Академический Документы

Профессиональный Документы

Культура Документы

HASCO Grades

Загружено:

vdj85Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

HASCO Grades

Загружено:

vdj85Авторское право:

Доступные форматы

Relaxed

mouldmaking.

www.hasco.com

HASCO App – HASCO Hasenclever GmbH + Co KG, Römerweg 4, D-58513 Lüdenscheid

find your HASCO steel. Certified to DIN EN ISO 9001; DIN EN ISO 50001

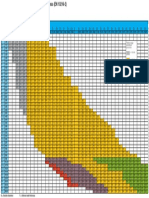

Material no. Abbreviated name Chemical analysis (%) Strength Working Properties Uses

hardness

DIN S 355 J2 G3 max. 180 HB Non-alloy structural steel, case hardenable, Mould unit components, base plates

EN S355 J2G3 C C 0.22 Si 0.55 Mn 1.6 (~ 625 N/mm²) with good weldability

1.0570

DIN C 45 U max. 190 HB Non-alloy mould steel, Used in mould and apparatus construction where unhardened

AFNOR XC 48 C 0.45 Si 0.3 Mn 0.7 (~ 650 N/mm²) readily machinable parts are used

1.1730 AISI 1045

DIN X 40 Cr 14 max. 241 HB 50 - 54 HRC Corrosion-resistant mould steel. Low distortion, a high wear Cavity plates and inserts when using corrosive and chemically

AFNOR Z 40 C 14 C 0.4 Cr 14.0 (~ 810 N/mm²) resistance and high compressive strength aggressive plastics

1.2083 AISI 420

DIN X 40 Cr 14 max. 241 HB 50 - 54 HRC High-purity, electroslag remelted, corrosion-resistant mould Cavity plates and inserts when using corrosive and chemically

AFNOR Z 40 C 14 C 0.4 Cr 14.0 (~ 810 N/mm²) steel with low distortion, a high wear resistance and high aggressive plastics requiring a particularly high degree of purity

1.2083ESR AISI 420 ESR compressive strength

DIN X 33 CrS 16 280 - 325 HB Corrosion-resistant, pre-hardened mould steel with high Cavity plates and inserts when using corrosive and chemically

AFNOR Z 35 CD 17.S C 0.3 Si 0.5 Mn 1.0 Cr 16.0 (950 - 1100 N/mm²) strength and without subsequent heat treatment aggressive plastics

1.2085 AISI 422+S

S 0.1

Special alloy 280 - 325 HB Corrosion-resistant, pre-hardened mould steel with outstanding Cavity plates and inserts when using corrosive and chemically

1.2099 C 0.04 Mn 1.2 S 0.12 Cr 13.0 (950 - 1100 N/mm²) machinability and dimensional stability aggressive plastics, very good machinability

HASCO.M

DIN 21 MnCr 5 max. 210 HB 58 - 61 HRC Standard case-hardened steel with good machinability, Cavity plates and inserts with stringent demands on surface

AFNOR 20 MC 5 C 0.21 Mn 1.3 Cr 1.2 (~ 710 N/mm²) after suitable heat treatment, a high surface hardness with hardness and core strength

1.2162 AISI 5120 good wear resistance and a tough core

DIN 40 CrMnMo 7 280 - 325 HB Used in supplied condition with high-level mechanical Cavity plates and inserts where high strength is needed without

AFNOR 40 CMD 8 C 0.4 Mn 1.5 Cr 1.9 Mo 0.2 (950 - 1100 N/mm²) properties, toughness and compressive strength subsequent heat treatment

1.2311 UNI 35 CrMo 8 KU

AISI P20

DIN 40 CrMnMoS 8-6 280 - 325 HB Used in supplied condition with very good machinability Cavity plates and frame plates for parts subjected to high

AFNOR 40 CMD 8.S C 0.4 Mn 1.5 S 0.07 Cr 1.9 (950 - 1100 N/mm²) pressures without subsequent heat treatment

1.2312 AISI P20+S

Mo 0.2

DIN X 37 CrMoV 5-1 max. 229 HB 30 - 53 HRC High-alloy, hot-work steel, electroslag remelted, with a high Cavity plates and inserts requiring high thermal conductivity

AFNOR Z 38 CDV 5 C 0.37 Si 1.0 Cr 5.3 Mo 1.3 (~ 770 N/mm²) resistance to changing temperatures and good heat resistance, and a high resistance to changing temperatures

