Академический Документы

Профессиональный Документы

Культура Документы

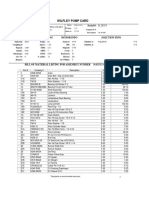

Balance MS5001

Загружено:

Sasongko Wahyu0 оценок0% нашли этот документ полезным (0 голосов)

37 просмотров2 страницыBalance ms5001

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документBalance ms5001

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

37 просмотров2 страницыBalance MS5001

Загружено:

Sasongko WahyuBalance ms5001

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

1.

Turn the Rotor vertical

2. Clamp the fwd. rotor coupling to the stacking table

3. Drill holes through the center of each marriage bolt on turbine distance piece

The drilled holes allow the bolts to be heated and expand in length

4. Use a torch and direct flame down through the center of each bolt

5. Heat the bolt until it expands in length

6. Turn the bolt and remove it

7. Repeat all marriage joint bolts

8. Pack dry ice around the Distance piece

9. Wait ½ hour for the distance piece rabbit fit to reduce in size

10. Lift the Turbine section away from the compressor section

11. Assemble bolt stretching fixture

12. Apply hydraulic jack pressure and pull the compressor bolt to increase in length

13. Loosen the nut from the stretched bolt

14. Release hydraulic jack pressure on the bolt

15. Remove the nut

16. Repeat the process on all 18 compressor thru bolts

17. Remove all compressor thru bolts

18. Use wedges to separate the compressor wheels

19. Clean all parts

20. Dimensionally inspect all parts

21. Run out inspect bladed compressor wheels

22. Check compressor wheel rabbit fits

23. Obtain engineering evaluation of dimensions and approval to proceed

24. Use bushings and re machine as required to repair damaged compressor wheel

rabbit fits.

25. Use balance mandrel to balance each compressor wheel

26. Balance Fwd. Compressor Stub Shaft

27. Take run out inspection of compressor thru bolts

28. Correct Compressor thru bolt run out to be below 0.005”

29. Assemble Fwd. stub shaft on stacking table

30. Stack each Compressor Disc on top of Compressor Stub Shaft

31. Use jack pressure Fixture to assemble rabbit fits in each Compressor wheel

assembly

32. Continue stacking until the 16 th stage wheel is assembled

33. Assemble bolt stretching fixture

34. Apply hydraulic jack pressure and pull the compressor bolt to increase in length

35. Obtain correct dimension of elongated compressor bolt

36. Tighten the nut to the stretched bolt

37. Release hydraulic jack pressure on the bolt

38. Repeat the process on all 18 compressor thru bolts

39. Put compressor in late and skim cut balance support on last stage disc

40. Balance compressor rotor

41. Repair Distance Piece mating Rabbit fit is required

42. Use balance mandrel and bolt it to the distance piece and then to balance

Turbine Section

43. Balance Turbine section

44. Remove Turbine section Balancing Fixture

45. Turn compressor section vertical on stacking table

46. Pack dry ice around the Distance piece

47. Assemble the Turbine Section to the compressor section

48. Install new Marriage bolts

49. Torque Distance piece marriage bolts to complete assembly

50. Perform run out inspection of rotor

51. Obtain Engineering review and approval to proceed

52. Balance Turbine Section

53. Complete al inspection reports

54. Package for shipment

MS5001 Rotor weight is @ 10 tons

Normal Balancing specs apply

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Mobile Handwash For Mobile People: Eberspächer Uk - Handwash SystemsДокумент4 страницыMobile Handwash For Mobile People: Eberspächer Uk - Handwash SystemsAleksander WójcikОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Fdq7238S: Dual Notebook Power Supply N Channel Powertrench in So-14 PackageДокумент10 страницFdq7238S: Dual Notebook Power Supply N Channel Powertrench in So-14 PackageEdy Valeriano ChicllaОценок пока нет

