Академический Документы

Профессиональный Документы

Культура Документы

QA - QC Test Format List

Загружено:

vikas kumar100%(2)100% нашли этот документ полезным (2 голоса)

378 просмотров8 страницThis document contains a list of quality assurance/quality control (QA/QC) lab testing formats for construction projects. It includes 11 categories of tests (aggregates, cement, bitumen, concrete, soil, granular sub-base, bituminous mixes, calibrations, miscellaneous, registers, and tunnel tests) with over 100 individual test descriptions and corresponding format codes. The tests cover materials, construction processes, and equipment to ensure specifications and standards are met.

Исходное описание:

Miy

Оригинальное название

QA.QC Test Format list

Авторское право

© © All Rights Reserved

Доступные форматы

XLSX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis document contains a list of quality assurance/quality control (QA/QC) lab testing formats for construction projects. It includes 11 categories of tests (aggregates, cement, bitumen, concrete, soil, granular sub-base, bituminous mixes, calibrations, miscellaneous, registers, and tunnel tests) with over 100 individual test descriptions and corresponding format codes. The tests cover materials, construction processes, and equipment to ensure specifications and standards are met.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLSX, PDF, TXT или читайте онлайн в Scribd

100%(2)100% нашли этот документ полезным (2 голоса)

378 просмотров8 страницQA - QC Test Format List

Загружено:

vikas kumarThis document contains a list of quality assurance/quality control (QA/QC) lab testing formats for construction projects. It includes 11 categories of tests (aggregates, cement, bitumen, concrete, soil, granular sub-base, bituminous mixes, calibrations, miscellaneous, registers, and tunnel tests) with over 100 individual test descriptions and corresponding format codes. The tests cover materials, construction processes, and equipment to ensure specifications and standards are met.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLSX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 8

