Академический Документы

Профессиональный Документы

Культура Документы

Successful Solution To The Challenge of Low RPM Bearing Monitoring PDF

Загружено:

DineshОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Successful Solution To The Challenge of Low RPM Bearing Monitoring PDF

Загружено:

DineshАвторское право:

Доступные форматы

ition

conditoring

mon ViB

vibration

Successful Solution

to the Challenge of Low RPM

Tim Sundström

Bearing Monitoring

Above: An SPM HD Spectrum measured on October 29 at 10.84

RPM. The outer race signal is clear, with several harmonics. The

Above: An SPM HD trend spanning between mid-June, 2010 to

amplitude has increased 20 times indicating more severe outer

end of November, 2010, showing 624 readings taken approxi- race damage.

mately 6 hours apart. The graph shows the primary parameter

produced by the SPM HD method: the strongest impact found

during the measuring time. The Y scale is logarithmic.

The difference between the lowest and the highest value in

U

the trend graph is about 30 dB (30 times on a linear scale). The

Low RPM applications have sing the newly developed SPM High Definition

(SPM HD) method, we have been able to reveal drop in the value from 40 dB to 8 dB is after bearing replacement.

been notoriously difficult to never-before-seen details at very low RPMs (< 5 A moving average filter has been applied with 10 average values.

monitor with traditional RPM). The SPM HD method is based on the fact that in This explains why the values seem to decrease slowly after the

the interface between the rolling elements and the race-

vibration-based techniques. ways in an antifriction bearing, elastic, very short dura-

replacement. Note the typical pattern of increasing values fol-

The energy involved at RPMs tion waves are generated. Damage—for example, a spall lowed by a period of decreasing values. This behavior is caused

by fresh spalling followed by a period of mechanical softening of

below 50 is very low, making it or a crack—will generate a high number of elastic waves

due to the metal-to-metal collision when the rolling ele- the sharp edges around the spall. When the rolling elements col-

a difficult task to extract mean- ments pass the damaged area. Using a transducer sen- lide with the sharp edges of the spall, strong elastic waves will be

ingful information from the sitive to these elastic waves makes it possible to record

generated at the point of collision. After some period of time (a Above: On November 6, 2010, a new frequency component be-

and quantify the waves. The transducers should be per-

measured signal. manently installed, either mounted in drilled, counter- couple of weeks in this application) the sharp edges wear down

comes visible in the spectrum, directly corresponding to the

BPFI. The outer race frequency is still there, and the typical 1X

sunk mounting holes on the bearing housings, or glued and the metal-to-metal collisions become less strong, hence modulation of the inner race signal is obvious. This measure-

onto the surface. For best results, the transducers should decreasing the strength of the elastic waves. The next spall will ment is at 10.85 RPM. This behavior of an initial steady increase of

be mounted close to the bearing load zone.

then generate a similar pattern. the outer race signal, followed by a distinct inner race signal, has

been found in several places on this application.

At Holmen Hallsta paper mill in Sweden, a field

test on four twin wire presses (used in the pulp

industry for dewatering purposes) has been running

for nineteen months. During this period, thirteen

bearing faults have been successfully identified.

There are examples from the test period where the

pre-warning time has been over fourteen months

between the first damage indication and replace-

ment of the bearing. A more typical pre-warning

time is about six months. Typical RPM ranges from

7 to 16. The system is taking measurements every 6 hours and a typical Above: An SPM HD Spectrum taken in a very early stage of the

measuring time at this RPM range is about 10 minutes.

bearing deterioration process. The Y scale is linear and 5 harmon-

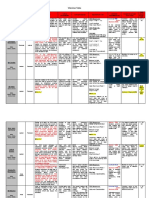

Using a real case example from the twin wire press application, Figure 1 is an account of the different

ics to the BPFO line can be seen. The reading was taken on Au-

stages of the bearing deterioration process, detected with the SPM HD method.

gust 23, 2010 and RPM on this occasion was 9.39. Above: An SPM HD Time signal with extraordinary sharpness.

