Академический Документы

Профессиональный Документы

Культура Документы

Mechanical Data Sheet

Загружено:

ktejankarОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Mechanical Data Sheet

Загружено:

ktejankarАвторское право:

Доступные форматы

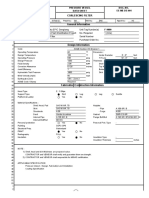

Design book no.: SHELL DEP 31.22.00.

31-Gen

Data requisition sheet for: Category 1 pressure vessels

Contr. job no.:

ENGINEERING REQUIREMENTS TO BE SUPPLIED TO MANUFACTURER

Design condition Vessel Jacket Coil

Specified internal design

pressure barg 16.5 NA NA

Internal design temp.

°C -29 to +57 NA NA

Specified external design

pressure barg FV (Note M. 03) NA NA

External design temperature °C 57 NA NA

Temp @ Press

MDMT -29 @ NA @ NA NA @ NA

°C barg

Low temperature due to: Normal process

Design specific gravity: 0.585 at 15°C NA NA

MAWP basis: Calculated NA

Construction code: PD 5500 and EEMUA 190 Edition 2018 and 2017 Addenda A1 Other: Note M. 02

Lethal service ASME code case(s)

Other markings: Other:

(ASME Section VIII Div. 1 only) See certification page

Capacity Cu. meter 701(Nominal) / 650(Pumpable) I.D mm 6000 Length (T/T) mm 24000

Installed position: Horizontal Maximum liquid level: mm 5700

Vessel interior Vessel exterior Nozzles Internals Corrosive service?

Corrosion allowance

3 NIL 3 3 No

Seal weld internals to pressure

Jacket internal Jacket external Coil Vessel supports

mm boundary?

NA NA NA NA No

Cyclic service Annual cycles – vessel Annual cycles – jacket Annual cycles – coil

No NA NA NA

Creep Temp @ Hour(s) Vessel Jacket Coil

No NA NA @ NA NA @ NA NA @ NA

Fatigue analysis not required

Yes Structural stress method

Design life: 30 Years Fatigue analysis by mfg. No based on comparable No

(Note M. 22) permitted

equipment experience

Wind loading

Wind speed Classification category Exposure category Topographic factor Elevation

(Code used)

NA NA NA NA NA

Seismic Applicable ASCE 7-10 / Peak ground Peak ground Peak ground

Yes Ground type Note M. 13 Note M. 13 Note M. 13 Note M. 13

loading code: IBC 2012 acceleration displacement velocity

Other loadings Note M. 03 NIL NIL

Head types Top / Bottom NA Nozzle dish 2:1 Ellipsoidal Domed Hemispherical

Body flange Type: ---- Facing: ----

Body flange finish NA Process side: µ-in. Service side: ----

Vortex breaker: Yes Projection: Flush Type: 4 Blade

Hardness control: Yes Max hardness value: Note M. 20

Joint efficiency: 1 PWHT: Yes(As per EEMUA 190 (2017 Edn.) and PD 5500(2018+A1))

Shop coat: Yes (Note M. 12) Primer specification: Yes (Note M. 12) Top coat specification: Yes (Note M. 12)

Fireproofing: No Type: NA Thickness: NA

By mfg. 2500

Insulation: Yes Thickness: mm. Note M. 05 Type: Sand Mound Density:

By others kg/m3

Vessel supports Lifting lugs Type : Perpendicular

No. Date Description By Check Appv

0 21-09-2019 Issued for Comments PW AT RM

1 10-10-2019 Issued for Approval PW AT RM

2 07-11-2019 Re-Issued for Approval RP PW RM

3 19-11-2019 Approved for Detail Design RP PW RM

Document No. 4126-RLLPGBP-5-13-0004 Page: 3 of 10

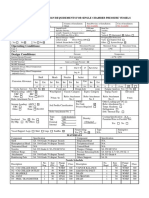

Design book no.: SHELL DEP 31.22.00.31-Gen

Data requisition sheet for: Category 1 pressure vessels

Contr. job no.:

MATERIALS

ALL MATERIALS MUST COMPLY WITH STATED CODE OF CONSTRUCTION & DEP 30.10.02.11-Gen

Component Material type Code specification Comments

Shell CS EN 10028-3 P355NL1

Clad lining - -

Heads CS EN 10028-3 P355NL1

Jacket - -

Reinforcing pads CS EN 10028-3 P355NL1 (Other than nozzles)

