Академический Документы

Профессиональный Документы

Культура Документы

Sop Opet 043

Загружено:

lets createОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sop Opet 043

Загружено:

lets createАвторское право:

Доступные форматы

SOP/OPET/043

ONGC Petro additions Ltd Rev. No 00

Dahej, Bharuch Rev.Date

01.09.2018

ECTS TITLE: SOP for VOC System Page 1 of 5

1. Scope:

This SOP is limited to safely and effectively carry out VOC system start-up/shutdown/operation for

discharging of Volatile organic compound to GIDC as per GPCB/CPCB norms.

2. Introduction:

Various contaminated effluents generated in the petrochemical complex is sent to ECTS plant to treat the

effluents and meet the GPCB/CPCB norms before discharge outside battery limit. The VOCs generated

from OWS effluent treatment System, CRW treatment System, Oily & Chemical sludge handling system,

Wet Slop oil handling system & Spent Caustic handling system. The VOCs from different effluent

treatment sections within battery limit is send to VOC Stack through ACH discharge to Atmosphere as

per GPCB/CPCB norms..

3. Principle:

VOC System start-up, shutdown and operation. This manual includes details of treatment philosophy,

equipment specification, start-up & stabilization procedure, shutdown procedure and safety

systems/parameters.

4. Design:

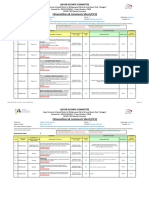

Design capacities of major equipment’s are tabulated below:

Description Design Capacity Quantity

VOC Blower 74-K-601A/B 2400 m3/hr 2 nos

Flame Arrestor 74-FA-01/02/03/04 804/612/639/2055 4 nos.

m3/hr

Activated Carbon Filter 2400 m3/hr 3 nos.

74-ACF-601 A/B/C

5. Safety:

Following mandatory PPE’s must be used for waste disposal system:-

Safety Shoes Safety Helmet Safety goggle Hand Gloves Ear Plugs

5.1. Safety& Health Hazards and Precautions:

HAZARD PRECAUTION

Leakage Ensure emergency safety shower, eye wash stations are provided

and is operational in all the areas for leakage of Hydrocarbon &

Carbon monoxide.

Ensure all equipment during maintenance that could unexpectedly

Electrical and start-up or release stored energy must be locked out and tagged out

Mechanical Hazards (LOTO) properly to protect against any accidental injury to working

personnel.

Permit system must be followed throughout any

maintenance/commissioning activities.

APPROVED BY

ISSUE/REV. NO DATE REVIEWED & ISSUED BY

01/00 01/09/2019 ECTS DMR HEAD U&O

SOP/OPET/043

ONGC Petro additions Ltd Rev. No 00

Dahej, Bharuch Rev.Date

01.09.2018

ECTS TITLE: SOP for VOC System Page 2 of 5

Ensure prompt disposal of cartons, crates and other flammable

Fire packing material and other debris from operational areas.

A fire extinguisher suitable to the type of fire needs to be provided at

various designated points in the plant.

Fire safety drill need to be periodically conducted for all operating

personnel.

Cut any grass or wild plantation inside battery limit

Snake bite Use flameproof torch while moving in night

Ensure proper illumination throughout plant area

6. Alarms & Interlocks:

Interlock Controller Function Set Point

Number Number

I-3701 TT-3701 & To trip Blower 74-K-601A/B at HH & Open XV-3701 & 85oC of ACF-A

TT-3704 XV-3704 temp

I-3702 TT-3702 & To trip Blower 74-K-601A/B at HH & Open XV-3702 & 85oC of ACF-B

TT-3705 XV-3705 temp

I-3703 TT-3703 & To trip Blower 74-K-601A/B at HH & Open XV-3703 & 85oC of ACF-C

TT-3706 XV-3706 temp

I-3704 74-K- To Trip Blower 74-K-601A/B due to drive failure & I-

601A/B 3701/3702/3703 is health than Stand by Blower 74-K-

601A/B is start.

