Академический Документы

Профессиональный Документы

Культура Документы

1226 Verification of Compendial Procedures PDF

Загружено:

maria mercedesОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1226 Verification of Compendial Procedures PDF

Загружено:

maria mercedesАвторское право:

Доступные форматы

Accessed from 10.6.1.

1 by spcafng3z on Tue Dec 01 06:02:31 EST 2015

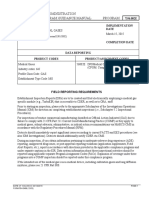

USP 38 General Information / á1226ñ Verification of Compendial Procedures 1451

á1226ñ VERIFICATION OF COMPENDIAL PROCEDURES

The intent of this general information chapter is to provide general information on the verification of compendial procedures

that are being performed for the first time to yield acceptable results utilizing the personnel, equipment, and reagents availa-

ble. This chapter is not intended for retroactive application to already successfully established laboratory procedures. The chap-

ter Validation of Compendial Procedures á1225ñ provides general information on characteristics that should be considered for

various test categories and on the documentation that should accompany analytical procedures submitted for inclusion in

USP–NF. Verification consists of assessing selected analytical performance characteristics, such as those that are described in

chapter á1225ñ, to generate appropriate, relevant data rather than repeating the validation process.

Users of compendial analytical procedures are not required to validate these procedures when first used in their laboratories,

but documented evidence of suitability should be established under actual conditions of use. In the United States, this require-

ment is established in 21 CFR 211.194(a)(2) of the current Good Manufacturing Practice regulations, which states that the

“suitability of all testing methods used shall be verified under actual conditions of use.”

Verification of microbiological procedures is not covered in this chapter because it is covered in USP general test chapters

Antimicrobial Effectiveness Testing á51ñ, Microbiological Examination of Nonsterile Products: Microbial Enumeration Tests á61ñ, Mi-

crobiological Examination of Nonsterile Products: Tests for Specified Microorganisms á62ñ, Sterility Tests á71ñ, and in general infor-

mation chapter Validation of Microbial Recovery from Pharmacopeial Articles á1227ñ.

VERIFICATION PROCESS

General Chapters

The verification process for compendial test procedures is the assessment of whether the procedure can be used for its inten-

ded purpose, under the actual conditions of use for a specified drug substance and/or drug product matrix.

Users should have the appropriate experience, knowledge, and training to understand and be able to perform the compen-

dial procedures as written. Verification should be conducted by the user such that the results will provide confidence that the

compendial procedure will perform suitably as intended.

If the verification of the compendial procedure is not successful, and assistance from USP staff has not resolved the problem,

it may be concluded that the procedure may not be suitable for use with the article being tested in that laboratory. It may

then be necessary to develop and validate an alternate procedure as allowed in the General Notices. The alternate procedure

may be submitted to USP, along with the appropriate data, to support a proposal for inclusion or replacement of the current

compendial procedure.

VERIFICATION REQUIREMENTS

Verification requirements should be based on an assessment of the complexity of both the procedure and the material to

which the procedure is applied. Although complete revalidation of a compendial method is not required to verify the suitabili-

ty of a procedure under actual conditions of use, some of the analytical performance characteristics listed in chapter á1225ñ,

Table 2, may be used for the verification process. Only those characteristics that are considered to be appropriate for the verifi-

cation of the particular procedure need to be evaluated. The process of assessing the suitability of a compendial analytical test

procedure under the conditions of actual use may or may not require actual laboratory performance of each analytical per-

formance characteristic. The degree and extent of the verification process may depend on the level of training and experience

of the user, on the type of procedure and its associated equipment or instrumentation, on the specific procedural steps, and

on which article(s) are being tested.

Verification should assess whether the compendial procedure is suitable for the drug substance and/or the drug product ma-

trix, taking into account the drug substance's synthetic route, the method of manufacture for the drug product, or both, if

applicable. Verification should include an assessment of elements such as the effect of the matrix on the recovery of impurities

and drug substances from the drug product matrix, as well as the suitability of chromatographic conditions and column, the

appropriateness of detector signal response, etc.

