.

2

2. Select the Pushover Load Cases Name as 6

‘Accel_X’. Clicking and scrolling

3. Select ‘Status of Yielding (EC8:2004)’.

4. Select the Components as ‘Ry’.

5. Check on ‘Legend’ and ‘Deform’.

6. Specify the desired step in the combo box. Clicking on the graph

The user can also check hinge status results for

each step by clicking on the step box and scroll

or clicking on the pushover graph which is

displayed in the black background.

3

4

1

24 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Step 11-2: Hinge Status Results

1. Select the Pushover Load Cases Name as 1

‘EY_Y’. 5

2. Select ‘Status of Yielding (EC8:2004)’.

3. Select the Components as ‘Ry’.

4. Check on ‘Legend’ and ‘Deform’.

5. Specify the desire step in the combo box.

25 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Step 12-1: Safety Verification Table

1. Click ‘Safety Verification Table’ in the Task Pane.

2. Select ‘Show All Elements’.

3. Click [OK] button.

4. Select Pushover Load Case as ‘Accel_x’.

5. Select ‘Significant Damage (SD)’.

6. Check on ‘My’ and ‘Fz’.

7. Click [OK] button.

2

3

Safety Verification Table displays the comparison results between the demand and

capacities of the elements as per EN1998-3:2004 Table 4.3. Safety verification shall be

conducted for both ductile and brittle elements respectively. For ductile elements,

verification will be conducted in terms of deformation using mean values of properties

6 divided by CF. For brittle elements, verification shall be conducted in terms of strength

using mean values of properties divided by CF and by partial factor.

7

26 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Step 12-2: Safety Verification Table

1. Right-click on the table and select ‘Set Safety

Verification’ in the Context menu.

2. Select Pushover Load Case as ‘EY_Y’.

3. Select ‘Significant Damage (SD)’.

4. Check on ‘My’ and ‘Fz’.

5. Click [OK] button.

1

2

Safety Verification Table displays the comparison results between the demand and

capacities of the elements as per EN1998-3:2004 Table 4.3. Safety verification shall be

conducted for both ductile and brittle elements respectively. For ductile elements,

verification will be conducted in terms of deformation using mean values of properties

4

divided by CF. For brittle elements, verification shall be conducted in terms of strength

using mean values of properties divided by CF and by partial factor.

5

27 MIDAS Information Technology Co., Ltd.

Gen Training Series Pushover Analysis as per EC8:2004

Capacity of Steel structures for assessment in the Safety Verification Table (Eurocode8-3:2004, Annex A.3.1)

Class Class 1 Class 2

DL 1.0θy 0.25 θy

Plastic rotation SD 6.0 θy 2.0 θy

capacity

NC 8.0 θy 3.0 θy

Shear capacity - Eurocode3:2005, equation (6.18)

*For ductile elements, mean values of properties divided by CF are used. For brittle members, mean values of properties

divided by CF and by partial factor.

*θy= MyL/6EI

Where, My: Yield moment, L: Length of a member, E: Elasticity of Modulus, I: moment of inertia

28 MIDAS Information Technology Co., Ltd.

Вам также может понравиться

- Basics of Wave MotionДокумент55 страницBasics of Wave Motionlalithkumar145100% (1)

- Seismic Assessment of Arch Bridge Across Slunjcica River in Slunj PDFДокумент10 страницSeismic Assessment of Arch Bridge Across Slunjcica River in Slunj PDFlorenzojovanotОценок пока нет

- Seismic Analysis and Design of Structures Using Response Spectra Time History MotionsДокумент60 страницSeismic Analysis and Design of Structures Using Response Spectra Time History MotionsFrancisco Héctor BañuelosОценок пока нет

- Demand Capacity Ratios Calculations For 3D Frame ElementsДокумент2 страницыDemand Capacity Ratios Calculations For 3D Frame ElementsLuis Martins0% (1)

- Analysis On The Causes of Cracks in BridgesДокумент14 страницAnalysis On The Causes of Cracks in BridgesNguyễn Văn MinhОценок пока нет

- Lib CivilДокумент13 страницLib CivilPandal RajОценок пока нет

- Noise WallДокумент20 страницNoise WallManiОценок пока нет

- Bda 5 25Документ34 страницыBda 5 25oОценок пока нет

- Civil Engineering Tools - TUYEN NGUYENNGOC List PDFДокумент4 страницыCivil Engineering Tools - TUYEN NGUYENNGOC List PDFCheng Por EngОценок пока нет

