Академический Документы

Профессиональный Документы

Культура Документы

24

Загружено:

Safety 01Charmie Balani ArkconsАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

24

Загружено:

Safety 01Charmie Balani ArkconsАвторское право:

Доступные форматы

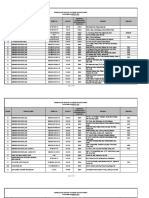

Risk Assessment & Safe Working Practice

RA Ref Number: 24 Revision: 3 Project/Job Number Reference Insert Job Number Approval Date: 30/03/2018

RA Description: Fibre Optic Cabling Next Review Date: 01/04/2019

Notes: Please refer to Safe Working Practices 24 for definitions of items in this assessment. Created by: Lee Davies

Risk Assessment The summary risk assessment is calculated as “Likelihood” x “Consequence” Issued by: Insert Name

Method & Scoring and categorised as follows; 1 to 6 = Low Risk – 7 to 16 = Medium Risk – 17 to 25 = High Risk Issue Date: Insert Date

TASK HAZARDS PERSONS INITIAL CONTROL MEASURES REVISED

AFFECTED RISK RISK LEVEL

LEVEL

Installation of Cuts from sharp ends Engineer Likelihood 4 Installation engineers are trained to install fibre optic cabling so as to Likelihood 1

fibre-optic of cable. Severity 4 minimise risks from cuts. Severity 4

cabling. Total 16 Cable ends are taped up after being cut, and prior to installation. Total 4

Medium Risk OR/ A fibre optic pulling sock is used to cover the cable end. Low Risk

Engineers are provided with suitable PPE / Gloves AC PN 5926 for hand

protection.

Termination of Eye injury from flying Engineer / Likelihood 4 Engineers are trained to cut / strip fibre-optic cabling to reduce the risks of Likelihood 1

fibre-optic glass. Passers by. Severity 4 flying particles. Severity 4

cabling. Total 16 Engineers are supplied with suitable PPE for the task / Gloves AC PN 5936 / Total 4

Medium Risk Eye goggles AC PN 5931,5932. Low Risk

Engineers are provided with, and use a sharps container in which to place

stripped cable ends.

Engineers are trained to dispose of off cuts and sharps in line with CDI

Environmental policy (Ref EMSP 2/1-01).

RA Number: 24 - Issue Revision: 3 Page 1 of 4

Risk Assessment & Safe Working Practice

TASK HAZARDS PERSONS INITIAL CONTROL MEASURES REVISED

AFFECTED RISK RISK LEVEL

LEVEL

Termination of Isopropanol Alcohol Engineer / Likelihood 4 Only trained fibre optic termination engineers use Isopropanol Alcohol. Likelihood 1

fibre-optic used for cleaning. Passers by. Severity 4 Seek immediate medical attention on exposure to these levels. Call 999 and tell Severity 4

cabling. Total 16 the operator that exposure to this substance has occurred. Very small amounts Total 4

Inhalation: Exposure Medium Risk of IA are used to clean fibre optic elements. PPE Gloves to EN3444 Parkers Low Risk

to 400ppm causes 1030015989 (size dependant part no).

headaches, irritation, Place cleaning cloths in a sealed jar straight after use.

dizziness, weakness, In open well-ventilated areas, where small amounts of IA are used, no mask is

nausea, and required. However if any quantity over 1 – 2 ml on a wiping cloth is required

asphyxiation. always ensure that adequate ventilation is available in the areas where IA is to

Ingestion: Causes be used.

nausea, vomiting, Use vent fans if required (HSS 56851) and provide engineers with the correct

diarrhoea, masks for the task. HSS 34055 Full face respirator gives maximum protection

gastrointestinal with P3 Filter.

irritation.

Eye contact: Causes

irritation, redness,

blurred sight.

Skin Contact: Causes

irritation defatting of

skin, dermatitis.

RA Number: 24 - Issue Revision: 3 Page 2 of 4

Risk Assessment & Safe Working Practice

Safe Working Practice: 24 – Fibre Optic Cabling

1 PURPOSE: The purpose of this guide is to highlight safe working practices for: Fibre Optic

Cabling.

THIS INSTRUCTION MUST NOT BE TREATED AS A SUBSTITUTE FOR TRAINING

All persons INSTALLING FIBRE OPTIC CABLES must receive appropriate training

2 PROTECTIVE CLOTHING AND EQUIPMENT

Operators must wear

➢ Safety Boots/Shoes incorporating steel toe-caps

➢ CDI issued work wear

➢ Gloves as per Risk Assessment

➢ Eye Protection as per Risk Assessment.

