Академический Документы

Профессиональный Документы

Культура Документы

Type AB Air Gaps - Practical Examples

Загружено:

Zack ZakariaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Type AB Air Gaps - Practical Examples

Загружено:

Zack ZakariaАвторское право:

Доступные форматы

Type ‘AB’ Air Gaps

Practical Examples and Calculations

Ian McCrone BSc. CEng. MIMechE., Chairman ATCM

This article is aimed at clarifying regulation requirements of Type ‘AB’

Air Gaps and the new thinking by the Water Companies in their practical

application.

The Regulations are quite specific, a type ‘AB’ Air Gap is, by definition is unrestricted. i.e. No

Screening of the Spill Slot.

However, as was further explained, due to practical considerations WRAS and the Water

Undertakers are now prepared to accept or recommend in certain circumstances, the need to

screen a Type ‘AB’ Spill Slot.

In practice, this will mean, most if not all Type ‘AB’ Spill Slots will be accepted when provided

with appropriate screening and cowl outlet.

The onus will still be with the Tank designer, for any given duty, to ensure the spill slot size and

configuration will be compliant with

the Regulations.

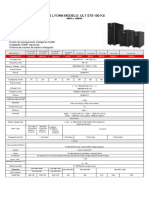

Type AB Weir Slot / Air Gap Calculator

Compliant to BS EN 13077:2003

The Fundamental’s "Devices to prevent pollution by backflow of potable water - Air Gap with non-circular overflow (unresticted) Family A, type B"

Calculations based on a maximum allowable flow of 3m/s unless a lower flow rate is known.

Enter data requested in yellow boxes only. i.e. Number of cistern Inlets and their respective

Diameters, Weir Width and % Open Area, Weir Crest Thickness and Distance from Weir Sill to Cistern

The determination of a Type ‘AA’ Base and the total maximum flow rate is automatically calculated. No. of Inlets 1

(Sample calc. Shown; for 1 - 25mm dia. inlet with a selected 400mm wide slot with 45% open area. Cw=50 & Uw=500mm)

and ‘AB’ Air Gaps and spill slot Inlet dia. mm

Inlet 1

For Multiple Inlets - Enter size of additional inlets as appropriate

No Inlet No Inlet No Inlet No Inlet

Total Max.

Inflow

design still rests, at the present time, 25

87.50 0.00 0.00 0.00 0.00

(Litres/min)

87.50

with BS 6281:Part1:1992 (BS EN Only enter data when using manual entry of a known value of "Q"

13077). The Specification for the now (Value must be less than that calculated for "Total Max. Infow")

superseded Type ‘A’ Air Gap. Q value used in the Critical Water Level calculation - (Litres/min.) 87.50

Enter Weir width "W" 400 mm Equivalent Inlet dia. "De" 25 mm

Min. height of Air Gap "A" 50 mm

The formula for determining the head Enter % Screen Open Area 45 Enter Weir Crest thickness "Cw" 50 mm

of water ‘h’ discharging over the weir (Note: Unscreened Weir =100) Enter distance from Weir Sill to Tank Base"Uw" 500 mm

the spill slot is advised as are the Calculations valid for single or multiple inlet arrangements if the following conditions are met

"h" = head over Weir at Total Maximum Flow.

other critical parameters related to the 1 W i d t h W is greater than or equal to 10h at the spillover level. (If not, increase W)

slot design. 2

3

Weir crest thickness Cw is less than or equal to 5h

Upstream face Uw of weir or notch is vertical to a depth of 2h

4 The depth of the weir Ow is greater than or equal to 2De+h

Acceptable Weir Sizes Validation Criteria (see above)

All dimentions in mm W Ow (4)

The ATCM web site Weir width Weir height h 1 2 3

Unrestricted Weir 400 67 17 YES YES YES

www.atcmtanks.org.uk, on its (No Insect Screen)

Technical / News page, provides the Weir width W increased to account

for insect screen obstruction

889 67 17 YES YES YES

ATCM “Type AB Air Gap and Spill Slot height Ow increased to account

for insect screen obstruction

400 79 29 YES YES YES

Slot Calculator” (as shown right) in

the form of an Excel Spreadsheet.

Inputting tank inlet diameter/s and

slot length the Calculator

automatically provides the value ‘h’

for an unscreened slot and minimum

slot height.

Additionally it advises i) for the same value of ‘h’ the required increased slot length for a screen

with a particular % free area or ii) for the same slot length the increase required in ‘h’.

The calculated results are only valid if the Validation’s 1 to 4 are met.

