Академический Документы

Профессиональный Документы

Культура Документы

Renderoc HSXtra

Загружено:

Mansoor AliИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Renderoc HSXtra

Загружено:

Mansoor AliАвторское право:

Доступные форматы

Fosroc Renderoc HSXtra constructive solutions

Shrinkage controlled, polymer modified, cementitious, Properties

high specification repair mortar system

The following typical results were obtained at a water to

Uses powder ratio of 0.18.

Renderoc HSXtra is suitable for hand and spray application Test method Typical result

for repairs where high load bearing is required. Typical ap- Drying shrinkage to ASTM C 157-93

plications would include, but not be limited to, the following: 7 days : < 300 microstrain

28 days : < 500 microstrain

Vertical and overhead repairs to restore ‘covercrete’

Permeability : < 5 mm

General concrete and masonry repairs (DIN 1048 Part 5)

Flexural strength : > 13 N/mm2 at 28 days

Voids greater than 10 mm deep

(BS EN 196-1)

Repairs to honeycombing Tensile strength : > 6 N/mm at 28 days

(BS 6319 Pt. 7)

Larger scale repairs where formwork cannot be erected

Compressive strength : Tolerance (±10%)

(BS EN 196-1) : 60 N/mm2 at 7 days

Advantages

80 N/mm2 at 28 days

Renderoc HSXtra features Dimensional Stability Technol- Water absorption : < 2%

ogy - a new materials technology which controls the rate of (BS 1881 Pt. 121)

drying shrinkage such that, when used correctly : Rapid chloride permeability : < 500 columbs

(ASTM C1202)

i. the dimensions of the repair remain stable; and thus

ii. eliminating failure, due to shrinkage cracking.

Design criteria

This in turn leads to a series of associated benefits :

Dimensional Stability Technology is a major step forward

Cost effective - shrinkage control enables repairs to be

in the general compatibility of repair mortar systems with the

completed ‘right first time’

host concrete, and the control of shrinkage in particular.

Enhanced durability - works in tandem with extremely

Attention to the basic design criteria given below should

low permeability to prolong effective working life

ensure that the full benefits of this technology are gained in

Compatibility - aligns performance closer than ever use :

before, to that of host concrete

(i) Recommended limits for a single application are:

User friendly - specifically developed to provide an easy- Minimum applied thickness : 10 mm

to-apply product, suitable for local conditions Overhead sections : up to 50 mm thick

Definable performance - positive benefits are easily Vertical sections : up to 75 mm thick

demonstrated via a single, simple measurement Small pockets or horizontal : up to 100 mm thick

Maximum length : up to 3 m

Description

NOTE : If the repair area exceeds 2.5 m2, consideration

Renderoc HSXtra is supplied as a ready to use blend of dry should be given to the use of mass fill by means

powders, which requires only the addition of clean water to of either Renderoc SPXtra*† spray applied mortar

produce a highly consistent, repair mortar suitable for struc- or Renderoc LAXtra*† microconcrete.

tural concrete and masonry repairs. Renderoc HSXtra may (ii) In situations where a substrate/repair barrier is required,

be hand applied or sprayed with suitable equipment, please or enhanced bond strength/working time is required, or

see application method statement for details. where the substrate is likely to be permanently wet or

“Renderoc HSXtra Complies with ASTM E84 for flame damp (e.g. seawalls, quays etc.), Nitobond EP*† epoxy

spread index (FSI) and smoke development index (SDI): bonding agent should be used.

Renderoc HSXtra

Class A” (iii) Water addition = 4.5 litres per 25 kg bag

Under no circumstances should part bags be used or

additional water be employed. Either of these two actions

will adversely affect material performance.

Fosroc Renderoc HSXtra

Instructions for use Storage

Renderoc HSXtra should only be mixed and applied in strict Shelf life

accordance with the Product Method Statement, a copy of

Renderoc HSXtra has a shelf life of 12 months; if kept in a

which may be obtained from your nearest Fosroc office.

dry environment, in its original, unopened packing. If stored

in conditions of high humidity and/or temperature, the shelf

Estimating

life will be reduced.

Supply

Standards compliance

Renderoc HSXtra : 25 kg bags

Renderoc HSXtra repair mortar system complies with the

Yield

following international standards :

Renderoc HSXtra : 13.4 litresper 25 kg bag

ASTM C157-93 : Test for drying shrinkage

DIN 1048 Pt. 5 : Test for permeability

Limitations

BS 1881 Pt. 121 : Test for water absorption

- Renderoc HSXtra should not be used when the ambient

temperature is below 5ºC and falling. Precautions

- Renderoc HSXtra should not be part mixed, nor part bags Health and safety

used.