- Ka * γs * h 0: Water Tank Design And Crack Width CalculationДокумент21 страницаKa * γs * h 0: Water Tank Design And Crack Width CalculationGandhi SagarОценок пока нет

- Chapter8 - Design Theory & Procedure PDFДокумент407 страницChapter8 - Design Theory & Procedure PDFJunwhan KimОценок пока нет

- CalTrans Trenching Shoring ManualДокумент409 страницCalTrans Trenching Shoring Manualpiggirl21_185916844Оценок пока нет

- OutputДокумент5 страницOutputMoch Raka RizkiОценок пока нет

- Structural CalcsДокумент48 страницStructural CalcsNasir Ullah100% (1)

- Shear Hinge For Coupling BeamДокумент7 страницShear Hinge For Coupling BeamLavender HoneyОценок пока нет

- Wall Design ACI318M-02 Bearing Designed by ACI Section 14.5Документ2 страницыWall Design ACI318M-02 Bearing Designed by ACI Section 14.5EngDbtОценок пока нет

- Beggs Deformeter CalculationsДокумент5 страницBeggs Deformeter CalculationsCivil EngineerОценок пока нет

- Cyclic Behavior and Seismic Design of Bolted Flange Plate Steel Moment ConnectionsДокумент12 страницCyclic Behavior and Seismic Design of Bolted Flange Plate Steel Moment ConnectionsJoaquin PalermoОценок пока нет

- Cellular Light Weight Concrete Manufacturing Process & Properties Full DetailsДокумент4 страницыCellular Light Weight Concrete Manufacturing Process & Properties Full Detailskinley dorjee100% (1)

- (Etic Far East) : TEST Post-Tensioning LTDДокумент39 страниц(Etic Far East) : TEST Post-Tensioning LTDKunto Dwi WicaksonoОценок пока нет

- Liquefaction Mechanism of SoilsДокумент11 страницLiquefaction Mechanism of SoilsCSEngineerОценок пока нет

- List Eurocode IBSTДокумент5 страницList Eurocode IBSTLeed ENОценок пока нет

- SP 17M (14) Student PreviewДокумент12 страницSP 17M (14) Student PreviewPrasanth B0% (1)

- Stability Analysis of Retaining StructuresДокумент15 страницStability Analysis of Retaining StructuresSanko Kosan100% (1)

- Benchmark Cases For Advanced Design of Structural Steel ConnectionsДокумент26 страницBenchmark Cases For Advanced Design of Structural Steel Connectionswendydy6Оценок пока нет

- Tutorial For LRBДокумент24 страницыTutorial For LRBcaptain_tamОценок пока нет

- Seismic Design of Concrete StructureДокумент56 страницSeismic Design of Concrete Structureclarkgagui100% (1)

- Applying Orthogonal Combination Procedure As Per ASCE-7-05 For SDC C in Etabs Program. - Computers and Structures - ETABS - Eng-TipsДокумент2 страницыApplying Orthogonal Combination Procedure As Per ASCE-7-05 For SDC C in Etabs Program. - Computers and Structures - ETABS - Eng-TipsCristian Camilo Londoño Piedrahíta100% (1)

- TEDDS Engineering Library (US)Документ15 страницTEDDS Engineering Library (US)werxcvfdsОценок пока нет

- 02 LoadRatingBasicsДокумент58 страниц02 LoadRatingBasicsRabi Shankar YadavaОценок пока нет

- A Fresh Look at Bolted End Plate Behaviour and DesignДокумент11 страницA Fresh Look at Bolted End Plate Behaviour and DesignSulaim Al KautsarОценок пока нет

- Design of Dome: Type: ProjectДокумент9 страницDesign of Dome: Type: ProjectdeponkkarОценок пока нет

- Eurocode 7 Geotechnical Limit AnalysisДокумент19 страницEurocode 7 Geotechnical Limit AnalysisPurdiansyahОценок пока нет

- Table of Design Properties For Metric Steel Bolts M5 To M39 - Eurocode 3Документ9 страницTable of Design Properties For Metric Steel Bolts M5 To M39 - Eurocode 3DEIVASIHAMANI PERUMALОценок пока нет

- Analysis and Design of Inclined ColumnsДокумент6 страницAnalysis and Design of Inclined ColumnsMouhamad WehbeОценок пока нет