I-3705 AI-3703 To trip Blower 74-K-601A/B at HH 60 PPM

7. Procedure:

Pre-Checks:

1. All safety showers and eye washes are operational.

2. All Flame Arrestor, blowers, XVs should be in auto mode.

3. All analyzers such as HC, CO should be in line.

4. Flame arrestor & ACF inlet and outlet valves GV-3701, 3702, 3703, 3704, 3709, 3710, 3712, 3713,

3715, 3716, 3720, 3721, 3725, 3726, 3730, 3731, 3733, 3799 should be in open condition.

Procedure for VOC System:

SN Activity Responsibility

1.0 Ensure All analysers such as HC, CO are line up. Panel/Field

Officer

2.0 Ensure all Pressure, temperature transmitter & indicators are lineup. Panel/Field

Officer

3.0 Flame Arrestor System lineup. (Before VOC Blower 74-K-601A Field Officer

/B is start up)

3.1 Flame arrestor of OWS system 74-FA-3701 is lineup. (GV-3701, Field Officer

3702, 3703, 3704 are in open condition).

3.2 Flame arrestor of CRWS system 74-FA-3703 is lineup. (GV-3709, Field Officer

3710, 3712, 3713 are in open condition).

APPROVED BY

ISSUE/REV. NO DATE REVIEWED & ISSUED BY

01/00 01/09/2019 ECTS DMR HEAD U&O

SOP/OPET/043

ONGC Petro additions Ltd Rev. No 00

Dahej, Bharuch Rev.Date

01.09.2018

ECTS TITLE: SOP for VOC System Page 3 of 5

3.3 Wet Slop oil Storage Flame Arrestor 74-FA-1301/1302 are lineup. Field Officer

3.4 Spent Caustic Storage Flame Arrestor 74-FA-07A/B are lineup. Field Officer

3.5 Flame arrestor of Oily & Chemical sludge handling system 74-FA- Field Officer

3702 is lineup. (GV-3715, 3716, 3720, 3721 are in open condition).

3.6 Flame arrestor 74-FA-3704 is lineup. (GV-3725, 3726, 3730, 3731 Panel Officer

are in open condition).

4.0 Service Water Lineup in ACF System of VOC.

4.1 Service Water Line Valve GV-3799 is in open condition. Field Officer

4.2 Service water line is lineup in ACF 74-ACF-601A/B/C. (XV-3701/ Panel/Field

3702/ 3703/ 3704/ 3705/ 3706 are in closed condition). Officer

5.. ACF Operation

5.1 Any Two ACF take in line out of three ACF-601 A/B/C. Panel/Field

Officer

5.2 Case:1 ACF -601A/B are take in line Panel/Field

Officer

5.2.1 GV-3733, 3736, 3737, 3739, 3742 ,3743, 3744, 3745 are in open Field Officer

condition & others all GVs are in closed condition

5.3 Case:2 ACF -601B/C are take in line Panel/Field

Officer

5.3.1 GV-3740, 3742, 3743, 3744, 3746, 3749, 3750, 3751, 3752 are in Field Officer

open condition & others all GVs are in closed condition

5.4 Case:3 ACF -601C/A are take in line Panel/Field

Officer

5.4.1 GV-3747, 3749, 3750, 3751, 3734, 3736, 3737, 3738 are in open Field Officer

condition & others all GVs are in closed condition

5.5 Case:4 ACF -601C/B are take in line Panel/Field

Officer

5.5.1 GV-3747, 3749, 3750, 3751, 3741, 3742, 3743, 3744, 3745 are in Field Officer

open condition & others all GVs are in closed condition

5.6 Case:5 ACF -601B/A are take in line Panel/Field

Officer

5.6.1 GV-3740, 3742, 3743, 3744, 3746, 3748, 3734, 3736, 3737, 3738 are Field Officer

in open condition & others all GVs are in closed condition

5.7 Case:6 ACF -601A/C are take in line Panel/Field

Officer

5.7.1 GV-3733, 3736, 3737, 3739, 3741 ,3748, 3749, 3750,3751,3752 are Field Officer

in open condition & others all GVs are in closed condition

6.0 74-HIC-3701 is open condition. Field Officer

7.0 VOC Blower 74-K-601A/B is lineup. ( BFV-3701 ,3702, 3703, 3704 Field Officer

are in open condition)

7.1 VOC blower 74-K-601A/B is started. Panel Officer

8.0 The service operation shall continue till High-High Alarm of CO & Panel Officer

Hydro Carbon Analyser.