3 BEFORE WORK

➢ Fibre-optic cabling is made up of several strands (elements) of finely drawn glass through

which light is passed by a laser to a binary encoded pattern. The glass itself is very fine, and

no larger than a human hair, what you see and handle is mostly the protection around the

elements.

➢ For an external installation steel tape armoured cable is used, to provide mechanical

protection for the cabling elements. For an internal installation an internal, or internal /

external cable is used. This may look like electrical cable, but if not handled correctly will

easily become damaged, or will injure a person working with it.

4 DURING WORK

➢ Never bend the cable at a rate more than 6 times it’s external diameter.

➢ Never allow a knot in the cable to form, or be pulled tight.

➢ Never let a cable become wrapped around another cable, or a pipe, conduit, or anything that

will cause it to wrap tightly around itself.

➢ Never allow a cable to be stepped on, a footstep could bend a cable over a curb stone for

example, and cause the glass to shatter.

➢ Never let a vehicle drive over the cable, although there may be no external sign of damage,

the glass inside can be shattered.

➢ Extra labour will be required to ensure that loops of cable left while manhole covers / floor

tiles etc are lifted do not get walked / driven over. Always use barriers and cones to mark out

a cable loop on the floor. Never leave a loop of cable unprotected.

➢ Should the open end of the cable become exposed do not handle it. Wrap the end completely

in protective film / tape before work continues. The end of the cable is VERY sharp.

➢ Never handle the ends of fibre optic cable without heavy duty gloves.

➢ When cutting a fibre optic cable you must use the following method;

➢ Use a hacksaw to cut around the sheathing armour only, never saw straight through a cable.

RA Number: 24 - Issue Revision: 3 Page 3 of 4

Risk Assessment & Safe Working Practice

➢ Once the armour is cut with a hacksaw, use very sharp side cutters to cut through the Kevlar

and the elements themselves. Use the tip of the cutter to nibble at the cable until the Kevlar

parts, pull it apart, then cut the fibre elements in one, holding the cable firmly, and away from

the body. Any off cuts must be stored in a sharps box straight away, never leave off cuts lying

around as they are VERY sharp.

➢ You must wear heavy-duty PVC gloves and eye protection goggles to do this, sawing through

a cable will result in flying glass splinters, these are so fine that medical eye examination

equipment cannot easily detect them.

➢ Within the terminating process there will be a requirement for the use of Isopropyl Alcohol.

➢ Isopropyl Alcohol is a hazardous substance and as such, its storage and usage should comply

with COSHH Regulations. See appendix B.

➢ To ensure compliance the following will apply:

➢ Isopropyl Alcohol will be stored/transported to site in a stainless steel vacuum flask, labelled

“Inflammable Liquid 3”

➢ The customer/client must be informed before taking onto site.

➢ Before commencement of work the following significant risks must be considered:

➢ Only the minimum amount required (typically 100m/litres) will be taken onto site, for the

duration of the process only.

5 AFTER WORK

➢ Glass fragmentation generated as a result of the process must be removed from site using a

“Sharps Container” and disposed of appropriately.

➢ See Appendix A (COSHH Assessment)

CDI GROUP LTD PLACES GREAT IMPORTANCE ON EVERYONE'S SAFETY:

FAILURE TO COMPLY WITH ANY OF THE ABOVE MAY RESULT IN DISCIPLINARY

ACTION

RA Number: 24 - Issue Revision: 3 Page 4 of 4

Вам также может понравиться

- Materials - Handling - & - Storage PDFДокумент15 страницMaterials - Handling - & - Storage PDFSafety 01Charmie Balani ArkconsОценок пока нет

- Construction Safety and Health Program TДокумент16 страницConstruction Safety and Health Program TSafety 01Charmie Balani ArkconsОценок пока нет

- TEAMWORKДокумент10 страницTEAMWORKSafety 01Charmie Balani ArkconsОценок пока нет

- Construction Safety and Health Program TДокумент16 страницConstruction Safety and Health Program TSafety 01Charmie Balani ArkconsОценок пока нет

- Tg12-10 Call Before You Dig-PDF-EnДокумент2 страницыTg12-10 Call Before You Dig-PDF-EnZeeshan BajwaОценок пока нет

- TEAMWORKДокумент10 страницTEAMWORKSafety 01Charmie Balani ArkconsОценок пока нет

- Seminar On Workplace Cooperation and Pertnership ProgramДокумент1 страницаSeminar On Workplace Cooperation and Pertnership ProgramSafety 01Charmie Balani ArkconsОценок пока нет