- Jlo Engines Rockwell L-227 L-230 L-252-l Jp-7710 IplДокумент8 страницJlo Engines Rockwell L-227 L-230 L-252-l Jp-7710 Ipljim1961Оценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Design A Inverter With Nmos Enhancement LoadДокумент8 страницDesign A Inverter With Nmos Enhancement LoadfuchsialifeОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Motortronics 2013 Product Selection Guide - SoftstarterДокумент121 страницаMotortronics 2013 Product Selection Guide - SoftstarterJoeDabidОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Manual Hokkaido-110 LowДокумент7 страницManual Hokkaido-110 LowGale GloryОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Sport GRTДокумент56 страницSport GRTCavok AvionicsОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Baxxdd0 e 208708Документ24 страницыBaxxdd0 e 208708Oscar OreaОценок пока нет

- SST25VF040B: 4 Mbit SPI Serial FlashДокумент33 страницыSST25VF040B: 4 Mbit SPI Serial FlashDario EzequielОценок пока нет

- Lista de Materiales 6KДокумент3 страницыLista de Materiales 6KRoyer SanchezОценок пока нет

- 9 How To Interface 4x4 Matrix Keypad With Lpc2148Документ9 страниц9 How To Interface 4x4 Matrix Keypad With Lpc2148KATKURI MANOJОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- DinsДокумент2 страницыDinsBladimirОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Dynamo - WikipediaДокумент13 страницDynamo - WikipediaIKENNAОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Pressure Switches - Square D™ NEMA - 9012GCW3Документ3 страницыPressure Switches - Square D™ NEMA - 9012GCW3Partagon PowОценок пока нет

- MD Totco Instrumentation Products CatalogДокумент9 страницMD Totco Instrumentation Products CatalogDaniel PaezОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Samsung RF22K9381SR RefrigeratorДокумент220 страницSamsung RF22K9381SR Refrigeratorhoward.deiner1674Оценок пока нет

- FD535 (Datasheet)Документ3 страницыFD535 (Datasheet)BlAdE 12Оценок пока нет

- Service 3121290Документ396 страницService 3121290fercho_50Оценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Award Checkpoint and Beep Code List PUBДокумент6 страницAward Checkpoint and Beep Code List PUBtfkillОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Rohini 85528101498Документ3 страницыRohini 85528101498Mustafa AlhumayreОценок пока нет

- 240, 260 Brakes Repair and MaintenanceДокумент35 страниц240, 260 Brakes Repair and Maintenancevanapeer100% (5)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Simulation & Modeling of BLDC MotorДокумент20 страницSimulation & Modeling of BLDC Motorsam clastineОценок пока нет

- J9A Manual English 1766 Adndm 2589Документ138 страницJ9A Manual English 1766 Adndm 2589static_fluxОценок пока нет

- SuSD.1.F.008-Electrical Data SheetДокумент6 страницSuSD.1.F.008-Electrical Data SheetHonnie Mae PaduaОценок пока нет

- 60x60 Led PanelДокумент3 страницы60x60 Led PanelKarthikeyan .NОценок пока нет

- Manual 6661 - InglesДокумент12 страницManual 6661 - InglesJose Afonso JuniorОценок пока нет

- Smart CounterДокумент2 страницыSmart CounterNooB SavitaRОценок пока нет

- DK-26 Instruction Manual (Maintenance) PDFДокумент191 страницаDK-26 Instruction Manual (Maintenance) PDFFernando César Carbone86% (7)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Advanced Digital VLSI Design (ECE 521) (Makeup) PDFДокумент2 страницыAdvanced Digital VLSI Design (ECE 521) (Makeup) PDFRahul PinnamaneniОценок пока нет

- CRAFTER 2,0D TDI CR 4motion Achleitner-CKUB-2 (2EX-2FX) 2.0 (2012-2017)Документ5 страницCRAFTER 2,0D TDI CR 4motion Achleitner-CKUB-2 (2EX-2FX) 2.0 (2012-2017)Matias Martinez100% (1)