9.0 Service Water line XV is open when ACF Temperature at high alarm. Panel Officer

10.0 Ensure HC and CO analyser reading as per GIDC discharge norms Panel/Field

and design parameters. Officer

11 Regular Samples to be sent to central lab for quality assurance. Field Officer

APPROVED BY

ISSUE/REV. NO DATE REVIEWED & ISSUED BY

01/00 01/09/2019 ECTS DMR HEAD U&O

SOP/OPET/043

ONGC Petro additions Ltd Rev. No 00

Dahej, Bharuch Rev.Date

01.09.2018

ECTS TITLE: SOP for VOC System Page 4 of 5

8. Record:

Shift In-Charge Logbook.

Shift Excel Logsheet.

Area Operator Logsheet.

9. Reference:

Refer P&ID 110804-F-74-1137.

OPaL Operation Manual Document Number OPaL/U&O/ECTS/Manual/001.

Simplified diagram for VOC system is shown below:

APPROVED BY

ISSUE/REV. NO DATE REVIEWED & ISSUED BY

01/00 01/09/2019 ECTS DMR HEAD U&O

Вам также может понравиться

- BS7-Touch Screen PanelДокумент96 страницBS7-Touch Screen PanelEduardo Diaz Pichardo100% (1)

- SOP For Compressed Air SystemДокумент14 страницSOP For Compressed Air SystemAbeer arif100% (1)

- Material Handling Study Report For Removable Tube BundleДокумент9 страницMaterial Handling Study Report For Removable Tube BundleMohamed FarisОценок пока нет

- 1 Boiler Cold Start UpДокумент77 страниц1 Boiler Cold Start UpSiddhant Satpathy100% (1)

- Standard Operating ProcedureДокумент55 страницStandard Operating Procedureboy tryadi100% (1)

- Operational Control Procedures BhelДокумент124 страницыOperational Control Procedures BhelKrishnan Rajappan100% (3)

- Doc. No. Page No: 1 OF 2: Integrated Departmental Manual Caustic Soda Unit Sop/Elect /10Документ2 страницыDoc. No. Page No: 1 OF 2: Integrated Departmental Manual Caustic Soda Unit Sop/Elect /10Ravi Shankar ChakravortyОценок пока нет

- C00M04 HPL E - MC 304a XX MDS 0001 PDFДокумент18 страницC00M04 HPL E - MC 304a XX MDS 0001 PDFRUPESH KUMARОценок пока нет

- HPT Stage 1 Blades and Duct SegmentsДокумент28 страницHPT Stage 1 Blades and Duct SegmentsArabyAbdel Hamed SadekОценок пока нет

- Purpose:: U&O-Effluent Collection and Treatment System Sop No: Opal/U&O/Ects/Xxxx SOP For Sequential Batch ReactorДокумент6 страницPurpose:: U&O-Effluent Collection and Treatment System Sop No: Opal/U&O/Ects/Xxxx SOP For Sequential Batch ReactorJayraj DaymaОценок пока нет

- Woc Hse Manual Standards: Woc LP EP DepartmentДокумент12 страницWoc Hse Manual Standards: Woc LP EP DepartmentAkram AlhaddadОценок пока нет

- Work Instruction VCBДокумент3 страницыWork Instruction VCBTAHIR HUSAINОценок пока нет

- Esa - PBC & PBST (E3280e)Документ28 страницEsa - PBC & PBST (E3280e)crvitor1Оценок пока нет

- SOP For Condenser Rubber Ball Cleaning System HBSДокумент8 страницSOP For Condenser Rubber Ball Cleaning System HBSAbeer arifОценок пока нет

- Estufa Thermo Scientific - 371Документ96 страницEstufa Thermo Scientific - 371Tincho ValleverdeОценок пока нет

