Академический Документы

Профессиональный Документы

Культура Документы

Painting Procedure 8 PDF

Загружено:

Jayasankar ManickamОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Painting Procedure 8 PDF

Загружено:

Jayasankar ManickamАвторское право:

Доступные форматы

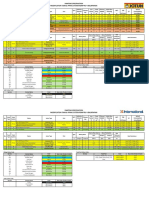

VS00580- SURFACE PAINTING SPECIFICATION

Revision No: 00

1.0 Paint Application:

1. 1 Painting System

Combustion Air Fan

Surface preparation : Blast Cleaning with minimum SSPC SP 10 to ISO 8501-1:1988

A882-000-07-41- Max. Temp. Paint System

SP-01121-02 Total DFT

Component

Rev0 ̊C Primer Coat Interm. coat Finish Coat Microns

Uninsulated

Table 12.1.1 Surfaces – 2 coats of F-6A

1 coat of F-9 @65-75 µ

Carbon Steel @100 µ DFT/coat

-14 - 80 DFT/coat + 1 coat of - 345-355

(e.g. Damper, +1 coat of F-2

P-6 @40 µ DFT/coat

Base frame, @40µ DFT/coat

Pedestal etc.)

A882-000-07-41- Max. Temp. Paint System

SP-01121-02 Surface preparation & Total DFT

Component Primer Coat /

Rev0 ̊C Pre erection / Shop Finish Coat Microns

Interm. coat

Primer

Insulated

Table 15.1.1 surfaces (e.g. SSPC-SP-10; 1 coat of F-15@ 2 coats of F-15@75

casing, inlet box -45 - 120 1 coat of F-15@ 75µ 75 µ DFT/coat; µ DFT/coat; 225-250

etc.) – Carbon DFT/coat (2x75=150)

Steel

NOTE: 1) Impeller & inlet cone shall be painted as per vendor standard.

2) Shaft & coupling guard colour shall be Alert Orange.

COLOUR SCHEME: DARK ADMIRALTY GREY (RAL 7012)

LEGENDS: -

1. F-9 = Two component inorganic zinc silicate coating

2. P-6 = Two component epoxy zinc phosphate primer cured with polyamine hardener

3. F-6A = High build epoxy finish coating cured with polyamine hardener

4. F-2 = Two component acrylic – Polyurethane finish paint

5. F-15 = Two component epoxy phenolic coating cured with polyamine adduct hardener system

Вам также может понравиться

- Mutations Worksheet 2Документ3 страницыMutations Worksheet 2Dazza DattoОценок пока нет

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsОт EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsРейтинг: 5 из 5 звезд5/5 (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Resin Finishes On Cellulosic FabricsДокумент28 страницResin Finishes On Cellulosic FabricsHina Arif100% (7)

- Paint Qty Calculation TemplateДокумент15 страницPaint Qty Calculation TemplateariyakkannaaОценок пока нет

- Muscles and Nerves: Anatomy and PhysiologyДокумент10 страницMuscles and Nerves: Anatomy and PhysiologyJoseph90% (10)

- STD 135Документ26 страницSTD 135Mathan Selva Kumar AОценок пока нет

- Paint Calculation NewДокумент2 страницыPaint Calculation NewAhmad Riyadinal Ricky100% (2)

- WSS M2P180 DДокумент12 страницWSS M2P180 DJuan Angel DechimaОценок пока нет

- SP Guide To CompositesДокумент69 страницSP Guide To CompositesCefirel_grifonОценок пока нет

- 660D14 Painting Schedule For Silo 1 - Rev 0Документ1 страница660D14 Painting Schedule For Silo 1 - Rev 0Mohammad AdilОценок пока нет

- Easy Care Finishing enДокумент32 страницыEasy Care Finishing enbigstar42Оценок пока нет

- Metco®73F-NS-1 (-2) 10-058 PDFДокумент7 страницMetco®73F-NS-1 (-2) 10-058 PDF張政雄Оценок пока нет

