Академический Документы

Профессиональный Документы

Культура Документы

Excavation and Embankment. (REV 10-31-0212-18-02) (FA 1-14-03) (7-03)

Загружено:

Pawan Kumar0 оценок0% нашли этот документ полезным (0 голосов)

13 просмотров1 страницаThis document discusses revisions to the construction of embankments and excavations. It deletes a previous subarticle and replaces it with information on the dry fill construction method. It specifies that embankments should be constructed in 6 inch compacted lifts, but allows for thicker lifts of up to 12 inches for certain material types if successful test sections are completed. It reserves the right of the engineer to terminate thick lift construction if satisfactory results are not being achieved. The document also provides guidance on dewatering requirements and equipment for construction.

Исходное описание:

Оригинальное название

1200008 Imp

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis document discusses revisions to the construction of embankments and excavations. It deletes a previous subarticle and replaces it with information on the dry fill construction method. It specifies that embankments should be constructed in 6 inch compacted lifts, but allows for thicker lifts of up to 12 inches for certain material types if successful test sections are completed. It reserves the right of the engineer to terminate thick lift construction if satisfactory results are not being achieved. The document also provides guidance on dewatering requirements and equipment for construction.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

13 просмотров1 страницаExcavation and Embankment. (REV 10-31-0212-18-02) (FA 1-14-03) (7-03)

Загружено:

Pawan KumarThis document discusses revisions to the construction of embankments and excavations. It deletes a previous subarticle and replaces it with information on the dry fill construction method. It specifies that embankments should be constructed in 6 inch compacted lifts, but allows for thicker lifts of up to 12 inches for certain material types if successful test sections are completed. It reserves the right of the engineer to terminate thick lift construction if satisfactory results are not being achieved. The document also provides guidance on dewatering requirements and equipment for construction.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

120 EXCAVATION AND EMBANKMENT.

(REV 10-31-0212-18-02) (FA 1-14-03) (7-03)

SUBARTICLE 120-8.2 (of the Supplemental Specifications) is deleted and the following

substituted:

120-8.2 Dry Fill Method:

120-8.2.1 General: Except as provided below for material placed on unstable ground and

for materials used for flattening slopes, construct embankments in successive layers of not more than 6

inches [150 mm] compacted thickness, for the full width of the embankment. Construct embankments to

meet compaction requirements in article 120-9 and in accordance with the acceptance program

requirements in article 120-10. Restrict the compacted thickness of the last embankment lift to 6 inches

maximum.

120-8.2.1.1 For A-3 and A-2-4 Materials (As Designated in Design Standard

Index 505) with up to 15% fines: Construct the embankment in successive layers with lifts up to a

maximum compacted thickness of 12 inches ([300 mm)]. Ensure Tthe percentage of fines ( minus 200)

passing the No.200 US Standard sieve in the A-2-4 material shalldoes not exceed 15%.

120-8.2.1.2 For A-1 and Plastic materials (As designated in Design Standard

Index 505) and A-2-4 Materials with greater than 15% fines: Construct the embankment in successive

layers with lifts up to a maximum compacted thickness of 6 inches ([150mm)].

Alternately, for A-1, and Plastic material and A-2-4 Materials with greater than

15% fines, construct embankments using thick lift construction in successive layers of not more than 12

inches [300 mm] compacted thickness, after having demonstrated with a successful test section, the

possession and control of compacting equipment sufficient to achieve density required by 120-10.2 for

the full depth of a thicker lift, and if the Engineer approves the compaction effort. Notify the Engineer

prior to beginning construction of a test section. Construct a test section of the length of one full LOT.

Perform five QC tests at random locations within the test section. All five QC tests and a Department

Verification test must meet the density required by 120-10.2 and be verified by the Engineer. Identify the

test section with the compaction effort and soil classification in the Density Log Book. In case of a

change in compaction effort or soil classification, failing QC test or when the QC tests cannot be verified,

construct a new test section. The Contractor may elect to place material in 6 inches [150 mm] compacted

thickness at any time. Construct all layers approximately parallel to the centerline profile of the road.