- O - (TOC) - SOP - 008 - R0 - SOP For Welding Consumables Handling and ControlДокумент8 страницO - (TOC) - SOP - 008 - R0 - SOP For Welding Consumables Handling and ControlMDhana SekarОценок пока нет

- OptiLobe - Bomba Coca-Cola - ManualДокумент32 страницыOptiLobe - Bomba Coca-Cola - ManualramiressОценок пока нет

- Self-Recuperative Burners High Speed Free FlameДокумент17 страницSelf-Recuperative Burners High Speed Free FlameKarl WeierstrassОценок пока нет

- Rotary Lobe Pumps Atex Addendum To SX Instruction ManualДокумент14 страницRotary Lobe Pumps Atex Addendum To SX Instruction ManualAbdellah IbrahimОценок пока нет

- Boiler ExplosionДокумент3 страницыBoiler ExplosionkuldeepОценок пока нет

- F O Flushing and Steam Blowing PDFДокумент8 страницF O Flushing and Steam Blowing PDFSendal BodolОценок пока нет

- 09.work Instruction For Operation of Additive Ball MillДокумент9 страниц09.work Instruction For Operation of Additive Ball MillRahul VermaОценок пока нет

- 3605 - SOP of Diesel DecatingДокумент5 страниц3605 - SOP of Diesel DecatingClash with HBОценок пока нет

- 100v0966 FG WOOBE MeterДокумент89 страниц100v0966 FG WOOBE Meterzakarianoui35Оценок пока нет

- Maint. SchedulesДокумент109 страницMaint. SchedulesShahriyar Kabir RistaОценок пока нет

- Procedure For Electrode Baking: Larsen & Toubro Limited - Ecc Division Work Procedures Sepco Iii Project, JharsugudaДокумент4 страницыProcedure For Electrode Baking: Larsen & Toubro Limited - Ecc Division Work Procedures Sepco Iii Project, JharsugudadiptiОценок пока нет

- BOP Function Test SOPДокумент1 страницаBOP Function Test SOPRajesh SharmaОценок пока нет

- Fire and Gas Detection Philosophy PDFДокумент22 страницыFire and Gas Detection Philosophy PDFOmar Tocmo100% (3)

- Hot Insulation Method Statement Rev.Документ25 страницHot Insulation Method Statement Rev.Hassan Helmy100% (1)

- MS (TP-50002)Документ13 страницMS (TP-50002)Benasher IbrahimОценок пока нет

- CMAS Training Plan: BP Tangguh LNGДокумент17 страницCMAS Training Plan: BP Tangguh LNGAenur RofiiqОценок пока нет

- Richland, Michigan 49083 269-629-5000: Pneumatic DivisionДокумент4 страницыRichland, Michigan 49083 269-629-5000: Pneumatic DivisionJavierLugoОценок пока нет

- Method Statement Format (CDRIHBIBSG and Silo DC Pipe Line Cleaning by Hydrojetting MOSДокумент11 страницMethod Statement Format (CDRIHBIBSG and Silo DC Pipe Line Cleaning by Hydrojetting MOSPrem Preetham Dsouza100% (1)

- Hazop Close Out Report V-8701 Flare Ko Drum Draining Facilities at Ngl-4Документ79 страницHazop Close Out Report V-8701 Flare Ko Drum Draining Facilities at Ngl-4Vedran KosanovicОценок пока нет

- CSU Vibration Acceptance Criteria ProcedureДокумент9 страницCSU Vibration Acceptance Criteria ProcedureDaniel Erasmo Avellaneda Sanchez100% (1)

- Procedure For Burner Handover and TakeoverДокумент7 страницProcedure For Burner Handover and TakeoverArjun Shantaram ZopeОценок пока нет

- Etuve HeraCell Operating and Maintenance Manual 7003422 Rev. 7Документ96 страницEtuve HeraCell Operating and Maintenance Manual 7003422 Rev. 7Sushee RawОценок пока нет