- XN90 N1 038Документ2 страницыXN90 N1 038ashleyОценок пока нет

- 4300-AI-VD-FPX4X40000A110002 FIДокумент7 страниц4300-AI-VD-FPX4X40000A110002 FIMurugesh SekarОценок пока нет

- QPS-C5 Industrial & Costal Painting Procedure-OP - PP - WI - 006 - C5 PDFДокумент4 страницыQPS-C5 Industrial & Costal Painting Procedure-OP - PP - WI - 006 - C5 PDFDeepak UpadhyayОценок пока нет

- 20000E05 - Painting Spec - 187 - 0 - AppendiceSistemasДокумент33 страницы20000E05 - Painting Spec - 187 - 0 - AppendiceSistemasRosaFОценок пока нет

- AA-000-TS-0014 - Item 9.7 - Paint System #2.2Документ1 страницаAA-000-TS-0014 - Item 9.7 - Paint System #2.2Viviane Alves Loureiro de SousaОценок пока нет

- High performance metallized polyester film capacitorsДокумент4 страницыHigh performance metallized polyester film capacitorsวรพงษ์ กอชัชวาลОценок пока нет

- 3 Painting and Coating Selection Schedules: 3.1 New Construction WorksДокумент2 страницы3 Painting and Coating Selection Schedules: 3.1 New Construction WorksmuthuvelaaОценок пока нет

- Paint SystemДокумент1 страницаPaint SystemTan Chen KiongОценок пока нет

- Maintenance Paint SpecificationДокумент5 страницMaintenance Paint SpecificationMukhlis AdamОценок пока нет

- 673 HN Ses 23Документ5 страниц673 HN Ses 23ZAHID IQBALОценок пока нет

- KI XL 03HS SC 10 HS LT XLPE Ambient CureableДокумент4 страницыKI XL 03HS SC 10 HS LT XLPE Ambient CureableAshish bhattОценок пока нет

- Tank Wise Paint RequirmentsДокумент1 страницаTank Wise Paint RequirmentsramaОценок пока нет

- PLC3PS8221 & 8229 Rev.01Документ7 страницPLC3PS8221 & 8229 Rev.01isan.structural TjsvgalavanОценок пока нет

- Thermo-Lag 3000-P PDS PDFДокумент7 страницThermo-Lag 3000-P PDS PDFskОценок пока нет

- Technical data sheet for Izocam stonewool flat roof boardДокумент1 страницаTechnical data sheet for Izocam stonewool flat roof boardzgrouproОценок пока нет

- Rekomendasi Painting JotunДокумент1 страницаRekomendasi Painting JotunmanthoexОценок пока нет

- Tds Isover TPДокумент1 страницаTds Isover TPBulent KABADAYIОценок пока нет

- Fujikura Splicer 12S - EДокумент2 страницыFujikura Splicer 12S - EAnonymous yugocxnОценок пока нет

- TechnicalDataSheet EffisusBreatherFR BMembrane - ENGДокумент1 страницаTechnicalDataSheet EffisusBreatherFR BMembrane - ENGPaula MoçoОценок пока нет

- DatasheetДокумент1 страницаDatasheetAli Civil007Оценок пока нет

- List of Consumables: ATA 61-90-00 (E-9000)Документ6 страницList of Consumables: ATA 61-90-00 (E-9000)kikeОценок пока нет

- A Guide For FLUOR & BASF Painting Specification of Typical Storage Tanks (Part 04 of 05)Документ5 страницA Guide For FLUOR & BASF Painting Specification of Typical Storage Tanks (Part 04 of 05)Adam Michael Green100% (1)

- Brick A 35 SДокумент1 страницаBrick A 35 SMuhammad TayyabОценок пока нет

- Ce Thermal and Moisture Emulsion Solvent RC-815 Inivest Haider Saleh Al-Haider & Partner CoДокумент1 страницаCe Thermal and Moisture Emulsion Solvent RC-815 Inivest Haider Saleh Al-Haider & Partner Cosudeep karunОценок пока нет

- Arkema Mbs Impact Modifiers PDFДокумент8 страницArkema Mbs Impact Modifiers PDFgjvoraОценок пока нет