As an example, an assessment of specificity is a key parameter in verifying that a compendial procedure is suitable for use in

assaying drug substances and drug products. For instance, acceptable specificity for a chromatographic method may be veri-

fied by conformance with system suitability resolution requirements (if specified in the procedure). However, drug substances

from different suppliers may have different impurity profiles that are not addressed by the compendial test procedure. Similar-

ly, the excipients in a drug product can vary widely among manufacturers and may have the potential to directly interfere with

the procedure or cause the formation of impurities that are not addressed by the compendial procedure. In addition, drug

products containing different excipients, antioxidants, buffers, or container extractives may affect the recovery of the drug

substance from the matrix. In these cases, a more thorough assessment of the matrix effects may be required to demonstrate

suitability of the procedure for the particular drug substance or product. Other analytical performance characteristics such as

an assessment of the limit of detection or quantitation and precision for impurities procedures may be useful to demonstrate

the suitability of the compendial procedure under actual conditions of use.

Official from December 1, 2015

Copyright (c) 2015 The United States Pharmacopeial Convention. All rights reserved.

Accessed from 10.6.1.1 by spcafng3z on Tue Dec 01 06:02:31 EST 2015

1452 á1226ñ Verification of Compendial Procedures / General Information USP 38

Verification is not required for basic compendial test procedures that are routinely performed unless there is an indication

that the compendial procedure is not appropriate for the article under test. Examples of basic compendial procedures include,

but are not limited to, loss on drying, residue on ignition, various wet chemical procedures such as acid value, and simple

instrumental determinations such as pH measurements. However, for the application of already established routine procedures

to compendial articles tested for the first time, it is recommended that consideration be given to any new or different sample

handling or solution preparation requirements.

á1227ñ VALIDATION OF MICROBIAL RECOVERY FROM

PHARMACOPEIAL ARTICLES

This chapter provides guidelines for the validation of methods for the estimation of the number of viable microorganisms,

for the detection of indicators or objectionable microorganisms, for the validation of microbiological methods used in antimi-

crobial effectiveness testing, and for the sterility testing of Pharmacopeial articles. It is generally understood that if a product

possesses antimicrobial properties because of the presence of a specific preservative or because of its formulation, this antimi-

crobial property must be neutralized to recover viable microorganisms. This neutralization may be achieved by the use of a

specific neutralizer, by dilution, by a combination of washing and dilution, or by any combination of these methods.

General Chapters

The tests under Antimicrobial Effectiveness Testing á51ñ, Sterility Tests á71ñ, and Microbial Enumeration Tests á61ñ and Tests for

Specified Microorganisms á62ñ require the validation of recovery methods. To ensure that the results of the tests are credible,

neutralization of antimicrobial properties of the test solution is required before estimating the number of viable microorgan-

isms.

INFLUENTIAL FACTORS

Several factors affect the measurement of a test solution's antimicrobial activity, and these must be considered in the valida-

tion design. They include the nature of the microorganisms used as challenge organisms, the preparation of the inoculum of

challenge organisms, the specific conditions of the test, and the conditions of recovery. These factors also affect the validation

of recovery methods for aqueous or nonaqueous products, irrespective of their antimicrobial properties; thus, all test methods

should be validated with these factors in mind.

The nature of the challenge microorganism exerts a strong effect upon the response to the antimicrobial agent, and so upon

the neutralization required for recovery. Represented among these organisms in compendial tests are Gram-positive bacteria,

Gram-negative bacteria, yeasts, and molds. Each organism to be used in the test must be included in the validation.

The preparation of the inoculum of challenge microorganisms also affects the testing of products having antimicrobial prop-

erties. The growth and preparation of the challenge organism determines the physiological state of the cell. This state has a

direct influence on the results of any test of antimicrobial efficacy. Microbial tests do not use individual cells; rather, popula-

tions of cells are harvested for study. The data generated from these studies are less variable if the cell populations are homo-

geneous. Liquid cultures or confluent growths on solid medium are best suited for reproducible culture preparation. The con-

ditions of organism preparation and storage must be standardized for the neutralizer evaluation and should reflect the condi-

tions of the antimicrobial assay.

The specific conditions of the test, including buffers used, water, light conditions, and temperature, must be reproduced in

the validation study. All test conditions also should be standardized and performed in the validation study exactly as per-

formed in the test.

The conditions of microbial recovery are among the most crucial in accurately estimating the number of microorganisms

present in a test solution. The first consideration is the recovery medium used to support the growth of survivors. This concern

is discussed in detail below. The second consideration is the incubation conditions. Optimal conditions for growth must be

present to ensure complete growth and reproducible results.

METHODS OF NEUTRALIZING ANTIMICROBIAL PROPERTIES

Three common methods are used to neutralize antimicrobial properties of a product: (1) chemical inhibition, (2) dilution,

and (3) filtration and washing.