The Engineer reserves the right to terminate the Contractor’s use of thick lift

construction. Whenever the Engineer determines that the Contractor is not achieving satisfactory results,

revert to the 6 inch [150 mm] compacted lifts.

As far as practicable, distribute traffic over the work during the construction of

embankments so as to cover the maximum area of the surface of each layer.

Construct embankment in the dry whenever normal dewatering equipment and

methods can accomplish the needed dewatering.

120-8.2.1.13 Equipment and Methods: Provide normal dewatering equipment

including, but not limited to, surface pumps, sump pumps and trenching/digging machinery. Provide

normal dewatering methods including, but not limited to, constructing shallow surface drainage

trenches/ditches, using sand blankets, sumps and siphons.

When normal dewatering does not adequately remove the water, the

Engineer may require the embankment material to be placed in the water or in low swampy ground in

accordance with 120-9.2.3.

Вам также может понравиться

- Sewage Disposal Works: Their Design and ConstructionОт EverandSewage Disposal Works: Their Design and ConstructionОценок пока нет

- SA Standard NotesДокумент22 страницыSA Standard Notesatiq0592Оценок пока нет

- MS Subgrade PreparationДокумент5 страницMS Subgrade PreparationAnduel SelamajОценок пока нет

- Cement Kiln Dust (CKD) Treated SubgradeДокумент4 страницыCement Kiln Dust (CKD) Treated SubgradeDevrim GürselОценок пока нет

- Item 804 - Embankment 804.1 DescriptionДокумент9 страницItem 804 - Embankment 804.1 DescriptionEster MarianОценок пока нет

- 204 - Subgrade Compaction and Proof Rolling-Test Rolling (2012)Документ6 страниц204 - Subgrade Compaction and Proof Rolling-Test Rolling (2012)roldski100% (1)

- Culvert ThicknessДокумент23 страницыCulvert ThicknessNilaAbubakarОценок пока нет

- Saudi Aramco Civil CBT Inspector Qualification Test: Excavation and BackfillingДокумент17 страницSaudi Aramco Civil CBT Inspector Qualification Test: Excavation and BackfillingUSMAN NAGTHAN100% (2)

- Method Statement For ConstructionДокумент8 страницMethod Statement For ConstructionTin DanОценок пока нет

- Section 200 Rock Base 200-1 DescriptionДокумент8 страницSection 200 Rock Base 200-1 Descriptionahmed afrozОценок пока нет

- Base CourseДокумент3 страницыBase Courseprobook450_ehsanОценок пока нет

- Soil - FillingДокумент6 страницSoil - FillingGiora RozmarinОценок пока нет

- 02225Документ6 страниц02225uddinnadeemОценок пока нет

- Quality Control Standards For Base CourseДокумент5 страницQuality Control Standards For Base Courseprobook450_ehsanОценок пока нет

- Tolerances and BackfillingДокумент4 страницыTolerances and BackfillingAjitesh YelisettyОценок пока нет

- Guidance Technical Specification Section 8 Trench Excavation, Backfill and ResurfacingДокумент9 страницGuidance Technical Specification Section 8 Trench Excavation, Backfill and ResurfacingElvi PapajОценок пока нет

- Faa P-209 Ac 150-5370-10G 2Документ6 страницFaa P-209 Ac 150-5370-10G 2Alejandro VelandiaОценок пока нет

- 236s 2007-08-20 Proof RollingДокумент5 страниц236s 2007-08-20 Proof RollingIbato RutaОценок пока нет

- Hot Chip Seal Specifications Description: Tests On CRS-2P Emulsion Minimum Maximum Test MethodДокумент6 страницHot Chip Seal Specifications Description: Tests On CRS-2P Emulsion Minimum Maximum Test MethodAnonymous iinjEi4E2Оценок пока нет

- Soil Cement SpecificationДокумент4 страницыSoil Cement SpecificationHoa PhamОценок пока нет

- 04-400. Sub-Bases, (Non-Bituminous) and ShouldersДокумент29 страниц04-400. Sub-Bases, (Non-Bituminous) and ShouldersAnonymous g1LSaAОценок пока нет