Nozzle neck (forgings) CS EN 10222-4 P355 QH

Nozzle neck (pipe) CS EN 10216-3 P355 NL1 / A 333 GR. 6

Nozzle flanges CS EN 10222-4 P355 QH

Manway neck (forgings) CS EN 10222-4 P355 QH

Manway neck (plate) CS EN 10028-3 P355NL1

Manway flange CS EN 10222-4 P355 QH

Manway cover CS EN 10222-4 P355 QH

Support strips SS * (Note M.09)

Lifting lugs / External cleats CS EN 10028-3 P355NL1

Pipe fittings CS A 420 WPL6

Stiffening rings CS EN 10028-3 P355NL1

Insulation supt. rings - -

Internal ladder along with clips CS EN 10028-3 P355NL1

Settling benchmark CS *EN 10216-3 P355 NL1 / A 333 GR. 6

EN 10216-3 P355 NL1 / A 333 GR.6 /

Other internals CS

EN 10028-3 P355NL1

Inlet distributor,still wells SS SS 316 3

Internal bolts - -

Internal nuts - -

External bolts CS EN 10269 42CrMo4 / A 193 GR. B7

External nuts CS EN 10269 C45E / A 194 GR. 2H

Vessel gaskets (external) - SS 316 spiral wound graphite filled

Name plate SS SS 316

3

No. Date Description By Check Appv

0 21-09-2019 Issued for Comments PW AT RM

1 10-10-2019 Issued for Approval PW AT RM

2 07-11-2019 Re-Issued for Approval RP PW RM

3 19-11-2019 Approved for Detail Design RP PW RM

Document No. 4126-RLLPGBP-5-13-0004 Page: 4 of 10

Design book no.: SHELL DEP 31.22.00.31-Gen

Data requisition sheet for: Category 1 pressure vessels

Contr. job no.:

NOZZLE SCHEDULE

PURCHASER SHALL ORIENT AND LOCATE NOZZLES ON MANUFACTURER’S APPROVAL DRAWINGS

Mark No. Req’d Size (DN) *Rating Type *Projection mm Description

SHELL NOZZLES

D1 1 *56" - SR *4100 Nozzle dome (with insert plate)

D2 1 *56" - SR *4100 Nozzle dome (with insert plate)

M1 1 30" 300# SRWNRF *4350 Access manway (with blind, davit and internal ladder)

M2 1 36" 300# SRWNRF *4350 Access manway (with blind, davit and internal ladder)

N12 1 12" - SR *4049 Liquid outlet ( with vortex breaker)

D1 NOZZLES

N1 1 6" 300# SRWNRF *4770 Filling inlet (with distributor)

N2 1 6" 300# SRWNRF *4770 Tanker offloading

N3 1 3" 300# SRWNRF *4770 Filling plant return

N5 1 3" 300# SRWNRF *4770 Vapor recovery

N7 1 2" 300# LWNRF *4770 Temperature indicator (with stilling well)

3

N9 1 6" 300# SRWNRF *4770 Level transmitter (Servo) (with 6" stilling well)

D2 NOZZLES

N4 1 6" 300# SRWNRF *4770 Vapour outlet

N6 1 2" 300# LWNRF *4770 Pressure transmitter

N8 1 2" 300# LWNRF *4770 Temperature indicator (with stilling well) 3

N10 1 6" 300# SRWNRF *4770 Level transmitter (Radar) (with 6" stilling well)

N11 1 8" 300# SRWNRF *4770 Relief valve (Hold H.01)

N13 1 2" 300# LWNRF *4770 Utility connection (N2 Purging)

MECHANICAL NOTES

M. 01 This datasheet shall be read in conjunction with process data sheet for LPG mounded storage vessel (Doc. No.: 4126-RLLPGBP-6-13-0001), specification

for LPG mounded storage vessel (Doc. No.: 4126-RLLPGBP-5-14-0001) and G.A. drawing for LPG mounded storage vessel (Doc. No.: 4126-RLLPGBP-5-

60-0001-001).

M. 02 Vessel shall be mechanically designed, fabricated, erected, inspected and tested in accordance with PD5500 (2018Edn. + Addendum A1), EEMUA 190

(2017 Edn.) and DEP's 31.22.00.31-Gen, 30.06.10.12-Gen and 34.51.11.30-Gen.

M. 03 The vessel design shall take into account of all the loads specified in clause 4.1.3 of EEMUA 190 (2017) and perform stress analysis of the vessel as per

appendix A of EEMUA 190 (2017).