Chemical Inhibition

Table 1 shows known neutralizers for a variety of chemical antimicrobial agents and the reported toxicity of some chemical

neutralizers to specific microorganisms. However, despite potential toxicity, the convenience and quick action of chemical in-

hibitors encourage their use. Chemical inhibition of bactericides is the preferred method for the antimicrobial efficacy test. The

Official from December 1, 2015

Copyright (c) 2015 The United States Pharmacopeial Convention. All rights reserved.

Вам также может понравиться

- Biocontamination Control for Pharmaceuticals and HealthcareОт EverandBiocontamination Control for Pharmaceuticals and HealthcareРейтинг: 5 из 5 звезд5/5 (1)

- ICH Quality Guidelines: An Implementation GuideОт EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleОценок пока нет

- Cleaning and disinfection of food factories: a practical guideОт EverandCleaning and disinfection of food factories: a practical guideОценок пока нет

- Practical Approaches to Method Validation and Essential Instrument QualificationОт EverandPractical Approaches to Method Validation and Essential Instrument QualificationОценок пока нет

- Pharmaceutical Quality Management System (QMS) Questions and AnswersОт EverandPharmaceutical Quality Management System (QMS) Questions and AnswersОценок пока нет

- Analytical Method Validation NutraceuticalsДокумент6 страницAnalytical Method Validation NutraceuticalsBhaskar NapteОценок пока нет

- Techniques for Downstream process for Biologic Drugs and VaccinesОт EverandTechniques for Downstream process for Biologic Drugs and VaccinesОценок пока нет

- Data Integrity and Compliance: A Primer for Medical Product ManufacturersОт EverandData Integrity and Compliance: A Primer for Medical Product ManufacturersОценок пока нет

- Microbial Testing in Support of Aseptic ProcessingДокумент6 страницMicrobial Testing in Support of Aseptic ProcessingmeghanalandeОценок пока нет

- Handbook of Investigation and Effective CAPA SystemsОт EverandHandbook of Investigation and Effective CAPA SystemsОценок пока нет

- ScanRDI Suitability of ScanRDI As A Rapid Sterility Testing MethodДокумент32 страницыScanRDI Suitability of ScanRDI As A Rapid Sterility Testing MethodSrijan SamantaОценок пока нет

- Portfolio, Program, and Project Management in the Pharmaceutical and Biotechnology IndustriesОт EverandPortfolio, Program, and Project Management in the Pharmaceutical and Biotechnology IndustriesPete HarpumОценок пока нет

- Production of Plasma Proteins for Therapeutic UseОт EverandProduction of Plasma Proteins for Therapeutic UseРейтинг: 3 из 5 звезд3/5 (5)

- People in CleanroomsДокумент13 страницPeople in CleanroomsshdphОценок пока нет

- Container Closure Integrity of Sterile Pharmaceutical Containers - Richard MilletДокумент36 страницContainer Closure Integrity of Sterile Pharmaceutical Containers - Richard MilletmsorianolОценок пока нет

- Cleaning Validation: Acme PharmaceuticalsДокумент43 страницыCleaning Validation: Acme PharmaceuticalsDebashisОценок пока нет

- Statistical Methods for Evaluating Safety in Medical Product DevelopmentОт EverandStatistical Methods for Evaluating Safety in Medical Product DevelopmentA. Lawrence GouldОценок пока нет

- WP GWP Global Weighing Standard en Final 2014Документ32 страницыWP GWP Global Weighing Standard en Final 2014H.AnhОценок пока нет

- Approaching Microbiological Method ValidationДокумент19 страницApproaching Microbiological Method ValidationUjang KarnaОценок пока нет

- 23635.1.5. Application of The F0 Concept To Steam Sterilisation of Aqueou - PDFДокумент1 страница23635.1.5. Application of The F0 Concept To Steam Sterilisation of Aqueou - PDFlilaОценок пока нет

- Yang 2013Документ9 страницYang 2013Tanneru Hemanth KumarОценок пока нет

- A Survey of Cleaning Validation General Principles and Best Practices 2013Документ35 страницA Survey of Cleaning Validation General Principles and Best Practices 2013edgar palominoОценок пока нет

- Water Quality. Sampling. Guidance On Quality Assurance and Quality Control of Environmental Water Sampling and Handling - Libgen - LiДокумент46 страницWater Quality. Sampling. Guidance On Quality Assurance and Quality Control of Environmental Water Sampling and Handling - Libgen - Lilouis bothe100% (1)