Practical Guidance

From a design and manufacturing viewpoint

limit the options available. Consider adopting

only two spill slot lengths suited to a specific

tank range. In the examples below 400mm and

800mm have been selected as ‘W’. Choose a

reasonable maximum value for ‘h’, say 20mm

for inlets up to and including 32mm for the

smaller slot and 50mm for the larger inlets and

slot size. This approach will provide compact

and economical designs.

Example Calculations

1) Determine relative inlet centreline level (c/l) of a 25mm dia. Equilibrium F/V above the

weir sill level of a Type ‘AB’ 400mm long Spill Slot (a - unscreened and b - screened.)

a) Unscreened Slot

‘h’ = 17mm

‘OW’ min. slot height = 67mm (2 x F/V dia. + head over

weir)

Equilibrium Float Valve inlet centreline is 1.5 x F/V dia.

above its discharging outlet = 1.5 x 25 = 38mm.

Therefore, F/V c/l is (‘OW’ + 38) = 105mm above weir

sill level.

b) Screened Slot

If this 400mm long Spill Slot is fitted with a 45% Free Area Screen the value of ‘h’ will

require to increase.

The Calculator provides the value of ‘hs’ = 29mm or the following formula advises how this is

derived.

2/3

S

Therefore ‘h’ increases until the same flow to passes through the screen. In this instance ‘h’ requires

to increase to - 2/3

S

Consequently F/V c/l is required to be positioned 117mm

117 above weir sill level.

S

Remember, ‘OW’ (spill slot height) requires to be increased to

2/3 79mm and is given by 2 x F/V dia. + head ‘hs ’ over weir.

For other typical inlet and slot size examples the following can be determined,

2) F/V = 50mm dia., Slot length = 800mm

Therefore -

‘h’ (unscreened) = 27mm

‘OW’ = 127mm.

F/V c/l to weir sill level = 202mm

For Slot with 45% free area screen

‘hs ’ (screened) = 46mm

‘OW’ = 146mm

F/V c/l to weir sill level = 221mm

3) F/V = 100mm dia. Slot length = 800mm

Therefore -

‘h’ (unscreened) = 68mm

‘OW’ = 268mm.

F/V c/l to weir sill level = 418mm

For Slot with 45% free area screen

‘hs ’ (screened) = 116mm

‘OW’ = 316mm

F/V c/l to weir sill level = 466mm

In this latter Screened Slot example the minimum requirement for the slot length of 10 x hs

(1160mm) is not met by a single 800mm weir slot. It is therefore a non-compliant design. It is

recommended 2 x 800mm wide slots be employed.

In example 3) a further benefit is obtained if 2 x 800mm long Spill Slots are employed. The values

of ‘h’ and ‘hs’ would reduce to 43 and 73mm with the effect of raising the TWL by some 25 and

43mm respectively and if tank surface area is large compared to its depth, considerably

increases the volume of water stored

Note: Information provided is advisory only.

Copyright

Вам также может понравиться

- Spreader BeamДокумент7 страницSpreader BeamAnonymous sfkedkymОценок пока нет

- Extruded Alloy 6063Документ0 страницExtruded Alloy 6063Lasantha DadallageОценок пока нет

- Data Assigment 1Документ32 страницыData Assigment 1Sukhwinder Kaur100% (1)

- Autocad 2019 Tips and Tricks A4 Landscape en PDFДокумент44 страницыAutocad 2019 Tips and Tricks A4 Landscape en PDFAndi Harta100% (1)

- Tank Design CalculatorДокумент19 страницTank Design CalculatorSunday PaulОценок пока нет

- Swimming Pool DesignДокумент49 страницSwimming Pool Designcashlover100% (1)

- FM130036 - EnC 18 - Stairway SpecificationДокумент20 страницFM130036 - EnC 18 - Stairway Specificationayman ammar100% (1)

- NORSOK Piping Details Standard for Instrument ConnectionsДокумент41 страницаNORSOK Piping Details Standard for Instrument ConnectionsAli BariОценок пока нет

- Double Wall TankДокумент1 страницаDouble Wall TankFerry Triyana AnirunОценок пока нет

- OxfordFiltration SelfCleaningFiltersДокумент2 страницыOxfordFiltration SelfCleaningFiltersgui51comlimaoОценок пока нет

- WRAS CWS CisternsДокумент8 страницWRAS CWS CisternsAdam ReesОценок пока нет

- ASME manual coil heating procedureДокумент8 страницASME manual coil heating procedurehgagОценок пока нет