M. 04 Deleted.

Vessel shall be fully covered with sand till the top of the vessel + 1000mm. The liquid outlet nozzle N12 shall be provided with 35mm thick cold insulation

M. 05

(BY OTHERS).

M. 06 All nozzles (including D1 and D2) and manholes shall be self reinforcement nozzle and set in type welded. All flanges size up to 24"NB shall be as per

ASME B16.5 and above 24"NB in accordance with ASME B16.47 Series-B.

M. 07 All data designated with (*) must be specified or verified by the Vendor

M. 08 The minimum requirements for the design of cathodic protection systems (Impressed cathodic protection system-BY OTHERS) along with corrosion

protection and coating requirements for mounded storage vessels shall be as per Shell DEP 30.10.73.10-Gen, NACE SP0285 and EEMUA 190.

M. 09 The requirements of bolted sleeve with flexible cover fixed with SS Strap around D1, D2 and manways to avoid any damage shall be met as per EEMUA

190 and specification for LPG mounded storage vessel (Doc. No.: 4126-RLLPGBP-5-14-0001). Supply by others.

M. 10 All non-destructive examination requirements shall be as per EEMUA 190, Table 3.2 of DEP 31.22.00.31-Gen and applicable QP standards.

M. 11 Lifting lugs shall be 100% MT/PT. Lifting lugs shall be designed for an Impact factor as 2.0

M. 12 Painting and coating:

Surface preparation and painting shall be as per schedule 11 of QP-SPC-L-002 rev.1.

M. 13 Seismic design code: ASCE 7-10, IBC 2012; importance factor: 1.5; response factor: 3; max. mapped res. acc. Ss: 0.147;

max. mapped res acc. S1: 0.065; site class: D

M. 14 The plate thickness of the hemispherical heads needs to be analyzed by the relevant percentage increase as per table of appendix A of EEMUA 190 (2017).

M. 15 All pressure parts material shall be EN 10204 type 3.1 (minimum) certified.

M. 16 Fabrication and welding processes shall be in accordance with PD5500, EEMUA 190 and DEP's 31.22.00.31-Gen, 30.10.60.18-Gen and DEP 30.10.60.32-

Gen as applicable

M. 17 Deleted.

M. 18 Preliminary weights:

Weight (Kgs)

Empty * 150000

Operating * 615000

Hydrotest * 945000

M. 19 The gasket seating surface finish shall be of 125-250 AARH.

M. 20 The requirements of material hardness testing shall be met as per APPENDIX H of EEMUA 190 (2017).

No. Date Description By Check Appv

0 21-09-2019 Issued for Comments PW AT RM

1 10-10-2019 Issued for Approval PW AT RM

2 07-11-2019 Re-Issued for Approval RP PW RM

3 19-11-2019 Approved for Detail Design RP PW RM

Document No. 4126-RLLPGBP-5-13-0004 Page: 5 of 10

Design book no.: SHELL DEP 31.22.00.31-Gen

Data requisition sheet for: Category 1 pressure vessels

Contr. job no.:

MECHANICAL NOTES (CONTINUED)

M. 21 Projection of nozzles D1 & D2 shall be measured from true horizontal line to tan line of nozzle head. Projection of nozzles and manway shall be measured

from true horizontal line to face of flange. VENDOR to advise. All top nozzle flanges shall be parallel to true horizontal plane and shall be in same plane.

M. 22 The LPG mounded storage vessel design shall be based on an overall long term settlement of 50mm and considered as supported on elastic foundations

Foundation shall be designed for following settlement values:

I) Immediate settlement value: - 25mm (MAX.)

II) Max. settlement value between centre and end of the bullet (at empty, operation, test case): 10mm (MAX.)

Vendor shall carry out a ‘beam on elastic foundation’ analysis using the long-term subgrade moduli due to uneven support using a finite element method as

per clause A.4.2.6 of EEMUA 190 (2017).

M. 23 Deleted.

PROCESS NOTES

P. 01 LPG storage vessel pumping-in flowrates are 30Mt/h & 38Mt/h (nor/max) and pumping-out flowrates are 22Mt/h, 62Mt/h & 124Mt/h (min/nor/ max).

P. 02 Liquid outlet line shall be welded to the ESD valve, which is to be located downstream of separation wall. The product line should be sloping downwards

from vessel to the pump suction. (1:200).