LIST OF QA/QC LAB TESTING FORMATS

SL.NO. TEST DESCRIPTION QF NO. Unit

1 COARSE & FINE AGGREGATE -

1 Sieve Analysis for Individual Aggregates 1.1 No.

2 Sieve Analysis for Coarse Aggregates 1.2 No.

1.3 Combined Gradation for Coarse Aggregates with 40mm 1.3 No.

1.4 Combined Gradation for Coarse Aggregates with 20mm 1.4 No.

1.5 Sieve Analysis for Fine Aggregates 1.5 No.

1.6 All in Aggregate - 20mm 1.6 No.

1.7 All in Aggregate - 40mm 1.7 No.

1.8 Aggregate Impact Value 1.8 No.

1.9 Flakiness and Elongation Index 1.9 No.

1.10 Los angeles Abrasion Value 1.10 No.

1.11 Specific Gravity and Water absorption-Basket Method 1.11 No.

1.12 Specific Gravity and Water absorption-Pycnometer Method 1.12 No.

1.13 Bulk Density of Aggregate 1.13 No.

1.14 Silt Content 1.14 No.

2 CEMENT -

2.1 Fineness of Cement 2.1 No.

2.2 Normal Consistency ,IST & FST of Cement 2.2 No.

2.3 Soundness of Cement 2.3 No.

2.4 Compressive Strength of Cement 2.4 No.

3 BITUMEN -

3.1 Penetration of Bitumen 3.1 No.

3.2 Softening Point of Bitumen 3.2 No.

3.3 Ductility of Bitumen 3.3 No.

3.4 Flash Point of Bitumen 3.4 No.

3.5 Elastic Recovery of Modified Bitumen 3.5 No.

3.6 Specific Gravity Test for Bitumen 3.6 No.

3.7 Specific Gravity Test for Filler 3.7 No.

3.8 Determination of Absolute Viscosity of Bitumen 3.8 No.

3.9 Solubility of bitumen 3.9 No.

3.10 Determination of Industrial Viscosity of Emulsion 3.10 No.

4 CONCRETE -

4.1 Compressive Strength of Concrete Cubes 4.1 No.

4.2 Concrete Delivery Card 4.2 No.

4.3 Concrete Pour Card 4.3 No.

4.4 Batching of Fresh concrete 4.4 No.

4.5 Concrete Requisition form 4.5 No.

4.6 Flexural Strength of Pavement Quality Concretre 4.6 No.

5 SOIL -

5.1 Moisture Density Relationship 5.1 No.

5.2 Atterberg Limits (Cone Penetration method) 5.2 No.

5.3 Atterberg Limits (Casagrande method) 5.3 No.

5.4 Grain Size Analysis 5.4 No.

5.5 Free Swell Index of Soil 5.5 No.

5.6 (i) CBR observation & Testing Sheet 5.6 (i) No.

5.6(ii) California Bearing Ratio Load Vs Penetration Graph Sheet 5.6(ii) No.

5.6(iii) Dry Density Vs CBR Graph Sheet 5.6(iii) No.

5.7 Field Density Test (Sand Replacement Method) 5.7 No.

5.8 Moisture Content 5.8 No.

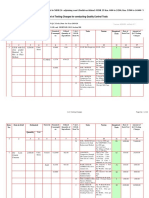

6 GSB AND WMM -

6.1 Test Result for Granular Sub- Base (GSB) 6.2 No.

6.2 Test Result for Wet Mix Macadam (WMM) 6.4 No.

6.3 Aggregate Crushing value 6.5 No.

7 BITUMINOUS MIXES -

7.1 Rate of Spray for Prime Coat/Tack Coat 7.1 No.

7.2 Binder Content (Centrifuge Extraction Method) 7.2 No.

7.3 Gradation of Bituminous Macadam (BM) 7.3 No.

7.4 (i) Gradation of Dense Bituminous Macadam (DBM-Grading.1) 7.4a No.

7.4 (ii) Gradation of Dense Bituminous Macadam (DBM-Grading.2) 7.4b No.

7.5 (ii) Gradation of Bituminous Concrete (BC-Grading.1) 7.5a No.

7.5 (ii) Gradation of Bituminous Concrete (BC-Grading.2) 7.5b No.

7.6 Marshall Stability Test 7.6 No.

7.7 Compaction Test of Bituminous Core 7.7 No.

7.8 Surface Regularity Test 7.8 No.

7.9 Temperature Record for Bituminous Mix at Site 7.9 No.

7.10 Maximum Specific Gravity of Bituminous Mix (GMM) 7.10 No.

7.11 Coating & Stripping of Bitumen Aggregate Mixture 7.11 No.

8 CALIBRATION RECORDS -

8.1 Modified Procter Moulds for Dimensional Accuracy 8.1 No.

8.2 Cube Mould 8.2 No.

8.3 CBR Moulds For Dimentional Accuracy 8.3 No.

8.4 (i) Concrete Batching Plant 8.4 (i) No.

8.4 (ii) WMM Plant 8.4 (ii) No.

8.4 (iii) Hot Mix Plant 8.4 (iii) No.

8.5 Sand used in Sand Replacement Method 8.5 No.

8.6 Rapid Moisture Meter (RMM) 8.6 No.

8.7 Flakiness and Elongation Index 8.7 No.

9 MISCELLANEOUS -

9.1 Request for Inspection 9.1 No.

9.2 Daily Programme 9.2 No.

9.3 Sample Slip 9.3 No.

9.4 Inspection check list for : Sub grade/GSB/DBM 9.4 No.

9.5 Inspection check list for : Prime coat / Tack coat 9.5 No.

9.6 Inspection check list for : BM / DBM / BC Layer 9.6 No.

9.7 Inspection check list for : C.C Works - Reinforcement 9.7 No.

9.8 Inspection check list for : Post - Concrete 9.8 No.

9.9 Inspection check list for : C.C Works - Form work 9.9 No.

9.10 Inspection check list for : Pre - Concrete 9.10 No.

9.11 Inspection check list for : Clearing & Grubbing 9.11 No.

9.12 Inspection check list for : DLC 9.12 No.

9.13 Inspection check list for : PQC 9.13 No.

9.14 Joint sampling slip 9.14 No.

9.15 Metrological format 9.15 No.

9.16 MPR Format 9.16 No.

9.17 Inspection check list for : Back Filling 9.17 No.

10 Register

10.1 PARTICULAR OF WORKS 10.1 No.

10.2 REGISTER OF DRAWINGS 10.2 No.

10.3 CEMENT REGISTER 10.3 No.

CONSUMPTION OF CEMENT ON DIFFERENT ITEMS OF WORKS

10.4 (THEORETICAL AND ACTUAL)

