Академический Документы

Профессиональный Документы

Культура Документы

Lecture 06 - Basis For Materials Selection

Загружено:

TimОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Lecture 06 - Basis For Materials Selection

Загружено:

TimАвторское право:

Доступные форматы

MME 3379a

Materials Selection

Initial Basis of Materials Selection

(Ch. 4)

Prof. Eric Johlin

September 19th 2018 MME 3379a - Materials Selection 1

Short Term Course Outline

• Today

• Basis for Material selection

• First part of Chapter 4 in the text

• Tomorrow

• Property relationships and charts

• Chapter 3 in the text

• Next week

• Materials selection using property charts

• Second part of Chapter 4 in the text

September 19th 2018 MME 3379a - Materials Selection 2

Administrative Items

• Assignment 1 out yesterday

• Assignments are now due on Tuesdays at 9:00 am (one

week from yesterday)

• Tuesday lecture time still uncertain; email today if issues

• Book is unavailable; three options:

• Buy directly from Elsevier

https://www.elsevier.com/books/title/author/9780081006108

• Use old version of the book online (4th edition) for now

https://ebookcentral.proquest.com/lib/west/reader.action?docID=4952361&query=

(Not complete – fewer examples, exercises, some sections missing wrt 5th edition)

• Use posted items on OWL (Appendix A is up)

September 19th 2018 MME 3379a - Materials Selection 3

iClicker – CO2 from Concrete

What percentage of total global CO2 production comes

from the production of concrete?

A – 0.1%

B – 1%

C – 5%

D – 8%

E – 27%

September 19th 2018 MME 3379a - Materials Selection 4

CO2 from Concrete

• Concrete = Cement + Additive (gravel, sand, etc.)

• Cement = Limestone @ 1,400 C, + Gypsum

• Limestone = CaCO3 + heat CaO + CO2

• 1,000 kg of cement

• 6 GJ (5.2M BTU)

• = 200 kg of coal,

• Generates ~1,000 kg of CO2

• 50% of CO2 from reaction

• 40% of CO2 from heating

• 10% from indirect processes

September 19th 2018 MME 3379a - Materials Selection 5

CO2 from Concrete

• Concrete = Cement + Additive (gravel, sand, etc.)

• Cement = Limestone @ 1,400 C, + Gypsum

• Limestone = CaCO

Materials 3 + heat CaO + CO2

selection:

• 1,000•kgRecognizing

of cement importance of

• 6 GJ (5.2M BTU)

material properties

• = 200 kg of coal,

• Motivating

• Generates ~1,000 kgdevelopment

of CO2 of new

materials

• 50% of CO 2 from reaction

• 40% of CO2 from heating

• 10% from indirect processes

September 19th 2018 MME 3379a - Materials Selection 6

Basis for Material Selection

Goals of this lecture

Be able to:

• Select and evaluate materials for engineering

applications based on required functions

• Identify, calculate and apply appropriate material

indices to select, rank and evaluate materials

September 19th 2018 MME 3379a - Materials Selection 7

Tasks of Materials Selection

1. Identifying the desired attribute profile, and then

2. comparing this with those of real engineering

materials to find the best match.

September 19th 2018 MME 3379a - Materials Selection 8

Establishment of Link between Function and Material

Material selection is determined by function.

Shape sometimes influences selection. This session

deals with materials selection when this is independent

of shape.

September 19th 2018 MME 3379a - Materials Selection 9

Previously…

• Single material charts for material families

September 19th 2018 MME 3379a - Materials Selection 10

Moving forward

All families

Single family

Single material

September 19th 2018 MME 3379a - Materials Selection 11

Need – Concept – Embodiment

Need Concepts

Embodiments

Direct pull Levered pull Geared pull Spring-assisted pull

September 19th 2018 MME 3379a - Materials Selection 12

Embodiment – Detail

Embodiment Detail

How are those choices made?

September 19th 2018 MME 3379a - Materials Selection 13

Taxonomy of Universe of Materials and their Attributes

Universe of materials is divided into families, classes,

subclasses, and members.

Each member is characterized by a set of attributes

(Property Profile)

September 19th 2018 MME 3379a - Materials Selection 14

~50 material Classes

September 19th 2018 MME 3379a - Materials Selection 15

Bar Charts – Material Class Properties

September 19th 2018 MME 3379a - Materials Selection 16

Appendix A

More detail

(~60 materials)

September 19th 2018 MME 3379a - Materials Selection 17

Strategy for Materials Selection

The four main steps:

- Translation

- Screening

- Ranking

- Documentation

September 19th 2018 MME 3379a - Materials Selection 18

Translation

Translation:

Translate design requirements (defining what it must do),

which are often vague, into a prescription for a material.