P. 03 LPG mounded bullet assessed temperature (Desert Climate). Refer Shell DEP 30.06.10.12

P. 04 Estimated minimum metal wall temperature due to LPG blowdown is -21.9°C.

P. 05 LPG composition with 30% : 70% (Propane : Butane) v/v considered

LPG storage vessel material shall be suitable for sweet service under low temperature condition. Inlet distributor shall be CS suitable for low temperature

P. 06

service

P. 07 Filling inlet nozzle with spraying (nozzles) arrangement shall be provided as per Shell DEP 30.06.10.12.

P. 08 Level and Temperature measurement shall be with stilling well. Perforations/slots shall be as per Instrumentation requirement.

HOLD

H. 01 Numbers and size of relief valve

H. 02 Nozzle orientation and elevation.

No. Date Description By Check Appv

0 21-09-2019 Issued for Comments PW AT RM

1 10-10-2019 Issued for Approval PW AT RM

2 07-11-2019 Re-Issued for Approval RP PW RM

3 19-11-2019 Approved for Detail Design RP PW RM

Document No. 4126-RLLPGBP-5-13-0004 Page: 6 of 10

Design book no.: SHELL DEP 31.22.00.31-Gen

Data requisition sheet for: Category 1 pressure vessels

Contr. job no.:

WELDED PRESSURE JOINT REQUIREMENTS

ALL JOINT DESIGNS AND SELECTED EFFICIENCIES MUST COMPLY WITH THE STATED CODE OF CONSTRUCTION

AND THE REQUIREMENTS OF DEP 31.22.00.31-Gen.

Component Joint efficiency Type joint NDE requirements

Head Type Extent Type Extent PMI

Category A 1.00 Butt weld RT 1 PT 1 1

Category B

Category C

Category D

Category E

Other requirements NA

Shell Type Extent Type Extent PMI

Category A 1.000 Butt weld RT 1 PT 1 1

Category B

Category C

Category D

Category E

Other requirements NA

Cone Type Extent Type Extent PMI

Category A

Category B

Category C

Category D

Category E

Other requirements NA

Other Type Extent Type Extent PMI

Skirt NA NA NA NA NA NA

No. Date Description By Check Appv

0 21-09-2019 Issued for Comments PW AT RM

1 10-10-2019 Issued for Approval PW AT RM

2 07-11-2019 Re-Issued for Approval RP PW RM

3 19-11-2019 Approved for Detail Design RP PW RM

Document No. 4126-RLLPGBP-5-13-0004 Page: 7 of 10

Design book no.: SHELL DEP 31.22.00.31-Gen

Data requisition sheet for: Category 1 pressure vessels

Contr. job no.:

REFERENCE SPECIFICATIONS

THE FOLLOWING ADDITIONAL SPECIFICATIONS ARE INCLUDED

Check if Check if

Spec no. Title Spec no. Title

applicable applicable

Appendix 1 Clad vessels S20.001 Skirts, cylindrical and conical

Appendix 4 Cr-Mo steels S20.002-001 Fireproof protection of skirts

Appendix 6 Storage spheres S20.002-002 Sphere support legs fireproofing and insulation

S10.010 Vortex breaker S20.003 Support skirts

Flanges for non-pressure pipe connections inside Support rings for insulation on vessels and

S10.016 S20.003-001

vessels heat exchangers

Lifting lug for top covers (Material: Carbon steel, low- Support rings for insulation on vessels and

S10.030 S20.003-002

alloy steel or stainless steel) heat exchangers

Pad-type hand holes with cover flange ANS class

Support rings for insulation on vessels and

S10.039 150 and 300 for unfired carbon steel, low-alloy steel S20.003-003

heat exchangers

and stainless steel pressure vessels

Support rings for insulation on vessels and

S10.053 Pad-type hand holes, carbon steel S20.003-004

heat exchangers

S10.054 Pad-type hand holes, carbon steel with lining S20.004 Anchor bolt ring or lugs and base plate for columns

S10.070 Davit for blind flange S22.001 Saddle supports – small

Bolt length and make-up requirements for tensioning

S10.071 S22.002 Saddle supports – large

tools

S10.101 Equipment nozzles S22.003 Sliding plate

Typical details of bush-lined, overlay welded and Supports for vertical vessels 350 mm OD to 1500 mm

S10.103-001 S22.005

clad steel nozzles OD (half skirts)

S10.103-002 Typical details for solid alloy nozzles in clad vessel S22.010 Vessel manway hinges