10.4 No.

10.5 RECORDS OF CALIBRATIION OF EQUIPMENT 10.5 No.

10.6 DAILY PROGRESS REPORT 10.6 No.

10.7 REGISTER OF INSPECTION NOTES 10.7 No.

REGISTER OF OBSERVATIONS MEMOS ISSUED FROM THE QUALITY

10.8 CONTROL CELL

10.8 No.

10.9 BITUMEN REGISTER 10.9 No.

10.10 NON CONFORMATION REPORT 10.10 No.

11 Tunnel -

11.1 Pull out test of Rock Bolts /SDA 11.1 No.

11.2 Compressive strength of Shotcrete 11.2 No.

11.3 Shotcrete Machine Calibration 11.3 No.

11.4 Penetration test of shotcrete 11.4 No.

11.5 Grouting test results 11.5 No.

11.6 Compressive strength of GROUT MIX 11.6 No.

11.7 Thickness of Shotcrete 11.7 No.

A/QC LAB TESTING FORMATS

Required

Вам также может понравиться

- DBM Mix Design No.-1Документ81 страницаDBM Mix Design No.-1pujan patel100% (1)

- WMM Mix DesignДокумент57 страницWMM Mix Designp. kiran kuamrОценок пока нет

- Field Density Test by Sand Replacement MethodДокумент1 страницаField Density Test by Sand Replacement MethodMangeysh S. Chauhan100% (1)

- GSB Trial Patch-3Документ2 страницыGSB Trial Patch-3Md YasinОценок пока нет

- Morth Section 900Документ256 страницMorth Section 900VikasMauryaОценок пока нет

- WMM Mix DesignДокумент44 страницыWMM Mix DesignAshok amlapure100% (1)

- DLC Design Mix Stipulation1Документ8 страницDLC Design Mix Stipulation1abhishek negiОценок пока нет

- GSBДокумент1 страницаGSBjitendraОценок пока нет

- WMM Construction & Quality ControlДокумент8 страницWMM Construction & Quality ControlRAMPALLI GATTAIAHОценок пока нет

- Test Report: Pavement Quality Concrete Mix Design of M-45 GradeДокумент20 страницTest Report: Pavement Quality Concrete Mix Design of M-45 GradeImran Khan100% (1)

- WMM Plant CalibrationДокумент5 страницWMM Plant CalibrationAnonymous zyIPjL9vОценок пока нет

- WMM Calibration 05.01.2016Документ8 страницWMM Calibration 05.01.2016SRR QAQCОценок пока нет

- Job Mix Formula For Cement Treated Sub Base: (IRC SP 89-2010)Документ1 страницаJob Mix Formula For Cement Treated Sub Base: (IRC SP 89-2010)Dwijendra Chanumolu100% (2)

- BC Job MixДокумент3 страницыBC Job MixSOIGNE ENGINEERING CONSULTANTSОценок пока нет

- Morth DLCДокумент9 страницMorth DLCAmit AbhangОценок пока нет

- WMM Plant Calibration (Fortune)Документ12 страницWMM Plant Calibration (Fortune)RSBIPL NH17 LABОценок пока нет

- Sand Calibration FormetДокумент2 страницыSand Calibration FormetAnish PanchalОценок пока нет

- Granular Sub-Base: Salient Features 2.1 MethodologyДокумент2 страницыGranular Sub-Base: Salient Features 2.1 Methodologyvijay kumarОценок пока нет