- Mechanical Properties ExplainedДокумент38 страницMechanical Properties ExplainedJamaica VelascoОценок пока нет

- Inner Scraper Self-Cleaning FiltersДокумент1 страницаInner Scraper Self-Cleaning FiltersCarlos BarriosОценок пока нет

- Dosing Unit Modifications FinalДокумент11 страницDosing Unit Modifications FinalMrОценок пока нет

- Weigh Bridge Endevour (4950 X 5000 X 4950 X 3000 X 587 Pitless), 16X3 MTR, 100MT 8 LC, Patel Infr - Vadodara. - WBI - 164Документ1 страницаWeigh Bridge Endevour (4950 X 5000 X 4950 X 3000 X 587 Pitless), 16X3 MTR, 100MT 8 LC, Patel Infr - Vadodara. - WBI - 164abhibawaОценок пока нет

- 17-Surface Roughness and Machining SymbolsДокумент3 страницы17-Surface Roughness and Machining SymbolsNilesh MahajanОценок пока нет

- Fire Water Storage Tank PDFДокумент2 страницыFire Water Storage Tank PDFsky7Оценок пока нет

- KT Penstock PDFДокумент24 страницыKT Penstock PDFKmi GutierrezОценок пока нет

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionОт EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionОценок пока нет

- Pump PresentationДокумент47 страницPump Presentationmdzuljpi100% (2)

- KITZ ProductДокумент44 страницыKITZ Productkingathur26681Оценок пока нет

- Storage Silo, Bolting Silo, Mild Steel Silo, Lime Storage Silo, Manufacturers, Ahmedabad, Gujarat, IndiaДокумент2 страницыStorage Silo, Bolting Silo, Mild Steel Silo, Lime Storage Silo, Manufacturers, Ahmedabad, Gujarat, Indiaaarticleseansmo50% (2)

- Roll Grooved Anti-Vortex Plate - Hot Dipped GalvanisedДокумент1 страницаRoll Grooved Anti-Vortex Plate - Hot Dipped GalvanisedNikhil RajanОценок пока нет

- Pump HandbookДокумент19 страницPump HandbookSuranga GayanОценок пока нет

- Validation Rules in SAP FIДокумент3 страницыValidation Rules in SAP FINethaji GurramОценок пока нет

- Polyurethane Insulated CO2 Storage TanksДокумент6 страницPolyurethane Insulated CO2 Storage TanksVPFQ24Оценок пока нет

- M30 Reinforced Concrete Column Design DetailsДокумент1 страницаM30 Reinforced Concrete Column Design DetailsCMM INFRAPROJECTS LTDОценок пока нет

- Agitated Nutsche FilterДокумент1 страницаAgitated Nutsche FilterHaseeb KhanОценок пока нет

- On-Site Electrolytic Chlorination Skid-Mounted OSEC B-Pak SystemДокумент4 страницыOn-Site Electrolytic Chlorination Skid-Mounted OSEC B-Pak SystemgohviccОценок пока нет

- Appendix A: Variable Ranges For Filter Cycle Calculations: Basic Properties of Solids, Solutes and FluidsДокумент10 страницAppendix A: Variable Ranges For Filter Cycle Calculations: Basic Properties of Solids, Solutes and FluidsBrendaline EnopiaОценок пока нет

- IIT Hyderabad Faculty Housing Design CalculationsДокумент33 страницыIIT Hyderabad Faculty Housing Design CalculationssmijusОценок пока нет

- Bunker StudyДокумент20 страницBunker StudySripara KrishnaОценок пока нет

- Unraveling the mysteries of pipe thread sizesДокумент1 страницаUnraveling the mysteries of pipe thread sizesJeffrey WalkerОценок пока нет

- Product Overview Dryers Filter-Dryers & MixersДокумент6 страницProduct Overview Dryers Filter-Dryers & Mixersviajes cdcОценок пока нет

- 2924-A110-13C67-DWG-0004 - R0.1 - Electrical Cable Routing and Tray Routing Layout AdsorberДокумент7 страниц2924-A110-13C67-DWG-0004 - R0.1 - Electrical Cable Routing and Tray Routing Layout AdsorberRonti ChanyangОценок пока нет

- Knife Gate Valve - For Reference OnlyДокумент16 страницKnife Gate Valve - For Reference Onlysj_scribdОценок пока нет

- Is 4894 1987Документ18 страницIs 4894 1987sajay2010Оценок пока нет

- High Speed DoorsДокумент64 страницыHigh Speed DoorsTgОценок пока нет

- Castors and WheelsДокумент29 страницCastors and WheelsJohan ConradieОценок пока нет