Renderoc HSXtra contains cement powders which, when

- Renderoc HSXtra should not be exposed to running wa- mixed with water or upon becoming damp, release alkalis

ter either during application or prior to final set. which can be harmful to the skin.

During use, avoid inhalation of the dust and contact with the

skin or eyes. Wear suitable protective clothing - eye protec-

tion, gloves and respiratory equipment (particularly in

confined spaces).

The use of barrier creams to provide additional skin protec-

tion is also advised. In case of contact with the skin, rinse

with plenty of clean water, then cleanse thoroughly with soap

“Refer to www.tbwcert.com for validity and full documentation” and water.

In case of contact with eyes, rinse immediately with plenty of

clean water and seek medical advice. If swallowed seek

medical attention immediately - do not induce vomiting.

Fire

Renderoc HSXtra, is non-flammable and thus presents no

fire hazard.

For further information, please refer to the Product Material

Safety Data Sheet for Renderoc HSXtra.

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions for the Supply of

Goods and Service. All Fosroc datasheets are updated on a regular basis. It is the user’s responsibility to obtain the latest version.

Head Office

telephone: (+9714) 2039699 fax: (+9714) 2859649 email: agf@fosroc.com

Al Gurg Fosroc LLC

Regional offices

Post Box 657, Dubai Abu Dhabi, Al Gurg Fosroc telephone: 673 1779 fax: 673 1449 email: abudhabi@fosroc.com

Bahrain, YBA Kanoo telephone: 17738200 fax: 17732828 email: bahrain@fosroc.com

United Arab Emirates Kuwait, Boodai telephone: 4817618 fax: 4832124 email: kuwait@fosroc.com

Oman, Al Amana telephone: 24815080 fax: 24817554 email: oman@fosroc.com

www.fosroc.com

UAE/0370/18/J

Вам также может понравиться

- African Traditional Medicine A PrimerДокумент5 страницAfrican Traditional Medicine A PrimerEditor IJTSRDОценок пока нет

- UltraTech Powergrout NS2Документ2 страницыUltraTech Powergrout NS2Savalia HardikОценок пока нет

- FR9500400 6ltaa9.5 G3 A303Документ5 страницFR9500400 6ltaa9.5 G3 A303Franyusmid Gomez BolivarОценок пока нет

- Methods of Testing Glassfibre Reinforced Concrete (GRC) MaterialДокумент20 страницMethods of Testing Glassfibre Reinforced Concrete (GRC) Materialwanksta67Оценок пока нет

- Avm Imnr70 17aДокумент2 страницыAvm Imnr70 17aRani HendrikusОценок пока нет

- Siremobil Compact MaintenanceДокумент22 страницыSiremobil Compact MaintenanceRafael Tejeda100% (1)

- Matter and Change 2008 Chapter 14Документ40 страницMatter and Change 2008 Chapter 14cattmy100% (1)

- Standard Specs For Racquetball Court Construction Rev 09Документ9 страницStandard Specs For Racquetball Court Construction Rev 09matador2013Оценок пока нет

- Technical Advisory T 5040Документ13 страницTechnical Advisory T 5040Tim_C100% (1)

- DIN EN 1504-4 - 2005-02eДокумент27 страницDIN EN 1504-4 - 2005-02eDumitru100% (1)

- Chan vs. ChanДокумент2 страницыChan vs. ChanMmm GggОценок пока нет

- Brosura Oxyhelp PDFДокумент12 страницBrosura Oxyhelp PDFAftab Naseem100% (1)

- Chapter 2 - Alkanes PDFДокумент54 страницыChapter 2 - Alkanes PDFSITI NUR ALISSA BINTI AHMAD RASMANОценок пока нет

- Box Culvert Joint SealantДокумент6 страницBox Culvert Joint SealantgemotorresОценок пока нет

- Leadership Roles and Management Functions in Nursing Theory and ApplicationДокумент2 страницыLeadership Roles and Management Functions in Nursing Theory and Applicationivan0% (3)

- Wound Dressing ChecklistДокумент3 страницыWound Dressing ChecklistBUAHIN JANNA100% (1)

- Renderoc LAXtraДокумент2 страницыRenderoc LAXtraMansoor Ali100% (1)

- Conbextra atДокумент4 страницыConbextra atsathishbe5Оценок пока нет

- KDIGO 2023 CKD Guideline Public Review Draft 5 July 2023Документ339 страницKDIGO 2023 CKD Guideline Public Review Draft 5 July 2023oscar coreaОценок пока нет