- Mix Design of Semi Dense Bituminous ConcreteДокумент18 страницMix Design of Semi Dense Bituminous ConcreteRahul GoyalОценок пока нет

- 1304..mix Design m25 Dalmia Cement... Mes JorhatДокумент16 страниц1304..mix Design m25 Dalmia Cement... Mes JorhatAbhishek KumarОценок пока нет

- (With Flyash) : M-20 KERBДокумент8 страниц(With Flyash) : M-20 KERBNaveen SinghОценок пока нет

- Bituminous Mix DesignДокумент62 страницыBituminous Mix DesignShaim RehanОценок пока нет

- 91 WMM Plant Calibration of DetailedДокумент8 страниц91 WMM Plant Calibration of DetailedkapishsharmaОценок пока нет

- WMM Mix DesignДокумент22 страницыWMM Mix DesignDivyesh AhirОценок пока нет

- Blending of Aggregate For Bituminous Concrete (As Per Ms-2 Table 2.1)Документ18 страницBlending of Aggregate For Bituminous Concrete (As Per Ms-2 Table 2.1)Krunal Shah100% (1)

- 1 WMM Mix DesignДокумент21 страница1 WMM Mix Designvikas kumar100% (1)

- SL - No. Name of Test Testing Method: Testing Frequency & Specification (As Per MORTH-5th Revision)Документ18 страницSL - No. Name of Test Testing Method: Testing Frequency & Specification (As Per MORTH-5th Revision)Ashok amlapure100% (1)

- WMM Design DataДокумент42 страницыWMM Design DatapreranaОценок пока нет

- Final BC Grade 2 With VG 40 Honeywell Titan Polymer 56 HMP 1 Lime and 0.8 PolymerДокумент15 страницFinal BC Grade 2 With VG 40 Honeywell Titan Polymer 56 HMP 1 Lime and 0.8 PolymerSunil BoseОценок пока нет

- Abstract of DBM Mix Design Gr-Ii (50-75 MM Thick)Документ6 страницAbstract of DBM Mix Design Gr-Ii (50-75 MM Thick)Santu Ghosh100% (1)

- Flakiness and Elongation IndexДокумент1 страницаFlakiness and Elongation IndexBscpl Repalle to EeppurpalemОценок пока нет

- 40mm Aggregate For Concrete Flakiness Elongation IndicesДокумент147 страниц40mm Aggregate For Concrete Flakiness Elongation IndicesV Venkata Narayana100% (6)

- Brick Test ReportДокумент1 страницаBrick Test Reportsudugouda100% (2)

- WMM Calibration of PlantДокумент7 страницWMM Calibration of PlantKaushlendra Singh80% (5)

- Job Mix FormulaДокумент10 страницJob Mix FormulaBijay Krishna Das100% (3)

- Irc SP &is ListДокумент53 страницыIrc SP &is ListAjay Kumar GuptaОценок пока нет

- Mastic Asphalt Design (With Ca)Документ36 страницMastic Asphalt Design (With Ca)Soundar Pachiappan100% (1)

- Designed Concrete MixДокумент6 страницDesigned Concrete MixniceseshaОценок пока нет

- Moisture Correction SheetДокумент4 страницыMoisture Correction SheetSasanka SekharОценок пока нет

- Kship GVR: Sorce: Sankanur Cross CrusherДокумент9 страницKship GVR: Sorce: Sankanur Cross CrusherVijay Jamadar100% (1)

- MSS Mix Design GradationДокумент4 страницыMSS Mix Design Gradationjitendra100% (1)

- Shotcrete Mix Design SummaryДокумент1 страницаShotcrete Mix Design SummaryRitik RajОценок пока нет

- Is 2720 Part28 Soil Replacement MethodДокумент23 страницыIs 2720 Part28 Soil Replacement MethodJoe Ps100% (3)

- DLC Degin GulbaxaniДокумент6 страницDLC Degin GulbaxaniImran KhanОценок пока нет