S10.107 Flanged thermowell nozzle DN40 mm on equipment

S10.114 Nameplate and bracket

S10.115 Typical detail of lifting trunnion for vertical vessels

S10.118 Reference-points for survey of steel vessels

S10.119 Grab rungs and steps for manways

No. Date Description By Check Appv

0 21-09-2019 Issued for Comments PW AT RM

1 10-10-2019 Issued for Approval PW AT RM

2 07-11-2019 Re-Issued for Approval RP PW RM

3 19-11-2019 Approved for Detail Design RP PW RM

Document No. 4126-RLLPGBP-5-13-0004 Page: 8 of 10

Design book no.: SHELL DEP 31.22.00.31-Gen

Data requisition sheet for: Category 1 pressure vessels

Contr. job no.:

3 OUTLINES OF EQUIPMENT AND DIMENSIONS THAT MANUFACTURER MUST HOLD

Document No. 4126-RLLPGBP-5-13-0004 Page: 9 of 10

Вам также может понравиться

- Pressure Vessel Data Sheet for TEG ContactorДокумент2 страницыPressure Vessel Data Sheet for TEG ContactorElias EliasОценок пока нет

- Coalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Документ2 страницыCoalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Elias EliasОценок пока нет

- Table-1 Scope of Work Supply (MR For ACHE)Документ6 страницTable-1 Scope of Work Supply (MR For ACHE)Avinash ShuklaОценок пока нет

- TBE For UG Knock Out Drum - Draft For Rev.C1Документ22 страницыTBE For UG Knock Out Drum - Draft For Rev.C1pragatheeskОценок пока нет

- Pressure VesselДокумент80 страницPressure Vesselkart_rl75% (4)

- Mechanical Specification - Instrument Air CompressorДокумент7 страницMechanical Specification - Instrument Air Compressorsajeesh5113699Оценок пока нет

- API 650 Datasheet 1Документ16 страницAPI 650 Datasheet 1alwacsОценок пока нет

- HSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterДокумент2 страницыHSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterThanh Phuc Nguyen100% (1)

- Technical Bid Evaluation FormДокумент2 страницыTechnical Bid Evaluation Formanon_213471744Оценок пока нет

- Technical Specification - Pressure VesselДокумент30 страницTechnical Specification - Pressure VesselMurli RamchandranОценок пока нет

- STD PIP VECQ1001 2009 Vessel Shop Qualification ProcedureДокумент27 страницSTD PIP VECQ1001 2009 Vessel Shop Qualification ProcedureNikunj KОценок пока нет

- Air Dryer - Tangguh PJДокумент64 страницыAir Dryer - Tangguh PJRanu JanuarОценок пока нет

- Reboiler DatasheetДокумент6 страницReboiler DatasheetMIHОценок пока нет

- 6684-EQS-101-CA-0001 - 000 - 03 - Contractor's Scope of Work - Static EquiДокумент15 страниц6684-EQS-101-CA-0001 - 000 - 03 - Contractor's Scope of Work - Static EquiAvinash ShuklaОценок пока нет

- Pressure Vessel FatigueДокумент3 страницыPressure Vessel Fatiguechemsac2100% (1)

- Mechanical Requirements for Packaged EquipmentДокумент34 страницыMechanical Requirements for Packaged EquipmentgustavoballettiОценок пока нет

- Gas-Gas Exchanger DatasheetДокумент3 страницыGas-Gas Exchanger DatasheetidilfitriОценок пока нет

- VEDST003 - Shell and Tube Heat Exchanger Specification SheetДокумент23 страницыVEDST003 - Shell and Tube Heat Exchanger Specification SheetyuganterОценок пока нет

- 18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Документ5 страниц18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Avinash ShuklaОценок пока нет

- MOUNDED BULLETS FOR LPG STORAGEДокумент41 страницаMOUNDED BULLETS FOR LPG STORAGEMarco Dos Santos NevesОценок пока нет

- PT VICO Indonesia heat exchanger designДокумент4 страницыPT VICO Indonesia heat exchanger designSoraya ZahraОценок пока нет

- Vessel Trays and InternalsДокумент13 страницVessel Trays and InternalsswatkoolОценок пока нет

- Tech. Spec. For Heat ExchangersДокумент5 страницTech. Spec. For Heat Exchangerssanjay421Оценок пока нет

- TBE-Pressure Vessel Standard TemplateДокумент4 страницыTBE-Pressure Vessel Standard TemplateSiva baalanОценок пока нет

- Column Data Sheet Distillation Column (T-2010)Документ12 страницColumn Data Sheet Distillation Column (T-2010)John Patrick Sanay NunezОценок пока нет

- TQ - Air Fin Cooler (CS) - ModificationДокумент6 страницTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaОценок пока нет