56 feb/march11 feb/march11 57

The reading was taken on November 12, 2010 and clearly As mentioned earlier, this is but one example from the twin

shows an inner race and an outer race signal in combination. The wire press application. The other twelve cases are similar to this

RPM is 10.84. Note the inner race modulation where the distance one. In most of the cases, the increasing/decreasing trends are

EMPLOYMENT OPPORTUNITY between the “bursts” is exactly 1 revolution. Also note the smaller more pronounced. Based on the twin wire press application as

signals from the outer race. well as other low RPM applications, our experience is that due

VIBRATION ANALYST/INSTRUCTOR

The typical time signal pattern from an inner race damage to the increasing/decreasing trends, measuring with handheld

as seen in this picture is explained by studying a bearing load equipment is not advisable for low RPM applications. There is an

zone. When the inner race damage enters the load zone, it will obvious risk that the measurement was taken during a period

collide with the rolling elements. In the middle of the load zone, where the edges of a possible spall are “soft,” and therefore pro- Disassembled

the forces are strongest, hence producing the strongest impacts.

duce low amplitude impacts. Unless measured very frequently bearing

When the damaged area of the inner race leaves the load zone,

with handheld equipment, we strongly recommend continuous with

the impacts will decrease again. spallings.

measurements using online equipment.

Immediate opening in Charlotte, NC (Relocation required) with The fact that the strongest impacts are not constant in ampli-

Technical Associates for an experienced person to do Vibration tude is an interesting observation. Studying the picture above,

Diagnostics, implement PdM programs and teach Vibration it is clearly seen that the strongest impact from each “burst” ex-

Analysis Seminars (Concentrating on Predictive Maintenance). US Conclusions Tim Sundström, born 1964 in Sweden, has a M.Sc.

Citizenship Required.

hibits a cyclic change. The explanation can be found in bearing degree in Applied Physics and Electrical Engineering

The SPM HD method enables measuring results with excep- from Linköping University, Sweden. For over twenty

geometry. Sometimes, the damaged area, the maximum load

The individual should have extensive Vibration Analysis experience tional clarity. Even on low RPM applications, spectrums and time years, he has been specializing in electronics develop-

on rotating equipment using FFT Analyzers. Good communication zone force, and a rolling element coincide, producing a strong ment and has held managerial positions in the field

skills are a necessity, along with the capability to instruct seminars collision. Sometimes they will not coincide, resulting in a lower signals are crisp. In field tests running for more than nineteen since 1992. In 2001, he joined SPM Instrument as head

for 15 to 25 people. amplitude impact. months, we have been successful in the identification of bearing of Research and Development, where he has been deeply

damages, typically with six months pre-warning time before the involved in SPM HD development and field evaluations.

Opportunity to work with leaders in the Vibration Industry for the

Visit www.spminstrument.com

past 32 years. For confidential consideration, please email resume to actual bearing replacement.

Ron Kretel at rkretel@technicalassociates.net

Technical Associates

347 N. Caswell Road, Charlotte, NC 28204

Phone: (704) 333-9011 • Fax: (704) 333-1728

APPLIED MODAL & ODS ANALYSIS SEMINAR

Technical Associates of Charlotte, P.C.

This 4.5 Day (36 hrs.) course provides a basic

understanding on how to use Experimental Modal

Analysis (EMA) and Operating Deflection Shape

Analysis (ODS). The focus of this entire class is

on Applying these powerful diagnostic tools on

Above: SPM HD Time signal immediately before bearing

real-world machinery and structures.

replacement.

Modal and Operating Deflection Shape Theory:

• How to Construct Meaningful Computer Models

• Choosing Required Numbers of Points & Directions

• Recommended Measurement Setups

• How to Properly Perform ODS & Modal Measurements

• How to Accurately Interpret Computer Model Animations

• How to Confirm What Component is Resonant

• How to Develop Optimum Corrective Actions

• Presentation of Numerous Demos & Class Exercises

• Presentation of Real-World ODS & Modal Case Studies

Hands-On ME’scopeVES Software Training

(Using Our Own Updated “ME’scopeVES Handbook”)

Covers the following ME’scopeVES topics:

• Creating a Structural or Machine Computer Model

• Importing Data From Your Acquisition Instrument

• Modal Analysis Curve Fitting

• Animating & Accurately Interpreting Modal & ODS Computer Models

• Work with Actual Modal/ODS Data

• Structural Dynamics Modification Capability (SDM)

Above: SPM HD Time signal immediately after bearing

replacement.

