Академический Документы

Профессиональный Документы

Культура Документы

UTP 6222 Mo

Загружено:

dantegimenezАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

UTP 6222 Mo

Загружено:

dantegimenezАвторское право:

Доступные форматы

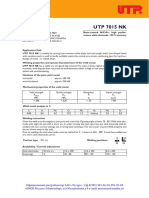

Standards : UTP 6222 Mo

Material-No. : 2.4621 Basic coated NiCrMo-stick electrode

EN ISO 14172 : E Ni 6625 for corrosion and heat resistant mate-

(NiCr22Mo9Nb) rials

AWS A5.11 : E NiCrMo-3

Application field

UTP 6222 Mo is particularly suited for joining and surfacing on nickel alloys, austenitic steels, low tempe-

rature nickel steels, austenitic-ferritic-joints and claddings of the same or similar nature, like 2.4856 (NiCr

22Mo 9 Nb), 1.4876 (X30 NiCrAlTi 32 20), 1.4529 (X2 NiCrMoCu 25 20 5).

Properties of the weld metal

The weld metal is heat resistant and suitable for operating temperatures up to 1000° C. It must be noted

that a slight decrease in ductility will occur if prolonged heat treatment is given within the temperature range

600 - 800° C. Scale-resisting in low-sulphur atmosphere up to 1100° C. High creep strength.

Mechanical properties of the weld metal

Yield strength Tensile strength Elongation Impact strength

Rp0,2 Rm A Kv Joule

MPa MPa % +20° C –196° C

> 450 > 760 > 30 > 75 45

Approximate weld metal analysis in %

C Si Mn Cr Mo Ni Nb Fe

0,03 0,4 0,6 22,0 9,0 balance 3,3 1,5

Welding instruction

Opening angle of the prepared seam approx. 70°, root gap approx. 2 mm. Weld stick electrode with slight

tilt and short arc. String beads are welded. The interpass temperature of 150° C and a max. weaving with

2,5 x diameter of the stick electrode core wire should not be exceeded. Re-dry the stick electrodes 2 – 3

hours at 250 – 300° C before use and weld them out of a warm electrode carrier.

Current type DC (+) Welding positions

PA PB PC PE PF

Availability / Current adjustment

Stick electrodes Ø mm x L 2,5 x 250 3,2 x 300 4,0 x 350 5,0 x 400

Amperage A 50 – 70 70 – 95 90 – 120 120 – 160

Approvals

TÜV (No. 03610), DNV, ABS, GL, BV

All data on our products are based upon careful investigation and intensive © UTP Schweissmaterial

research. However, we do not assume any liability for their correctness. Zweigniederlassung der Böhler Schweisstechnik Deutschland GmbH

www.utp-welding.com Edition: 08/2010 Rev.: 0

Вам также может понравиться

- Официальный дистрибьютор ЗАО «Ресурс» т/ф 8 (383) 363-26-24, 291-93-02 630020 Россия г.Новосибирс ул.Объединения д.9 e-mail: resurszao@Документ1 страницаОфициальный дистрибьютор ЗАО «Ресурс» т/ф 8 (383) 363-26-24, 291-93-02 630020 Россия г.Новосибирс ул.Объединения д.9 e-mail: resurszao@brayanОценок пока нет

- Utp 068 HHДокумент1 страницаUtp 068 HHRoberto_PrrОценок пока нет

- Utp 7015 NKДокумент1 страницаUtp 7015 NKsergey.pu4kaОценок пока нет

- مكونات نقط اللحام شامل بنط اللحامДокумент2 страницыمكونات نقط اللحام شامل بنط اللحامdaha333Оценок пока нет

- UTP A 6222 MoДокумент1 страницаUTP A 6222 MoKara WhiteОценок пока нет

- Utp 7015Документ1 страницаUtp 7015cesarlopezpolysiusОценок пока нет

- 02112015000000B - Boehler FOX EASN 25 M - CeДокумент1 страница02112015000000B - Boehler FOX EASN 25 M - CeABОценок пока нет

- Thermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicДокумент1 страницаThermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicbrayanОценок пока нет

- Böhler Cat 409 Cb-Ig: Classifi CationsДокумент1 страницаBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakОценок пока нет

- L1 34264 en T Thermanit MTS 3 Se en v2Документ1 страницаL1 34264 en T Thermanit MTS 3 Se en v2Enrique MurgiaОценок пока нет

- 570 950mpa High Tensile Strength SteelДокумент32 страницы570 950mpa High Tensile Strength SteelAde Aidil SyuhadaОценок пока нет