- Methodology For Soil ShoulderДокумент7 страницMethodology For Soil ShoulderAkash SarkarОценок пока нет

- Section 606 Bridge Restoration and Waterproofing With Concrete OverlaysДокумент12 страницSection 606 Bridge Restoration and Waterproofing With Concrete OverlaysSuranga ManuОценок пока нет

- Sub Base CourseДокумент6 страницSub Base CourseReynaldo T. Bas-ongОценок пока нет

- Road Pavements Bituminous MaterialsДокумент22 страницыRoad Pavements Bituminous Materialsmayur_lanjewarОценок пока нет

- Method of StatementДокумент8 страницMethod of StatementHisham BerrasaliОценок пока нет

- Irc DLCДокумент56 страницIrc DLCAniket Salvi100% (5)

- Excavation and Backfill For Major Structures Cubic Yard Unsuitable Material Excavation Cubic YardДокумент3 страницыExcavation and Backfill For Major Structures Cubic Yard Unsuitable Material Excavation Cubic YardOpata OpataОценок пока нет

- Geotextile Fabric General SpecificationДокумент3 страницыGeotextile Fabric General SpecificationjovindhaОценок пока нет

- Item 200Документ4 страницыItem 200Marc Dared Cagaoan50% (2)

- 330 2013Документ11 страниц330 2013Hewa Wedage Niroshan AnuruddhaОценок пока нет

- 7 Sc&s7 RoadworkДокумент5 страниц7 Sc&s7 RoadworkdophongxdОценок пока нет

- TxDot Specs CTB s275Документ4 страницыTxDot Specs CTB s275layisoОценок пока нет

- Flexible Pavement ConstructionДокумент18 страницFlexible Pavement ConstructionThopuri Maruthi Chowdary100% (1)

- Section 02000: Milling, Hot Mix Asphalt and Patching Procedures: A. MillingДокумент12 страницSection 02000: Milling, Hot Mix Asphalt and Patching Procedures: A. MillingJojo DejucosОценок пока нет

- Example of Stress Absorbing Membrane InterlayerДокумент7 страницExample of Stress Absorbing Membrane Interlayershanil3001Оценок пока нет

- Rammed Earth Construction Specs (De)Документ4 страницыRammed Earth Construction Specs (De)jjmetalestudio2124Оценок пока нет

- Specification For Prefabricated Vertical DrainsДокумент7 страницSpecification For Prefabricated Vertical DrainsRecep Caner Akyılmaz100% (2)

- Standard Specifications and Minimum TestingДокумент19 страницStandard Specifications and Minimum TestingCarjez LoveОценок пока нет

- 2013 BSR NewДокумент583 страницы2013 BSR NewSamanmala Senarath100% (1)

- Appendix A - 1 - 26Документ1 страницаAppendix A - 1 - 26Ahmad Ramin AbasyОценок пока нет

- Roadway BaseДокумент3 страницыRoadway Basesethu1091Оценок пока нет

- Bottom Feed Stone Column (Dry)Документ3 страницыBottom Feed Stone Column (Dry)volkanОценок пока нет

- Department of Transportation Engineering: Dry Lean Cement ConcreteДокумент19 страницDepartment of Transportation Engineering: Dry Lean Cement ConcreteMOHANSHU BHARDWAJ 22910013Оценок пока нет

- Example Specifications For CEMATRIX Cellular ConcreteДокумент9 страницExample Specifications For CEMATRIX Cellular ConcreteRaffy Shaun CentenoОценок пока нет

- LAPRIL-C103 enДокумент5 страницLAPRIL-C103 enalpha NEPALОценок пока нет

- General Building Spec.Документ20 страницGeneral Building Spec.Barry Daniel Saunders0% (1)

- 1001Документ6 страниц1001enterlogОценок пока нет

- Section 400 - (Granular-Sub-Base) - Finally CorrectedДокумент16 страницSection 400 - (Granular-Sub-Base) - Finally CorrectedTousifAnwar MundaragiОценок пока нет