4 Hour Hands-On Workshop Using ME’scopeVES on Final Class Day

March 28 – April 1, 2011; Charlotte, NC - $1995

Contact Cheryle Benton at cbenton@technicalassociates.net In the two figures above, note the amplitude compared with

Tel: (704) 333-9011 the picture from before bearing replacement. The amplitude dif-

ference between a damaged bearing and a new one is obvious.

58 feb/march11 feb/march11 59

Вам также может понравиться

- Vibration Table: Stick-SlipДокумент4 страницыVibration Table: Stick-SlipGlebОценок пока нет

- B&C Catalogue 2017Документ128 страницB&C Catalogue 2017Luis Bernardo Choque Sallama100% (1)

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresОт EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresРейтинг: 4 из 5 звезд4/5 (1)

- CA2IДокумент12 страницCA2IayjezОценок пока нет

- Note4 PreClass PDFДокумент27 страницNote4 PreClass PDFSimon SiuОценок пока нет

- PHY04Документ1 страницаPHY04ben harrisОценок пока нет

- Drilling Dynamics Sensors Opt BR PDFДокумент16 страницDrilling Dynamics Sensors Opt BR PDFhamed1725Оценок пока нет

- Determination of Molecular Structures by FTIRДокумент40 страницDetermination of Molecular Structures by FTIRMUHAMAD NURUL AIMAN BIN YUNUS / UPMОценок пока нет

- Lecture 3Документ12 страницLecture 3Ayeneshu BОценок пока нет

- Digital Clippers and Compressors Reduce Audible AliasingДокумент6 страницDigital Clippers and Compressors Reduce Audible AliasingJuan Lorenzo Osorio GómezОценок пока нет

- 00-Basic VibrationДокумент91 страница00-Basic VibrationMohamed Al-OdatОценок пока нет

- Magnetic Resonance Sounding SystemsДокумент6 страницMagnetic Resonance Sounding SystemsMatar NdiayeОценок пока нет

- 10 InductionДокумент28 страниц10 InductionRahmaan P AlamОценок пока нет

- PTTN8 OMT ReliableShockPulseEvaluationofAnti-frictionBearingConditionДокумент3 страницыPTTN8 OMT ReliableShockPulseEvaluationofAnti-frictionBearingConditionFélixОценок пока нет

- The Delta-Sigma Modulator: A Circuit For All SeasonsДокумент6 страницThe Delta-Sigma Modulator: A Circuit For All SeasonsSohaib AkhtarОценок пока нет

- Note4 PDFДокумент24 страницыNote4 PDFSimon SiuОценок пока нет

- DBM DBC AptInfo PDFДокумент1 страницаDBM DBC AptInfo PDFRaja Bharath DonthiОценок пока нет

- DBM DBC AptInfo PDFДокумент1 страницаDBM DBC AptInfo PDFagus mulyadiОценок пока нет

- Successful Solution: To The Challenge ofДокумент2 страницыSuccessful Solution: To The Challenge ofKenny RuizОценок пока нет

- Chapter 13 Radiographic TechniqueДокумент9 страницChapter 13 Radiographic TechniqueCziara JustineОценок пока нет

- Anti-Friction - Bearing - Stages - of - FailureДокумент8 страницAnti-Friction - Bearing - Stages - of - FailuresaeedhayatiОценок пока нет

- Forensic Chemistry Suzanne Bell Second EditionДокумент7 страницForensic Chemistry Suzanne Bell Second EditionAntonio CamarilloОценок пока нет

- PDL05 - RangeResolution 2019Документ14 страницPDL05 - RangeResolution 2019Wuri Puspita SariОценок пока нет

- 4.7 Free and Forced VibrationsДокумент20 страниц4.7 Free and Forced Vibrations316126520271 MALIPEDDI JAGADEESWARA RAOОценок пока нет