- ATF1FRДокумент1 страницаATF1FRFaridОценок пока нет

- Hospital Painting QuotationДокумент1 страницаHospital Painting Quotationgesta anwarОценок пока нет

- Thermo Lag - 3000 SP - PDS FireproofingДокумент4 страницыThermo Lag - 3000 SP - PDS FireproofingAdil KhanОценок пока нет

- BASF MasterTop 1273 ESD ENДокумент4 страницыBASF MasterTop 1273 ESD ENIgor DzuklevskiОценок пока нет

- Blowers: TMO-O 0000-E Je / 18.08.07 VKIДокумент375 страницBlowers: TMO-O 0000-E Je / 18.08.07 VKIJairoQuirozGomezОценок пока нет

- FDS THERMOLAG 3000 P Part B - 04 2016..Документ7 страницFDS THERMOLAG 3000 P Part B - 04 2016..Ayman JadОценок пока нет

- Polyester Resins For Filled Fire Retardant Applications: Firepel K320-A Series Polyester ResinДокумент3 страницыPolyester Resins For Filled Fire Retardant Applications: Firepel K320-A Series Polyester ResinA.Subin DasОценок пока нет

- Vendor Document Cover SheetДокумент75 страницVendor Document Cover Sheetmujahed_muhammedОценок пока нет

- 01-Firecel 100 9 - SR-114HДокумент1 страница01-Firecel 100 9 - SR-114HMohammed MustafaОценок пока нет

- Paint System: Cargotec Finland Oy TampereДокумент1 страницаPaint System: Cargotec Finland Oy TampereEdward Erney Salas ValenzuelaОценок пока нет

- Paint SystemДокумент1 страницаPaint Systemmiladshabani.7777Оценок пока нет

- FK 5 1 12 42 BarДокумент8 страницFK 5 1 12 42 BarAshish MalikОценок пока нет

- Simplest FM - With - Mic Kogawa'sДокумент2 страницыSimplest FM - With - Mic Kogawa'sFlorencio cancheОценок пока нет

- Passive Fire Protection Design Report For Fire Walls H-60 at BM-6 On CPP-2Документ5 страницPassive Fire Protection Design Report For Fire Walls H-60 at BM-6 On CPP-2Bui PhiОценок пока нет

- Web Publish 2361972 1 A 1 Pintura DroДокумент12 страницWeb Publish 2361972 1 A 1 Pintura DroJuan Arturo Hernandez RamosОценок пока нет

- Clean Agent System: Ul Listed 25 Bar FK 1230 (FK-5-1-12)Документ8 страницClean Agent System: Ul Listed 25 Bar FK 1230 (FK-5-1-12)Rico Eka ArfiansyahОценок пока нет

- Fujikura 12S CДокумент2 страницыFujikura 12S CCristian BolañosОценок пока нет

- 253 PDS AiДокумент4 страницы253 PDS AiAchraf BoudayaОценок пока нет

- Lds 0287Документ8 страницLds 0287asif.binance1988Оценок пока нет

- CELLFLEX® Factory-Fit Jumper Assembly, Weatherproof Boot 7-16 DIN Male/7-16 DIN Male, 1/2" Low Loss Foam, 2 MДокумент2 страницыCELLFLEX® Factory-Fit Jumper Assembly, Weatherproof Boot 7-16 DIN Male/7-16 DIN Male, 1/2" Low Loss Foam, 2 MnguyentraihdОценок пока нет

- Paint system for above ground pipe field weldsДокумент2 страницыPaint system for above ground pipe field weldsSam JoseОценок пока нет

- TDS - en - Atk Foam - 30DДокумент4 страницыTDS - en - Atk Foam - 30DMangalagiu BogdanОценок пока нет

- Service Bulletin Copier: Location: SubjectДокумент16 страницService Bulletin Copier: Location: SubjectAmer RafiqueОценок пока нет

- ES-0405 - 2 Pintura PS14Документ1 страницаES-0405 - 2 Pintura PS14Carlos Miguel Barrena TorresОценок пока нет