- Six Lan Road ConstructionДокумент25 страницSix Lan Road ConstructionDevendra SharmaОценок пока нет

- Rock EmbankmentДокумент8 страницRock EmbankmentSuhaidi AliasОценок пока нет

- Section 530 Riprap 530-1 DescriptionДокумент5 страницSection 530 Riprap 530-1 DescriptionmrlobboОценок пока нет

- Atk SSA Presentation R2Документ38 страницAtk SSA Presentation R2Gaurav MathurОценок пока нет

- Bedding & Back Filling SpecificationДокумент3 страницыBedding & Back Filling SpecificationMohammed Asimuddin Farooqui100% (1)

- Earthquake Drain Installation SpecificationДокумент3 страницыEarthquake Drain Installation SpecificationOctavstoicescu1876Оценок пока нет

- Chapter 62C-27 Conservation of Oil and Gas: DrillingДокумент4 страницыChapter 62C-27 Conservation of Oil and Gas: DrillingAry RachmanОценок пока нет

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringОт EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringРейтинг: 4 из 5 звезд4/5 (5)

- Soil Investigation and Foundation DesignОт EverandSoil Investigation and Foundation DesignРейтинг: 4.5 из 5 звезд4.5/5 (9)

- Serpentines of The San Francisco Bay Region - VegetДокумент118 страницSerpentines of The San Francisco Bay Region - VegetPawan KumarОценок пока нет

- Board For Professional Engineers, Land Surveyors, and GeologistsДокумент5 страницBoard For Professional Engineers, Land Surveyors, and GeologistsPawan KumarОценок пока нет

- BoardrulesДокумент51 страницаBoardrulesPawan KumarОценок пока нет

- Shear Wave Velocity Profiling in Melbourne SiluriaДокумент10 страницShear Wave Velocity Profiling in Melbourne SiluriaPawan KumarОценок пока нет

- California Professional Engineers State Laws and Board Rules Examination (Take Home Examination)Документ7 страницCalifornia Professional Engineers State Laws and Board Rules Examination (Take Home Examination)Pawan KumarОценок пока нет

- What Is The Basic Objective in Selecting Design Ground Motions?Документ1 страницаWhat Is The Basic Objective in Selecting Design Ground Motions?Pawan KumarОценок пока нет

- Handbook PDFДокумент116 страницHandbook PDFPawan KumarОценок пока нет

- California Drivers Handbook 2014Документ116 страницCalifornia Drivers Handbook 2014giovas1Оценок пока нет

- The Second James K Mitchell Lecture Undisturbed Sand Strength From Seismic Cone TestsДокумент20 страницThe Second James K Mitchell Lecture Undisturbed Sand Strength From Seismic Cone TestsPawan KumarОценок пока нет

- Kumar Et Al (2018) - Comparison of Code-Based Vs Site-Specific Spectra in San FranciscoДокумент15 страницKumar Et Al (2018) - Comparison of Code-Based Vs Site-Specific Spectra in San FranciscoPawan KumarОценок пока нет

- Analysis of Blocky Rock Slopes With The Shear Strength Reduction MethodДокумент6 страницAnalysis of Blocky Rock Slopes With The Shear Strength Reduction MethodPawan KumarОценок пока нет

- FE Civil Review - Structural AnalysisДокумент7 страницFE Civil Review - Structural AnalysisPawan Kumar100% (1)

- 2012 FE Student Course InfoДокумент3 страницы2012 FE Student Course InfoPawan KumarОценок пока нет

- FEM in Geotech EngineeringДокумент21 страницаFEM in Geotech EngineeringPawan Kumar100% (1)

- Manual IDEC FC5A AdvancedДокумент343 страницыManual IDEC FC5A AdvancedJoako FilipovichОценок пока нет

- Sap WM Organization StructureДокумент7 страницSap WM Organization StructureNarendra KumarОценок пока нет

- Conceptual Study of Migraine in Ayurveda (Ardhavbhedaka)Документ5 страницConceptual Study of Migraine in Ayurveda (Ardhavbhedaka)Editor IJTSRDОценок пока нет