- Observations & Comments Sheet (OCS) : Qatar Olympic CommitteeДокумент2 страницыObservations & Comments Sheet (OCS) : Qatar Olympic CommitteeIbrahim SirpiОценок пока нет

- BOP FF August 2023Документ6 страницBOP FF August 2023Bheramara CCPPОценок пока нет

- Work - Instruction AIS HT PANELДокумент3 страницыWork - Instruction AIS HT PANELTAHIR HUSAINОценок пока нет

- Checklist - LDO-UnLoading PumpДокумент12 страницChecklist - LDO-UnLoading PumpBandi Suryakanthareddy V G0% (1)

- Pre-Commissioning and Commissioning ProceduresДокумент34 страницыPre-Commissioning and Commissioning ProceduresSaheb Yadav100% (1)

- Dry Out Procedure For Refractory Lining at SiteДокумент9 страницDry Out Procedure For Refractory Lining at SiteEnimizufa DiepreyeОценок пока нет

- Flare Jide9Документ17 страницFlare Jide9samuel100% (3)

- Project Specification For Fire and Gas SystemДокумент16 страницProject Specification For Fire and Gas SystemOmar TocmoОценок пока нет

- Procedure No. L&T/ Kkro / Mech / WP 05: Procedure For Ag Piping Fabrication & ErectionДокумент10 страницProcedure No. L&T/ Kkro / Mech / WP 05: Procedure For Ag Piping Fabrication & ErectiondiptiОценок пока нет

- 34 CT FAN OperationДокумент16 страниц34 CT FAN OperationSiddhant SatpathyОценок пока нет

- Ses-Pgb-Co-Otp-0034 Otp For Hot Reheat Steam System Rev.0Документ36 страницSes-Pgb-Co-Otp-0034 Otp For Hot Reheat Steam System Rev.0zhangОценок пока нет

- SOP For Closed Cooling Water SystemДокумент16 страницSOP For Closed Cooling Water SystemAbeer arif100% (1)

- SMP For Calibration of Gauges & TransmittersДокумент3 страницыSMP For Calibration of Gauges & Transmitterspradeep1987coolОценок пока нет

- BC01C1-Soot Blower Spec - R0Документ6 страницBC01C1-Soot Blower Spec - R0JKKОценок пока нет

- Oxygen & Nitrogen Gas Lines: Page 1 of 4Документ4 страницыOxygen & Nitrogen Gas Lines: Page 1 of 4qamar sayedОценок пока нет

- Specification For Jet A1 Filtration and Flow MEASUREMENT PACKAGE (SKZZ-47401/02/03)Документ8 страницSpecification For Jet A1 Filtration and Flow MEASUREMENT PACKAGE (SKZZ-47401/02/03)CRISTIAN ANDRES SANABRIA MARTINEZОценок пока нет

- C.02 - Gas-Freeing and Cleaning of TanksДокумент7 страницC.02 - Gas-Freeing and Cleaning of TanksmkkamarajОценок пока нет

- Job Procedure For Earthing SystemДокумент7 страницJob Procedure For Earthing SystemNisith SahooОценок пока нет

- Sop For Refractory Dry OutДокумент5 страницSop For Refractory Dry OutRakesh VermaОценок пока нет

- Ascott Manual S Ip RangeДокумент80 страницAscott Manual S Ip Rangejeremias100% (1)

- Ut - Bhe Nde Nu 700mw RH RT Rev 00 Latest Ut Procedure 14-02-2014Документ17 страницUt - Bhe Nde Nu 700mw RH RT Rev 00 Latest Ut Procedure 14-02-2014JoelОценок пока нет

- GTG-EXP-000-EXP-PRO-0010 - Desorption Procedure Rev 01Документ19 страницGTG-EXP-000-EXP-PRO-0010 - Desorption Procedure Rev 01Boussebha NoureddineОценок пока нет

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- FRM Valuation & Risk Models Dowd, Chapter 2: - Hosted by David Harper Cfa, FRM, Cipm - Published April 22, 2012Документ19 страницFRM Valuation & Risk Models Dowd, Chapter 2: - Hosted by David Harper Cfa, FRM, Cipm - Published April 22, 2012BeastОценок пока нет