- Norsok M-501: Teknos' Coating System GuideДокумент8 страницNorsok M-501: Teknos' Coating System GuideĐức LêОценок пока нет

- UmaPET EC104 - 140Документ2 страницыUmaPET EC104 - 140Luz Angela GuerreroОценок пока нет

- MFC Technical DataДокумент4 страницыMFC Technical Datapraise tomОценок пока нет

- Nash Paiting RepairДокумент2 страницыNash Paiting RepairAhmed GamalОценок пока нет

- Shellac Paint ReportДокумент17 страницShellac Paint ReportQUIMAT, Stellina Rose M.Оценок пока нет

- Tech CR Next Gen Novolac Epoxy VEДокумент8 страницTech CR Next Gen Novolac Epoxy VEanggiОценок пока нет

- Cosasco Side Tee Access Fittings PDFДокумент2 страницыCosasco Side Tee Access Fittings PDFEdgar I RamirezОценок пока нет

- Personal Care North America: Natural Products GuideДокумент17 страницPersonal Care North America: Natural Products Guidecontentdrive4 drive4Оценок пока нет

- DOWSIL™ 3074 Intermediate: Features & BenefitsДокумент3 страницыDOWSIL™ 3074 Intermediate: Features & BenefitsZhan FangОценок пока нет

- International Journal of Biological Macromolecules: Bai Qu, Yangchao LuoДокумент12 страницInternational Journal of Biological Macromolecules: Bai Qu, Yangchao LuoFaizhal Dimas LeksonoОценок пока нет

- Isin LankaДокумент8 страницIsin LankaThilinaAbhayarathne100% (1)

- Adhesives SealantsДокумент2 страницыAdhesives SealantsCARMEN LINARESОценок пока нет

- SiliconesДокумент19 страницSiliconesprabhuОценок пока нет

- Comparing Soap and Detergent PropertiesДокумент19 страницComparing Soap and Detergent PropertiesNajihah JaffarОценок пока нет

- EPR and Silicon CatalogueДокумент6 страницEPR and Silicon CatalogueHarshad ChauhanОценок пока нет

- Materials For Laptop BodyДокумент6 страницMaterials For Laptop BodySuparna KhasnabisОценок пока нет

- Float Switch Pepperh N FunchДокумент5 страницFloat Switch Pepperh N FunchAgus Itonk SuwardonoОценок пока нет

- TEPZZ 79 - Z77B - T: European Patent SpecificationДокумент23 страницыTEPZZ 79 - Z77B - T: European Patent SpecificationLong An DoОценок пока нет

- Biomolecules QuizДокумент6 страницBiomolecules QuizDiana Jean Alo-adОценок пока нет

- SAS Automation: Gripper Mounting ArmsДокумент9 страницSAS Automation: Gripper Mounting ArmsMichael KrummОценок пока нет

- PreservativeДокумент4 страницыPreservativeHayyyNakuNeilОценок пока нет

- Soaps and SyndetsДокумент15 страницSoaps and Syndetsestefani fernnadezОценок пока нет

- Air Flow MERV 8 High Cap Air FiltersДокумент2 страницыAir Flow MERV 8 High Cap Air FiltersTreyflyОценок пока нет

- TCMT0021 1210 PDFДокумент48 страницTCMT0021 1210 PDFduongpnОценок пока нет

- Higher TG Based On Triple Hydrogen Bond Interactions - Jean Claude MBULU AGALIAДокумент20 страницHigher TG Based On Triple Hydrogen Bond Interactions - Jean Claude MBULU AGALIAabhijeetanand2010Оценок пока нет

- Developments in Environmental ChemistryДокумент4 страницыDevelopments in Environmental ChemistrysanjigonnastudyОценок пока нет

- 2nd Year Chemistry Full Book MCQs TitleДокумент52 страницы2nd Year Chemistry Full Book MCQs TitleMalaika MinerОценок пока нет

- BRE-N Valva EvacuareДокумент1 страницаBRE-N Valva EvacuareVlad Nicolae SebastianОценок пока нет