Академический Документы

Профессиональный Документы

Культура Документы

MS Contiguous Bored Pile

Загружено:

syariffahnorazmaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

MS Contiguous Bored Pile

Загружено:

syariffahnorazmaАвторское право:

Доступные форматы

GRAND DYNAMIC BUILDERS SDN BHD

SAFE WORK METHOD STATEMENT

FOR

CONTIGUOUS BORED PILE

GRAND DYNAMIC BUILDERS SDN BHD

A. CONTIGUOUS BORED PILE WORKS- GENERAL

1.0 SUPERVISION TEAM

The Site Supervisory Team shall be headed by the Site Agent and assisted by

the Site Supervisors to ensure that the requirements of approved designs are

strictly implemented.

2.0 MATERIALS

2.1 Concrete

The concrete to be used in this work shall be based on concrete supplier

determine by Main-Contractor.

2.2 Steel Bars

Steel bars of Grade 460 weldable to be used in the works shall comply with

B.S. 4449: 1997. The steel bar to be used in this work shall be based on

materials supplied by Main-Contractor.

3.0 QA/QC PROCEDURE FOR BORED PILING WORKS

3.1 Survey Work/Setting Out Work

In order to ensure that the physical work is constructed at location as

designed the following checks will be executed. (To be provided by main

contractor)

3.1.1 The Contractor shall use the block pegging drawing as endorsed by licensed

surveyor in accordance with architect’s setting out plan. Temporary Bench

Mark (TBM) and the established TBMs will now be the datum for daily use for

surveying of ground level (To be provided by main contractor)

3.1.2 All pile positions will be pre-surveyed and properly marked using suitable

steel bars. The peg(s) will be planted such that about 25-50mm of the peg

protruded above the ground level.

3.1.3 Every peg position will be randomly checked again by the Contractor’s

Supervisor prior to boring.

3.1.4 Each of the TBM’s will be rechecked against the original

control points periodically.

GRAND DYNAMIC BUILDERS SDN BHD

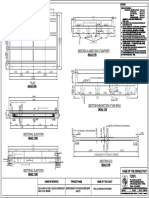

B. CONTIGUOUS BORED PILE WORKS - INSTALLATION PROCESS

General

Contiguous bored pile walls are formed by constructing continuity of reinforced concrete

bored piles. The piles are reinforced with steel rebar and construct similarly as per

methodology construction of bored pile.

1.0 Position of Bored Pile

As similarly of the construction of bored pile, peg will be given by surveyor (Provided

by Main Contractor) for the center position of each bored pile. The gap between two

bored piles is typically 50mm.

2.0 Installation of Casing

The vibro-hammer drives a casing into the ground, leaving about 1 meter length of

the casing protruding from the ground

3.0 Augering of Borehole

The auger, a drilling tool, cuts and removes the soil within the casing to form primary

borehole. The soil surrounding the borehole is supported by the casing. If the casing

is not long enough to reach the required depth in the ground, water will be use as

stability fluid to support the soil below the casing.

4.0 Installation of Steel Cage

The crane lifts up the steel cage and places it within the borehole.

5.0 Concreting of Borehole

Concrete is poured into the borehole to form the bored pile.

6.0 Extraction of Casing

The Vibro-hammer used to extracts the casing after completion of concreting.

7.0 Repetition of Process

Step 1.0 – 6.0 are repeated till the entire length of the bored pile wall construction is

completed.

Grout Column behind Contiguous Bored Pile Wall

100mm diameter grout columns are provided behind the interfacing area of contiguous

bored piles to act as water-barrier system to prevent loss of water and fine materials behind

the contiguous bored pile wall. A gunite wall with BRC will be formed in front of the

contiguous bored pile wall to further block any ingress of water or alternatively skin wall will

be cast against the contiguous bored pile wall.