- Project PlanДокумент55 страницProject PlanAlfredo SbОценок пока нет

- Imagine Unit 1 P 10 11Документ1 страницаImagine Unit 1 P 10 11נויה לבדובОценок пока нет

- The Ego and Analysis of Defense-Jason Aronson, Inc. (2005) Paul GrayДокумент356 страницThe Ego and Analysis of Defense-Jason Aronson, Inc. (2005) Paul GrayClinica MonserratОценок пока нет

- CampingДокумент25 страницCampingChristine May SusanaОценок пока нет

- AcquaculturaДокумент145 страницAcquaculturamidi64100% (1)

- MSU-Iligan Institute of TechnologyДокумент5 страницMSU-Iligan Institute of TechnologyYuvi Rociandel LUARDOОценок пока нет

- Hydrogen Production From The Air: Nature CommunicationsДокумент9 страницHydrogen Production From The Air: Nature CommunicationsdfdffОценок пока нет

- Factory OverheadДокумент2 страницыFactory OverheadKeanna Denise GonzalesОценок пока нет

- Rahu Yantra Kal Sarp Yantra: Our RecommendationsДокумент2 страницыRahu Yantra Kal Sarp Yantra: Our RecommendationsAbhijeet DeshmukkhОценок пока нет

- AQ-101 Arc Flash ProtectionДокумент4 страницыAQ-101 Arc Flash ProtectionYvesОценок пока нет

- Arann Magazine, Issue 1-2-Online VersionДокумент36 страницArann Magazine, Issue 1-2-Online VersionmujismileОценок пока нет

- Recipe: Patisserie Method: Eclair Cake RecipeДокумент3 страницыRecipe: Patisserie Method: Eclair Cake RecipeEisha BibiОценок пока нет

- Citizen's 8651 Manual PDFДокумент16 страницCitizen's 8651 Manual PDFtfriebusОценок пока нет

- TC 000104 - VSL MadhavaramДокумент1 страницаTC 000104 - VSL MadhavaramMK BALAОценок пока нет

- Faculty Based Bank Written PDFДокумент85 страницFaculty Based Bank Written PDFTamim HossainОценок пока нет

- Formulas Related Question, PebcДокумент1 страницаFormulas Related Question, PebcBhavesh NidhiОценок пока нет

- Cooling Tower (Genius)Документ7 страницCooling Tower (Genius)JeghiОценок пока нет

- Mental Status ExaminationДокумент34 страницыMental Status Examinationkimbomd100% (2)

- Chan v. ChanДокумент2 страницыChan v. ChanjdpajarilloОценок пока нет

- Sindh Rescue 1122 Test Sample PapersДокумент12 страницSindh Rescue 1122 Test Sample PapersMAANJONY100% (1)

- 1 Nitanshi Singh Full WorkДокумент9 страниц1 Nitanshi Singh Full WorkNitanshi SinghОценок пока нет

- Assignment Nutrition and HydrationДокумент17 страницAssignment Nutrition and Hydrationmelencio olivasОценок пока нет

- Sedation and Analgesia in Critically Ill Neurologic PatientsДокумент24 страницыSedation and Analgesia in Critically Ill Neurologic PatientsrazaksoedОценок пока нет

- Deloitte Uk Mining and Metals DecarbonizationДокумент10 страницDeloitte Uk Mining and Metals DecarbonizationfpreuscheОценок пока нет

- Soil Chapter 3Документ67 страницSoil Chapter 3Jethrone MichealaОценок пока нет

- Benefits of Silicone Coated Glass InsulatorsДокумент10 страницBenefits of Silicone Coated Glass InsulatorsMuhammad Waseem AhmadОценок пока нет

- Ineffective Breastfeeding - NCPДокумент10 страницIneffective Breastfeeding - NCPJullian PloyaОценок пока нет

- Analyzing Activity and Injury: Lessons Learned From The Acute:Chronic Workload RatioДокумент12 страницAnalyzing Activity and Injury: Lessons Learned From The Acute:Chronic Workload RatioLukas ArenasОценок пока нет