- PHSS - Clarity - On - GMP - Guidance - No.2 - Version 2Документ14 страницPHSS - Clarity - On - GMP - Guidance - No.2 - Version 2AkuWilliamsОценок пока нет

- Quality Risk Management PDFДокумент9 страницQuality Risk Management PDFisak23Оценок пока нет

- A Final Floor Show For Bugs (Sandle)Документ4 страницыA Final Floor Show For Bugs (Sandle)Tim Sandle100% (1)

- Comprehensive Quality by Design for Pharmaceutical Product Development and ManufactureОт EverandComprehensive Quality by Design for Pharmaceutical Product Development and ManufactureGintaras V. ReklaitisОценок пока нет

- Continuous Manufacturing of PharmaceuticalsОт EverandContinuous Manufacturing of PharmaceuticalsPeter KleinebuddeОценок пока нет

- An Inside Look at USP71Документ22 страницыAn Inside Look at USP71Dante IulliОценок пока нет

- Basic Guide To Particle Counters and Particle CountigДокумент60 страницBasic Guide To Particle Counters and Particle CountigJoel CunhaОценок пока нет

- Regulatory Aspects of Pharmaceutical Quality System: Brief IntroductionОт EverandRegulatory Aspects of Pharmaceutical Quality System: Brief IntroductionОценок пока нет

- An Introduction To Proteomics: The Protein Complement of The GenomeДокумент40 страницAn Introduction To Proteomics: The Protein Complement of The GenomeJohn Louie BarquerosОценок пока нет

- Compressed Medical Gases PDFДокумент34 страницыCompressed Medical Gases PDFRaúl DonosoОценок пока нет

- Altekar Giacoletti NA17CESEP1 Process Validation Statistical Tool Overvi...Документ31 страницаAltekar Giacoletti NA17CESEP1 Process Validation Statistical Tool Overvi...Haroon RasheedОценок пока нет

- Multicenter Study On Incubation Conditions For Environmental Monitoring and Aseptic Process SimulationДокумент9 страницMulticenter Study On Incubation Conditions For Environmental Monitoring and Aseptic Process SimulationBLUEPRINT Integrated Engineering ServicesОценок пока нет

- Disinfectant QualificationДокумент10 страницDisinfectant QualificationfarОценок пока нет

- Quality Control of Microbiological Culture MediaДокумент7 страницQuality Control of Microbiological Culture Mediamustea_ana9616Оценок пока нет

- Cun Dell Objectionable Microorganism Sept 2015Документ36 страницCun Dell Objectionable Microorganism Sept 2015KuldeepОценок пока нет

- Technology TransferДокумент68 страницTechnology TransferPhúc CaoОценок пока нет

- A History of The OOS ProblemДокумент5 страницA History of The OOS ProblemmcyqcbsacОценок пока нет

- Recovery Factor Determination in Cleaning ValidationДокумент1 страницаRecovery Factor Determination in Cleaning ValidationPrince MoniОценок пока нет

- T309 - Microbiological Quality Control Requirements in An ISO 17025 Laboratory PDFДокумент26 страницT309 - Microbiological Quality Control Requirements in An ISO 17025 Laboratory PDFПламен ЛеновОценок пока нет

- Validation Protocol For Disinfectant Efficacy ValidationДокумент12 страницValidation Protocol For Disinfectant Efficacy ValidationMubarak PatelОценок пока нет

- Settle Plate Exposure Under Unidirectional Airflow and The Effect of Weight Loss Upon Microbial GrowthДокумент6 страницSettle Plate Exposure Under Unidirectional Airflow and The Effect of Weight Loss Upon Microbial GrowthKraken UrОценок пока нет

- Clean Vald Article JEMДокумент7 страницClean Vald Article JEMzer-otakuОценок пока нет

- IPQA A Beginner's GuideДокумент170 страницIPQA A Beginner's GuideGoran MickoОценок пока нет

- USP - 1058 (Original)Документ8 страницUSP - 1058 (Original)michaeljkellyОценок пока нет

- A Guide To ATP Hygiene MonitoringДокумент32 страницыA Guide To ATP Hygiene MonitoringGaganpreet KaurОценок пока нет

- Establishing A CGMP Laboratory Audit System: A Practical GuideОт EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideОценок пока нет