1.2343 UNI X 37 CrMoV 5-1

V 0.4 high thermal conductivity and toughness

AISI H11

DIN X 37 CrMoV 5-1 max. 229 HB 30 - 53 HRC High-alloy, hot-work steel with a high resistance to changing Cavity plates and inserts requiring high thermal conductivity

AFNOR Z 38 CDV 5 C 0.37 Si 1.0 Cr 5.3 Mo 1.3 (~ 770 N/mm²) temperatures and good heat resistance, particularly high purity, and a high resistance to changing temperatures with particular

1.2343ESR UNI X 37 CrMoV 5-1

V 0.4 high thermal conductivity and toughness need for a high degree of purity

AISI H11

DIN X 40 CrMoV 5-1 max. 229 HB 53 - 55 HRC Hot-work steel with a high heat resistance, a high temperature Commonly-used material for hot-work tools and plastics

AFNOR Z 40 CDV 5 C 0.4 Si 1.0 Cr 5.3 Mo 1.4 (~ 770 N/mm²) wear resistance and a high thermal conductivity processing moulds

1.2344 UNI X 40 CrMoV 5-1 KU

V 1.0

AISI H13

DIN X 40 CrMoV 5-1 max. 229 HB 53 - 55 HRC Electroslag remelted and hence exceedingly pure and Commonly-used material for hot-work tools and plastics

AFNOR Z 40 CDV 5 C 0.4 Si 1.0 Cr 5.3 Mo 1.4 (~ 770 N/mm²) polishable to a high gloss processing moulds

1.2344ESR UNI X 40 CrMoV 5-1 KU

V 1.0

AISI H13 ESR

DIN X 100 CrMoV 5 max. 241 HB 58 - 62 HRC Dimensionally stable cold-work steel with a very high Cavity plates and inserts for cutting and punching tools

UNI X 100 CrMoV 5-1 KU C 1.0 Cr 5.2 Mo 1.2 V 0.3 (~ 810 N/mm²) toughness, good machinability and a high through-hardening

1.2363 AISI A2 capacity

DIN X 155 CrVMo 12-1 max. 255 HB 58 - 62 HRC High chrome-alloyed steel, cold-work steel with good Compression moulding and injection moulding tools for

AFNOR Z 160 CDV 12 C 1.53 Cr 12.0 Mo 0.7 V 1.0 (~ 860 N/mm²) dimensional stability and toughness combined with high reinforced plastics, cutting, punching and thermoforming

1.2379 UNI X 155 CrVMo 12-1 KU compressive strength tools and other applications where a high level of toughness

is required

DIN X 210 CrW 12 max. 255 HB 59 - 63 HRC Dimensionally stable chrome steel with high wear resistance Cutting, bending and embossing tools, thermoforming

AFNOR Z 210 CW 12 C 2.1 Cr 12.0 W 0.7 (~ 855 N/mm²) and good compressive strength plus adequate toughness and honing mandrels

1.2436 AISI D6

DIN 55 NiCrMoV 7 max. 400 HB Very good toughness with good heat resistance Cavity inserts and plates, slides and cores for plastics

AFNOR 55 NCDV 7 C 0.55 Cr 1.1 Mo 0.5 Ni 1.7 (~ 1350 N/mm²) and through-hardening processing moulds

1.2714HH AISI L6

V 0.1

Special alloy 310 - 355 HB Hardened and tempered steel with a homogeneous strength Big cavity plates with deep cavities

C 0.25 Mn 1.4 Cr 1.3 Ni 1.0 (1050 - even for large dimensions, can easily be polished, grained

1.2738HH Mo 0.5 1200 N/mm²) and welded

DIN 45 NiCrMo 16 max. 285 HB 50 - 56 HRC Due to the high nickel and corresponding carbon content, Cavity plates and inserts especially for demanding surface

AFNOR 45 NCD 16 C 0.45 Cr 1.4 Mo 0.3 Ni 4.0 (~ 965 N/mm²) this material is a very evenly hardening, dimensionally requirements, and high compressive and flexural stresses

1.2767 UNI 40 NiCrMoV 16 KU stable steel with high toughness and resistance to impact

AISI 6F7

and compressive stress

DIN 90 MnCrV 8 max. 229 HB 57 - 62 HRC High hardness and compressive strength with outstanding Pressure and guide strips, ejectors and cutting stamps