- OSHA standards for portable ladders, stairways and fixed laddersДокумент45 страницOSHA standards for portable ladders, stairways and fixed laddersAMITОценок пока нет

- GondolaДокумент1 страницаGondolascax25Оценок пока нет

- CFD ApplicationsДокумент5 страницCFD ApplicationsavailmeОценок пока нет

- Petroleum Tanks BrochureДокумент12 страницPetroleum Tanks BrochureM.Sreeram SanjayОценок пока нет

- 2 1 PDFДокумент162 страницы2 1 PDFyvanmmuОценок пока нет

- Piping FabricationДокумент3 страницыPiping FabricationNa100% (2)

- Storage Tanks Made of SteelДокумент6 страницStorage Tanks Made of SteelHakan Şahinoğlu100% (1)

- Conical Base Cylindrical PE Tanks SpecsДокумент4 страницыConical Base Cylindrical PE Tanks SpecsAmoolia Ngo0% (1)

- Fire Pump FAQДокумент2 страницыFire Pump FAQK SubramaniОценок пока нет

- Pressure Vacuum Relief Valve Flame Arrester 102Документ3 страницыPressure Vacuum Relief Valve Flame Arrester 102vikramОценок пока нет

- Brochure SMBДокумент24 страницыBrochure SMBfelipeОценок пока нет

- Atmatec - Fibreglass Products For Drainage Systems PDFДокумент44 страницыAtmatec - Fibreglass Products For Drainage Systems PDFHafiz KamalОценок пока нет

- Filter Press QuestionnaireДокумент3 страницыFilter Press QuestionnaireRakhee SinhaОценок пока нет

- Agitated Nutsche FilterДокумент9 страницAgitated Nutsche FilterSulabhKumarJainОценок пока нет

- Non-Slip Floor Aggregates for Industrial AreasДокумент2 страницыNon-Slip Floor Aggregates for Industrial AreasBalasubramanian AnanthОценок пока нет

- Blower SilencersДокумент25 страницBlower SilencersManuel Javier G'Оценок пока нет

- Woods Silencer Catalogue and Technical DataДокумент12 страницWoods Silencer Catalogue and Technical DataJagatjeet MaanОценок пока нет

- ASCE 7-05 Table 15-4-2Документ1 страницаASCE 7-05 Table 15-4-2barouniamineОценок пока нет

- ESP Insulation Thickness CalculationДокумент1 страницаESP Insulation Thickness CalculationaruntpeОценок пока нет

- Pressure Vessel DesignДокумент8 страницPressure Vessel DesignHector Javier Cruz CampaОценок пока нет

- Through Conduit Gate Valves Slab & ExpandingДокумент7 страницThrough Conduit Gate Valves Slab & ExpandingRockny310Оценок пока нет

- Piping MaterialsДокумент3 страницыPiping MaterialsMurtadda MohammedОценок пока нет

- Final Dwg-Sludge Pump-4178Документ93 страницыFinal Dwg-Sludge Pump-4178erol100% (1)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryОт EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryОценок пока нет

- PROPOSED 5-STOREY RESIDENTIAL BLOCK WITH SWIMMING POOLДокумент6 страницPROPOSED 5-STOREY RESIDENTIAL BLOCK WITH SWIMMING POOLZack ZakariaОценок пока нет

- List of DrawingДокумент1 страницаList of DrawingZack ZakariaОценок пока нет

- p1200 - Water Consumption CalculationДокумент1 страницаp1200 - Water Consumption CalculationZack ZakariaОценок пока нет

- Guidance Note On Improving Ventilation and Indoor Air Quality in BuildingsДокумент5 страницGuidance Note On Improving Ventilation and Indoor Air Quality in BuildingsZack ZakariaОценок пока нет

- Project water calculation for 24 unit developmentДокумент3 страницыProject water calculation for 24 unit developmentZack ZakariaОценок пока нет

- Butterfly ValvesДокумент3 страницыButterfly Valvesgepewin2009Оценок пока нет

- Air Gap Calculations - Multiple Cistern InletsДокумент2 страницыAir Gap Calculations - Multiple Cistern InletsZack ZakariaОценок пока нет

- GWMJ020 1002 AДокумент1 страницаGWMJ020 1002 AZack ZakariaОценок пока нет

- Servo Fans and BlowersДокумент69 страницServo Fans and BlowersZack ZakariaОценок пока нет