- Design Life of Pressure VesselsДокумент5 страницDesign Life of Pressure VesselsChanchal GuptaОценок пока нет

- Pipe Support Details SheetДокумент2 страницыPipe Support Details SheetSeungmin PaekОценок пока нет

- Heat Exchanger Checklist As Per TEMAДокумент6 страницHeat Exchanger Checklist As Per TEMAMONAОценок пока нет

- Vessel Data SheetДокумент1 страницаVessel Data SheetMichael HaiseОценок пока нет

- Index - Amendment To TBPДокумент4 страницыIndex - Amendment To TBPVineet 01Оценок пока нет

- Standard Shell. Specifications Pressure VesselДокумент20 страницStandard Shell. Specifications Pressure Vesseledwin100% (1)

- Re 622761 - A 1 Datasheet Anti Scale Anti CorrosionДокумент8 страницRe 622761 - A 1 Datasheet Anti Scale Anti Corrosion张强Оценок пока нет

- TBE Inlet Separator V 2100 FLNG2Документ6 страницTBE Inlet Separator V 2100 FLNG2halipzramlyzОценок пока нет

- Data Sheet For Silencer PDFДокумент3 страницыData Sheet For Silencer PDFAlvin Smith0% (1)

- Welker 2Документ2 страницыWelker 2faradbОценок пока нет

- Hmel GGSRP Bathinda 16/43: Piping Material Specification 6922-6-44-0005 Rev. 0Документ81 страницаHmel GGSRP Bathinda 16/43: Piping Material Specification 6922-6-44-0005 Rev. 0Krunal Shaj100% (1)

- NL-WI-236-04 Nozzle Loads EquipmentДокумент3 страницыNL-WI-236-04 Nozzle Loads EquipmentChirag ShahОценок пока нет

- TBE Pumps CP 16Документ21 страницаTBE Pumps CP 16ivomОценок пока нет

- Welding ChartДокумент2 страницыWelding Chartjmcorsame777100% (2)

- API 676 DatasheetДокумент2 страницыAPI 676 DatasheetTony_Black9950% (2)

- Design Philosophy - StaticДокумент61 страницаDesign Philosophy - StaticDarshan PanchalОценок пока нет

- ASME VIII-1 Calculations for Sample Pressure VesselДокумент21 страницаASME VIII-1 Calculations for Sample Pressure VesselTrishul Nath Pallay100% (1)

- Technical Notes and Specifications Part CДокумент29 страницTechnical Notes and Specifications Part Cهيمنت بيلوديا100% (1)

- 10P87-D0003-046-R0-WHRU by TEPLДокумент23 страницы10P87-D0003-046-R0-WHRU by TEPLjigarОценок пока нет

- Skirt To Dish Joint PDFДокумент64 страницыSkirt To Dish Joint PDFPrajwal ShettyОценок пока нет

- Piping PhilosophyДокумент15 страницPiping PhilosophyRagh100% (1)

- 6 44 0005 A1 PDFДокумент15 страниц6 44 0005 A1 PDFS.selvakumarОценок пока нет

- MR For Ball ValvesДокумент12 страницMR For Ball Valvesengr_umer_01100% (1)

- EIL-STD Specifiction For Centrifugal Pumps PDFДокумент21 страницаEIL-STD Specifiction For Centrifugal Pumps PDFM Danish john paul100% (1)

- 6-41-0006 Rev 3 - EIL STD Specs For Centrifugal PumpsДокумент20 страниц6-41-0006 Rev 3 - EIL STD Specs For Centrifugal PumpsSachinShinde100% (2)

- 15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)Документ22 страницы15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)sudokuОценок пока нет

- PZ D CS Pi SP 015 02Документ60 страницPZ D CS Pi SP 015 02epbamdadОценок пока нет

- Piping Spec - Piping ClassДокумент53 страницыPiping Spec - Piping Classalin2005100% (1)

- 254624-400-DS-PRO-310, Rev F - Datasheet of VRUДокумент18 страниц254624-400-DS-PRO-310, Rev F - Datasheet of VRURamesh SharmaОценок пока нет

- TEMA Sheet Heat Exchanger SpecificationДокумент3 страницыTEMA Sheet Heat Exchanger SpecificationSonNguyenОценок пока нет

- U Stamp - KK Form - SampleДокумент5 страницU Stamp - KK Form - SampleshazanОценок пока нет