- UTP 3545 NB PDFДокумент1 страницаUTP 3545 NB PDFhqnscОценок пока нет

- Avesta 316L-SKRДокумент1 страницаAvesta 316L-SKRIuliu HurducaciОценок пока нет

- Product Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenДокумент3 страницыProduct Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLОценок пока нет

- Utp 34 NДокумент1 страницаUtp 34 NbrayanОценок пока нет

- T - Thermanit 25 - 09 CuT - de - en - 5Документ1 страницаT - Thermanit 25 - 09 CuT - de - en - 5NAVANEETH NAVANIОценок пока нет

- 1 - UTP 614 KBДокумент1 страница1 - UTP 614 KBKrishna VachaОценок пока нет

- L1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1Документ1 страницаL1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1cristian popescuОценок пока нет

- B Boehler Aws E316l 17 Se en 5a Mds PDFДокумент1 страницаB Boehler Aws E316l 17 Se en 5a Mds PDFInaamОценок пока нет

- Product Data Sheet OK 75.75: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenДокумент3 страницыProduct Data Sheet OK 75.75: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLОценок пока нет

- Böhler CN 13/4-Mc Hi: Classifi CationsДокумент1 страницаBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakОценок пока нет

- Product Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenДокумент2 страницыProduct Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB Swedentungau87Оценок пока нет

- Utp 630Документ1 страницаUtp 630brayanОценок пока нет

- Boehler FOX CN 25 9 CuT - CeДокумент1 страницаBoehler FOX CN 25 9 CuT - CeNiranjan Fakirchand YadavОценок пока нет

- Product Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'Документ2 страницыProduct Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'rajОценок пока нет

- BÖHLER Alform® 960-IG: Standard Designations EN ISO 16834-A AWS A5.28Документ1 страницаBÖHLER Alform® 960-IG: Standard Designations EN ISO 16834-A AWS A5.28JORAMОценок пока нет

- Utp 63Документ1 страницаUtp 63brayanОценок пока нет

- Thermanit P23Документ1 страницаThermanit P23Branko FerenčakОценок пока нет

- Carbocast 1 - eДокумент1 страницаCarbocast 1 - eali torabiОценок пока нет

- B - Boehler NiMo 1-IG - de - en - 5Документ1 страницаB - Boehler NiMo 1-IG - de - en - 5cristian popescuОценок пока нет

- B - Boehler CN 25 9 CuT IG - TRДокумент1 страницаB - Boehler CN 25 9 CuT IG - TRalbertorebellatoОценок пока нет

- Boehler CN 13 4-MC - SWДокумент1 страницаBoehler CN 13 4-MC - SWSebastian AcostaОценок пока нет

- L1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Документ1 страницаL1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Dimitris NikouОценок пока нет

- Cromarod Duplex B-1Документ1 страницаCromarod Duplex B-1Matija BušićОценок пока нет

- Boehler CM2-UPДокумент1 страницаBoehler CM2-UPdiahОценок пока нет

- Boehler CN 13 4-MC FДокумент1 страницаBoehler CN 13 4-MC FFilipe CordeiroОценок пока нет

- Datasheet Sanicro 69Документ1 страницаDatasheet Sanicro 69Agustin CesanОценок пока нет

- Fincord DB: MMA Electrodes C-MN and Low-Alloy SteelsДокумент1 страницаFincord DB: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaОценок пока нет

- Utp Af A7Документ1 страницаUtp Af A7VIRPOPОценок пока нет

- Thermanit P24Документ1 страницаThermanit P24Branko FerenčakОценок пока нет

- 03112015000000B - Boehler FOX NiCr 70 NB - CeДокумент1 страница03112015000000B - Boehler FOX NiCr 70 NB - CeFlori MovОценок пока нет

- WB5525E ENiCrMo-5Документ1 страницаWB5525E ENiCrMo-5cwiksjОценок пока нет

- Fluxofil M42: Cored Wires High-Strength SteelsДокумент1 страницаFluxofil M42: Cored Wires High-Strength SteelsCristian BoselliОценок пока нет

- CERTILAS EN Edition2023 320Документ1 страницаCERTILAS EN Edition2023 320Alireza KhodabandehОценок пока нет

- Thermanit Nicro 82: TIG Rods, Nickel-AlloyДокумент2 страницыThermanit Nicro 82: TIG Rods, Nickel-AlloyMaximiliano Ezequiel LopezОценок пока нет

- Wb2092e E7024Документ1 страницаWb2092e E7024cwiksjОценок пока нет

- YAWATA 7018: Classification Applications Characteristics ApprovalsДокумент1 страницаYAWATA 7018: Classification Applications Characteristics ApprovalsDenny AgusОценок пока нет