The first step is to make a clear statement of function,

objectives, constraints, and free variables.

Function: - What does the component do?

Objective: - What is to be maximized or minimized?

Constraints: - What nonnegotiable conditions must be met?

(Hard constraint)

- What negotiable but desirable conditions must be met?

(Soft constraint)

Free variable: - Which parameters of the problem is the designer free

to change?

They define the boundary conditions for selecting a

material.

September 19th 2018 MME 3379a - Materials Selection 19

Screening: Attribute Limits

Unbiased selection requires that all materials be

considered candidates.

Screening eliminates candidates that cannot do the job

at all because one or more of their attributes lies

outside the limits set by the constraints.

Limits on attributes that successful candidates must

meet are referred to as attribute limits.

September 19th 2018 MME 3379a - Materials Selection 20

Ranking: Material Indices

Attribute limits do not help with ordering the candidates that

remain.

The property or property group that maximizes or minimizes

performance for a given design is called its material index.

Material indices provide criteria of excellence that allow

ranking of materials by their ability to perform well in the

given application.

Performance is sometimes limited by a single property,

sometimes by a combination of them. But it is more usual

that performance is limited not by one property but by a

combination of them. Next time

September 19th 2018 MME 3379a - Materials Selection 21

Documentation

The outcome of the steps so far is a ranked short-list of

candidates that meet the constraints and that maximize or

minimize the criterion of excellence.

To proceed further we seek a detailed profile of each candidate:

its documentation.

Documentation differs greatly from the structured property data

used for screening. Typically, it is descriptive, graphical, or

pictorial.

Documentation helps narrow the short-list to a final choice,

allowing a definitive match to be made between design

requirements and material attributes.

Why are all these steps necessary?

Without screening and ranking, the candidate pool is enormous

and the volume of documentation overwhelming.

September 19th 2018 MME 3379a - Materials Selection 22

“Toy” example – Car selection

September 19th 2018 MME 3379a - Materials Selection 23

Materials Selection Example: Visor of a Safety Helmet

September 19th 2018 MME 3379a - Materials Selection 24

Translating Design Requirements - Visor of a Safety Helmet

September 19th 2018 MME 3379a - Materials Selection 25

iClicker – What would be the Material

Index?

• Constraints – Optically transparent (& moldable)

• Objective – Maximize protection against impact,

avoid fracture

• Material Index?

• (use word not symbol)

September 19th 2018 MME 3379a - Materials Selection 26

From before…

September 19th 2018 MME 3379a - Materials Selection 27

Translating Design Requirements - Visor of a Safety Helmet

September 19th 2018 MME 3379a - Materials Selection 28

Screening and Ranking - Visor of a Safety Helmet

September 19th 2018 MME 3379a - Materials Selection 29

Screening and Ranking - Visor of a Safety Helmet

• Is 𝐾1𝑐 the right property to optimize?

September 19th 2018 MME 3379a - Materials Selection 30

Ranking based on fracture toughness

𝐾1𝑐 and toughness 𝐺

Name Fracture toughness 𝑲𝟐𝟏𝒄

Toughness 𝑮 = 𝑬

𝑲𝟏𝒄

Polycarbonate (PC) 2.1 - 4.6 1.99 - 9.61

Cellulose polymers 1 - 2.5 0.558 - 3.5

(CA)

Polymethyl 0.7 - 1.6 0.165 - 0.891

methacrylate

(Acrylic, PMMA)

Polystyrene (PS) 0.7 - 1.1 0.25 - 0.759

September 19th 2018 MME 3379a - Materials Selection 31

Ranking based on fracture toughness

𝐾1𝑐 and toughness 𝐺

Polycarbonate is best using either property, but the advantage is larger if G is used as

the property for ranking.

7

6

Arbitrary units (relative only)

0

Polycarbonate Cellulose Polymers Acrylic Polystyrene

K1c G

September 19th 2018 MME 3379a - Materials Selection 32

Documentation - Visor of a Safety Helmet

September 19th 2018 MME 3379a - Materials Selection 33

Choosing a Material - Protective Visor of a Safety Helmet

Design requirements are first expressed as constraints and objectives.

The constraints are used for screening.

The survivors are ranked by the objective.