- Chapter 8Документ12 страницChapter 8gilbert850507Оценок пока нет

- Cmci Cmci: CEMTEC 227 P.UДокумент2 страницыCmci Cmci: CEMTEC 227 P.Upravi3434Оценок пока нет

- Arabic XPS Data SheetДокумент1 страницаArabic XPS Data SheetmelsabaeОценок пока нет

- Conmix LTD.: Ultimate Sparkling Finish..Документ2 страницыConmix LTD.: Ultimate Sparkling Finish..Shaik QutubuddinОценок пока нет

- 3M Fiber BrochureДокумент6 страниц3M Fiber Brochuremujahaddad100% (1)

- TDS - Bronco Cemgrout SP75Документ4 страницыTDS - Bronco Cemgrout SP75Jignessh JoshiОценок пока нет

- Circular Precastconcrete Manholes PDFДокумент13 страницCircular Precastconcrete Manholes PDFBalaji NaikОценок пока нет

- Benefits From The Use of Standard Prefabricated Building Components IncludeДокумент3 страницыBenefits From The Use of Standard Prefabricated Building Components Includeप्रणव कडूОценок пока нет

- Sika Carbodur Plate PdsДокумент6 страницSika Carbodur Plate PdsJesieca SiemaОценок пока нет

- Effect of Waterproofing (Admixture) On ConcreteДокумент5 страницEffect of Waterproofing (Admixture) On ConcreteInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Vibropipe CatalougeДокумент4 страницыVibropipe CatalougeRavishankar GowdaОценок пока нет

- PDS Sika AnchorFix SДокумент6 страницPDS Sika AnchorFix SdostjanОценок пока нет

- Conplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsДокумент2 страницыConplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsPrasantaОценок пока нет

- Fosroc GeotexДокумент3 страницыFosroc GeotexBalasubramanian AnanthОценок пока нет

- Cold-Formed Steel Flexural Member With Edge Stiffened Holes Behavior, Optimization, and DesignДокумент9 страницCold-Formed Steel Flexural Member With Edge Stiffened Holes Behavior, Optimization, and Designchristos032Оценок пока нет

- Base Concrete Placement: 1. SubgradeДокумент1 страницаBase Concrete Placement: 1. Subgradeapuhapuh_153349Оценок пока нет

- TCVN 9394Документ4 страницыTCVN 9394Ha HoangОценок пока нет

- Pelecanos L 2014 PHD ThesisДокумент409 страницPelecanos L 2014 PHD ThesisLance Johnpaul SyОценок пока нет

- Deco Heavy Duty Adjustable Anchors Sales SheetsДокумент2 страницыDeco Heavy Duty Adjustable Anchors Sales SheetsPete SwiftОценок пока нет

- Structural ShapesДокумент48 страницStructural ShapesTimbo6808Оценок пока нет

- Concrete&baseplate PDFДокумент18 страницConcrete&baseplate PDFmitimas2003Оценок пока нет

- Steel FiberДокумент1 страницаSteel FiberMustafaMahdiОценок пока нет

- Construction Equipment Management-1Документ4 страницыConstruction Equipment Management-1Tewodros TadesseОценок пока нет

- Material Particulars Unit Quantity Rate AmountДокумент4 страницыMaterial Particulars Unit Quantity Rate Amountsam_bhopОценок пока нет

- Concrete Quality and Homogeneity Evaluation 58 E4900Документ4 страницыConcrete Quality and Homogeneity Evaluation 58 E4900dimitrios25Оценок пока нет

- Case History For Basal Reinforced Platform On A40 Carmarthen Eastern Bypass, Wales (Constucted Sept 1998) (Maccaferri, Rev 02, Nov 2008)Документ2 страницыCase History For Basal Reinforced Platform On A40 Carmarthen Eastern Bypass, Wales (Constucted Sept 1998) (Maccaferri, Rev 02, Nov 2008)sandycastleОценок пока нет

- Masterflex 700 PGДокумент3 страницыMasterflex 700 PGHaresh BhavnaniОценок пока нет

- Conplast SP423Документ2 страницыConplast SP423Tori SmallОценок пока нет

- Softscaping Methodology - PHILAM PolygonДокумент7 страницSoftscaping Methodology - PHILAM PolygonLiselle CustodioОценок пока нет

- Presentation Capital Sealers PDFДокумент87 страницPresentation Capital Sealers PDFENGR SHER MUHAMMADОценок пока нет

- Cementitious-Grout MasterFlow 718Документ2 страницыCementitious-Grout MasterFlow 718Abhi MitraОценок пока нет