- Bitumen VG 30 & VG 40 Mix DesignДокумент5 страницBitumen VG 30 & VG 40 Mix DesignPoirei Zildjian0% (1)

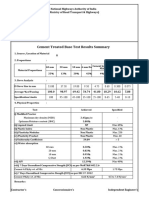

- Cement Treated Base Test Results Summary: National Highways Authority of India (Ministry of Road Transport & Highways)Документ61 страницаCement Treated Base Test Results Summary: National Highways Authority of India (Ministry of Road Transport & Highways)Fariha Azad100% (2)

- Road Infrastructure Development Company of Rajasthan LTD.: I. Source and Location of All MaterialsДокумент53 страницыRoad Infrastructure Development Company of Rajasthan LTD.: I. Source and Location of All Materialssunil kuldeepОценок пока нет

- WBMДокумент19 страницWBMAnshul Tiwari75% (4)

- Methology For Mastic AshphaltДокумент6 страницMethology For Mastic Ashphaltvenkateswara rao PothinaОценок пока нет

- Dense Bitumen Macadam (DBM) LayerДокумент12 страницDense Bitumen Macadam (DBM) LayerPathankot MandiОценок пока нет

- SR No Description of Material & Test Specifications Charges M.E Testing PNC Existing Rates CementДокумент3 страницыSR No Description of Material & Test Specifications Charges M.E Testing PNC Existing Rates CementAtulОценок пока нет

- In This Article We Shall Discuss Three Important Points About Wet Mix Macadam (WMM)Документ6 страницIn This Article We Shall Discuss Three Important Points About Wet Mix Macadam (WMM)RAMPALLI GATTAIAHОценок пока нет

- WMM 1067-1Документ14 страницWMM 1067-1Imran Khan100% (1)

- RMM CalibrationДокумент18 страницRMM CalibrationPrasanna S KulkarniОценок пока нет

- M20 Kerb - Mix Design Calculation: Volume of Cementicious Materials+Water+AdmixtureДокумент1 страницаM20 Kerb - Mix Design Calculation: Volume of Cementicious Materials+Water+Admixturevdbshamsabad labОценок пока нет

- Quality TestДокумент22 страницыQuality TestUmair Shaikh100% (1)

- FCE345 Highway MaterialsДокумент43 страницыFCE345 Highway Materialsjava nameОценок пока нет

- S. No. Page No. I List of Tables II List of Figures III Chapter - 1 1 Chapter - 2 2. Literature Review 3 Chapter - 3 3. Raw Materials 5Документ2 страницыS. No. Page No. I List of Tables II List of Figures III Chapter - 1 1 Chapter - 2 2. Literature Review 3 Chapter - 3 3. Raw Materials 5Pavanasuta VishnuОценок пока нет

- Chloride Diffusion CoefficientДокумент7 страницChloride Diffusion CoefficientAkhtar BahramОценок пока нет

- List of Content SK - Doc1Документ8 страницList of Content SK - Doc1SHANKAR PRINTINGОценок пока нет

- 1 WMM Mix DesignДокумент21 страница1 WMM Mix Designvikas kumar100% (1)

- List-HO Manpower AsДокумент15 страницList-HO Manpower Asvikas kumarОценок пока нет

- GSB Design Mix Ashapuri CrusherДокумент36 страницGSB Design Mix Ashapuri Crushervikas kumarОценок пока нет

- P 4 IVUQVEIGPr P7 yДокумент2 страницыP 4 IVUQVEIGPr P7 yvikas kumarОценок пока нет

- Ashok Chauhan & Company: M/s Shapoorji Pallonji Pandoh Takoli Highway Private LimitedДокумент2 страницыAshok Chauhan & Company: M/s Shapoorji Pallonji Pandoh Takoli Highway Private Limitedvikas kumarОценок пока нет

- PT Formate of Steel Fibre ContentДокумент1 страницаPT Formate of Steel Fibre Contentvikas kumarОценок пока нет

- PT Formate of Steel Fibre ContentДокумент1 страницаPT Formate of Steel Fibre Contentvikas kumarОценок пока нет