1.2842 AFNOR 90 MV 8 C 0.9 Mn 2.0 Cr 0.4 V 0.1 (~ 770 N/mm²) machining properties and good dimensional stability where high compressive strength and adequate toughness

AISI ~ O2

(1.2510*) W 0.6 * are specified

DIN AlZnMgCu 1.5 max. 150 HB High-strength, aluminium-zinc alloy, hardened Mould unit components requiring a high strength

AFNOR A-Z5GU Si 0.4 Fe 0.5 Cu 1.6 Mn 0.3 (~ 500 N/mm²)

3.4365 UNI 9007/2

Mg 2.4 Cr 0.23 Zn 5.6 Ti 0.2

Special alloy max. 300 HB Dimensionally stable, pre-hardened material with high Cavity plates and inserts for the plastics and die-casting

C 0.23 Si 0.75 Mn 0.8 Cr 1.2 (~ 1000 N/mm²) toughness, excellent machining properties with a minimum industry as well as other mould components subject to

Toolox33 V 0.1 Ni ≤1.0 Mo 0.3 sulphur content high pressure

Special alloy max. 450 HB Dimensionally stable, pre-hardened material with high Cavity plates and inserts for the plastics and die-casting

C 0.32 Si 0.75 Mn 0.8 Cr 1.35 (~ 1530 N/mm²) toughness and hardness, good machining properties industry as well as other mould components subject to

Toolox44 V 0.14 Ni ≤1.0 Mo 0.8 with a minimum sulphur content high pressure without subsequent heat treatment

Further material on request. Subject to technical modifications. Please always check all the data against the product information we publish in the internet 07 17 1 1 o16

Вам также может понравиться

- Steel GradesДокумент32 страницыSteel GradesAnoop R.KОценок пока нет

- Material GradesДокумент32 страницыMaterial GradesMarius PopaОценок пока нет

- Knock OUT: IntroducingДокумент10 страницKnock OUT: IntroducingMuhammad QusyairiОценок пока нет

- Mild Steel SpecificationДокумент1 страницаMild Steel SpecificationSteinol SolutionsОценок пока нет

- Okicat07 StoodyДокумент12 страницOkicat07 StoodyGianfranco CopelloОценок пока нет

- Aalco Metals LTD Stainless Steel 14571 Bar 40Документ3 страницыAalco Metals LTD Stainless Steel 14571 Bar 40raduonoОценок пока нет

- X65Cr13 C 0.58 - 0.70 CR 12.50 - 14.50 S Max. 0.015Документ2 страницыX65Cr13 C 0.58 - 0.70 CR 12.50 - 14.50 S Max. 0.015Jim SmithОценок пока нет

- Structural Stainless Steel Designing With Stainless Steel: Ing. Maarten FortanДокумент153 страницыStructural Stainless Steel Designing With Stainless Steel: Ing. Maarten FortanJohn Philip Neri BesedillasОценок пока нет

- Assab TableДокумент8 страницAssab TableIhfan MohdОценок пока нет

- Hard - Facing Welding - Electrodes PDFДокумент3 страницыHard - Facing Welding - Electrodes PDFreeet87Оценок пока нет

- Colour ChartДокумент1 страницаColour ChartgawaОценок пока нет

- High-Carbon, High Chromium Cold Work Tool Steel: Z Similar SteelsДокумент3 страницыHigh-Carbon, High Chromium Cold Work Tool Steel: Z Similar Steelsjaskaran singhОценок пока нет

- Materialqualitaeten EДокумент2 страницыMaterialqualitaeten EjvilamaiorОценок пока нет

- ASSAB Tool Steel Performance Comparison ChartДокумент1 страницаASSAB Tool Steel Performance Comparison ChartNugroho Faris Sudrajat100% (2)

- Material Grades enДокумент30 страницMaterial Grades enEmmanuel Lugo BeltranОценок пока нет

- Technical Data: Drillfast Stainless Df12-Ss Standard FastenersДокумент6 страницTechnical Data: Drillfast Stainless Df12-Ss Standard FastenersJonathan DouglasОценок пока нет

- AW - Datasheet - ALLOY 20 CB 3Документ2 страницыAW - Datasheet - ALLOY 20 CB 3.xОценок пока нет

- Fabory Fasteners ASTM StudboltДокумент13 страницFabory Fasteners ASTM StudboltJohan ConradieОценок пока нет

- 20Mn2, GB T 3077-1999 20Mn2 Steel, 20Mn2 Stainless SteelДокумент2 страницы20Mn2, GB T 3077-1999 20Mn2 Steel, 20Mn2 Stainless Steeltiele_barcelosОценок пока нет