September 19th 2018 MME 3379a - Materials Selection 34

Example 2 – High temperature components

• Silica glass tubes are to be heated in a furnace

• Need a material to hold the tubes, easy to form

• Highest service temperature possible ( > silica glass)

• Need to be machinable (>3)

September 19th 2018 MME 3379a - Materials Selection 35

Example 2 – High temperature components

September 19th 2018 MME 3379a - Materials Selection 36

Example 2 – High temperature components

September 19th 2018 MME 3379a - Materials Selection 37

Example 2 – High temperature components

September 19th 2018 MME 3379a - Materials Selection 38

Example 2 – High temperature components

September 19th 2018 MME 3379a - Materials Selection 39

Summary (Materials Selection—The Basics)

Material selection is tackled in four steps:

Translation—reinterpreting the design requirements in terms of

function, objectives, constraints, and free variables.

Screening—deriving attribute limits from the constraints and

applying these to isolate a subset of viable materials.

Ranking—ordering the viable candidates by the value of a

material index, the criterion of excellence that maximizes or

minimizes some measure of performance.

Documentation—seeking documentation for the top-ranked

candidates, exploring aspects of their history, their established

uses, their behavior in relevant environments, their availability,

and more, until a sufficiently detailed picture is built up that a final

choice can be made.

September 19th 2018 MME 3379a - Materials Selection 40

Questions?

September 19th 2018 MME 3379a - Materials Selection 41

Next time:

Material Property

Relationships & Charts

September 19th 2018 MME 3379a - Materials Selection 42

Вам также может понравиться

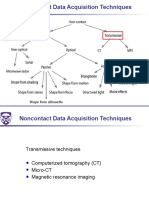

- 08 No Contact Data Asquisition Misc 2019 09 19Документ47 страниц08 No Contact Data Asquisition Misc 2019 09 19TimОценок пока нет

- 20 Feature Works 2019 10 17Документ10 страниц20 Feature Works 2019 10 17TimОценок пока нет

- 05 No Contact Passive Data Acquisition 2019 09 17Документ45 страниц05 No Contact Passive Data Acquisition 2019 09 17TimОценок пока нет

- 07 Data Processing 2019 09 17Документ37 страниц07 Data Processing 2019 09 17TimОценок пока нет

- Reverse Engineering Process OverviewДокумент19 страницReverse Engineering Process OverviewTim100% (1)

- Rankine Cycle Power AnalysisДокумент5 страницRankine Cycle Power AnalysisTimОценок пока нет

- Measure and compare drag forces on scaled models and prototypesДокумент8 страницMeasure and compare drag forces on scaled models and prototypesTimОценок пока нет

- 04 Data Acquisition Contact 2019 09 12Документ53 страницы04 Data Acquisition Contact 2019 09 12TimОценок пока нет

- Tutorial+3+ ProblemsДокумент1 страницаTutorial+3+ ProblemsTimОценок пока нет

- Lab 3-Lift and Drag On An Airfoil PDFДокумент5 страницLab 3-Lift and Drag On An Airfoil PDFTimОценок пока нет

- Business 299E: Introduction To Financial StatementsДокумент42 страницыBusiness 299E: Introduction To Financial StatementsTimОценок пока нет

- Tutorial+2+ ProblemsДокумент2 страницыTutorial+2+ ProblemsTimОценок пока нет

- Prairies - Agricultural Belts and Climate of Alberta, Saskatchewan, ManitobaДокумент47 страницPrairies - Agricultural Belts and Climate of Alberta, Saskatchewan, ManitobaTimОценок пока нет

- Tutorial 1 (Sept. 24) Tips To Solving Questions:: (Constant Density) and Is Not Driven by A Pressure GradientДокумент1 страницаTutorial 1 (Sept. 24) Tips To Solving Questions:: (Constant Density) and Is Not Driven by A Pressure GradientTimОценок пока нет

- Vegetation in CanadaДокумент31 страницаVegetation in CanadaTimОценок пока нет

- Stress CalculationsДокумент22 страницыStress CalculationsTimОценок пока нет

- Vegetation in CanadaДокумент31 страницаVegetation in CanadaTimОценок пока нет

- The Sense of PlaceДокумент68 страницThe Sense of PlaceTimОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Reset Printer Canon MP140Документ7 страницReset Printer Canon MP140bim2009Оценок пока нет

- Power Transformer Testing ProcedureДокумент4 страницыPower Transformer Testing ProcedureJustin Taylor100% (4)

- U.S. Naval Academy Computer Science Department Technical Report. Resource Contrained Network Design and ImplementationДокумент25 страницU.S. Naval Academy Computer Science Department Technical Report. Resource Contrained Network Design and ImplementationSewist ManОценок пока нет

- DATA CENTER EXAM COVERS HOSPITALITY INDUSTRY TRENDS AND INNOVATIONSДокумент3 страницыDATA CENTER EXAM COVERS HOSPITALITY INDUSTRY TRENDS AND INNOVATIONSRegina IldefonsoОценок пока нет