- Wts & Measurement Dept MandiДокумент1 страницаWts & Measurement Dept Mandivikas kumar0% (1)

- Project: Construction of A Factory Shed For ABC Co. LTD: Planned Start Date: 05 April, 2021Документ7 страницProject: Construction of A Factory Shed For ABC Co. LTD: Planned Start Date: 05 April, 2021Mayank GhaiwatkarОценок пока нет

- Upholstery Catalogue PDFДокумент15 страницUpholstery Catalogue PDFDo Van LuanОценок пока нет

- Excel Sheets For RC DesignДокумент30 страницExcel Sheets For RC Designامين الزريقي100% (1)

- Howrah BridgeДокумент23 страницыHowrah BridgeMOHIT KUMAR100% (2)

- Shoring & UnderpinningДокумент25 страницShoring & UnderpinningNadira Islam NilaОценок пока нет

- Combined Foundation Design PDFДокумент8 страницCombined Foundation Design PDFkvamshi_1971Оценок пока нет

- NFPA - Grooved FittingsДокумент1 страницаNFPA - Grooved FittingsShaban SarwarОценок пока нет

- Private Villa B+G+1+P+PoolДокумент2 страницыPrivate Villa B+G+1+P+PoolErwinBascon100% (1)

- General Notes: Rebulic of KenyaДокумент1 страницаGeneral Notes: Rebulic of Kenyagregg bluОценок пока нет

- OPC-53 TC KDP For 6th Week 2020 (7 Days) PDFДокумент1 страницаOPC-53 TC KDP For 6th Week 2020 (7 Days) PDFSahul Ahameed100% (1)

- Filipino Construction TermsДокумент3 страницыFilipino Construction Termspaul2reebok71% (21)

- Purlin DesignДокумент9 страницPurlin DesignVhorn TiuОценок пока нет

- General: Material SpecificationДокумент8 страницGeneral: Material SpecificationMuthu GaneshОценок пока нет

- ASTM Comparison PDFДокумент1 страницаASTM Comparison PDFRaja HoneОценок пока нет

- Design of Slab BridgesДокумент12 страницDesign of Slab BridgesEna Mie CambaОценок пока нет

- Sm-Etabs GuideДокумент5 страницSm-Etabs GuidetaroОценок пока нет

- Glulam: "Glue Laminated Timber"Документ9 страницGlulam: "Glue Laminated Timber"JishaОценок пока нет

- Unit - 1Документ40 страницUnit - 1rajeshОценок пока нет

- Tiling Works PDFДокумент64 страницыTiling Works PDFKian InductivoОценок пока нет

- Wood-Plastic Composites (WPC) and Natural Fibre Composites (NFC)Документ16 страницWood-Plastic Composites (WPC) and Natural Fibre Composites (NFC)Ric MnsОценок пока нет

- Company ProfileДокумент40 страницCompany ProfileMuzamal HussainОценок пока нет

- EstimateДокумент23 страницыEstimategagajain33% (3)

- Early Detection of Building Collapse Using IotДокумент14 страницEarly Detection of Building Collapse Using IotAfraa AnwarОценок пока нет

- Data Sheet: Global Truss F34P Truss SystemДокумент1 страницаData Sheet: Global Truss F34P Truss SystempblОценок пока нет

- Chapter 5 Shear, Bond and TorsionДокумент82 страницыChapter 5 Shear, Bond and TorsiondavidОценок пока нет

- Nnovations: WWW - Buildinginnovations.co - UkДокумент35 страницNnovations: WWW - Buildinginnovations.co - UkSakthivelОценок пока нет

- Tube Clamps Series C - Complete RangeДокумент1 страницаTube Clamps Series C - Complete RangeZoran JankovОценок пока нет

- Attic Trusses Site Infill DetailДокумент1 страницаAttic Trusses Site Infill DetailRathish RathizОценок пока нет

- CH 9 StevensonДокумент53 страницыCH 9 StevensonPetersonОценок пока нет