Академический Документы

Профессиональный Документы

Культура Документы

M Bow String Girder-10408-9-R PDF

Загружено:

Phanindra MajetiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

M Bow String Girder-10408-9-R PDF

Загружено:

Phanindra MajetiАвторское право:

Доступные форматы

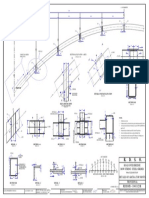

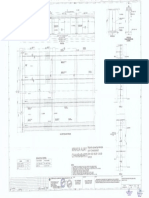

50 690 50

50 690 50 50 690 50 50 690 50

A F G

H

B B B

C C C C

208

208

208

208

D D D D

E E E 50 40 640 40 50

E

820 820 820

820

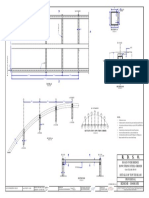

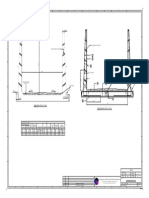

LONG.-GUIDE BEARING ASSEMBLY LGB TRANS.-GUIDE BEARING ASSEMBLY TGB FREE - BEARING ASSEMBLY FB

(SCALE 1:5) (SCALE 1:5) (SCALE 1:5) FREE - BEARING FXB

(SCALE 1:5)

X-SECTIONAL VIEW ACROSS LONGITUDINAL AXIS OF GIRDER (CENTER LINE OF THE GIRDER COINCIDES WITH CENTER LINE OF BEARING SHOWN)

400 3

2+2

STAINLESS STEEL PLATE 20

5

790 6 MM THICK, WELD 3mm

35

358

690 100 100

40

ELEVATION 10

(SCALE 1:7.5)

10

STAINLESS STEEL PLATE

25x3x528, R200

50

3

538

528

WELD 2 MM 400

70

37

STAINLESS STEEL PLATE LEGEND SYMBOL

40 40x3x690, WELD 2mm

40

PTFE SHEET 4.5 MM THICK, HARDENED SURFACE 300 BHN MINIMUM

ELEVATION DIMPLED OR MODULAR, 50 62 597 50

(SCALE 1:7.5) PASTED IN 2.5 MM DEEP RECESS 820

DUST SEAL

10

5

790 ELEVATION POLY TETERA FLUORO ETHYLENE (PTFE)

(SCALE 1:7.5)

50

50 32 40 546 40 32 50 538 HIGH STRENGTH BOLT

VIEW FROM TOP 358

(SCALE 1:7.5)

PISTON BASE

DUST SEAL 10x15 ALLROUND

500 49 400 10 398 SURFACE HARDENED TO

300 BHN MINIMUM

NOTE:

150

35

10

VIEW FROM TOP

45

399 R199.50

PART C: BRASS RINGS 1. All dimensions are in MM.

396

STAINLESS STEEL PLATE 25x3x528, FOR RETAINING NUT

2. The design is in accordance with IRC- 83 (PART-III)-2002.

SURFACE HARDENED TO WELD 2 MM ELASTOMER IN POT 3. The concrete in bed block shall be of min M40 GRADE.

4

ELEVATION

PISTON WALL

300 BHN MINIMUM (NOT TO BE PROVIDED IN FREE BEARING) (SCALE 1:7.5)

4. Bearings shall be provided before concreting of deck slab is taken up.

90

(SCALE 1:7.5)

700

500

300

398 5. Bearings shall be protected during concreting or providing holding down bolts

operations. Any mortar or foreign material contaminating the bearing shall be

KNURLING TOOL OR CHISELLING

32

ROUND WASHER FOR 32 DIA. BOLT

ELEVATION completely removed.

ISOMETRIC THREAD

STAINLESS STEEL PLATE

5

DIA.

MIN EMBEDDED LENGTH 330

(SCALE 1:7.5) 6. Manufacture & finishing of bearings shall be as per para 927.2 & 927.3 of IRC 83

6 MM THK, WELD 3 MM

SURFACE ROUGHENED BY

ALL ROUND Part III

SURFACE HARDENED TO 7. Manufacturing tolerances shall be as per para 927.1 of IRC 83 Part III

150

300 BHN MINIMUM ELASTOMERIC PAD

8. Acceptance of bearing shall be as per para 928 of IRC 83 Part III.

538

9. Material to be used for pot, piston and top plate including all guides, lugs etc shall

be of cast steel to IS 1030:1989 grade 340-570W.