- Creusabro MДокумент4 страницыCreusabro MhealgoseОценок пока нет

- Wegusta Caststeel CastironДокумент3 страницыWegusta Caststeel CastironPandurang KadamОценок пока нет

- ASSAB Tool Steel Performance Chart A4 enДокумент2 страницыASSAB Tool Steel Performance Chart A4 en631052Оценок пока нет

- GD - PG - $KT DBL Mqu $KP Mqu $PG 12311 - inДокумент1 страницаGD - PG - $KT DBL Mqu $KP Mqu $PG 12311 - inTran PhuОценок пока нет

- Mold Steel 1.2311Документ1 страницаMold Steel 1.2311Muslim N FОценок пока нет

- ZOLLERN-Broschuere ZGM Sandguss ENG 8.816Документ16 страницZOLLERN-Broschuere ZGM Sandguss ENG 8.816Shariq KhanОценок пока нет

- Wear Resistant Steel: Product DescriptionДокумент6 страницWear Resistant Steel: Product DescriptionoomoomОценок пока нет

- GD - PG - $KT DBL Mqu $KP Mqu $PG 12083 - inДокумент1 страницаGD - PG - $KT DBL Mqu $KP Mqu $PG 12083 - inTran PhuОценок пока нет

- Egger Werkstoffe eДокумент3 страницыEgger Werkstoffe esf wОценок пока нет

- Assab Royalloy: Prehardened Free Machining Stainless Holder SteelДокумент7 страницAssab Royalloy: Prehardened Free Machining Stainless Holder SteelNugroho Faris SudrajatОценок пока нет

- Carbocast 1 - eДокумент1 страницаCarbocast 1 - eali torabiОценок пока нет

- NAK80 MaterialДокумент3 страницыNAK80 MaterialRicky Indra DjunawanОценок пока нет

- Manganese Steel: Hard, Abrasive and Unique Are Some of The Qualities Our Manganese Steel Can Be, What Do You Need?Документ3 страницыManganese Steel: Hard, Abrasive and Unique Are Some of The Qualities Our Manganese Steel Can Be, What Do You Need?hhОценок пока нет

- Universidad Técnica de Ambato: Facultad de Ingeniería Civil Y MecánicaДокумент3 страницыUniversidad Técnica de Ambato: Facultad de Ingeniería Civil Y MecánicaJoelОценок пока нет

- Screw CharacteristicsДокумент18 страницScrew CharacteristicsJaokОценок пока нет

- DIE CASTING GUIDELINESДокумент12 страницDIE CASTING GUIDELINESstalinb618Оценок пока нет

- 32 Koenig 2013Документ1 страница32 Koenig 2013shashibagewadiОценок пока нет

- Chronifer M-4108Документ3 страницыChronifer M-4108IltefatОценок пока нет

- Compozitie MaterialeДокумент25 страницCompozitie MaterialeGross Meltiade AlexanderОценок пока нет

- GD - PG - $KT DBL Mqu $KP Mqu $PG 12312 - inДокумент1 страницаGD - PG - $KT DBL Mqu $KP Mqu $PG 12312 - inTran PhuОценок пока нет

- CuZn20-convertedДокумент2 страницыCuZn20-convertedwjjt6chgtmОценок пока нет

- 014 ToolsteelДокумент36 страниц014 ToolsteelSamrat SinghОценок пока нет

- AISI 1024 Steel, 1024 Stainless Steel, 1024 Alloy Structural SteelДокумент2 страницыAISI 1024 Steel, 1024 Stainless Steel, 1024 Alloy Structural SteelDhileepan Kumarasamy67% (3)

- CDP 4666Документ2 страницыCDP 4666sareddytejaaeОценок пока нет

- kme_STOL76_C19010_enДокумент1 страницаkme_STOL76_C19010_enMattia Terri TerrandoОценок пока нет

- Stainless Steel 321 Technical DataДокумент2 страницыStainless Steel 321 Technical Datasmith willОценок пока нет

- 3 X210Cr12Документ20 страниц3 X210Cr12david marceloОценок пока нет

- 25CR20NIДокумент2 страницы25CR20NIShariq KhanОценок пока нет

- Cutting oil drilling tapping technical sheetДокумент1 страницаCutting oil drilling tapping technical sheetgopalakrishna100% (1)