- CA LPG 5b STD 0 RepairedДокумент27 страницCA LPG 5b STD 0 RepairedMadiaw NajaОценок пока нет

- 31220098Документ9 страниц31220098Muhammad AliОценок пока нет

- Operating Conditions:: Form Kk3-U-DrДокумент2 страницыOperating Conditions:: Form Kk3-U-DrshazanОценок пока нет

- Roark's Formulas For Excel Universal Technical Systems, IncДокумент26 страницRoark's Formulas For Excel Universal Technical Systems, Incktejankar100% (1)

- Usfos HydrodynamicsДокумент95 страницUsfos Hydrodynamicsabhinavka123Оценок пока нет

- Support Load CalcДокумент11 страницSupport Load CalcktejankarОценок пока нет

- Spring Hanger DetailsДокумент3 страницыSpring Hanger DetailsktejankarОценок пока нет

- Pressure Vessel Ansys 2Документ13 страницPressure Vessel Ansys 2Bruna Macedo100% (1)

- Weld Calc PDFДокумент1 страницаWeld Calc PDFktejankarОценок пока нет

- Flow and Accoustically Induced Vibrations A Real Problem For LNG Facilities PDFДокумент12 страницFlow and Accoustically Induced Vibrations A Real Problem For LNG Facilities PDFSargunam SankaravadivelОценок пока нет

- Plate Circular CentralДокумент9 страницPlate Circular CentralRiyazuddin MahamadОценок пока нет

- Pipe Bridge Design SheetДокумент1 страницаPipe Bridge Design SheetktejankarОценок пока нет

- Api 1111 Collapse Pressure CalcДокумент2 страницыApi 1111 Collapse Pressure CalcktejankarОценок пока нет

- Intraday Using BreakoutДокумент6 страницIntraday Using Breakoutmanoharreddy_g100% (1)

- Instructions For Using Abaqus/cae in Analyzing Pipe CrackДокумент10 страницInstructions For Using Abaqus/cae in Analyzing Pipe CracknxdavidОценок пока нет

- Piping Isometric Check ListДокумент1 страницаPiping Isometric Check ListktejankarОценок пока нет

- Pipe Wall Thickness DesignДокумент13 страницPipe Wall Thickness DesignktejankarОценок пока нет

- Pipe Support Span CalculationsДокумент2 страницыPipe Support Span CalculationsktejankarОценок пока нет

- Pipe Wall THK Calc For External PressureДокумент2 страницыPipe Wall THK Calc For External PressurektejankarОценок пока нет

- Fire Water System Design PDFДокумент22 страницыFire Water System Design PDFktejankarОценок пока нет

- Pipe Wall Thickness Calc Per ASME B31.8Документ1 страницаPipe Wall Thickness Calc Per ASME B31.8ktejankarОценок пока нет

- Cryogenic Fluid Storage & Transfer Systems: Module 5: Cryogenic Engineering ME 467Документ33 страницыCryogenic Fluid Storage & Transfer Systems: Module 5: Cryogenic Engineering ME 467meeraОценок пока нет

- Cryogenic Fluid Storage & Transfer Systems: Module 5: Cryogenic Engineering ME 467Документ33 страницыCryogenic Fluid Storage & Transfer Systems: Module 5: Cryogenic Engineering ME 467meeraОценок пока нет

- Questions & Answers: Webinar: Static Load Case EditorДокумент4 страницыQuestions & Answers: Webinar: Static Load Case EditorktejankarОценок пока нет

- Hexagon PPM L-T Chiyoda C2 Engineering Analysis Case Study USДокумент2 страницыHexagon PPM L-T Chiyoda C2 Engineering Analysis Case Study USktejankarОценок пока нет

- HAZOP Hazard Operability StudiesДокумент4 страницыHAZOP Hazard Operability StudiesSrinivas BobbyОценок пока нет

- Mod6 PDFДокумент29 страницMod6 PDFsalman1566Оценок пока нет

- Design For Pressure VesselДокумент18 страницDesign For Pressure VesselktejankarОценок пока нет

- A4 SPEC Surge Control Dynamics FIV AIV Station2014 PDFДокумент4 страницыA4 SPEC Surge Control Dynamics FIV AIV Station2014 PDFJose BijoyОценок пока нет

- Tutorial de Mecánica de La Fractura (Ansys APDL)Документ14 страницTutorial de Mecánica de La Fractura (Ansys APDL)omarihuanoОценок пока нет

- Stress Extended Report - Diffuser LineДокумент348 страницStress Extended Report - Diffuser LinektejankarОценок пока нет