- Documenting Childrens Learning Examples PDFДокумент19 страницDocumenting Childrens Learning Examples PDFArief lukman100% (1)

- Learning Chara Dasa K N RaoДокумент34 страницыLearning Chara Dasa K N RaoVikram Kumar100% (3)

- Army Launched Feeding Program in ComValДокумент2 страницыArmy Launched Feeding Program in ComVal10idphilippinearmyОценок пока нет

- Workers Participation in ManagementДокумент4 страницыWorkers Participation in Managementabi_krish_1Оценок пока нет

- 4 Clay ChemistryДокумент41 страница4 Clay ChemistryMohamed HamdyОценок пока нет

- Business Continuity Template ReportДокумент4 страницыBusiness Continuity Template ReportHostmaster BIOSОценок пока нет

- Strategi Pengembangan Dan Analisis Swot Pada Pt. Garuda Indonesia TBKДокумент12 страницStrategi Pengembangan Dan Analisis Swot Pada Pt. Garuda Indonesia TBKtedzmedicalОценок пока нет

- HRIS Chap 2Документ33 страницыHRIS Chap 2Mahbub67% (3)

- A2 UNIT 1 Culture Teacher's NotesДокумент1 страницаA2 UNIT 1 Culture Teacher's NotesCarolinaОценок пока нет

- PSC Issue 30Документ32 страницыPSC Issue 30nkosidlaminiОценок пока нет

- Web Lab Manual Nhce - UpdatedДокумент41 страницаWeb Lab Manual Nhce - Updatedpoornima venkateshОценок пока нет

- Heat Treatment Procedure Qualification 836878 R20070802BДокумент96 страницHeat Treatment Procedure Qualification 836878 R20070802BrecnessОценок пока нет

- Median10.05 Qu25Z MidtermДокумент3 страницыMedian10.05 Qu25Z MidtermLuwalhati TomilasОценок пока нет

- TCR PDF Spring 2013 Vol 25 No 1Документ224 страницыTCR PDF Spring 2013 Vol 25 No 1Teresinha Pereira100% (1)

- How To Get Google Maps API Key For Android. Issues and Errors SolvedДокумент11 страницHow To Get Google Maps API Key For Android. Issues and Errors SolvedFrancisco FeitosaОценок пока нет

- Prometheus 2.0 - New Storage Layer Dramatically Increases Monitoring Scalability For Kubernetes and Other Distributed Systems - CoreOSДокумент10 страницPrometheus 2.0 - New Storage Layer Dramatically Increases Monitoring Scalability For Kubernetes and Other Distributed Systems - CoreOSFrankie LiuОценок пока нет

- d17 Vega Using SqltraceДокумент66 страницd17 Vega Using SqltraceViorel PanaiteОценок пока нет

- Why Air Bearing? 3. Why Air Bearing? 5. Working PrincipleДокумент18 страницWhy Air Bearing? 3. Why Air Bearing? 5. Working PrinciplesachinОценок пока нет

- EmulsionsДокумент85 страницEmulsionsRamchandra Keny100% (2)

- Report (Surface Plasmon Resonance)Документ8 страницReport (Surface Plasmon Resonance)waseemwaseem33Оценок пока нет

- CofisaДокумент2 страницыCofisaTony Starks0% (1)

- Bojan ResumeДокумент2 страницыBojan ResumebokiОценок пока нет

- Contemporary PluralismДокумент8 страницContemporary PluralismTerence BlakeОценок пока нет

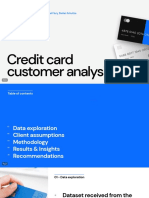

- Credit Card Customer AnalysisДокумент18 страницCredit Card Customer AnalysisBetka AbОценок пока нет

- Statistics PDFДокумент17 страницStatistics PDFSauravОценок пока нет

- BILLE-SØRENSEN.2007.an Anthropology of Luminosity-The Agency of LightДокумент22 страницыBILLE-SØRENSEN.2007.an Anthropology of Luminosity-The Agency of LightnaihloanОценок пока нет