- Alloy321 SpecSheetДокумент2 страницыAlloy321 SpecSheetVinod tiwariОценок пока нет

- Ak Steel Armco® Nitronic® 50 Product Data Bulletin - Jan 2019 - 94Документ28 страницAk Steel Armco® Nitronic® 50 Product Data Bulletin - Jan 2019 - 94st_calvoОценок пока нет

- 011.897 EN - Donaldson P-EG Filter HousingДокумент5 страниц011.897 EN - Donaldson P-EG Filter HousingNg MeriedОценок пока нет

- UntitledДокумент2 страницыUntitledGyurmoooОценок пока нет

- RECLAMATION LOW HEAT IN-PUT WELDING ELECTRODE RECOMMEDATIONДокумент5 страницRECLAMATION LOW HEAT IN-PUT WELDING ELECTRODE RECOMMEDATIONDIBYENDU MONDALОценок пока нет

- Sandvik SAF 2507: Duplex Stainless SteelДокумент8 страницSandvik SAF 2507: Duplex Stainless SteelmattiaОценок пока нет

- Manganese 12 14%Документ3 страницыManganese 12 14%Sreedhar Rakesh VellankiОценок пока нет

- Electronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionОт EverandElectronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionОценок пока нет

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonОт EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonРейтинг: 4 из 5 звезд4/5 (1)

- Oil Cooler-ORДокумент1 страницаOil Cooler-ORvdj85Оценок пока нет

- Metal Spinning Lathe TutorialДокумент15 страницMetal Spinning Lathe TutorialMike SullivanОценок пока нет

- Husky HRPG enДокумент136 страницHusky HRPG envdj85Оценок пока нет

- DELRINДокумент35 страницDELRINIsczuОценок пока нет

- Metal Cutting Tools SmallДокумент498 страницMetal Cutting Tools SmallМарио ПармантијеОценок пока нет

- Correas HUTCINSON Poly V PDFДокумент44 страницыCorreas HUTCINSON Poly V PDFJoaquin FasabiОценок пока нет

- Index PDFДокумент80 страницIndex PDFvdj85Оценок пока нет

- ZYTEL Molding Guide PDFДокумент44 страницыZYTEL Molding Guide PDFvdj85Оценок пока нет

- Part and Mold Design GuideДокумент170 страницPart and Mold Design GuideminhtintinОценок пока нет

- Spruit Transmissies Hutchinson Catalogus PDFДокумент27 страницSpruit Transmissies Hutchinson Catalogus PDFvdj85Оценок пока нет

- Mendel90 Dibond PDFДокумент82 страницыMendel90 Dibond PDFvdj85Оценок пока нет

- Tech Manual Ribbed Belts PDFДокумент68 страницTech Manual Ribbed Belts PDFindrajithОценок пока нет

- Delta Asda-B2 M en 20130906Документ335 страницDelta Asda-B2 M en 20130906Joao RobertoОценок пока нет

- Manufacturing program wall thickness EN 10216-2Документ1 страницаManufacturing program wall thickness EN 10216-2vdj85Оценок пока нет

- G-Codes Samples - Helical InterpolationДокумент2 страницыG-Codes Samples - Helical Interpolationvdj85Оценок пока нет

- White Paper Aluvac Knife Edge Stability Web enДокумент5 страницWhite Paper Aluvac Knife Edge Stability Web enRodolfo M. PortoОценок пока нет

- Correlations Between Electral Conductivity and Aging Behaviour of 7010 Base AluminiumДокумент7 страницCorrelations Between Electral Conductivity and Aging Behaviour of 7010 Base Aluminiumferhat aydoganОценок пока нет

- Geochemical Analyses For Mapping Geological Processes - Webinar Handout PDFДокумент98 страницGeochemical Analyses For Mapping Geological Processes - Webinar Handout PDFFrancisco AlfaroОценок пока нет

- Extrusion Basic MetallurgyДокумент28 страницExtrusion Basic MetallurgyAry OctavianiОценок пока нет

- Introduction To MTripleP IMetalДокумент21 страницаIntroduction To MTripleP IMetalKrishna Mohan T.RОценок пока нет

- Periodic TableCheap Charts Frank Schaffer Publications - BarCharts QuickStudyДокумент2 страницыPeriodic TableCheap Charts Frank Schaffer Publications - BarCharts QuickStudyMatheus Eduardo100% (1)