- EN1994 4 HanswilleДокумент73 страницыEN1994 4 Hanswilleoluomo1Оценок пока нет

- Time Dependent Analysis in SAP2000Документ7 страницTime Dependent Analysis in SAP2000Reynaldo Valdez HerreraОценок пока нет

- ACI 318M-11 RC Beam Ledge Design - v0.04 - 2020-07-23Документ5 страницACI 318M-11 RC Beam Ledge Design - v0.04 - 2020-07-23Vietanh PhungОценок пока нет

- Appendix A - Example 2.1Документ71 страницаAppendix A - Example 2.1JustinОценок пока нет

- AISI Appendix BДокумент9 страницAISI Appendix Brk_vijay81Оценок пока нет

- Probabilistic Seismic Hazard Analysis Nepal (Solukhumbu) Complete ReportДокумент74 страницыProbabilistic Seismic Hazard Analysis Nepal (Solukhumbu) Complete ReportSabin AcharyaОценок пока нет

- Laterally Loaded Pile Analysis Program For The MicrocomputerДокумент510 страницLaterally Loaded Pile Analysis Program For The MicrocomputerAmrut BhattОценок пока нет

- Bridge Design Standard - IntroductionДокумент1 страницаBridge Design Standard - IntroductionA. S. M. Elias ShahОценок пока нет

- Brochure Sheet PilesДокумент2 страницыBrochure Sheet PilesdadОценок пока нет

- Case 1-During ErectionДокумент15 страницCase 1-During Erectionmohamedadel100Оценок пока нет

- Inverted-T Capacity Calculation@Phase1v2Документ11 страницInverted-T Capacity Calculation@Phase1v2satyaОценок пока нет

- Kh-CFEM (1992)Документ5 страницKh-CFEM (1992)DM DIAZ BLANDONОценок пока нет

- Design and Construction of Reinforced Concrete Chimneys (ACI 307-98) PDFДокумент17 страницDesign and Construction of Reinforced Concrete Chimneys (ACI 307-98) PDFCristobal Jimenez MuchoОценок пока нет

- Chapter05 - Plane Frame and Grid EqДокумент63 страницыChapter05 - Plane Frame and Grid EqAgus BaeОценок пока нет

- Two Dimensional Analysis of Frame StructuresДокумент54 страницыTwo Dimensional Analysis of Frame StructuresFrank PuchiОценок пока нет

- Wind Induced Vibration and Dynamic Response On Concrete ColumnДокумент23 страницыWind Induced Vibration and Dynamic Response On Concrete ColumnAndres FernandezОценок пока нет

- Composite Bridge: Prepared By: Jay BhavsarДокумент15 страницComposite Bridge: Prepared By: Jay BhavsarJay BhavsarОценок пока нет

- Timber Joist Design BS5268Документ3 страницыTimber Joist Design BS5268Zheny FortinОценок пока нет

- Underground Water TankДокумент18 страницUnderground Water TankMohonAliОценок пока нет

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionОт EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionОценок пока нет

- Site Office Design Report - 201118Документ47 страницSite Office Design Report - 201118SardimalAmirОценок пока нет

- Struture Design Jetty LontarДокумент12 страницStruture Design Jetty LontarSardimalAmir100% (2)

- Pt. Diachems Resins Indonesia 5Th Train Expansion Project Production Building Calculation ReportДокумент42 страницыPt. Diachems Resins Indonesia 5Th Train Expansion Project Production Building Calculation ReportSardimalAmirОценок пока нет

- Foundation Design by Using AfesДокумент31 страницаFoundation Design by Using AfesSardimalAmirОценок пока нет

- This Study Resource Was: MCV4U Exam ReviewДокумент9 страницThis Study Resource Was: MCV4U Exam ReviewNathan WaltonОценок пока нет

- Web Programming: GET / HTTP/1.1 ..Документ16 страницWeb Programming: GET / HTTP/1.1 ..Alecu IlieОценок пока нет

- Environmental and Chemical Policy Module3Документ47 страницEnvironmental and Chemical Policy Module3jahazi1Оценок пока нет

- Using The Words in The Box, Fill in All The GapsДокумент23 страницыUsing The Words in The Box, Fill in All The GapsMo NoОценок пока нет