- Tencord KB (E 42 4 Z B 42 h5)Документ1 страницаTencord KB (E 42 4 Z B 42 h5)brunizzaОценок пока нет

- 055 PDFДокумент1 страница055 PDFantonio111aОценок пока нет

- Supercito (E 42 5 B 32 h5)Документ1 страницаSupercito (E 42 5 B 32 h5)brunizzaОценок пока нет

- Bohler Fox S 308L-16Документ1 страницаBohler Fox S 308L-16HAKANОценок пока нет

- 02112015000000B - Boehler FOX EV 65 - CeДокумент1 страница02112015000000B - Boehler FOX EV 65 - CeMohamed AdelОценок пока нет

- X Bond: Welding Electrode For Structural Welding ApplicationДокумент1 страницаX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainОценок пока нет

- L1 - 14983 - en - T - Thermanit Nicro 82 - Se - en - 5Документ2 страницыL1 - 14983 - en - T - Thermanit Nicro 82 - Se - en - 5Απόστολος ΣτεργιάδηςОценок пока нет

- UTP A 3545 NB PDFДокумент1 страницаUTP A 3545 NB PDFNОценок пока нет

- UTP A 3545 NB PDFДокумент1 страницаUTP A 3545 NB PDFNОценок пока нет

- UTP A 3545 NBДокумент1 страницаUTP A 3545 NBNapol HengbumrungОценок пока нет

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Electric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesОт EverandElectric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesОценок пока нет

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesОт EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesРейтинг: 4.5 из 5 звезд4.5/5 (7)

- Lnm309h-Eng Stainless Steel Solid WireДокумент1 страницаLnm309h-Eng Stainless Steel Solid WiredantegimenezОценок пока нет

- Fly Ash Particle Formation in Kraft Recovery Boilers: Pirita MikkanenДокумент71 страницаFly Ash Particle Formation in Kraft Recovery Boilers: Pirita MikkanendantegimenezОценок пока нет

- Degradation Machanism of Heat Resistant Steel at Elevated TemperaturesДокумент180 страницDegradation Machanism of Heat Resistant Steel at Elevated TemperaturesdantegimenezОценок пока нет

- Presentation Teledyne ICM NDT 2019 - DD - DIGITAL RADIOGRAPHY 1 SVДокумент21 страницаPresentation Teledyne ICM NDT 2019 - DD - DIGITAL RADIOGRAPHY 1 SVdantegimenezОценок пока нет

- CAPILLA - Welding Consumables For Welding of Creep and Heat ResistantДокумент40 страницCAPILLA - Welding Consumables For Welding of Creep and Heat ResistantdantegimenezОценок пока нет

- Magnetic Field IndicatorsДокумент2 страницыMagnetic Field IndicatorsdantegimenezОценок пока нет

- A Guide To Etching Specialty Alloys For Microstructural EvaluationДокумент15 страницA Guide To Etching Specialty Alloys For Microstructural EvaluationdantegimenezОценок пока нет

- Couplant Feature Comparison Chart: N/A N/AДокумент1 страницаCouplant Feature Comparison Chart: N/A N/AdantegimenezОценок пока нет

- Widmanstätten StructuresДокумент3 страницыWidmanstätten StructuresdantegimenezОценок пока нет

- Disbonding: Industrial Solutions EnglishДокумент8 страницDisbonding: Industrial Solutions EnglishdantegimenezОценок пока нет

- Types of Magnetizing CurrentДокумент3 страницыTypes of Magnetizing Currentdantegimenez0% (1)

- KOBELCO Welding Handbook 2009Документ202 страницыKOBELCO Welding Handbook 2009shamsabbasОценок пока нет

- Thyseenkrup - Stainless Steel 1-4713Документ3 страницыThyseenkrup - Stainless Steel 1-4713dantegimenezОценок пока нет

- HILCO Stick Electrodes at A GlanceДокумент6 страницHILCO Stick Electrodes at A Glanceziaee950Оценок пока нет

- Turbine Generator OverviewДокумент24 страницыTurbine Generator OverviewdantegimenezОценок пока нет

- Evaluation of The Performance of Computed Radiography Systems With Different Sources and Different ConfigurationsДокумент12 страницEvaluation of The Performance of Computed Radiography Systems With Different Sources and Different ConfigurationsdantegimenezОценок пока нет

- Turbine Generator OverviewДокумент24 страницыTurbine Generator OverviewdantegimenezОценок пока нет

- Microeconomics Term 1 SlidesДокумент494 страницыMicroeconomics Term 1 SlidesSidra BhattiОценок пока нет