- PART 142 What Is Corrosion - Definition and PreventionДокумент3 страницыPART 142 What Is Corrosion - Definition and Preventionravindra_jivaniОценок пока нет

- Ultrasonic Testing Level I - Material Data Sheet - Velocity ChartДокумент1 страницаUltrasonic Testing Level I - Material Data Sheet - Velocity Chartbenderman1Оценок пока нет

- Sinter Plant Presentation (Sinter Operation)Документ30 страницSinter Plant Presentation (Sinter Operation)aashulheda75% (8)

- REMOTE VISUAL EXAMINATIONДокумент9 страницREMOTE VISUAL EXAMINATIONRolando Nuñez MonrroyОценок пока нет

- Diamonds & Diamond Grading Book 2 (Assignments 7-11) 2019Документ170 страницDiamonds & Diamond Grading Book 2 (Assignments 7-11) 2019Paul MessinaОценок пока нет

- Copper, Bronze, IronДокумент15 страницCopper, Bronze, IronDerick BrinОценок пока нет

- Technical InformationДокумент78 страницTechnical InformationCarlos Barrachina Martínez100% (2)

- MINERAL (Autosaved) EDITДокумент32 страницыMINERAL (Autosaved) EDITCharlie DanforthОценок пока нет

- En 8Документ1 страницаEn 8Devendera TripathiОценок пока нет

- Material Safety Data Sheet: Section I - IdentificationДокумент2 страницыMaterial Safety Data Sheet: Section I - IdentificationMohamed AdelОценок пока нет

- Fulltext PDFДокумент151 страницаFulltext PDFAhmed GomaaОценок пока нет

- Laboratorio 5Документ15 страницLaboratorio 5Manuel ShishidoОценок пока нет

- Submit abstracts for 16th International Mineral Processing Conference by March 19Документ1 страницаSubmit abstracts for 16th International Mineral Processing Conference by March 19rodrigo pineda schleefОценок пока нет

- 312 - Welding of Domex and Docol Advanced High Strength SteelsДокумент24 страницы312 - Welding of Domex and Docol Advanced High Strength SteelsmustafagoresОценок пока нет

- Material Design Properties For Structural Steel S235, S275, S355, S420, S450, S460 According To EN1993-1-1 3.2.6Документ2 страницыMaterial Design Properties For Structural Steel S235, S275, S355, S420, S450, S460 According To EN1993-1-1 3.2.6yusuf akkuşОценок пока нет

- 2020 Huggies Earring SeriesДокумент51 страница2020 Huggies Earring Serieslaila89Оценок пока нет

- Specialty Steels Catalog Provides Insights Into Cutting-Edge MaterialsДокумент16 страницSpecialty Steels Catalog Provides Insights Into Cutting-Edge Materialsyadu kumar singhОценок пока нет

- SPADA Soal Ujian Semester TK 1 EC D3 Sem 1 TA 2020 2021 (11) - Converted - by - AbcdpdfДокумент3 страницыSPADA Soal Ujian Semester TK 1 EC D3 Sem 1 TA 2020 2021 (11) - Converted - by - AbcdpdfAlwin Arrahman NasutionОценок пока нет

- IV B. Tech II Sem Metallurgy and Material Technology 2019-2020 Project Viva VoceДокумент4 страницыIV B. Tech II Sem Metallurgy and Material Technology 2019-2020 Project Viva Voceshyamkumar rakotiОценок пока нет

- Certificate of Sampling and AnalysisДокумент5 страницCertificate of Sampling and AnalysisifabasirОценок пока нет

- Simulation and analysis of turning and WEDM of magnesium alloyДокумент186 страницSimulation and analysis of turning and WEDM of magnesium alloyMohammed EndrisОценок пока нет

- Effect of Austenitizing Temperature and Cooling Rate On The Structure and Properties of A Ultrahigh Strength Low Alloy SteelДокумент10 страницEffect of Austenitizing Temperature and Cooling Rate On The Structure and Properties of A Ultrahigh Strength Low Alloy SteelMilena StajicОценок пока нет

- Ultrasonic Machining Engineering Materials And Manufacuring Technology اشع ديعس نزام ديعس 0147566Документ8 страницUltrasonic Machining Engineering Materials And Manufacuring Technology اشع ديعس نزام ديعس 0147566Saeed AshaОценок пока нет

- Cambridge IGCSE: CHEMISTRY 0620/42Документ16 страницCambridge IGCSE: CHEMISTRY 0620/42Kohinoor BegumОценок пока нет