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Draughtsman Civil - 1st Year - TP EnglishДокумент290 страницDraughtsman Civil - 1st Year - TP EnglishJiyaОценок пока нет

- Home Inspection Checklist For BuyersДокумент2 страницыHome Inspection Checklist For Buyersmohd sumerОценок пока нет

- NEOM-NEN-TGD-304 - 01.00 - Wind Design Requirements For Building StructuresДокумент11 страницNEOM-NEN-TGD-304 - 01.00 - Wind Design Requirements For Building Structuresmahmudulalam konokОценок пока нет

- Volume of FootingДокумент20 страницVolume of FootingShady RainОценок пока нет

- Cladding Details PDFДокумент144 страницыCladding Details PDFzaki_th00880% (5)

- BKC Complex RegulationsДокумент8 страницBKC Complex RegulationsSanjay MohanОценок пока нет

- TEVRAGH ZEINA - ZRE MD 6060, Nouakchott BP: 6090 Nouakchott, Mauritanie MauritaniaДокумент2 страницыTEVRAGH ZEINA - ZRE MD 6060, Nouakchott BP: 6090 Nouakchott, Mauritanie MauritaniaKubilay H.Оценок пока нет

- Michelangelo Carlo MadernoДокумент1 страницаMichelangelo Carlo Madernoapi-596255492Оценок пока нет

- Construction and Demolition Waste ManageДокумент9 страницConstruction and Demolition Waste ManageWulan DariОценок пока нет

- Test Report: M/S Pcil & MBPCL Joint VentureДокумент7 страницTest Report: M/S Pcil & MBPCL Joint VentureImran KhanОценок пока нет

- Final Thesis DATAДокумент60 страницFinal Thesis DATAdahaletushar75Оценок пока нет

- Sagar Final PPT FullДокумент13 страницSagar Final PPT FullPramod Kumar HTОценок пока нет

- PSS 5.2-780 V4A - Parts List - 2020Документ9 страницPSS 5.2-780 V4A - Parts List - 2020Centrifugal SeparatorОценок пока нет

- National Building Code of The PhilippinesДокумент32 страницыNational Building Code of The PhilippinesMark Edmine GonzalesОценок пока нет

- 3 - Fineness of Portland CementДокумент8 страниц3 - Fineness of Portland Cementkervin manilaОценок пока нет

- 20.0 M Span & 12.00 M Clear Carriageway High Level Bridge Shruti-Layout2Документ1 страница20.0 M Span & 12.00 M Clear Carriageway High Level Bridge Shruti-Layout2samir bendreОценок пока нет

- Dayworks Schedule of RatesДокумент4 страницыDayworks Schedule of RatesRW Ponce BuildersОценок пока нет

- En SNR Muctbl205Документ2 страницыEn SNR Muctbl205Koen BidlotОценок пока нет

- Vinra Group PortfolioДокумент40 страницVinra Group PortfolioDerlyn RichardОценок пока нет

- 39 - (Systems) (12) Radial Frame (2016)Документ64 страницы39 - (Systems) (12) Radial Frame (2016)mohammedОценок пока нет

- Steel-Based Applications in Earthquake-Prone areas-KINA28459ENNДокумент98 страницSteel-Based Applications in Earthquake-Prone areas-KINA28459ENNDany BelОценок пока нет

- ColdGuard Sliding Cold Storage DoorsДокумент1 страницаColdGuard Sliding Cold Storage DoorsgamunozdОценок пока нет

- Technical Data Sheet For HUD 1 Universal Anchor Technical Information ASSET DOC 2331339Документ6 страницTechnical Data Sheet For HUD 1 Universal Anchor Technical Information ASSET DOC 2331339ARYAОценок пока нет

- Floor Gully Trap Installation Manual - Spind Malaysia - Floor Trap Manufacturer MalaysiaДокумент5 страницFloor Gully Trap Installation Manual - Spind Malaysia - Floor Trap Manufacturer MalaysiaApoorvaОценок пока нет

- Pre Cast Construction: Room1 DДокумент1 страницаPre Cast Construction: Room1 DAsHu ArYaОценок пока нет

- T ISS PX01 Instruction Manual Rev.01Документ9 страницT ISS PX01 Instruction Manual Rev.01Louis Marino100% (1)

- Personal Information:: Name Syed Sardar Hussain ShahДокумент3 страницыPersonal Information:: Name Syed Sardar Hussain ShahHussain ShahОценок пока нет

- ATT - 1.2.0 - Global GC Bid Template MV1 - CGK-063 - CIVIL EXT WORKS REVДокумент2 страницыATT - 1.2.0 - Global GC Bid Template MV1 - CGK-063 - CIVIL EXT WORKS REVDeri AnggaraОценок пока нет

- Pricelist 2022 - Oct22 - AreaA ConwoodДокумент1 страницаPricelist 2022 - Oct22 - AreaA ConwoodSupriyono AgungОценок пока нет

- API-650 SECTION 8.1 Radiographic ExaminationДокумент6 страницAPI-650 SECTION 8.1 Radiographic ExaminationHassan Ali HassanОценок пока нет