- DigivibeMX M30 KitДокумент1 страницаDigivibeMX M30 KitAhmad TalaatОценок пока нет

- Temperature - 1Документ2 страницыTemperature - 1ksshashidharОценок пока нет

- Rolltec Coupler BrochureДокумент4 страницыRolltec Coupler BrochureMohammad Aasimuddin100% (1)

- Hilti Drilling Screw DocumentДокумент8 страницHilti Drilling Screw DocumentGregory Alan Francisco IIОценок пока нет

- Sheet Pile Brochure 2022Документ8 страницSheet Pile Brochure 2022bayzuraОценок пока нет

- Mac GuideДокумент16 страницMac GuideColin SillmanОценок пока нет

- Epoxy Structural Steel Plate BondingДокумент5 страницEpoxy Structural Steel Plate BondingShepherd NhangaОценок пока нет

- Quotation For CG Kerbstone 165 MM PDFДокумент1 страницаQuotation For CG Kerbstone 165 MM PDFGovind GyawaliОценок пока нет

- Hilti HSL-3-GДокумент8 страницHilti HSL-3-GDaniel RabascallОценок пока нет

- Nitoflor BrochureДокумент13 страницNitoflor BrochureMaha MuflehОценок пока нет

- Setseal B - TDSДокумент4 страницыSetseal B - TDShussam jumah100% (1)

- Standard Room Sizes and Room Area - Detailed InformationДокумент9 страницStandard Room Sizes and Room Area - Detailed InformationTATA STEELОценок пока нет

- Final Aac PDFДокумент7 страницFinal Aac PDFindrajit sodhaОценок пока нет

- Building Management System (BMS) OR Building Automation System (BAS)Документ23 страницыBuilding Management System (BMS) OR Building Automation System (BAS)NIRU CHAUDHARYОценок пока нет

- Cement Concrete Tiles and Paving BlocksДокумент8 страницCement Concrete Tiles and Paving BlocksNipan DekaОценок пока нет

- Geomembrane: Geosynthetic Lining Systems For Solids and Liquid ContainmentДокумент4 страницыGeomembrane: Geosynthetic Lining Systems For Solids and Liquid ContainmentErnie ErnieОценок пока нет

- Brushbond RFX PDFДокумент2 страницыBrushbond RFX PDFpiyu114Оценок пока нет

- TDS Conbextra EP10M IndiaДокумент2 страницыTDS Conbextra EP10M Indiasyed AffanОценок пока нет

- Fosroc Renderoc Hsxtra: Constructive SolutionsДокумент2 страницыFosroc Renderoc Hsxtra: Constructive Solutionsanon_550534553Оценок пока нет

- Civil Engineering Standard Data - 2Документ2 страницыCivil Engineering Standard Data - 2talatzahoorОценок пока нет

- 07Документ8 страниц07Mansoor Ali0% (1)

- 02 (2) Dubai-Traffic Control Device ManualДокумент7 страниц02 (2) Dubai-Traffic Control Device ManualMansoor AliОценок пока нет

- Renderoc TGXTRAДокумент2 страницыRenderoc TGXTRAMansoor AliОценок пока нет

- Dubai-Traffic Control Device ManualДокумент3 страницыDubai-Traffic Control Device ManualMansoor Ali50% (2)

- Interview Preparation UAEДокумент136 страницInterview Preparation UAEMansoor AliОценок пока нет

- 01 (2) Dubai-Traffic Control Device ManualДокумент3 страницы01 (2) Dubai-Traffic Control Device ManualMansoor AliОценок пока нет

- Renderoc SXtraДокумент2 страницыRenderoc SXtraMansoor AliОценок пока нет

- Renderoc PlugДокумент2 страницыRenderoc PlugMansoor AliОценок пока нет

- Renderoc SPXtraДокумент2 страницыRenderoc SPXtraMansoor AliОценок пока нет

- Nitomortar TSДокумент2 страницыNitomortar TSMansoor AliОценок пока нет

- Renderoc TGДокумент2 страницыRenderoc TGMansoor Ali50% (2)

- Renderoc RSXtraДокумент4 страницыRenderoc RSXtraMansoor AliОценок пока нет

- Renderoc La80Документ2 страницыRenderoc La80Mansoor Ali0% (1)

- Renderoc SДокумент2 страницыRenderoc SMansoor AliОценок пока нет

- Renderoc BF2Документ2 страницыRenderoc BF2MOHAMED.NOUSAR100% (1)

- Renderoc LAДокумент2 страницыRenderoc LAMansoor AliОценок пока нет

- Renderoc LAXtra PlusДокумент2 страницыRenderoc LAXtra PlusMansoor AliОценок пока нет