- Stress Extended Report - Diffuser LineДокумент348 страницStress Extended Report - Diffuser LinektejankarОценок пока нет

- Input Echo - Diffuser LineДокумент39 страницInput Echo - Diffuser LinektejankarОценок пока нет

- Quad Sym 600 Manuel ServiceДокумент96 страницQuad Sym 600 Manuel ServiceAndriamaro RajaonarifetraОценок пока нет

- MM Buyers Guide Flange Facing-1.1Документ38 страницMM Buyers Guide Flange Facing-1.1muhamadrafie1975100% (1)

- (3D) Air Vent Head & Expansion JointДокумент65 страниц(3D) Air Vent Head & Expansion JointTrần Trung DũngОценок пока нет

- Content AccessHatchBrochure 2012 LR 10-30-12 PDFДокумент24 страницыContent AccessHatchBrochure 2012 LR 10-30-12 PDFJizelle JumaquioОценок пока нет

- GF - Installation Instructions For FlangesДокумент6 страницGF - Installation Instructions For FlangesHafiz KamalОценок пока нет

- List of Manufacturing DocumentsДокумент49 страницList of Manufacturing DocumentsRaghu KОценок пока нет

- V0lvo &scaniaДокумент41 страницаV0lvo &scaniairawan budi santosaОценок пока нет

- Centrifugal Pumps Updated 02-04Документ13 страницCentrifugal Pumps Updated 02-04EfrainОценок пока нет

- Spare Parts Catalogue: Triplex Mud PumpДокумент87 страницSpare Parts Catalogue: Triplex Mud PumpemilianoОценок пока нет

- India: 1UBK7-470E1Документ67 страницIndia: 1UBK7-470E1harish kumar100% (1)

- Gasket Design HDBKДокумент69 страницGasket Design HDBKsoftechq1809Оценок пока нет

- 3196xbulletin Read 06Документ20 страниц3196xbulletin Read 06bryandownОценок пока нет

- Rates for Cummins 125 KVA DG set spare partsДокумент2 страницыRates for Cummins 125 KVA DG set spare partskewalpal singhОценок пока нет

- Id Number Title Year OrganizationДокумент42 страницыId Number Title Year Organizationsuneesh50% (2)

- Underground ConduitsДокумент25 страницUnderground ConduitsAbdul AzimОценок пока нет

- Polaris BrochureДокумент5 страницPolaris BrochureschrienerОценок пока нет

- Service Manual Salisbury 5ha AxlesДокумент44 страницыService Manual Salisbury 5ha AxlesCarlos Gabriel EstergaardОценок пока нет

- Spare Parts Catalog: 4 WG-200 Case Material Number: 4644.024.131Документ78 страницSpare Parts Catalog: 4 WG-200 Case Material Number: 4644.024.131Teknik MakinaОценок пока нет

- Comparative Finite Element Analysis of Pikotek VCS and RTJ PDFДокумент28 страницComparative Finite Element Analysis of Pikotek VCS and RTJ PDFAbigor45Оценок пока нет

- Agility City 125Документ104 страницыAgility City 125pfonsecaОценок пока нет

- Operations Maintenance Manual Style 129 Reliant Fire Hydrant 3fd60382Документ14 страницOperations Maintenance Manual Style 129 Reliant Fire Hydrant 3fd60382Abdul KarimОценок пока нет

- PROCEDURE For Tightening of Flange GasketsДокумент6 страницPROCEDURE For Tightening of Flange GasketsAnonymous gr5Pr9AVОценок пока нет

- PDF en Funke Phe En-Gb PDFДокумент12 страницPDF en Funke Phe En-Gb PDFStoianovici CristianОценок пока нет

- Tunnel Broschuere 1Документ12 страницTunnel Broschuere 1juli_radОценок пока нет

- Neoprene Data SheetДокумент1 страницаNeoprene Data SheetsuriantoОценок пока нет

- 7.service ManualДокумент7 страниц7.service ManualOrlando MantillaОценок пока нет

- Catalogo Afa Cummins Isx15Документ79 страницCatalogo Afa Cummins Isx15Alexis Sanchez100% (2)

- Tripac Technical Data - Bolt - Wrench Sizes ChartДокумент19 страницTripac Technical Data - Bolt - Wrench Sizes Chartcmms88100% (2)

- Saran Project 1Документ34 страницыSaran Project 1MANOJKUMAR VОценок пока нет

- Arita KatalogДокумент58 страницArita KatalogAhmed Beaet83% (6)