- Resign 2Документ1 страницаResign 2Zack ZakariaОценок пока нет

- How to Size a Grease Trap: A Guide to Finding the Proper DimensionsДокумент6 страницHow to Size a Grease Trap: A Guide to Finding the Proper DimensionsZack ZakariaОценок пока нет

- fp2 PDFДокумент1 страницаfp2 PDFZack ZakariaОценок пока нет

- How To Fix - User Profile Service Failed The Logon - Profile Is Corrupted (Solved) - Wintips - Org - Windows Tips & How-TosДокумент13 страницHow To Fix - User Profile Service Failed The Logon - Profile Is Corrupted (Solved) - Wintips - Org - Windows Tips & How-TosZack ZakariaОценок пока нет

- GD-1884 Manual PDFДокумент10 страницGD-1884 Manual PDFAnonymous srwHCpAОценок пока нет

- Timetable Saturday 31 Dec 2022Документ1 страницаTimetable Saturday 31 Dec 2022Khan AadiОценок пока нет

- SVCE Seminar Report Format (FINAL)Документ6 страницSVCE Seminar Report Format (FINAL)Vinod KumarОценок пока нет

- ELEN3017A Project Brief 2022 Rev2Документ3 страницыELEN3017A Project Brief 2022 Rev2Dick MabhidaОценок пока нет

- ZIEHL ABEGG Main Catalogue Centrifugal Fans With IEC Standard MotoДокумент285 страницZIEHL ABEGG Main Catalogue Centrifugal Fans With IEC Standard MotoTomislav BrezicОценок пока нет

- Heliosit OrthodonticДокумент20 страницHeliosit OrthodonticAndhika Galih PrasetyoОценок пока нет

- Maths EnglishДокумент26 страницMaths EnglishmeenasarathaОценок пока нет

- Preventing Generator Damage from Hydrogen MoistureДокумент27 страницPreventing Generator Damage from Hydrogen MoistureIskerОценок пока нет

- 19Ma2Icmat Module 5 - Elementary Numerical MethodsДокумент4 страницы19Ma2Icmat Module 5 - Elementary Numerical Methods1DS19CH011 Jashwanth C RОценок пока нет

- HP Application Lifecycle Management Readme: What's New Installation InstructionsДокумент36 страницHP Application Lifecycle Management Readme: What's New Installation InstructionsBrandon GarciaОценок пока нет

- Búsqueda Del Medio - RENR6305 - 994F Wheel Loader Power TrainДокумент5 страницBúsqueda Del Medio - RENR6305 - 994F Wheel Loader Power TrainDavidCPОценок пока нет

- ES Q2 Mod8Документ26 страницES Q2 Mod8maacovsОценок пока нет

- FragAnal RC QДокумент26 страницFragAnal RC QhjmaranhaoОценок пока нет

- Single Point of Failure (SPOF) Transmission - MaintenanceДокумент10 страницSingle Point of Failure (SPOF) Transmission - MaintenanceInam M. KhanОценок пока нет

- AP+Bio 013+Photosynthesis++Respiration+Worksheet WLДокумент2 страницыAP+Bio 013+Photosynthesis++Respiration+Worksheet WLVincent SuarezОценок пока нет

- Ae53 Ac53 At53Документ4 страницыAe53 Ac53 At53M Taher BamyaniОценок пока нет

- Introduction To AcousticsДокумент4 страницыIntroduction To AcousticsClarence MamucodОценок пока нет

- 5.1.2. Biological Indicators of SterilisationДокумент1 страница5.1.2. Biological Indicators of SterilisationSurendar KesavanОценок пока нет

- Atht Model Ques 2017Документ1 страницаAtht Model Ques 2017Jeyakumar VenugopalОценок пока нет

- Narayana Iit Academy India: Paper - IДокумент39 страницNarayana Iit Academy India: Paper - Iaatt aattОценок пока нет

- Zebralette User GuideДокумент24 страницыZebralette User GuideGiacomo TimbrelloОценок пока нет

- Ups Lyonn Modelo: Ult St5-100 KS: 10KVA A 120KVAДокумент1 страницаUps Lyonn Modelo: Ult St5-100 KS: 10KVA A 120KVASebastian Matias CruzОценок пока нет

- Problem 13.3Документ2 страницыProblem 13.3kannyОценок пока нет

- Touareg FL Dimensions PDFДокумент2 страницыTouareg FL Dimensions PDFZeljko PekicОценок пока нет

- Spread of Virus ModelledДокумент2 страницыSpread of Virus ModelledDouglas TanОценок пока нет

- Manual ApolloДокумент263 страницыManual ApolloJose Luis CristanchoОценок пока нет