- Elements QuickstartДокумент2 страницыElements QuickstartGonzalo Navarro GarcíaОценок пока нет

- Doppler Shift ExplainedДокумент4 страницыDoppler Shift Explainedbocko976Оценок пока нет

- Scanning Probe Microscopy TechniquesДокумент62 страницыScanning Probe Microscopy TechniquesAnurag SrivastavaОценок пока нет

- takamoriДокумент9 страницtakamoriRamdani SaputraОценок пока нет

- EP 309: Photonics Chapter 14: Lasers - Laser Oscillation and CharacteristicsДокумент27 страницEP 309: Photonics Chapter 14: Lasers - Laser Oscillation and CharacteristicsMounesh MoniОценок пока нет

- Semiconductor LasersДокумент17 страницSemiconductor LasersazanОценок пока нет

- Shock/Boundary-Layer Interaction Control With Vortex Generators and Passive CavityДокумент6 страницShock/Boundary-Layer Interaction Control With Vortex Generators and Passive CavityRitwick NandiОценок пока нет

- Paper DispersãoДокумент8 страницPaper Dispersãomarcocotta777Оценок пока нет

- Bode Plots: Appendix BДокумент3 страницыBode Plots: Appendix BAnonymous e3XZzQОценок пока нет

- Infrared Spectroscopy:: Fundamentals and Interpretation of Organic CompoundsДокумент75 страницInfrared Spectroscopy:: Fundamentals and Interpretation of Organic CompoundsRajkishor YadavОценок пока нет

- Sunny@OFC3Документ45 страницSunny@OFC3suneelОценок пока нет

- Lecture 6Документ42 страницыLecture 6Martian 07Оценок пока нет

- Seismic Attribute 2009Документ51 страницаSeismic Attribute 2009Mohamed Ibrahim ShihataaОценок пока нет

- High Definition Induction Log (HDIL)Документ10 страницHigh Definition Induction Log (HDIL)Djibril Idé AlphaОценок пока нет

- 4.7 Free and Forced VibrationsДокумент20 страниц4.7 Free and Forced VibrationsHiwetОценок пока нет

- Channel 1Документ18 страницChannel 1parandhamaiahОценок пока нет

- Loudspeaker nonlinearities cause distortion and dc offsetДокумент1 страницаLoudspeaker nonlinearities cause distortion and dc offsetIulianCioarcaОценок пока нет

- Antenna Noise Temperature: - Contributes For T - Natural Sources (Sky Noise)Документ46 страницAntenna Noise Temperature: - Contributes For T - Natural Sources (Sky Noise)shrey saxenaОценок пока нет

- VIBRATION ANALYSIS FUNDAMENTALSДокумент110 страницVIBRATION ANALYSIS FUNDAMENTALSDede Kaladri100% (1)

- Nmo & DmoДокумент29 страницNmo & DmoJessica Julien100% (1)

- EP 309: Photonics Chapter 14: Lasers - Laser Oscillation and CharacteristicsДокумент18 страницEP 309: Photonics Chapter 14: Lasers - Laser Oscillation and CharacteristicsSikander Hayaat BhattiОценок пока нет

- Ds4f06p36u D - (Iu D)Документ1 страницаDs4f06p36u D - (Iu D)Bao Quoc MaiОценок пока нет

- Training-Pertamina Well LoggingДокумент99 страницTraining-Pertamina Well LoggingTarek100% (13)

- Metalense Visible WavelengthДокумент6 страницMetalense Visible WavelengthalvinОценок пока нет

- Presentation 1Документ67 страницPresentation 1Heri YantoОценок пока нет

- VSP - Reporte Final - 59039001000440001 - 854-4405 - 06022019Документ47 страницVSP - Reporte Final - 59039001000440001 - 854-4405 - 06022019Roberto NaranjoОценок пока нет

- Weekly - Report - 09-07-21 - ARUP BHAUMIKДокумент12 страницWeekly - Report - 09-07-21 - ARUP BHAUMIKarupОценок пока нет

- Chladni Figures With FG-ModuleДокумент1 страницаChladni Figures With FG-ModuleJose GalvanОценок пока нет