STAINLESS STEEL PLATE 10. All the flame cut, sawn or planed edges of the plates should be machined. All

3

33x3x690 WELD 2 mm sheared corners shall be rounded off with 2 MM radius.

5

50

11. For welding stainless steel sheet, M1 electrode type with stainless steel core wire as

VIEW FROM BOTTOM per IRS: M-28-2012 shall be used.

PART A: TOP PLATE FOR LONG. GUIDE PISTON

358

12. PTFE sheet shall be pure poly tetra fluoro ethylene, and shall be 4.5 mm thick,

(SCALE 1:7.5) having either dimples (hot pressed or moulded) or modules as per IRC 83 Part III.

398

398 ANCHOR BOLT These shall be pasted in recess 2.5 MM deep in the bearing and the peel strength of

3 538 3 (SCALE 1:5) glue to be used shall not be less than 4 N/MM.

13. Material to be used for wiper seal and dust seal shall be of microcellular

VIEW FROM BOTTOM VIEW FROM TOP VIEW FROM TOP polychloroprene rubber or polythene foam & it's adhesion to metal shall be with

PART D: ELASTOMER PART E: POT FOR BEARINGS polychloroprene rubber based adhesive dunlop S-758, dendrite PC-65 or any other

790 PART B: PISTON FOR (SCALE 1:7.5) equivalent brands.

PAD FOR BEARINGS

FREE/SLIDING BEARINGS

30

690 (SCALE 1:7.5) 14. All non-working surfaces shall be given protective coating comprising of 2 coats

(SCALE 1:7.5) of epoxy primer enriched with metallic zinc, one intermediate coat of high build

790 50 690 50 epoxy paint reinforced with mio (micaceous iron oxide) & one coat of high

performance epoxy finish paint as per para 39.2.2 of IRS B1.

50 690 50

50

15. All bearings shall be sent by manufacturer duly set. Marked with center line of

bearing along the girder and across it, along with the shipping mark of the bearing

78

ELEVATION and fitted with transportation clamps. It is prohibited to open transportation clamps

(SCALE 1:7.5) 399 R199.50 before final assembly of the bearing on the girder without the presence of bearing

520 manufacturer representative.

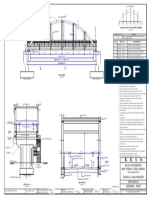

SURFACE HARDENED TO

35

396

50

STAINLESS STEEL PLATE 300 BHN MINIMUM

ELEVATION

50

16. After the girders are properly leveled/ aligned and bearings tied to the girder using

ELEVATION

40

40x3x780 WELD 2mm

Class 8.8 bolts, transportation clamps shall be opened and all expansion type

50

(SCALE 1:7.5)

(SCALE 1:7.5) bearing shall be set properly as per ambient temperature. Thereafter holes in

substructure already provided (shall be drilled at this stage if not already provided),

40 32

SURFACE HARDENED shall be filled with holding down bolts and quickly grouted.

OF BOTTOM LONG. BEAM

5 TO 300 BHN MINIMUM

17. Anchor bolts shall be provided in holes (max. dia 40 MM) made in pier top/

173

5 OF SYMMETRY

150

pedestals.

600

500

150

FIXED BEARING BOTTOM LONG. BEAM LONG. GUIDE BEARING 18. Anchor bolts and nuts shall be hot dip galvanized 100 micron thick, as per IS:

4759.

BOTTOM CROSS BEAM

300

700

R. D. S. O.

345

500

546

790

300

700

12000

STAINLESS STEEL PLATE DIRECTION OF TRAFFIC ROAD OVER BRIDGE

OF BOTTOM LONG. BEAM

6 MM THICK, WELD 3 MM

150

5 ALL ROUND BOW STRING STEEL GIRDER

150

PISTON

173

42m CLEAR SPAN

32 40

50

50

WELD 2 MM ALL ROUND

3

50 690 50

50

50 690 50 44000

790

DETAILS OF PTFE POT BEARING

600

50 690 50 790 TRANS. GUIDE BEARING FREE BEARING

790

VIEW FROM BOTTOM VIEW FROM BOTTOM ARRANGEMENT OF POT PTFE BEARINGS

PART G: TOP PLATE FOR PART H: PISTON FOR FIXED (SCALE 1:200) PROVISIONAL

VIEW FROM BOTTOM

BEARING

PART F: TOP PLATE FOR TRANSVERSE GUIDE

(SCALE 1:7.5)