- August 2019 Consolidated-REDP As of 09 Septemeber 2019Документ57 страницAugust 2019 Consolidated-REDP As of 09 Septemeber 2019Safety 01Charmie Balani ArkconsОценок пока нет

- 11 TESDA OP CO 05 - Competency - Assessment FormsДокумент2 страницы11 TESDA OP CO 05 - Competency - Assessment FormsSafety 01Charmie Balani ArkconsОценок пока нет

- 24Документ4 страницы24Safety 01Charmie Balani ArkconsОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Occupational Health Management in The Workplace Advice GuideДокумент28 страницOccupational Health Management in The Workplace Advice Guidenestor sanchezОценок пока нет

- Strategic ManagmentДокумент23 страницыStrategic ManagmentKayla SheltonОценок пока нет

- Framework For Improving Critical Infrastructure Cybersecurity CoreДокумент30 страницFramework For Improving Critical Infrastructure Cybersecurity CoreivanpmnОценок пока нет

- Risk Appetite: Institute of Risk Management South AfricaДокумент19 страницRisk Appetite: Institute of Risk Management South Africamuratandac3357Оценок пока нет

- Principles of Universal LoveДокумент7 страницPrinciples of Universal LoveRadha K dasОценок пока нет

- Entrepreneurship Oct 2020Документ120 страницEntrepreneurship Oct 2020Shifa ChairunnisaОценок пока нет

- Decision Making2Документ3 страницыDecision Making2imran27pkОценок пока нет

- Certified Professional Contract Manager: HandbookДокумент24 страницыCertified Professional Contract Manager: HandbookQNBОценок пока нет

- Clinical Risk ManagementДокумент6 страницClinical Risk ManagementJaparaj PeterОценок пока нет

- mdhs100 PDFДокумент44 страницыmdhs100 PDFdenar zuliandanuОценок пока нет

- Risk Management in Physical EducationДокумент3 страницыRisk Management in Physical Educationसंजेश सुधेश शर्मा100% (1)

- Exposure and VulnerabilityДокумент125 страницExposure and VulnerabilityMark Rouie FelicianoОценок пока нет

- Preventing and Mitigating COVID-19 at Work: Policy Brief 19 May 2021Документ21 страницаPreventing and Mitigating COVID-19 at Work: Policy Brief 19 May 2021Desy Fitriani SarahОценок пока нет

- NR 10 EnglishДокумент12 страницNR 10 EnglishMakiber100% (1)

- Iso18562-1 2017 PDFДокумент30 страницIso18562-1 2017 PDFRafael Esparza100% (1)

- The Effects of Silver Dressings On Chronic and Burns Wound HealingДокумент5 страницThe Effects of Silver Dressings On Chronic and Burns Wound HealingNandea Zulfana HendrawanОценок пока нет

- Transparent Data Mining For Big and Small DataДокумент224 страницыTransparent Data Mining For Big and Small DataKoen VerbekeОценок пока нет

- FinalДокумент69 страницFinalMuste KaafiОценок пока нет

- Summary of Ifrs 7Документ5 страницSummary of Ifrs 7Divine Epie Ngol'esueh100% (1)

- Thesis FinalДокумент88 страницThesis Finalfms162100% (1)

- Quant Trading NotesДокумент20 страницQuant Trading NotesDanieОценок пока нет

- Using PDRI For Project Risk ManagementДокумент9 страницUsing PDRI For Project Risk Management4jawwy markme026Оценок пока нет

- ISO 22301 ChecklistДокумент3 страницыISO 22301 ChecklistAkbar AnsariОценок пока нет

- Igc 1 PDFДокумент52 страницыIgc 1 PDFNizar AhamedОценок пока нет

- RBI Brochure WebДокумент5 страницRBI Brochure Webmega rahayuОценок пока нет

- Term-Paper - Personal Finance and New TechnologiesДокумент11 страницTerm-Paper - Personal Finance and New TechnologiesMae Ann BongcoОценок пока нет

- New Normal CBC Acp Ncii 2021 Gold FarmДокумент75 страницNew Normal CBC Acp Ncii 2021 Gold FarmGold Farm100% (1)

- How Risk Management Prepared Disruptive TechnologyДокумент6 страницHow Risk Management Prepared Disruptive TechnologySazones Perú Gerardo SalazarОценок пока нет

- Contingency Planning For Supply Chain DisruptionsДокумент3 страницыContingency Planning For Supply Chain DisruptionsRamJagannathanОценок пока нет

- Accounting Accreditation Standard 7 AACSB PDFДокумент9 страницAccounting Accreditation Standard 7 AACSB PDFDeanne ColeenОценок пока нет