- Explore The WorldДокумент164 страницыExplore The WorldEduardo C VanciОценок пока нет

- Code ExplanantionДокумент4 страницыCode ExplanantionVivek JadiyaОценок пока нет

- Holiday AssignmentДокумент18 страницHoliday AssignmentAadhitya PranavОценок пока нет

- DISCHARGE PLAN CuyosДокумент6 страницDISCHARGE PLAN CuyosShaweeyah Mariano BabaoОценок пока нет

- The Piano Lesson Companion Book: Level 1Документ17 страницThe Piano Lesson Companion Book: Level 1TsogtsaikhanEnerelОценок пока нет

- Chap9 PDFДокумент144 страницыChap9 PDFSwe Zin Zaw MyintОценок пока нет

- FSM Syllabus20071228 1Документ3 страницыFSM Syllabus20071228 1Institute of Fengshui BaziОценок пока нет

- Aquaculture - Set BДокумент13 страницAquaculture - Set BJenny VillamorОценок пока нет

- Ubi Caritas Guitar Solo Arrangement by Patrick Glenn BalanzaДокумент8 страницUbi Caritas Guitar Solo Arrangement by Patrick Glenn BalanzaPatrick Glenn BalanzaОценок пока нет

- Project Manager PMP PMO in Houston TX Resume Nicolaas JanssenДокумент4 страницыProject Manager PMP PMO in Houston TX Resume Nicolaas JanssenNicolaasJanssenОценок пока нет

- Lecture Notes 3A - Basic Concepts of Crystal Structure 2019Документ19 страницLecture Notes 3A - Basic Concepts of Crystal Structure 2019Lena BacaniОценок пока нет

- Mark Magazine#65Документ196 страницMark Magazine#65AndrewKanischevОценок пока нет

- Asan Visa Ae102901499Документ2 страницыAsan Visa Ae102901499hardeep ranaОценок пока нет

- 21st CENTURY TECHNOLOGIES - PROMISES AND PERILS OF A DYNAMIC FUTUREДокумент170 страниц21st CENTURY TECHNOLOGIES - PROMISES AND PERILS OF A DYNAMIC FUTUREpragya89Оценок пока нет

- BECIL Registration Portal: How To ApplyДокумент2 страницыBECIL Registration Portal: How To ApplySoul BeatsОценок пока нет

- Tachycardia Algorithm 2021Документ1 страницаTachycardia Algorithm 2021Ravin DebieОценок пока нет

- Object-Oriented Design Patterns in The Kernel, Part 2 (LWN - Net)Документ15 страницObject-Oriented Design Patterns in The Kernel, Part 2 (LWN - Net)Rishabh MalikОценок пока нет

- Ginger Final Report FIGTF 02Документ80 страницGinger Final Report FIGTF 02Nihmathullah Kalanther Lebbe100% (2)

- Financial Accounting 1: Chapter 5 Cash and Short Term InvestmentДокумент31 страницаFinancial Accounting 1: Chapter 5 Cash and Short Term InvestmentCabdiraxmaan GeeldoonОценок пока нет

- Antibiotics MCQsДокумент4 страницыAntibiotics MCQsPh Israa KadhimОценок пока нет

- Pest of Field Crops and Management PracticalДокумент44 страницыPest of Field Crops and Management PracticalNirmala RameshОценок пока нет

- Vedic Maths Edited 2Документ9 страницVedic Maths Edited 2sriram AОценок пока нет

- Will Smith BiographyДокумент11 страницWill Smith Biographyjhonatan100% (1)

- Redirection & PipingДокумент16 страницRedirection & PipingPraveen PatelОценок пока нет

- Metalcor - 1.4507 - Alloy - F255 - Uranus 52N - S32520Документ1 страницаMetalcor - 1.4507 - Alloy - F255 - Uranus 52N - S32520NitinОценок пока нет

- Baxter - Heraeus Megafuge 1,2 - User ManualДокумент13 страницBaxter - Heraeus Megafuge 1,2 - User ManualMarcos ZanelliОценок пока нет

- Topic Group Present (Week 8) Chapter 1:sociology and Learning ManagementДокумент2 страницыTopic Group Present (Week 8) Chapter 1:sociology and Learning ManagementLEE LEE LAUОценок пока нет

- International Patient Referral - Part 2 - Revised - 29-04-2010 - 2Документ2 страницыInternational Patient Referral - Part 2 - Revised - 29-04-2010 - 2Fatah AssadОценок пока нет

- Accounting Worksheet Problem 4Документ19 страницAccounting Worksheet Problem 4RELLON, James, M.100% (1)