FREE BEARING

(SCALE 1:7.5)

(SCALE 1:7.5) (PAPER SIZE A1) RDSO/B - 10408/9/R

DRAWN BY: M/S Abhinav Associates DESIGNED BY: SCRUTINIZED & CHECKED BY: APPROVED BY:

"THIS DRAWING IS THE PROPERTY OF RESEARCH DESIGN AND STANDARD ORGANIZATION ( MINISTRY

CALCULATION REGISTER NO. DD/2014/9 AutoCAD FILE NO.: B-10408 OF RAILWAY ), LUCKNOW-226011, INDIA, AND SHALL NOT BE USED, COPIED OR REPRODUCED IN PART

CHECKED BY: V.K.PANDEY (SSE) VIVEK KUMAR (XEN/NCR/B&S/RDSO) SRIJAN TRIPATHI (DBS /SB-I) A. K. DADARYA (EDBS) OR WHOLE, WITHOUT PRIOR CONSENT IN WRITING."

Вам также может понравиться

- Joint Details of Bridge StructureДокумент1 страницаJoint Details of Bridge StructurePhanindra MajetiОценок пока нет

- 42 M Bow String Girder-10408-8-R1 PDFДокумент1 страница42 M Bow String Girder-10408-8-R1 PDFPhanindra MajetiОценок пока нет

- 42 M Bow String Girder-10408-3-R PDFДокумент1 страница42 M Bow String Girder-10408-3-R PDFPhanindra MajetiОценок пока нет

- 42 M Bow String Girder-10408-2-R PDFДокумент1 страница42 M Bow String Girder-10408-2-R PDFPhanindra MajetiОценок пока нет

- 42 M Bow String Girder-10408-R PDFДокумент1 страница42 M Bow String Girder-10408-R PDFPhanindra MajetiОценок пока нет

- 42 M Bow String Girder-10408-1-RДокумент1 страница42 M Bow String Girder-10408-1-RPhanindra MajetiОценок пока нет

- 60 M.bow String Girder-10411-4-RДокумент1 страница60 M.bow String Girder-10411-4-RkesharinareshОценок пока нет

- 60 M.bow String Girder-10411-RДокумент1 страница60 M.bow String Girder-10411-Rkesharinaresh80% (5)

- 30 M Bow String Girder-10409-7rДокумент1 страница30 M Bow String Girder-10409-7rprejithОценок пока нет

- 42 M Bow String Girder-10408-7-R PDFДокумент1 страница42 M Bow String Girder-10408-7-R PDFPhanindra MajetiОценок пока нет

- Rdso B-11753 5R1Документ1 страницаRdso B-11753 5R1shibnath lahiriОценок пока нет

- R. D. S. O.: Rdso/b - 10408/6Документ1 страницаR. D. S. O.: Rdso/b - 10408/6MUTHU PANDIОценок пока нет

- Key elevation of bow string girderДокумент1 страницаKey elevation of bow string girdergoutammand100% (1)

- 54 M.bow String Girder-10410-9Документ1 страница54 M.bow String Girder-10410-9SANJEEV VERMAОценок пока нет

- 36m BowString PDFДокумент1 страница36m BowString PDFgoutammand100% (2)

- Link Road DRGSДокумент8 страницLink Road DRGSBasava Sowmya100% (2)

- Rdso Bow String Girder-10411-9Документ1 страницаRdso Bow String Girder-10411-9a Rawat100% (1)

- 60 M.bow String Girder-10411-7-RДокумент1 страница60 M.bow String Girder-10411-7-RkesharinareshОценок пока нет

- 60 M.bow String Girder 10411 1 RДокумент1 страница60 M.bow String Girder 10411 1 RkesharinareshОценок пока нет

- 42m BowStringДокумент1 страница42m BowStringsorowareОценок пока нет

- Bow-String Girder - Design & Construction AspectsДокумент12 страницBow-String Girder - Design & Construction Aspectsepcepcepc100% (1)

