Академический Документы

Профессиональный Документы

Культура Документы

Workshop 7 PDF

Загружено:

kadir demirciОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Workshop 7 PDF

Загружено:

kadir demirciАвторское право:

Доступные форматы

UCK 328E STRUCTURAL DESIGN COURSE

WORKSHOP 8

The half wing of a model airplane that its dimensions are given in Figure 2. The wing section

coordinates are given in Table 1. The wing is made by composite materials which its mechanical

properties are given in Table 2. The maximum take-off weight of airplane is 1.622 kg. The

airplane is designed for a 3g applied normal maneuver acceleration. For the ultimate load case,

apply a load coefficient of 1.5.

(a) Create a surface model of airplane wing. The wing half-span is 750 mm.

(b) Create a finite element mesh using shell elements. The thickness of main spar is 0.5 mm and

the thickness of skins and rear spar is 0.3 mm.

(c) Apply the clamped boundary conditions at the end of main spar and rear spar. Apply a

parabolic aerodynamic pressure distribution corresponding to maximum wing load. A

uniform pressure variation can be taken along the chord direction for the sake of simplicity.

(d) Determine the deformations and stress distributions. Use proper failure criteria for the

composite structure.

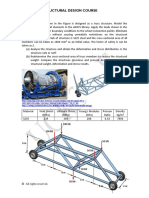

Figure 1 Cessna 182 ST model aircraft

© All rights reserved.

UCK 328E STRUCTURAL DESIGN COURSE

50 mm

750 mm

30 mm

130 mm

Figure 2 Cessna 182 ST model aircraft wing geometry

© All rights reserved.

UCK 328E STRUCTURAL DESIGN COURSE

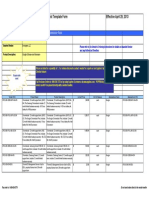

Table 2. Coordinates of wing section.

NO. x (mm) y (mm) z (mm)

1 -60 0 0

2 -57,5 7,52 0

3 -57,5 -4,22 0

4 -55 10 0

5 -55 -5,98 0

6 -50 13,5 0

7 -50 -8,12 0

8 -45 16,12 0

9 -45 -9,34 0

10 -40 18,22 0

11 -40 -10,12 0

12 -30 21,32 0

13 -30 -10,98 0

14 -20 23,44 0

15 -20 -11,12 0

16 -10 24,8 0

17 -10 -10,98 0

18 0 25,52 0

19 0 -10,52 0

20 20 25,4 0

21 20 -9,4 0

22 40 23,7 0

23 40 -8,04 0

24 60 20,88 0

25 60 -6,48 0

26 80 17,1 0

27 80 -4,9 0

28 100 12,44 0

29 100 -3,34 0

30 120 6,92 0

31 120 -1,86 0

32 130 3,78 0

33 130 -1,1 0

34 140 0 0

© All rights reserved.

UCK 328E STRUCTURAL DESIGN COURSE

Table 2 High Strength Carbon/Epoxy (the thickness of layer is 0.1 mm)

EX 90 GPa

EY 3.8 GPa

EZ 3.8 GPa (http://www.hexcel.com/Resources/DataSheets/Br

ochure-Data-Sheets/Prepreg_Technology.pdf)

PRXY 0.29

PRXY 0.29

PRXY 0.29

GXY 2.1 GPa

GYZ 0.9 GPa

GXY 0.9 GPa

1150 kg/m3

SXt 1100 MPa

SYt 12 MPa

SXc 190 MPa

SYc 32 MPa

SXY 11MPa

© All rights reserved.

Вам также может понравиться

- Workshop 4Документ2 страницыWorkshop 4kadir demirciОценок пока нет

- Workshop 3Документ2 страницыWorkshop 3kadir demirciОценок пока нет

- Workshop 2Документ1 страницаWorkshop 2kadir demirciОценок пока нет

- Workshop 5 PDFДокумент3 страницыWorkshop 5 PDFkadir demirciОценок пока нет

- Workshop 3Документ2 страницыWorkshop 3kadir demirciОценок пока нет

- Workshop 1Документ1 страницаWorkshop 1kadir demirciОценок пока нет

- Workshop 4.1Документ2 страницыWorkshop 4.1kadir demirciОценок пока нет

- Workshop 2Документ1 страницаWorkshop 2kadir demirciОценок пока нет

- Workshop 4Документ2 страницыWorkshop 4kadir demirciОценок пока нет

- Workshop 6 PDFДокумент3 страницыWorkshop 6 PDFkadir demirciОценок пока нет

- Workshop 1Документ1 страницаWorkshop 1kadir demirciОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- South 4Документ24 страницыSouth 4LariОценок пока нет