- Two Occult Philosophers in The Elizabethan Age: by Peter ForshawДокумент10 страницTwo Occult Philosophers in The Elizabethan Age: by Peter ForshawFrancesco VinciguerraОценок пока нет

- Ruby Onyinyechi Amanze - Werte Magazine - 2019Документ2 страницыRuby Onyinyechi Amanze - Werte Magazine - 2019José LaertonОценок пока нет

- GCGM PDFДокумент11 страницGCGM PDFMiguel Angel Martin100% (1)

- Pipetite: Pipetite Forms A Flexible, Sanitary Seal That Allows For Pipeline MovementДокумент4 страницыPipetite: Pipetite Forms A Flexible, Sanitary Seal That Allows For Pipeline MovementAngela SeyerОценок пока нет

- Learning Activity No.2Документ1 страницаLearning Activity No.2Miki AntonОценок пока нет

- Maxwell's Equations and Stoke's TheoremДокумент26 страницMaxwell's Equations and Stoke's TheoremTuya ErdenejargalОценок пока нет

- Pamphlet On Arrangement of Springs in Various Casnub Trolleys Fitted On Air Brake Wagon PDFДокумент9 страницPamphlet On Arrangement of Springs in Various Casnub Trolleys Fitted On Air Brake Wagon PDFNiKhil GuPtaОценок пока нет

- RS577 - Civil Engineering Curriculum 2073Документ90 страницRS577 - Civil Engineering Curriculum 2073mahesh bhattaraiОценок пока нет

- Questionnaire OriginalДокумент6 страницQuestionnaire OriginalJAGATHESANОценок пока нет

- 1939 - Hammer - Terrain Corrections For Gravimeter StationsДокумент11 страниц1939 - Hammer - Terrain Corrections For Gravimeter Stationslinapgeo09100% (1)

- NEW Sample ISAT Questions RevisedДокумент14 страницNEW Sample ISAT Questions RevisedHa HoangОценок пока нет

- Ddec VДокумент30 страницDdec Vllama100% (1)

- TuberkulosisДокумент285 страницTuberkulosisTeuku M. FebriansyahОценок пока нет

- DesignДокумент402 страницыDesignEduard BoleaОценок пока нет

- Reforms of Parvez MusharifДокумент8 страницReforms of Parvez MusharifTalha AslamОценок пока нет

- AnnexIIRecommendationsbyHOTCCommittee06 11 18Документ6 страницAnnexIIRecommendationsbyHOTCCommittee06 11 18Bilal AbbasОценок пока нет

- Automatic Tools For High Availability in Postgresql: Camilo Andrés EcheverriДокумент9 страницAutomatic Tools For High Availability in Postgresql: Camilo Andrés EcheverriRegistro PersonalОценок пока нет

- Diagnostic Test - Tle8Документ2 страницыDiagnostic Test - Tle8rose mae marambaОценок пока нет

- 2009-04-CEN-TC121 N1574 Working Programme CEN TC 121Документ28 страниц2009-04-CEN-TC121 N1574 Working Programme CEN TC 121Manuel ValenteОценок пока нет

- 4040 SERIES: Hinge (Pull Side) (Shown) Top Jamb (Push Side) Parallel Arm (Push Side)Документ11 страниц4040 SERIES: Hinge (Pull Side) (Shown) Top Jamb (Push Side) Parallel Arm (Push Side)Melrose FabianОценок пока нет

- MAPEH-Arts: Quarter 3 - Module 2Документ24 страницыMAPEH-Arts: Quarter 3 - Module 2Girlie Oguan LovendinoОценок пока нет

- Calculating Staff Strength:: Find Latest Hospitality Resources atДокумент8 страницCalculating Staff Strength:: Find Latest Hospitality Resources atPriyanjali SainiОценок пока нет

- Refrigerant Unit Lab ReportДокумент19 страницRefrigerant Unit Lab Reportakmal100% (2)

- IRAQ Reproductive Maternal, Newborn, Child and Adolescent HealthДокумент32 страницыIRAQ Reproductive Maternal, Newborn, Child and Adolescent HealthbejarhasanОценок пока нет

- Yazaki BrochureДокумент4 страницыYazaki Brochureguzman_10Оценок пока нет

- Pavlishchuck Addison - 2000 - Electrochemical PotentialsДокумент6 страницPavlishchuck Addison - 2000 - Electrochemical PotentialscomsianОценок пока нет