- 60 M.bow String Girder-10411-5-RДокумент1 страница60 M.bow String Girder-10411-5-RkesharinareshОценок пока нет

- RDSO B 11754 4R1 (Mod)Документ1 страницаRDSO B 11754 4R1 (Mod)shibnath lahiriОценок пока нет

- Package V bridge drawingsДокумент67 страницPackage V bridge drawingsMandeep Singh100% (1)

- All RDSO Bow String Girder of Span 60-72 MДокумент9 страницAll RDSO Bow String Girder of Span 60-72 MAjay Sinha60% (5)

- RDSO Guidelines On Seismic Design of Railway Bridges PDFДокумент95 страницRDSO Guidelines On Seismic Design of Railway Bridges PDFSreeraja Sreevilasan57% (7)

- Well Tilt and Shift-Bangraghat1Документ3 страницыWell Tilt and Shift-Bangraghat1ShaileshRastogiОценок пока нет

- PSC Standard Drawing PDFДокумент45 страницPSC Standard Drawing PDFSajib100% (1)

- Commentary With Worked Examples FOR IRC:6-2017: Indian Association of Structural EngineersДокумент3 страницыCommentary With Worked Examples FOR IRC:6-2017: Indian Association of Structural EngineersNarayanan Jayachandran100% (3)

- Handouts - Refresher Course of IRC:SP:114Документ103 страницыHandouts - Refresher Course of IRC:SP:114Gaurav GhaiОценок пока нет

- 1.0 Bearing-38.973 (Skew)Документ37 страниц1.0 Bearing-38.973 (Skew)vinoraamОценок пока нет

- 60 M.bow String Girder 10411 3 RДокумент1 страница60 M.bow String Girder 10411 3 RkesharinareshОценок пока нет

- Bow String Girder QuantityДокумент3 страницыBow String Girder Quantityvsballa25% (4)

- Extradosed Cable Stayed Bridge Design in BSДокумент111 страницExtradosed Cable Stayed Bridge Design in BSSANDIPОценок пока нет

- DN-101A-Design of Friction Slab-R1Документ4 страницыDN-101A-Design of Friction Slab-R1jithinОценок пока нет

- Design of PSC Box 45.0 M Span PDFДокумент89 страницDesign of PSC Box 45.0 M Span PDFsiddharth yadavОценок пока нет

- PipeДокумент30 страницPipepudumai100% (1)

- Calculate spherical bearing loadsДокумент5 страницCalculate spherical bearing loadsSHARATH VASUPRADA100% (1)

- DESIGN OF PIER CAPДокумент13 страницDESIGN OF PIER CAPRohit VermaОценок пока нет

- IRC Amendments - 2017 - 2020 PDFДокумент156 страницIRC Amendments - 2017 - 2020 PDFNilay Gandhi100% (1)

- 60 M.bow String Girder 10411 2 RДокумент1 страница60 M.bow String Girder 10411 2 Rkesharinaresh100% (1)

- Construction of Road Over Bridge in Manduadih yardДокумент21 страницаConstruction of Road Over Bridge in Manduadih yardkesharinaresh100% (1)

- IRC - SP Well Foundation by Balwant Rao PDFДокумент133 страницыIRC - SP Well Foundation by Balwant Rao PDFAnoopОценок пока нет

- Amendment To IRC 24 - 2010Документ6 страницAmendment To IRC 24 - 2010mrraee4729100% (1)

- RDSO Drawing ListДокумент42 страницыRDSO Drawing Listkaushik96040% (5)

- RoB Cost Estimates For Alt - 1, 63m Bowstringer GirderДокумент10 страницRoB Cost Estimates For Alt - 1, 63m Bowstringer GirderHegdeVenugopal100% (1)

- Typical Design Calculations of PierДокумент40 страницTypical Design Calculations of PierAjayvidyanand Sharma100% (1)

- 36m BowString PDFДокумент1 страница36m BowString PDFD SRINIVASОценок пока нет

- M Bow String Girder-10409-9Документ1 страницаM Bow String Girder-10409-9prejithОценок пока нет

- StaaloverzichtДокумент1 страницаStaaloverzichtKoreji WaОценок пока нет

- 1077mmx1087 5mmx50mmДокумент1 страница1077mmx1087 5mmx50mmmajidhaghpanahfbcОценок пока нет