- CQ Amateur Radio 08-2019Документ116 страницCQ Amateur Radio 08-2019testОценок пока нет

- Applications of Dynamic Range ControlДокумент5 страницApplications of Dynamic Range Controlmailmanager8946Оценок пока нет

- Optical fibers and their key parametersДокумент5 страницOptical fibers and their key parametersFauza KhairОценок пока нет

- T187981 - AvanceCore Lock CouplingДокумент6 страницT187981 - AvanceCore Lock CouplingLaiza Bruzadelle LoureiroОценок пока нет

- PDT-00 2D Survey Processing FlowДокумент2 страницыPDT-00 2D Survey Processing Flowprouserdesigner77Оценок пока нет

- Oscor BlueДокумент6 страницOscor BlueOpiniОценок пока нет

- 71932B SPM HDДокумент12 страниц71932B SPM HDDineshОценок пока нет

- 72164B HD Technologies LR SpreadsДокумент9 страниц72164B HD Technologies LR SpreadsDineshОценок пока нет

- Vibration Severity - IsO 2372 ChartДокумент1 страницаVibration Severity - IsO 2372 Chartramnadh803181100% (1)

- Sensors 19 02548 PDFДокумент36 страницSensors 19 02548 PDFmohit narayanОценок пока нет

- RCM Project Managers Guide 2014Документ66 страницRCM Project Managers Guide 2014Сергей Фандей94% (17)

- Aladon Products Brochure Coco Net v01 PDFДокумент23 страницыAladon Products Brochure Coco Net v01 PDFDineshОценок пока нет

- ISO 55001 Standard Certification Plant Wellness WayДокумент18 страницISO 55001 Standard Certification Plant Wellness WayRoberto Angel Grangeno100% (4)

- CEDR Contractor Report 2017 1 Implementation Guide For An ISO 55001 Managementt System PDFДокумент176 страницCEDR Contractor Report 2017 1 Implementation Guide For An ISO 55001 Managementt System PDFDineshОценок пока нет

- Aladon Products Brochure Coco Net v01 PDFДокумент23 страницыAladon Products Brochure Coco Net v01 PDFDineshОценок пока нет

- ISO 55001 Standard Certification Plant Wellness WayДокумент18 страницISO 55001 Standard Certification Plant Wellness WayRoberto Angel Grangeno100% (4)

- CEDR Contractor Report 2017 1 Implementation Guide For An ISO 55001 Managementt System PDFДокумент176 страницCEDR Contractor Report 2017 1 Implementation Guide For An ISO 55001 Managementt System PDFDineshОценок пока нет

- Failure Mode and Effects Analysis FMEAДокумент8 страницFailure Mode and Effects Analysis FMEADineshОценок пока нет

- Effective FMEAДокумент51 страницаEffective FMEAAshok DevarajОценок пока нет

- Sabic PC PC1003RДокумент5 страницSabic PC PC1003RrtsultanОценок пока нет

- Nano TribologyДокумент96 страницNano TribologyMinh Tâm PhạmОценок пока нет

- Negative Numbers PDFДокумент8 страницNegative Numbers PDFMuqeem ahmadОценок пока нет

- "Fundamentals of College Physics" Third Edition: Dr. Peter J. Nolan, SUNY FarmingdaleДокумент15 страниц"Fundamentals of College Physics" Third Edition: Dr. Peter J. Nolan, SUNY Farmingdalehari prasadОценок пока нет

- Calculation of Electric and Magnetic Field Safety Limits Under UHV AC Transmission LinesДокумент6 страницCalculation of Electric and Magnetic Field Safety Limits Under UHV AC Transmission LinesMauro Ignacio Nogales VillavicencioОценок пока нет

- BiologyДокумент2 страницыBiologyMeet ChauhanОценок пока нет

- Lesson Plan 4 - Kinematics: BackgroundДокумент5 страницLesson Plan 4 - Kinematics: BackgroundĐinh Nguyễn Ngọc MaiОценок пока нет

- Cambridge International As A Level Mathematics Probability StatisticsДокумент142 страницыCambridge International As A Level Mathematics Probability StatisticsKeaОценок пока нет