- Renderoc HSДокумент2 страницыRenderoc HSMansoor AliОценок пока нет

- Renderoc FCДокумент4 страницыRenderoc FCMansoor AliОценок пока нет

- Renderoc LA55Документ2 страницыRenderoc LA55Mansoor AliОценок пока нет

- Renderoc FCXtraДокумент4 страницыRenderoc FCXtraMansoor AliОценок пока нет

- Nitomortar FCДокумент2 страницыNitomortar FCMansoor AliОценок пока нет

- Nitowrap FRCДокумент2 страницыNitowrap FRCMansoor AliОценок пока нет

- Renderoc BFДокумент2 страницыRenderoc BFMansoor AliОценок пока нет

- Nitomortar SДокумент4 страницыNitomortar SMansoor AliОценок пока нет

- Nitomortar FCFSДокумент2 страницыNitomortar FCFSMansoor AliОценок пока нет

- Nitomortar MHДокумент4 страницыNitomortar MHMansoor AliОценок пока нет

- Nitoplate CP - Formerly Known Nitoplate CP StripsДокумент3 страницыNitoplate CP - Formerly Known Nitoplate CP StripsMansoor AliОценок пока нет

- Nitomortar HBДокумент4 страницыNitomortar HBMansoor AliОценок пока нет

- The Zombie in The Brain and The Woman Who Died LaughingДокумент40 страницThe Zombie in The Brain and The Woman Who Died Laughingcory_ruda100% (1)

- Modeling, Control and Simulation of A Chain Link Statcom in Emtp-RvДокумент8 страницModeling, Control and Simulation of A Chain Link Statcom in Emtp-RvBožidar Filipović-GrčićОценок пока нет

- Introduction To Destructive & Nondestructive TestingДокумент38 страницIntroduction To Destructive & Nondestructive Testingshubham sinhaОценок пока нет

- Ansi Asa S3.22 - 2014Документ54 страницыAnsi Asa S3.22 - 20147620383tlОценок пока нет

- Peritoneal Dialysis Unit Renal Department SGH PD WPI 097 Workplace InstructionДокумент10 страницPeritoneal Dialysis Unit Renal Department SGH PD WPI 097 Workplace InstructionAjeng SuparwiОценок пока нет

- Eliasmith2012-Large-scale Model of The BrainДокумент5 страницEliasmith2012-Large-scale Model of The Brainiulia andreeaОценок пока нет

- Respirator LangmanДокумент10 страницRespirator LangmanSavu MalinaОценок пока нет

- GST15!16!17-Bad Debt Relief RecoverДокумент10 страницGST15!16!17-Bad Debt Relief RecoverDaud Farook IIОценок пока нет

- Cat 4401 UkДокумент198 страницCat 4401 UkJuan Ignacio Sanchez DiazОценок пока нет

- TableBookErrata PDFДокумент4 страницыTableBookErrata PDFIbnuyusoff77Оценок пока нет

- Implementation Plan SLRPДокумент6 страницImplementation Plan SLRPAngelina SantosОценок пока нет

- Victron Orion-Tr - Smart - DC-DC - Charger-Manual Non IsolatedДокумент19 страницVictron Orion-Tr - Smart - DC-DC - Charger-Manual Non IsolatedThomist AquinasОценок пока нет

- TOCДокумент14 страницTOCAthirah HattaОценок пока нет

- Unit: 3 - Vouching: by Mahitha VasanthiДокумент15 страницUnit: 3 - Vouching: by Mahitha VasanthianuragОценок пока нет

- Tokyo Fact SheetДокумент17 страницTokyo Fact Sheethoangnguyen2401Оценок пока нет

- To Be or Not To Be Healthy 4144Документ3 страницыTo Be or Not To Be Healthy 4144Vesna Milosavljevic100% (1)

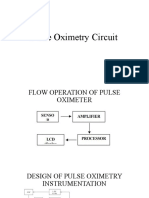

- Pulse Oximetry CircuitДокумент19 страницPulse Oximetry Circuitنواف الجهنيОценок пока нет

- (R#1) XQ-450 - 600-800VДокумент121 страница(R#1) XQ-450 - 600-800VFrancisco PestañoОценок пока нет

- 9ha Power PlantsДокумент2 страницы9ha Power PlantsGaurav DuttaОценок пока нет

- IJARIE Paper 17936 PDFДокумент7 страницIJARIE Paper 17936 PDFArbelyn RoblesОценок пока нет

- Data NX 45-5-1800-4Документ1 страницаData NX 45-5-1800-4BHILLA TORRESОценок пока нет