- IE02 INSTALACIONES ELECTRICASДокумент1 страницаIE02 INSTALACIONES ELECTRICASmarcelo.uculmana.rosasОценок пока нет

- Scci - Udh Baguio Topographic Map - 092321Документ1 страницаScci - Udh Baguio Topographic Map - 092321Staff05 GMTSОценок пока нет

- ChederRib PDFДокумент1 страницаChederRib PDFZaharia NicuОценок пока нет

- " '!I OLT, - I I: HingeДокумент1 страница" '!I OLT, - I I: HingeFarhani YaakonОценок пока нет

- Midterm Examination: Ce 322 - Building Systems DesignДокумент5 страницMidterm Examination: Ce 322 - Building Systems DesignJEAN KATHLEEN SORIANOОценок пока нет

- KLINIK DOKTER ANAK MAJENANG Rev 4Документ26 страницKLINIK DOKTER ANAK MAJENANG Rev 4Ilyas MОценок пока нет

- Ground Floor Plan: Fire Exit Stair (See Attached File For Details)Документ1 страницаGround Floor Plan: Fire Exit Stair (See Attached File For Details)Mark Kristoffer HilarionОценок пока нет

- 86500dy000 01 86500dy00001 1Документ1 страница86500dy000 01 86500dy00001 1khanОценок пока нет

- Chassis TA41-40026AДокумент2 страницыChassis TA41-40026ARodrymix SoriaОценок пока нет

- AppcancelДокумент1 страницаAppcancelPhanindra MajetiОценок пока нет

- Reinforcement details of abutment capДокумент1 страницаReinforcement details of abutment capPhanindra MajetiОценок пока нет

- U - TYPE-Layout1 WITH SIGNATUREДокумент1 страницаU - TYPE-Layout1 WITH SIGNATUREPhanindra MajetiОценок пока нет

- U - TYPE-Layout1 WITH SIGNATUREДокумент1 страницаU - TYPE-Layout1 WITH SIGNATUREPhanindra MajetiОценок пока нет

- Q EBNNAw ZIk Nhee DEДокумент2 страницыQ EBNNAw ZIk Nhee DEPhanindra MajetiОценок пока нет

- Scan 963Документ1 страницаScan 963Phanindra MajetiОценок пока нет

- Screenshot 2021-05-31 at 11.42.00 AMДокумент64 страницыScreenshot 2021-05-31 at 11.42.00 AMPhanindra MajetiОценок пока нет

- Bs 110 (R) With A&c Guidelines For Fabrication of Steel Girder Procedure March 16Документ57 страницBs 110 (R) With A&c Guidelines For Fabrication of Steel Girder Procedure March 16Vvs RayuduОценок пока нет

- Office of The: South East Central Railway Chief Engineer (Con) DДокумент2 страницыOffice of The: South East Central Railway Chief Engineer (Con) DPhanindra MajetiОценок пока нет

- Notes:-: Section A-A Section B-B Section C-CДокумент1 страницаNotes:-: Section A-A Section B-B Section C-CPhanindra MajetiОценок пока нет

- Is 2911 1 4 2010Документ30 страницIs 2911 1 4 2010Tanvir0801094Оценок пока нет

- 42 M Bow String Girder-10408-7-R PDFДокумент1 страница42 M Bow String Girder-10408-7-R PDFPhanindra MajetiОценок пока нет

- 42 M Bow String Girder-10408-4-R PDFДокумент1 страница42 M Bow String Girder-10408-4-R PDFPhanindra MajetiОценок пока нет

- 42 M Bow String Girder-10408-6-R PDFДокумент1 страница42 M Bow String Girder-10408-6-R PDFPhanindra MajetiОценок пока нет

- Storm Water DesignДокумент1 страницаStorm Water DesignPhanindra MajetiОценок пока нет

- 42 M Bow String Girder-10408-1-RДокумент1 страница42 M Bow String Girder-10408-1-RPhanindra MajetiОценок пока нет