- Bike TyresДокумент22 страницыBike Tyreshari kumarОценок пока нет

- Revised Research Proposal 1Документ3 страницыRevised Research Proposal 1Gold BlandoОценок пока нет

- DMAIC Method in Six Sigma - 5 Phases Complete OverviewДокумент16 страницDMAIC Method in Six Sigma - 5 Phases Complete OverviewEngFaisal AlraiОценок пока нет

- StruBIM Suite User's ManualДокумент38 страницStruBIM Suite User's ManualJEMAYERОценок пока нет

- Torrico, Lara Jane G. Ged0104 - Section 34 MN FORMATIVE ASSESSMENT #5: Column Paper On Dr. Tapang Philippines vs. Industrial Revolution 4.0Документ5 страницTorrico, Lara Jane G. Ged0104 - Section 34 MN FORMATIVE ASSESSMENT #5: Column Paper On Dr. Tapang Philippines vs. Industrial Revolution 4.0Lara Jane TorricoОценок пока нет

- Project Management-Session Planning-V1Документ6 страницProject Management-Session Planning-V1neily fertadoОценок пока нет

- Chapter 16 Quality Assurance and Implementation: Systems, Roles, and Development Methodologies, 8e (Kendall/Kendall)Документ12 страницChapter 16 Quality Assurance and Implementation: Systems, Roles, and Development Methodologies, 8e (Kendall/Kendall)Matin OdoomОценок пока нет

- Testing The Disaster Recovery PlanДокумент4 страницыTesting The Disaster Recovery PlanFred JokuОценок пока нет

- Track and Trace Your Delivery StatusДокумент1 страницаTrack and Trace Your Delivery StatusCrissy NonОценок пока нет

- Robert Smith: Freelance Full Stack DeveloperДокумент1 страницаRobert Smith: Freelance Full Stack DeveloperYousuf HussainОценок пока нет

- Integrity Testing of Aboveground Storage TanksДокумент43 страницыIntegrity Testing of Aboveground Storage TanksMakhfud Edy100% (1)

- PERFORMANCE TASK-GR8 (2023-23) - Term 2Документ8 страницPERFORMANCE TASK-GR8 (2023-23) - Term 2Sabahath KhanОценок пока нет

- Spotify Premium Method #Noob FriendlyДокумент5 страницSpotify Premium Method #Noob FriendlyJulian SuitsОценок пока нет

- Basic Parts of Alarm System 2Документ7 страницBasic Parts of Alarm System 2benitotumolva942Оценок пока нет

- AFROZEДокумент11 страницAFROZEtaimoor hasanОценок пока нет

- India's Growing Smartphone Market Dominated by Chinese BrandsДокумент3 страницыIndia's Growing Smartphone Market Dominated by Chinese BrandsAnshika YadavОценок пока нет

- Course Details & Program SyllabusДокумент7 страницCourse Details & Program SyllabusParitosh SinghОценок пока нет

- MATH101 Lecture1Документ21 страницаMATH101 Lecture1Cristhian Aldana YarlequeОценок пока нет

- Google pricing templateДокумент42 страницыGoogle pricing templatevinay_kОценок пока нет

- Global Mobility Specialist Cover LetterДокумент8 страницGlobal Mobility Specialist Cover Letterpodajokityk2100% (2)

- Application LetterДокумент2 страницыApplication LetterShasha MahmudОценок пока нет

- Lab 02 - Boolean Function Implementation PDFДокумент10 страницLab 02 - Boolean Function Implementation PDFNashowan Gamal AlhadrmiОценок пока нет

- Service Software Manual Alegria PDF PDFДокумент17 страницService Software Manual Alegria PDF PDFYousra ZeidanОценок пока нет

- 00250600BCST49051 Cdfe02 38Документ38 страниц00250600BCST49051 Cdfe02 38Mohammed HijaziОценок пока нет

- Pioneer djm-600 SДокумент32 страницыPioneer djm-600 SΝίκος ΑνδριανάκηςОценок пока нет

- Manual TMD-SeriesДокумент1 страницаManual TMD-SeriesAlex VargasОценок пока нет

- 2.1. Gazebo SimulatorДокумент2 страницы2.1. Gazebo Simulatordanang januariОценок пока нет

- COMPUTER SCIENCE PRACTICAL EXERCISES 2022-23Документ39 страницCOMPUTER SCIENCE PRACTICAL EXERCISES 2022-23Bhoomi GoelОценок пока нет

- GV3000/SE Operator Interface Module (OIM) User Guide: M/N 2RK3000Документ112 страницGV3000/SE Operator Interface Module (OIM) User Guide: M/N 2RK3000marco_christoforidisОценок пока нет