- Falling From Grace by S L Naeole PDFДокумент2 страницыFalling From Grace by S L Naeole PDFDeniseОценок пока нет

- 5.1 (A) Bhel B.O.QДокумент20 страниц5.1 (A) Bhel B.O.Qdeepti sharmaОценок пока нет

- MicroTech III Chiller UC ModbusДокумент34 страницыMicroTech III Chiller UC ModbusNMP Kumar UОценок пока нет

- Mit Quiz 1 ReviewerДокумент6 страницMit Quiz 1 ReviewerEleina Bea BernardoОценок пока нет

- Integration PDFДокумент12 страницIntegration PDFMd. Raihan Habib Rafi Mazumder 191-35-2768Оценок пока нет

- Form o - Quality AssuranceДокумент93 страницыForm o - Quality AssuranceonutocsОценок пока нет

- What Are The Ways We Can Use Images To Create and Manipulate Images To Convey Information?Документ5 страницWhat Are The Ways We Can Use Images To Create and Manipulate Images To Convey Information?Mode John CuranОценок пока нет

- Girl On Fire - Alicia Keys Sheet Music For Vocals (Solo)Документ3 страницыGirl On Fire - Alicia Keys Sheet Music For Vocals (Solo)Jéssica E DiegoОценок пока нет

- Digital Technology For Infrastructure Asset ManagementДокумент8 страницDigital Technology For Infrastructure Asset ManagementHitachi America, Ltd.Оценок пока нет

- Rational FunctionsДокумент27 страницRational FunctionsCarl Joseph Baluarte SamsonОценок пока нет

- Openwind Tutorial: ../tutorial - Data/Gis/Shape - Vectors/ and Select All The Shape Files in That Directory. ThenДокумент18 страницOpenwind Tutorial: ../tutorial - Data/Gis/Shape - Vectors/ and Select All The Shape Files in That Directory. ThenStaffs INSОценок пока нет

- How To Use Zoom For The First TimeДокумент2 страницыHow To Use Zoom For The First TimeSupportОценок пока нет

- 1150 DVOR Overheads Selex Rev - TRДокумент125 страниц1150 DVOR Overheads Selex Rev - TRdulli fitriantoОценок пока нет

- PC Monitor Manual PDFДокумент8 страницPC Monitor Manual PDFFagner Fernandes AraujoОценок пока нет

- Bel Adv Details For Senior Assistant Engineer Posts - Jobalertshub 2Документ5 страницBel Adv Details For Senior Assistant Engineer Posts - Jobalertshub 2Palani AppanОценок пока нет

- Timothy Pratt, Charles W. Bostian, Jeremy E. Allnutt - Satellite Communications-Wiley Indian (2003)Документ557 страницTimothy Pratt, Charles W. Bostian, Jeremy E. Allnutt - Satellite Communications-Wiley Indian (2003)Anonymous 4bUl7jzGq100% (4)

- Interactive File Cabinets by SlidesgoДокумент58 страницInteractive File Cabinets by Slidesgojakson bueberОценок пока нет

- 4.4 Software Upgrade and Software Configuration Activation: CautionДокумент50 страниц4.4 Software Upgrade and Software Configuration Activation: CautionRene GonzalesОценок пока нет

- Regression Analysis For Transport Trip GenerationДокумент6 страницRegression Analysis For Transport Trip GenerationAlsya MangessiОценок пока нет

- Stuck Pipe Prevention: Dr. Qamar J. SharifДокумент5 страницStuck Pipe Prevention: Dr. Qamar J. SharifMohamded100% (1)

- HTP40 - B - 40854 - GB (Instruction Manual)Документ95 страницHTP40 - B - 40854 - GB (Instruction Manual)Marlon CardosОценок пока нет

- Experiments Using MatlabДокумент8 страницExperiments Using MatlabAnanyaNairОценок пока нет

- TLC Online Learning Pack ContentДокумент15 страницTLC Online Learning Pack ContentjennoОценок пока нет

- IB - SWAYAM July 2022 Semester 21.12.2022Документ54 страницыIB - SWAYAM July 2022 Semester 21.12.2022prabhajeswinОценок пока нет

- Algebra Revision Assignment 1Документ5 страницAlgebra Revision Assignment 1Deepak KanchanОценок пока нет

- Basic-Input-Output-System (BIOS) Configuration: Information Sheet 1.1-4Документ2 страницыBasic-Input-Output-System (BIOS) Configuration: Information Sheet 1.1-4Donn SabalОценок пока нет