- 1x3 5x1 5Документ1 172 страницы1x3 5x1 5Phanindra MajetiОценок пока нет

- Gate2012 2100672Документ5 страницGate2012 2100672Jasmit GuptaОценок пока нет

- Rubber MoldingДокумент33 страницыRubber MoldingFurqan AlamОценок пока нет

- Bearing Pad - 2007Документ4 страницыBearing Pad - 2007Kumar JbsОценок пока нет

- IronwearCatalog Edit PDFДокумент113 страницIronwearCatalog Edit PDFAnonymous f945oLJОценок пока нет

- Compressor Explosion!: Updated!Документ3 страницыCompressor Explosion!: Updated!aisman8100% (1)

- 3.1 Catalog - RubbertechДокумент3 страницы3.1 Catalog - RubbertechSajad PkОценок пока нет

- Siemens Cable Catalogue Australia v2Документ276 страницSiemens Cable Catalogue Australia v2jaimeОценок пока нет

- 5 ElastomersДокумент74 страницы5 ElastomersZeel PatelОценок пока нет

- Control Solution: Technical BrochureДокумент32 страницыControl Solution: Technical BrochurestarkingrefrigerationОценок пока нет

- Use of Unbonded Caps in Determination of Compressive Strength of Hardened Concrete CylindersДокумент5 страницUse of Unbonded Caps in Determination of Compressive Strength of Hardened Concrete CylindersqsegaqgОценок пока нет

- Cable AbbreviationДокумент3 страницыCable Abbreviationدهلن سامتОценок пока нет

- SECTION 07910 Preformed Joint Seals Rev 0Документ16 страницSECTION 07910 Preformed Joint Seals Rev 0Azhar AliОценок пока нет

- 015 Chloroprene RubberДокумент5 страниц015 Chloroprene RubberanbuchelvanОценок пока нет

- Hartalega SDN BHD - PNB 40203 Strategic ManagementДокумент54 страницыHartalega SDN BHD - PNB 40203 Strategic ManagementAfiqah Marshall100% (4)

- Sundow Polymers Co., LTD.: Surpren SN232Документ2 страницыSundow Polymers Co., LTD.: Surpren SN232Phuong The NguyenОценок пока нет

- Polychloroprene ContДокумент10 страницPolychloroprene ContGilberto Monteiro100% (1)

- Gloves - EurekaДокумент2 страницыGloves - EurekaPeter DavidsonОценок пока нет

- Hvac Catalogue 201710 25 (3.8 MB)Документ20 страницHvac Catalogue 201710 25 (3.8 MB)AMEENОценок пока нет

- Vax Catalog 2012Документ36 страницVax Catalog 2012Kean Kin PhangОценок пока нет

- Elastomer For Heavy Engineering ApplicationsДокумент23 страницыElastomer For Heavy Engineering Applicationsalwil144548Оценок пока нет

- MAXGRIPДокумент1 страницаMAXGRIPjchessaОценок пока нет

- Engd2051 - Group Assignment v2.0Документ27 страницEngd2051 - Group Assignment v2.0LegendaryNОценок пока нет

- Expansion Joint PSДокумент2 страницыExpansion Joint PSYoga SaputraОценок пока нет

- Freyssinet Bearings (Presentation)Документ16 страницFreyssinet Bearings (Presentation)VCОценок пока нет

- Acoustic Room Treatment Technical SpecsДокумент5 страницAcoustic Room Treatment Technical Specsmazumdar_satyajitОценок пока нет

- NeopreneДокумент48 страницNeoprenest_calvoОценок пока нет

- Entrepreneurship Business Plan Format GuideДокумент11 страницEntrepreneurship Business Plan Format GuideJovelyn MagnayeОценок пока нет

- Type C: Banded Elastomeric BearingsДокумент4 страницыType C: Banded Elastomeric Bearingsflorin_iacob2001Оценок пока нет

- WARCO BILTRITE Rubber Products Catalog PDFДокумент39 страницWARCO BILTRITE Rubber Products Catalog PDFsurjeetsandhuria4481Оценок пока нет

- D3542-08 (2013) Standard Specification For Preformed Polychloroprene Elastomeric Joint Seals For BridgesДокумент4 страницыD3542-08 (2013) Standard Specification For Preformed Polychloroprene Elastomeric Joint Seals For BridgesAlabbas FadhelОценок пока нет

- 2009 Remington ClothingДокумент24 страницы2009 Remington ClothingAmmoLand Shooting Sports NewsОценок пока нет