- Measures of Central Tendency and VariationДокумент32 страницыMeasures of Central Tendency and VariationasratОценок пока нет

- Extension of The Double-Ellipsoidal Heat Source Model Tonarrow-Groove and Keyhole Weld ConfigurationsДокумент13 страницExtension of The Double-Ellipsoidal Heat Source Model Tonarrow-Groove and Keyhole Weld Configurationsal-masriОценок пока нет

- Ulr - TC752121000004643FДокумент16 страницUlr - TC752121000004643FKishore KumarОценок пока нет

- INTEGRAL REPRESENTATIONS OF ζ(n) INVOLVING NIELSEN'S POLYLOGARITHMSДокумент16 страницINTEGRAL REPRESENTATIONS OF ζ(n) INVOLVING NIELSEN'S POLYLOGARITHMSSam TaylorОценок пока нет

- BS en 1402-6 2003+a1-2007Документ18 страницBS en 1402-6 2003+a1-2007Khaled BOUALIОценок пока нет

- Euro Calibration Technique Scope Location 1 CC-2519Документ22 страницыEuro Calibration Technique Scope Location 1 CC-2519kumarОценок пока нет

- Fabrication and Experimental Evaluation of A Polymer-Based Flexible Pulsating Heat PipeДокумент7 страницFabrication and Experimental Evaluation of A Polymer-Based Flexible Pulsating Heat PipeBibhu ShaОценок пока нет

- Section Description:: Manual Calculation Sheet For Reinforced Concrete Beam B 25 75Документ8 страницSection Description:: Manual Calculation Sheet For Reinforced Concrete Beam B 25 75Lavender HoneyОценок пока нет

- ADDING AND SUBTRACTING FRACTIONSДокумент2 страницыADDING AND SUBTRACTING FRACTIONScmisaacОценок пока нет

- Our Future Motive Power, Everyday Science and Mechanics, December 1931Документ7 страницOur Future Motive Power, Everyday Science and Mechanics, December 1931nenadmncОценок пока нет

- Applied Energy: Brecht Baeten, Frederik Rogiers, Lieve HelsenДокумент12 страницApplied Energy: Brecht Baeten, Frederik Rogiers, Lieve HelsenSindhu KanyaОценок пока нет

- 1684468-Helical SpringДокумент219 страниц1684468-Helical SpringzohebОценок пока нет

- What Is EDM?: Non-Traditional Machining ProcessДокумент19 страницWhat Is EDM?: Non-Traditional Machining ProcessAlankrit SrivastavaОценок пока нет

- Problems For PH1016: Chapter 31: 37, 41, 43, 45 (Op.), 57, 59, 61 (Op.) Chapter 32. 35 (Op.), 37, 39, 45, 47, 49, 51Документ9 страницProblems For PH1016: Chapter 31: 37, 41, 43, 45 (Op.), 57, 59, 61 (Op.) Chapter 32. 35 (Op.), 37, 39, 45, 47, 49, 51Vũ Đức TuânОценок пока нет

- Wbjee 2024 Chapter WeightageДокумент4 страницыWbjee 2024 Chapter Weightageaneesh.paul006Оценок пока нет

- Direct & Inverted PendulumДокумент2 страницыDirect & Inverted PendulumAnonymous kxOcSmhcОценок пока нет

- Using Some of Microsoft Office Excel FunДокумент79 страницUsing Some of Microsoft Office Excel FunPal RichardОценок пока нет

- MELCS For Bulletin in Science 10 Per QuarterДокумент4 страницыMELCS For Bulletin in Science 10 Per QuarterMARIANNE SORIANO100% (1)

- Space UnitДокумент1 страницаSpace Unitapi-547027274Оценок пока нет

- Cet 423 - Mod 2Документ100 страницCet 423 - Mod 2Shreyas ManuОценок пока нет

- Question ReportДокумент18 страницQuestion ReportnptidksharmaОценок пока нет

- Biaxial Bending in Columns: Icon LegendДокумент2 страницыBiaxial Bending in Columns: Icon LegendGaurav BhendeОценок пока нет