- SPL Lab Report3Документ49 страницSPL Lab Report3nadif hasan purnoОценок пока нет

- Design and Development of Automatic Pneumatic Jack in Four Wheeler Ijariie5374Документ5 страницDesign and Development of Automatic Pneumatic Jack in Four Wheeler Ijariie5374Saravanan ViswakarmaОценок пока нет

- Immigrant Italian Stone CarversДокумент56 страницImmigrant Italian Stone Carversglis7100% (2)

- From Input To Affordance: Social-Interactive Learning From An Ecological Perspective Leo Van Lier Monterey Institute Oflntemational StudiesДокумент15 страницFrom Input To Affordance: Social-Interactive Learning From An Ecological Perspective Leo Van Lier Monterey Institute Oflntemational StudiesKayra MoslemОценок пока нет

- Eldritch HighДокумент39 страницEldritch Highteam_moОценок пока нет

- Gypsum Plasterboard: National Standard of The People'S Republic of ChinaДокумент15 страницGypsum Plasterboard: National Standard of The People'S Republic of ChinaGarry100% (2)

- Electric ScootorДокумент40 страницElectric Scootor01fe19bme079Оценок пока нет

- Kinematics in One DimensionДокумент4 страницыKinematics in One DimensionAldrin VillanuevaОценок пока нет

- Lafarge Interior Building Solutions BrochureДокумент24 страницыLafarge Interior Building Solutions BrochuretwinpixtwinpixОценок пока нет

- 12.5 Collision Theory - ChemistryДокумент15 страниц12.5 Collision Theory - ChemistryAri CleciusОценок пока нет

- Native Data Sheet Asme b73.1Документ4 страницыNative Data Sheet Asme b73.1Akhmad Faruq Alhikami100% (1)

- American BreakfastДокумент4 страницыAmerican BreakfastHamilton Valenzuela ChipongianОценок пока нет

- EXP4 The Diels Alder ReactionsДокумент3 страницыEXP4 The Diels Alder ReactionsLaura GuidoОценок пока нет

- Port Name: Port of BaltimoreДокумент17 страницPort Name: Port of Baltimoremohd1khairul1anuarОценок пока нет

- RACI Matrix Design For Managing Stakeholders in PRДокумент12 страницRACI Matrix Design For Managing Stakeholders in PRRheza Nugraha Prabareswara100% (1)

- JKJKJДокумент3 страницыJKJKJjosecarlosvjОценок пока нет

- Logic NotesДокумент19 страницLogic NotesCielo PulmaОценок пока нет

- EPCC Hydrocarbon Downstream L&T 09.01.2014Документ49 страницEPCC Hydrocarbon Downstream L&T 09.01.2014shyaminannnaОценок пока нет

- BC-6000 Installation Guide V7.0 enДокумент111 страницBC-6000 Installation Guide V7.0 enmentule88Оценок пока нет

- Biophoton RevolutionДокумент3 страницыBiophoton RevolutionVyavasayaha Anita BusicОценок пока нет

- Ali Erdemir: Professional ExperienceДокумент3 страницыAli Erdemir: Professional ExperienceDunkMeОценок пока нет

- Ham Radio Balu N ManualДокумент7 страницHam Radio Balu N Manualcolinbeeforth100% (1)

- Elements of Romanticism in The Poetry of W. B. Yeats: Romantic InfluencesДокумент8 страницElements of Romanticism in The Poetry of W. B. Yeats: Romantic InfluencesSadman Shaid SaadОценок пока нет

- Cross Talk Details and RoutingДокумент29 страницCross Talk Details and RoutingRohith RajОценок пока нет

- ZF-FreedomLine TransmissionДокумент21 страницаZF-FreedomLine TransmissionHerbert M. Zayco100% (1)

- Lesson Plan in Science 9: I. ObjectivesДокумент8 страницLesson Plan in Science 9: I. ObjectivesmarichuОценок пока нет

- H107en 201906 r4 Elcor Elcorplus 20200903 Red1Документ228 страницH107en 201906 r4 Elcor Elcorplus 20200903 Red1mokbelОценок пока нет

- Twilight PrincessДокумент49 страницTwilight PrincessHikari DiegoОценок пока нет

- Straight LineДокумент15 страницStraight LineAyanОценок пока нет

- Food Taste Panel Evaluation Form 2Документ17 страницFood Taste Panel Evaluation Form 2Akshat JainОценок пока нет